Punching Metal Holes Using Jigs and Other Methods

Punching metal holes into our stainless steel and anodized aluminium custom tags is something that CNCROi.com does on a regular basis due to a customer’s request for a project that’s either very low volume or a very tight deadline where CNC tooling wouldn’t be able to satisfy.

For this project, the customer wanted to do a test run of anodized aluminium tags and their specs were very close to what we offer using anodized aluminium business cards so we decided to just use that format which we keep inventory of here at CNCROi.com and after the engrave, punch holes in all four corners.

When it comes to options, my goal with CNCROi.com is to keep our materials that we have in inventory as RAW and BIG for as long as possible, that gives us endless possibilities when it comes to creative and customer requests.

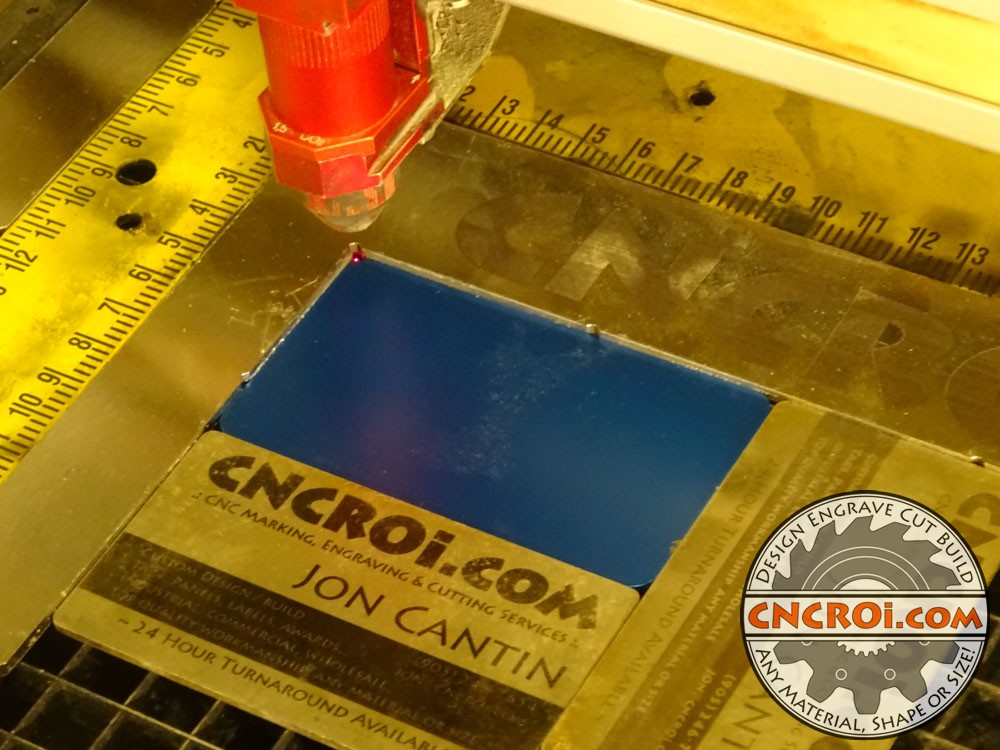

Above is a picture of our dead-simple little jig that I used for this customer project that I put my info on the anodized aluminium business card sized machine tag due to NDAs.

Of course, we can make big jigs, small jigs, totally crazy jigs out of pretty much anything just as easily but the most efficient jig for the job always works best.

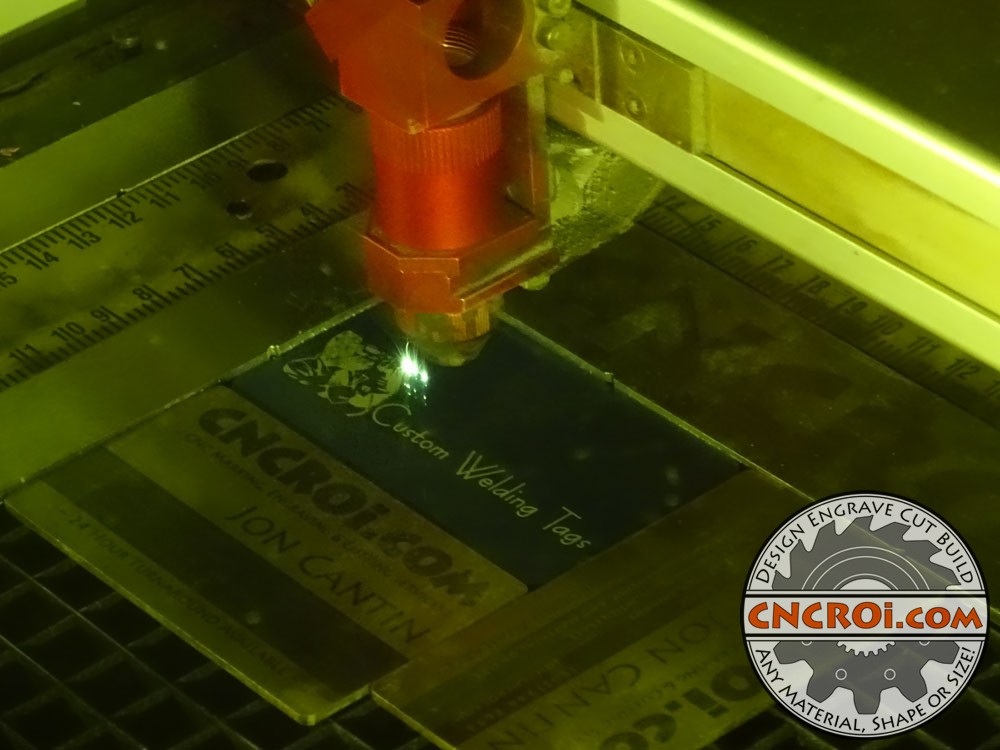

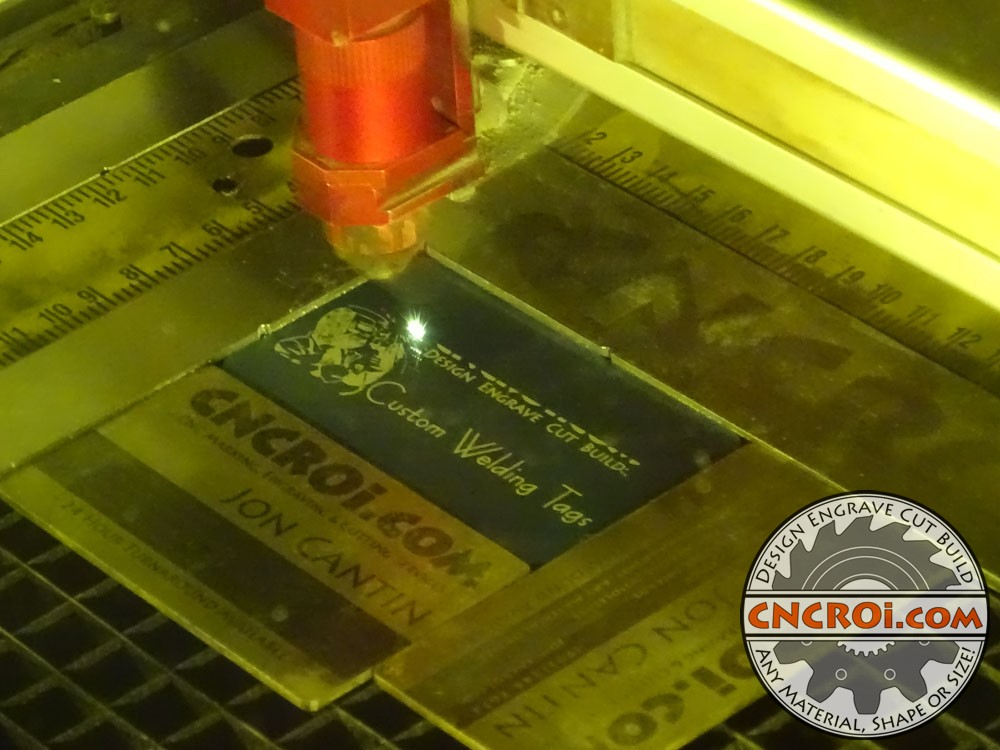

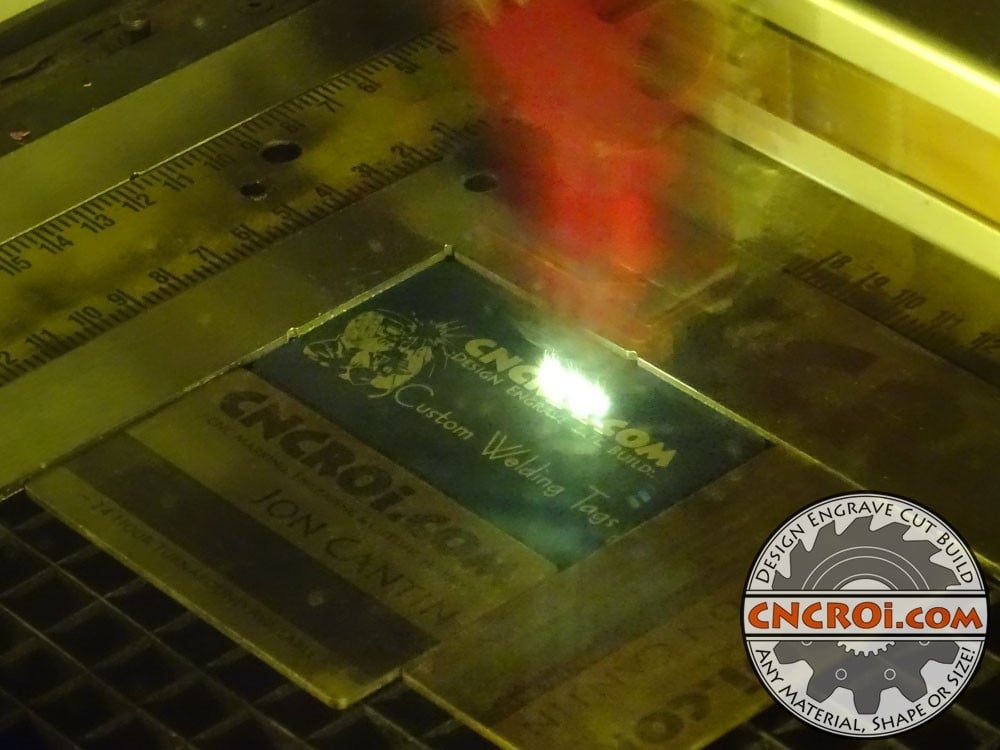

The first step towards making metal holes in this anodized aluminium tag production run is actually engraving the tag, CNCROi.com keeps a huge variety of “standard custom” stuff in the shop which work great for a whole bunch of applications.

The reason why we engrave the tag first before making the metal holes are so that everything is as flat as possible, producing consistency is important and that’s also why I bought our Austrian wide-format industrial laser.

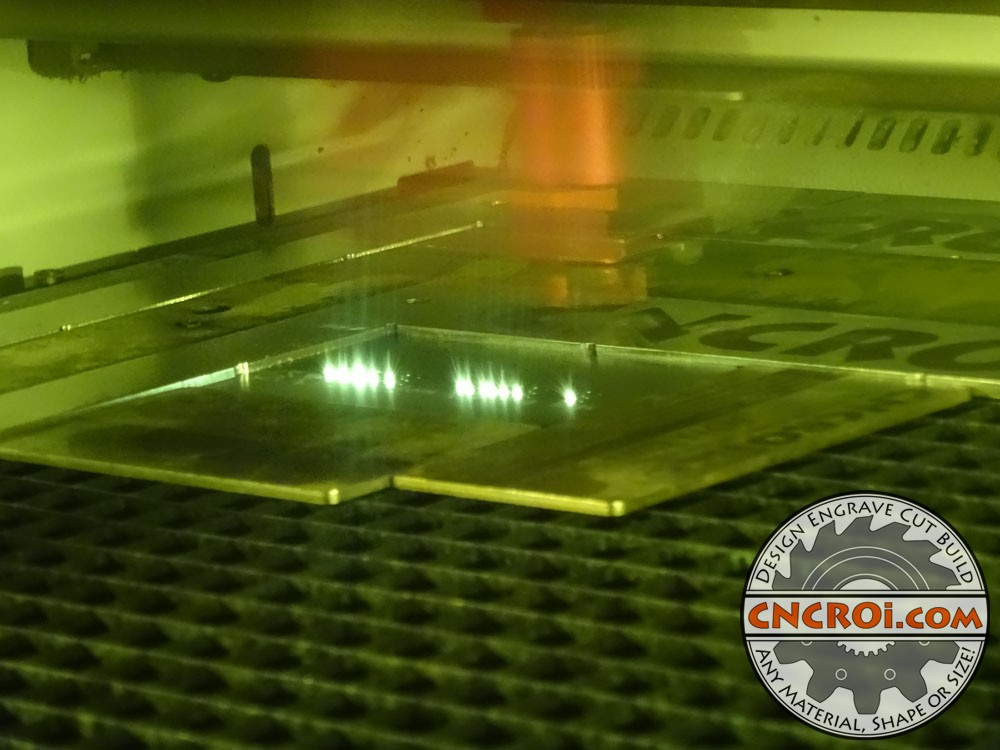

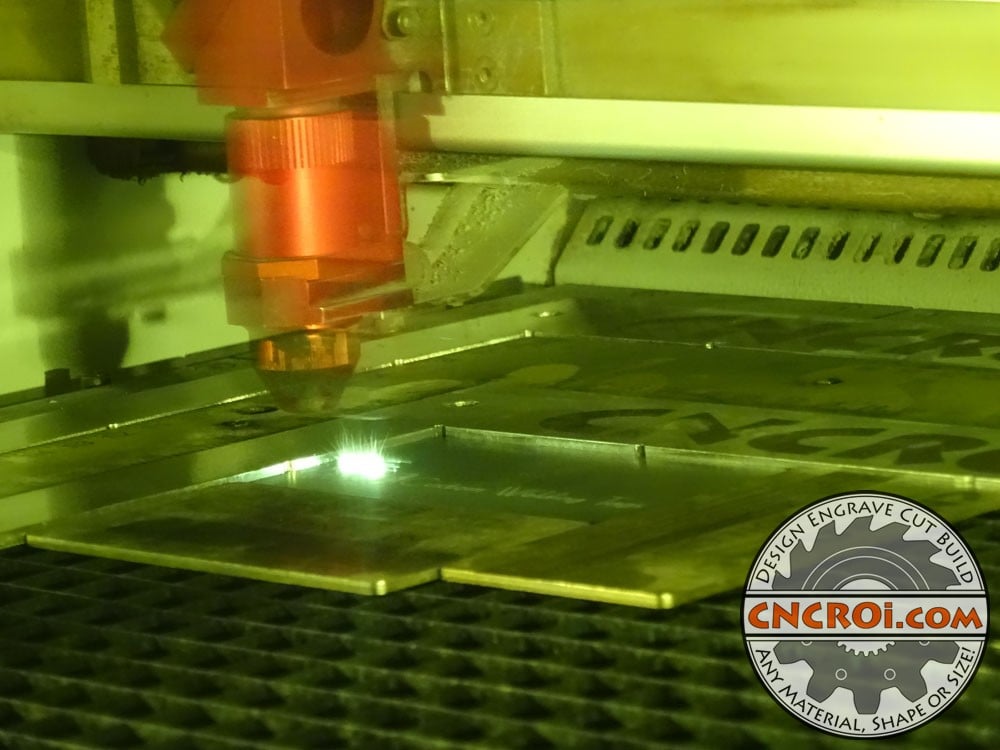

How precise is our Austrian laser? CNCROi.com regularly uses it to make custom measuring cards for engineering firms for use out in the field!

Making positioning for metal holes can be accomplished a few ways, the easiest is to simply engrave cross-hatches right onto the tag to make reference to when we make the holes, another is actually engraving a small hole using our fiber laser into the tag for the center calibration punch to slot into.

Just to give you an idea of what CNCROi.com is capable of, whether you wanted a custom metal sign or a whole bunch of tags at different sizes and shapes in one production run, with or without metal holes made during this run, we can do that no problem!

But in this case, I decided to use another method and that’s making no marks at all and relying instead on a thin piece of plywood with holes in it to make the holes, that’s the same dimensions as the anodized aluminium business card we will make metal holes into.

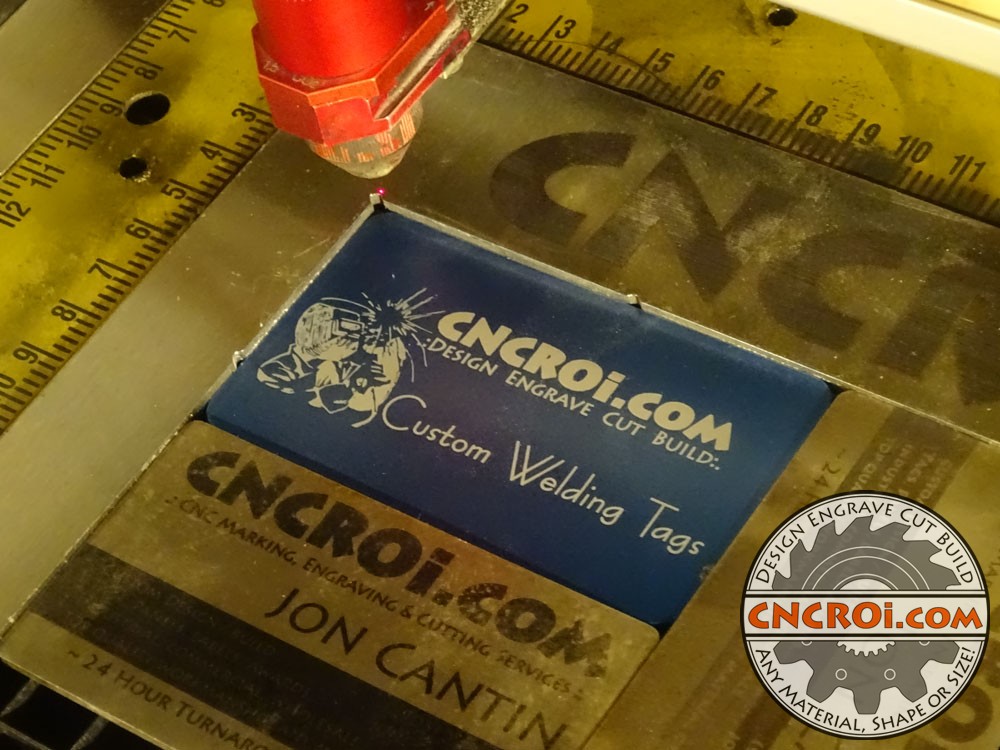

This anodized aluminium machine tag that will soon have metal holes in it is just about completion, once this customer gave us go-ahead on this project, we turned it around within 24 hours like most of our jobs… sure it leads to late nights (early mornings) on some days but our customers can’t benefit from CNCROi.com‘s work until they get it and our priority is for them to benefit from their investment in us ASAP!

As for other shapes CNCROi.com can work with that we have punched metal holes through for things like valve clocks and steering mechanisms, there really are no limits when it comes to permanent branding of our metal products.

All the dust you see around the CNCROi.com imagery and text is actually anodized aluminium dust that was vaporized when our 140W CO2 laser source blasted it, that’s really nice about anodized aluminium though is that unlike stainless steel, it doesn’t get hot and thus, not prone to heat warping.

CNCROi.com could have also made this tag out of lamacoids that would have looked and felt pretty close to this blue anodized aluminium tag but as the client wanted to screw this into their product, using aluminium with metal holes was by far a superior choice.

You can now see the finished anodized aluminium machine tag but it’s missing the metal holes!

There we go, using a punch over a drill (in this case) provides a nice smooth surface with minimal clean-up, that’s why CNCROi.com used the punch in this case, if this was stainless steel, then generally we’d use a drill especially for thicker pieces and then use an angle grinder in the back to deburr it.

If you are curious as to what a machine tag like this would look like if it was stainless steel or plate metal, see the options we offer on that medium in the CNCROi.com video below.

If you are a wood shop, CNCROi.com could have just as easily produced the same tag out of a whole holes of different woods as well, here’s my solid Oak name badge that I have to a customer a while back as a sample of our craftmanship.

And of course, the same precision and dependability follows through when it comes to making custom Trodat rubber stamps so if you wanted to just use paper and stamp out your reference tags, we can help you on that front as well!

When it comes to custom production, CNCROi.com is passionate about helping you find a permanent solution to your branding requirements, whether you are a welder who wants to have custom welding tags made to help you get more business…

Or an artist looking at having some fish made for an upcoming special event where you group paint…

Or even just a simple dimensional cottage sign, CNCROi.com has the passion and expertise to help your product dreams become reality.

Be sure to contact us, we give no-obligation quotes generally within a few hours of getting the RFQ (request for quote) and depending on the project at hand, it’s generally out the door and in the mailman’s hands the next day.

CNCROi.com works with anything from technical CAD documentation to sketches on pieces of paper to produce what you require, I look forward to making something awesome for you!