Prototyping… a time intensive task!

Running a custom fabrication shop is fun, due to its very nature though, quite often CNCROi.com needs to make some prototyping not only to prove that we can do the design requested but to make sure our process for making them in volume is as efficient as possible.

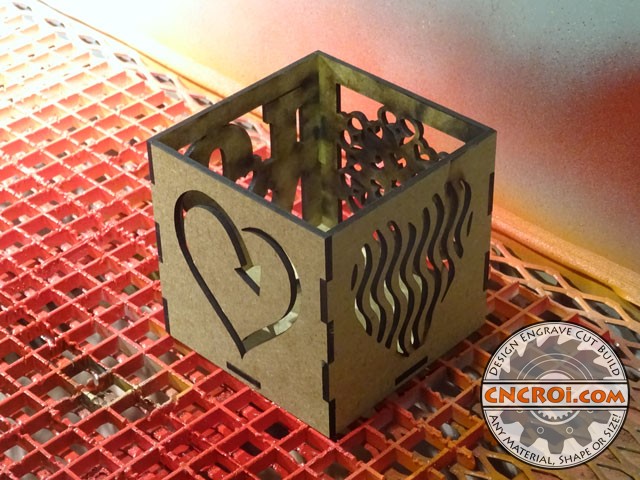

The above pencil holder is a great example of the prototyping process, the finished version you see in this video is actually version two but we’ve gone through quite a few other versions for an upcoming project based on customer spec requirements.

Generally the client conveys to CNCROi.com what they want with measurements and/or sketches (example below isn’t the pencil holder – that came from a CAD document).

The prototyping process has become intuitive to me now, the first is generally what you “think” is the easiest way to accomplish a project and based on that experience, generally another prototype is made to refine the issue or try something completely different.

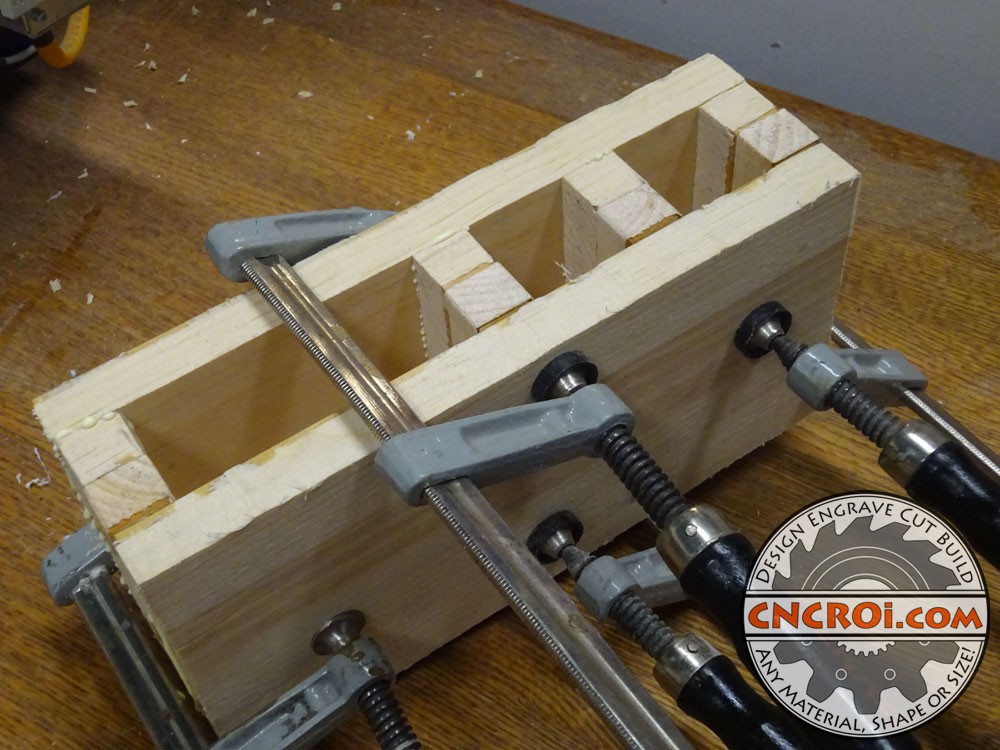

In the case of the pencil holder, the above picture shows exactly the worse way to accomplish this project and as the specs for this project have changed, it was a very good decision to completely drop the process of “glue and drill” as the finished product now looks way better and dramatically easier to accomplish.

The goal of prototyping isn’t just proof of concept and refining production methods but most importantly, bringing in processes to make sure that 100 of them look pretty closely to the same which is something that wouldn’t really be possible at that volume using the initial fabrication method I thought of.

Truth be told, anybody can get lucky to make something amazing “the first time” but replication removes that luck big time as the volumes start to go up and the time constraints kick-in.

I’ve been prototyping for decades, both virtually and in the physical world with both my own designs and those of others where sometimes the simplest little details you think will be the easiest end-up being the most difficult to achieve, it requires patience and proper equipment to get things to a commercial or industrial scale.

Whether it’s custom MDF furniture made with our CNC router or metal cut tooling using the waterjet, every material, every design and every process has it’s own quirks that generally only reveal themselves when you have to make many multiples.

Another great example of prototyping was my initial TeaLightBox.com website, I made A TON of tea light boxes and continue to do so, but based on customer feedback, I realized that my design was fine “for me” but not “for them” so I had to think of a more efficient method of assembly, and not production, to help the end-user to put it together!

So even the most perfect design is worthless if the customer at the end has challenges putting what you made together!

An extreme version of this was the steamboat that I designed and cut out of thin MDF – the design was actually perfect except for one small problem, two set of parts looked so similar that I obviously use one in the place of the other and it caused me to lose half an hour wondering what the heck happened during the cutting process!

Of course, the laser was 100% perfect, it was ME as the assembler who had things reversed so in the future, I’d make a small physical cut to indicate orientation on some parts and most importantly, a physical cut to remind myself as to the position of similar looking parts so they are more easily visually separated.

The reason I bring all this up now and if you’ve been tracking my blog posts recently, they’ve been down from the usual “post every two days” and that’s because I’m about to launch a custom bike tool that I’ve designed and cut and wow did I learn a lot during that process.

It’s amazing how much time can be eaten away trying to bring something to market at the consumer level!

People think CNC machines are amazing, and they are, but they don’t replace the head on your shoulders and the challenges that mass production bring especially for a consumer product that I hope will gain huge steam in the coming months!

Of course, sometimes CNC machines are also the WRONG tool to be using too!

Looking for something custom? Contact CNCROi.com right now!

We’ve got you covered prototype to production.