Puzzle UV Printer Jigs V2: CNC Routing 3/4″ MDF

I showed a puzzle UV printer jigs a few blog posts ago, consider this V2 based on customer feedback for another set of their custom products they print upon.

You can really see the evolution of this design from the V1 video below – that’s what I enjoy about ongoing projects with customers such as these, because they get something then improve upon it and it’s very much a back and forth process.

I haven’t posted in a while because I’m in the middle of a massive shop renovation, we got a new CNC router and it’s even bigger than the one you’ll see in these photos and the video, that meant I essentially has to reconfigure the entire shop for it to work well in our environment, which takes a lot of time but at least now I’m seeing the light at the end of that tunnel.

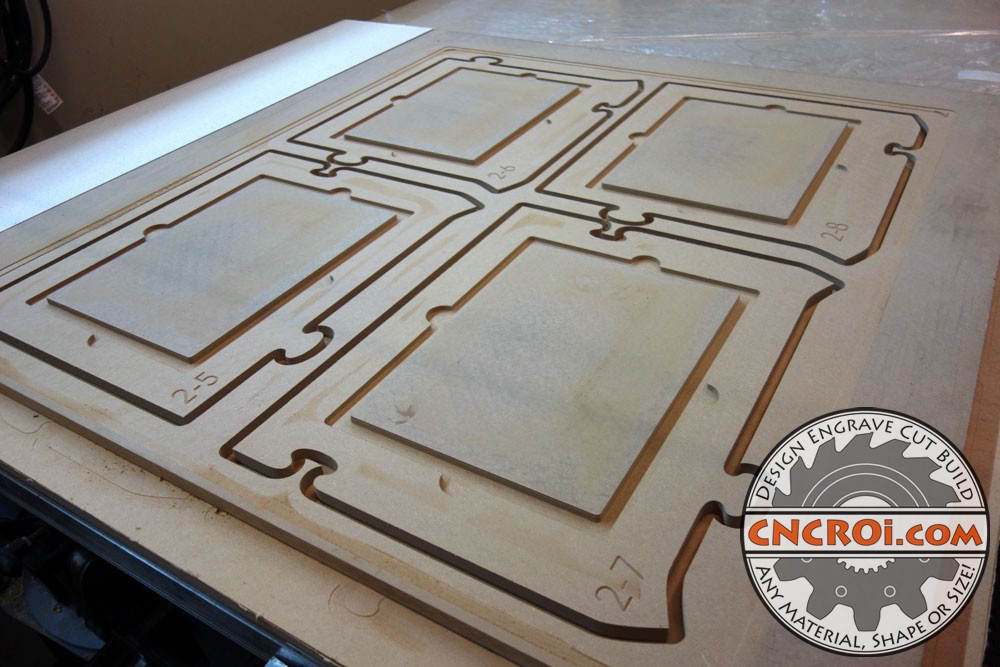

For this project, CNCROi.com used two full sheets 4 x 8 ft of 3/4″ MDF in order to produce amazing puzzle uv printer jigs for use at their factory.

CNCROi.com has years of producing custom jigs using a variety of materials for our customers far and wide, some jigs we make are quite simple, and others, like this one, have lots of parts to them for massive production runs our customers use these for.

It’s a bit nostalgic to look at these photos and videos, they were done more than a month ago, the new machine is very different in some ways but similar in others, regardless though, it has the same tolerances though with a much more updated platform than shown here.

I’m certainly no stranger to MDF, haven used it for years across various machines for many different processes, from mold making to custom name badges and even furniture.

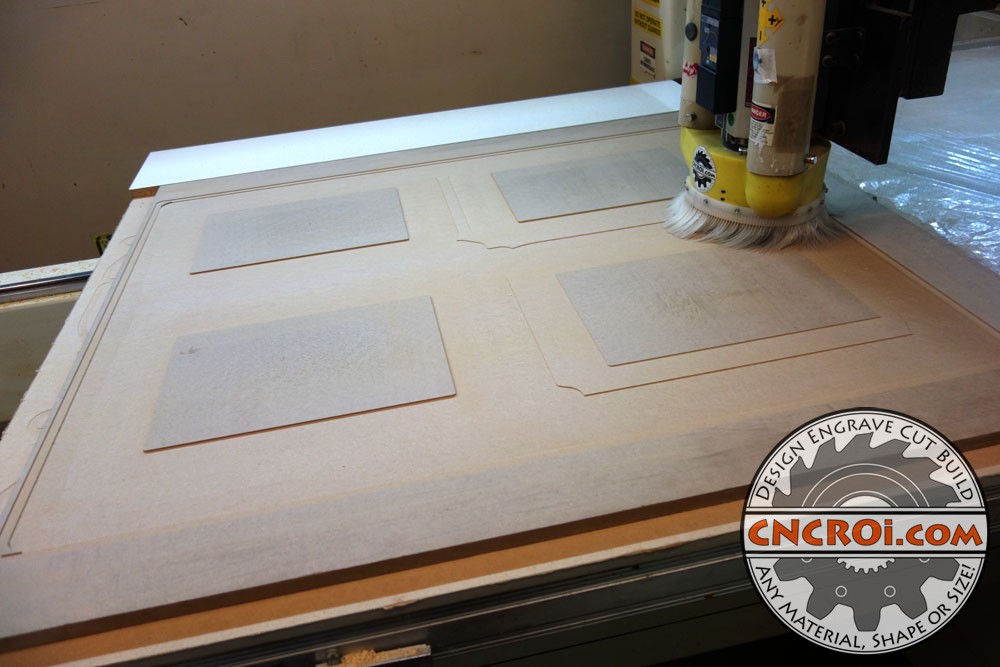

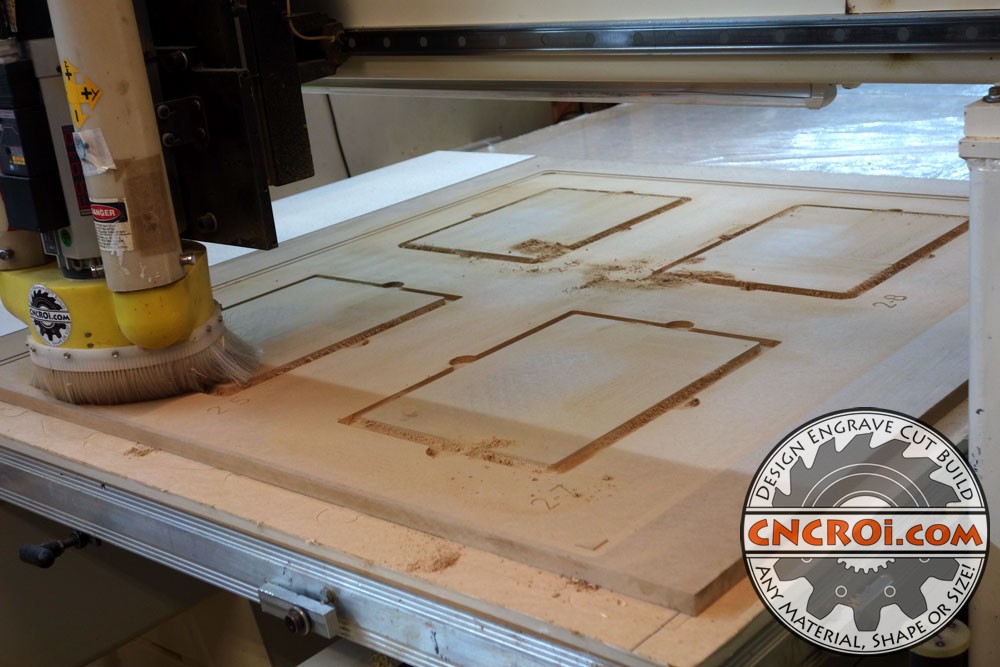

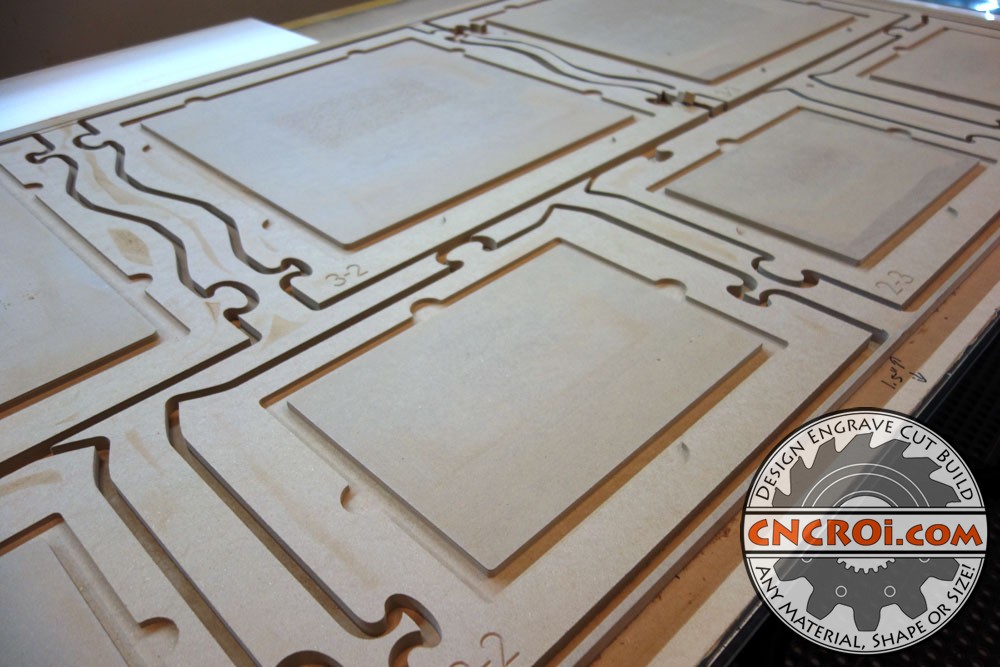

With the CNC router, it’s best to slowly go down through the layers work wise than try to rip everything up in the first pass, the goal here isn’t speed for these puzzle UV printer jigs, it’s precision, and as such, it’s better to do everything slowly and methodically yet precisely at CNCROi.com.

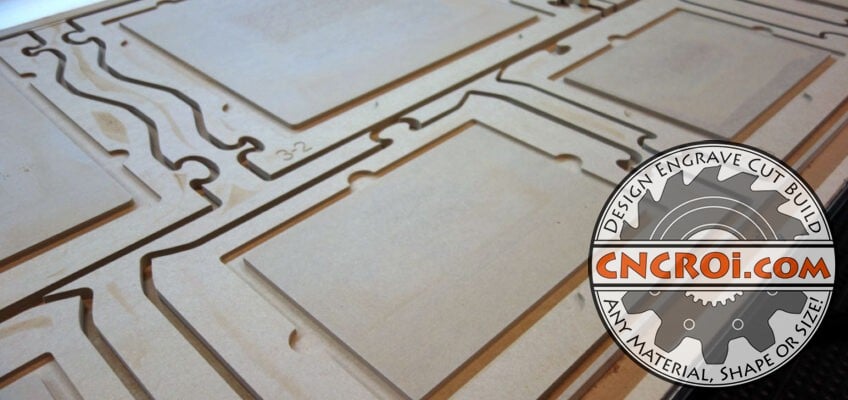

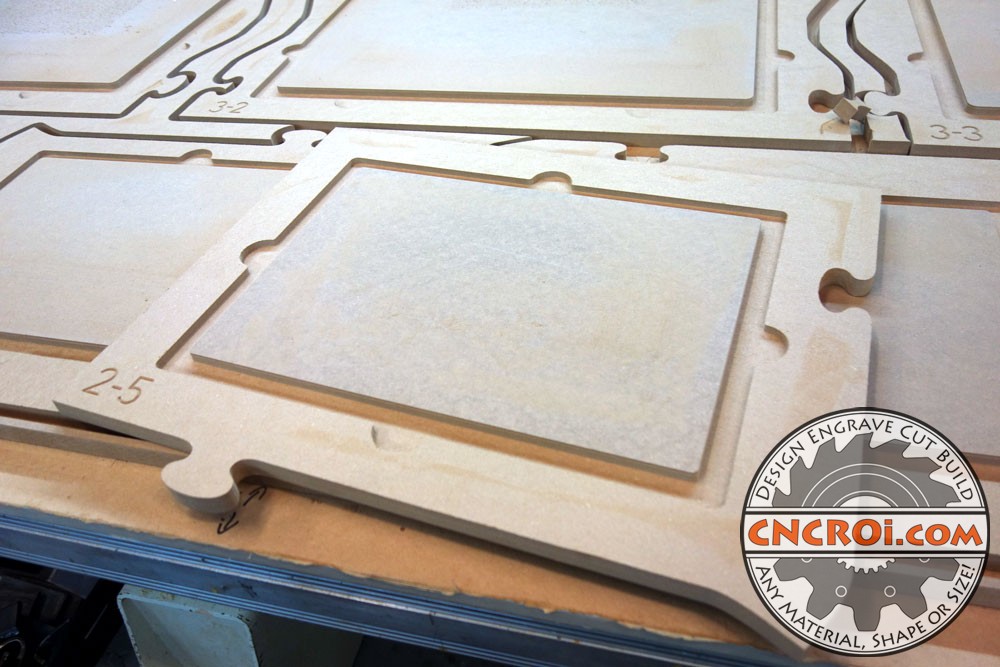

Another area we improved upon was starting to identify the jigs, not just their time but also their location, this speeds-up the set-up at their end production wise as they plow through project after project, streamlining their use dramatically so the worker doesn’t have to figure-out a puzzle before doing a UV printing run.

MDF is basically saw dust and glue that’s pressed with heat, as such, the dust we produce at CNCROi.com producing these puzzle uv printer jigs is quickly whisked away from our vacuum system but there is so much of it produced that our system can’t keep-up, again, always an excuse at the shop to upgrade equipment.

There are just so many uses of MDF at CNCROi.com that I keep a steady supply for rush jobs just incase something comes-up, we can laser cut it, router it and even use it as a backboard for waterjet cutting.

When it comes to these puzzle UV printer jigs, we are essentially pealing away the layers of an onion skin, the very top is untouched, next to it a bit more and the grooves and channels every more so.

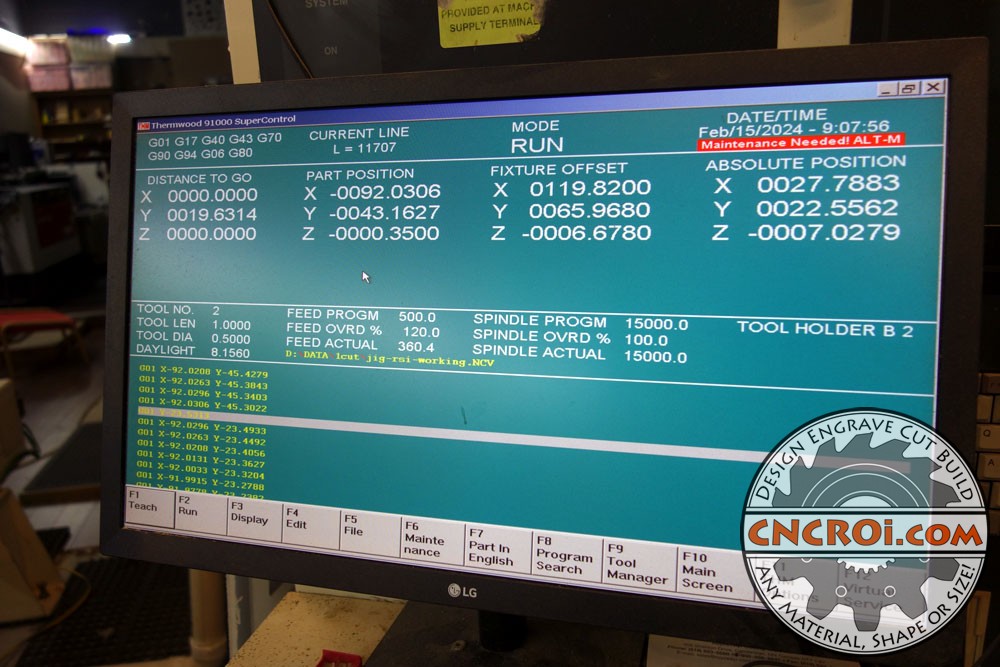

It’s actually quite interesting to see the entire process of manufacturing these puzzle UV printer jigs take shape while it’s happening realtime, CNCROi.com‘s CNC router changes tooling for the next path, runs the code for that tool, then flips to another for the next process, of course, this is sped-up in the video but it’s neat watching a robot go to work.

Of course, this project was initially set-up to run off two full sheets but I was able to manually nest the pieces in such a way that I’d only use a sheet and a half, that’s why you see in the video me programming a light parameter pass around the puzzle pieces just to make sure everything fit on the sheet I was about to cut.

Something I’ve done a lot of through the years with MDF is actually carving it, that’s where our small desktop Shopbot excells, it doesn’t tie-up a huge hulking machine that to be honest, engraves only slightly faster because the diameter of the bit is the limiting factor more than anything.

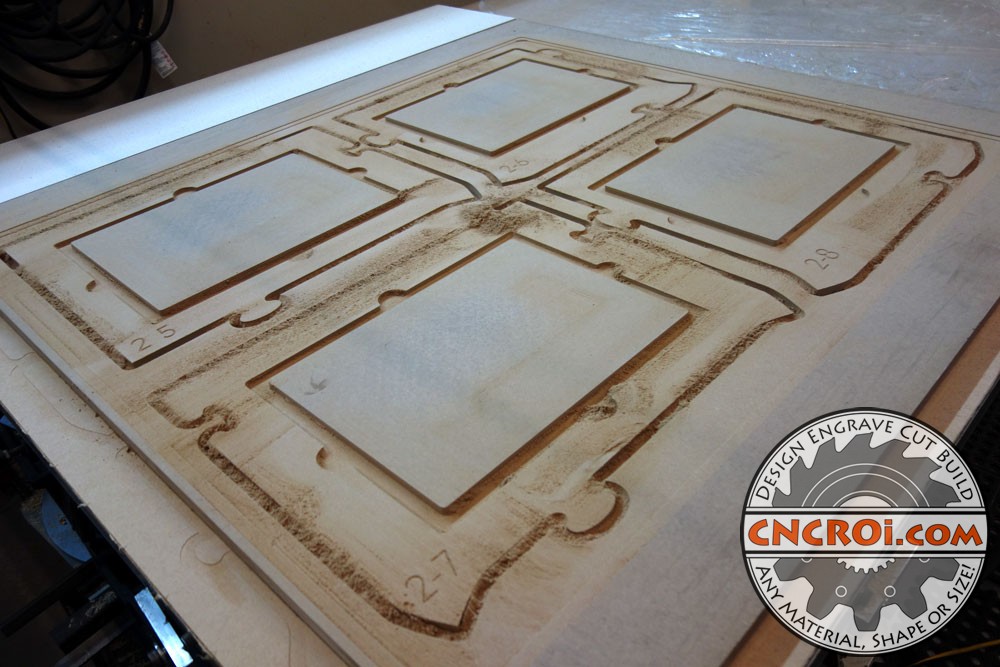

In the above picture you can see the numbering system and get a feel at just how powerful of an advantage this can offer, when it comes to quickly placing these puzzle UV printer jigs for production then back away for storage once again.

The nice thing about these jigs is that what was originally going to be one MASSIVE JIG was able to be brought down to size for something far more manageable in size and storage for the client by breaking it up into individual puzzle UV printer jigs.

Regardless of the client needing one or a thousand of these puzzle UV printer jigs, our “old” CNC router was more than happy to do as the client requested as our “new” one will as well now that it’s almost all set-up and ready to start making some wood chips at CNCROi.com.

MDF also makes for wonderful signage, the above sign is now in my son’s room and guess what, years later, it still looks brand new, thanks to its dimensional stability over just any other “wood” out there.

What’s great about our CNC router is how optimized our software is to the hardware, meaning, when we tell it to move 0.01″ to the left, it does it exactly at those steps!

As you can tell from the picture below, our CNC router has an easy life, it’s never done kitchen cabinets or heavy day and night shifts, as such, it will last it’s next owner for another good long time now that it has left CNCROi.com, ironically, to a cabinet shop not too far from here.

CNCROi.com could have made this puzzle UV printer jigs using any host of other materials, from aluminium to Corian, each has a plus and minus to it, there is no perfect material, just the best given timelines, design, budget and other considerations.

I’ve honestly lost count of how many custom tea light boxes I’ve made through the years and sold both online and off, these may be laser cut but if they were needed in a larger format, I’d router them out.

When it comes to making these puzzle UV printer jigs, literally any parameter could be changed, from size to thickness, so if you for instance, wanted to have this further cut down to smaller pieces to be 12 or even 24 a sheet, that’s not a problem for CNCROi.com because, as you can see, each one of these is essentially made one at a time.

CNC routing using industrial machinery is very different than consumer routing platforms, industrial is made to run 4/7 when things are critical to be made, and are able to maintain and even self-correct when things go out of wack… this does come with a big price tag of course, but the moment you cannot rely on a machine is the moment that machine becomes worthless.

Here’s the results of a full sheet of puzzle UV printer jigs, the spacing is almost dead-on fit wise, you always want to leave a bit along the edges and other areas but as you can see, I couldn’t have fit this tighter than it is, and this is why originally, the software told me this fit on two full sheets but with years of doing this, I knew I could make it better.

Yes, you can use a laser to carve out MDF, I’ve done a ton of this at CNCROi.com for endless applications, the most popular was actually adding details to furniture a customer was making.

The bed size on this CNC router is 5ft x 10 ft, our “new” router has the same, but with dual sliding beds and a 19 place tool changer, with some doing so at the head, as a result, we will be able to produce jigs like this in a more efficient manner when it matters for CNCROi.com customers.

I’ve never been a huge fan of MDF, but like any other material, it has it’s place and for this project, it absolutely was the best material for the job given the constraints we had to needle our way through to make this happen.

I’m very happy with how this puzzle UV printer jigs project came-out and the customer couldn’t be any more happy with the results they are enjoying with them too.

Need custom jigs? Contact CNCROi.com right now!