Round Metal Coasters: Custom Fabrication Options

When it comes to round metal coasters, there are a lot of options but CNCROi.com will cover the main ones when it comes to custom fabrication options.

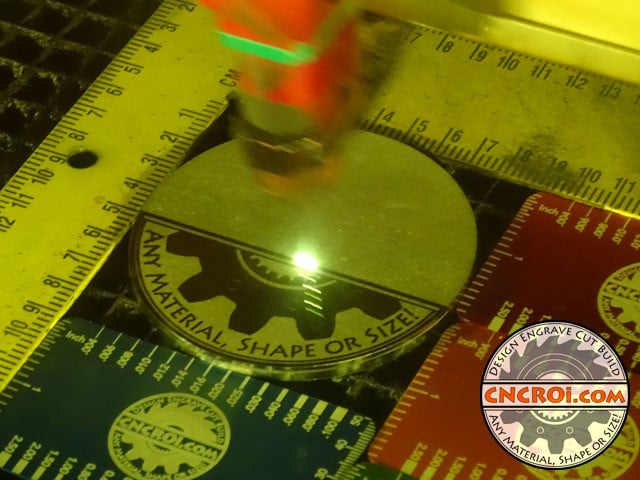

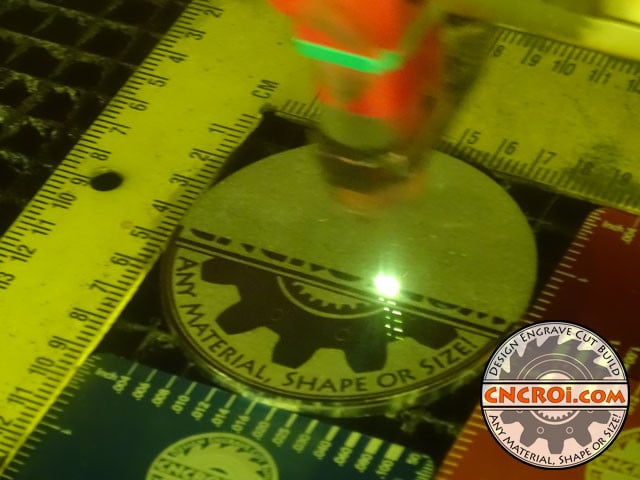

Due to the amount of “blackness” that my logo has in such a small space, going with a thinner gauge stainless steel won’t work because it will actually start to bend from the heat.

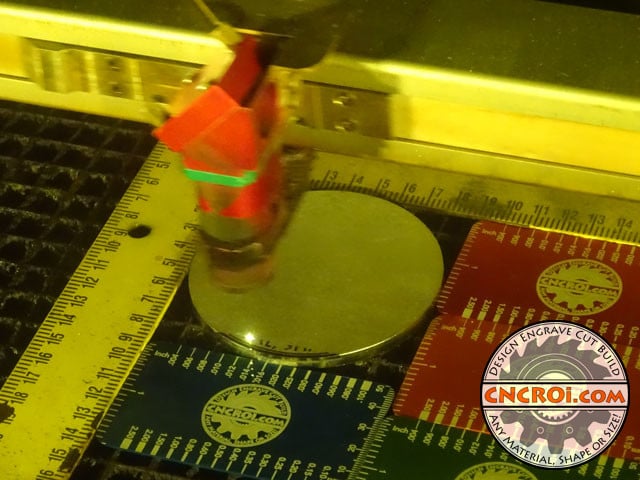

Whether CNCROi.com is fiber annealing or fiber etching, regardless of the shape, if the metal it too thin, it will warp and go from annealing to etching, which produces a dramatically different surface and reflective effect on stainless steel.

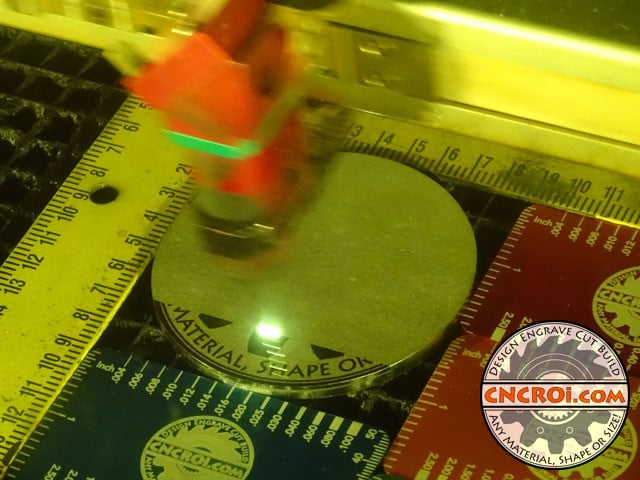

As my logo is totally round, it makes sense to make the round metal coasters in the same fashion to fully fill the area of interest.

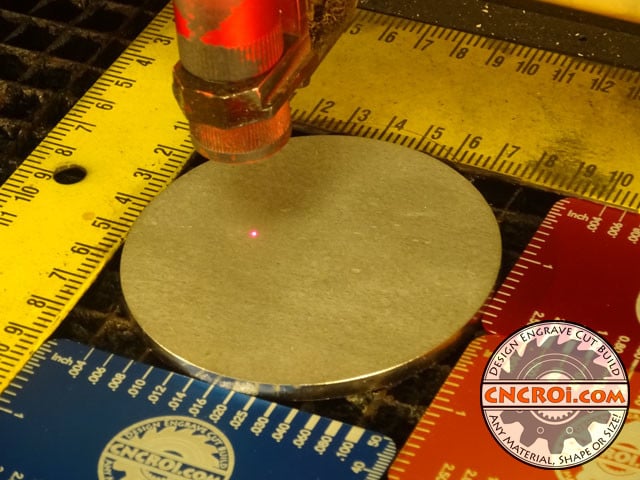

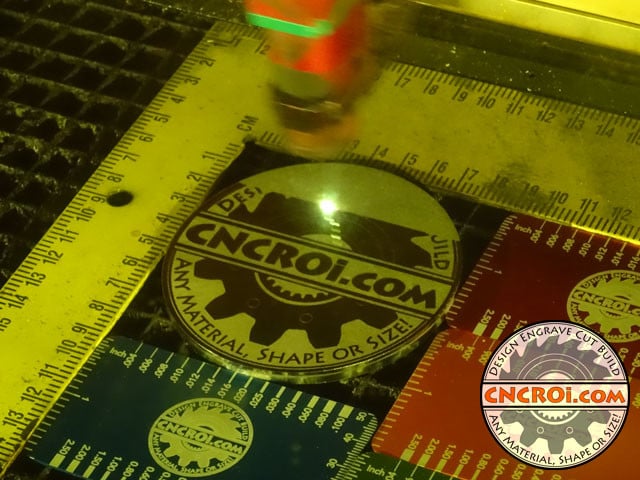

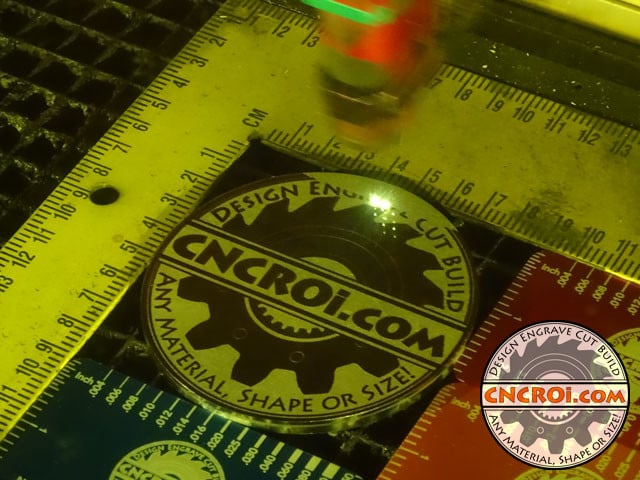

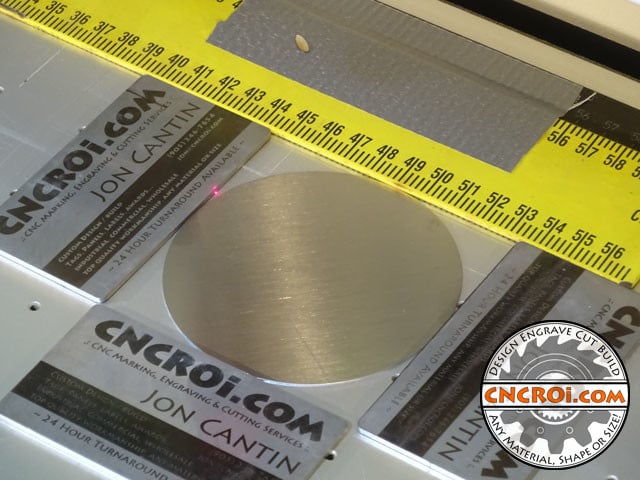

In this case, quarter-inch or 6 mm thick stainless steel without any finish on it, so the surface isn’t as shiny as the #4 finish in the video above nor is it as “flat” relatively speaking as a result, there are slightly high and low points across the round metal coaster.

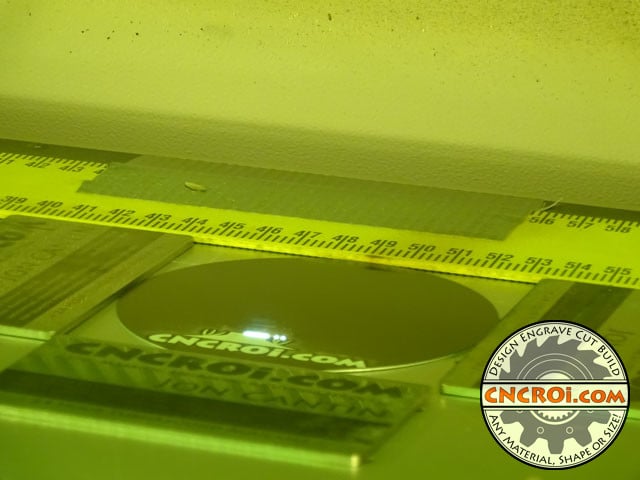

As this is a thick round metal coaster made out of stainless steel, after production, it’s super hot and needs to be allowed to cool down.

Annealing also happens across the entire surface, even on the outer edge, as a result, that’s where the bending would happen at the most extreme as there is little metal there to hold it together.

When it comes to making custom round metal coasters, the thickness when it comes to stainless steel is vitally important, this design would not work with a thinner gauge as a result, that’s why CNCROi.com is doing it on a thick one instead!

Especially when it comes to etching, in which we are really scratching the surface, going too thin just causes the metal to warp even more spontaneously.

You might think fiber annealing or etching round metal coasters is easy, but the results very much depend on the design you are wanting to permanently brand onto it.

CNCROi.com has the same issues with our custom stainless steel welding tags, some clients want a very full tag with lots of information, which is fine, but there is a balance that must be kept to keep the integrity of the tag good enough for use.

And that’s why CNCROi.com came out with the thicker option, just to allow our customers to put even more of the surface black while keeping the tag relatively flat, additionally, they can now have it etched, which isn’t something we can do on the thinner tags.

As these very thick custom fiber laser cut then annealed custom round metal coasters go into production, in this case, with just my logo on it, the branding will not fade, crack or peel over time.

If this was to be put in a marine environment or somewhere corrosive, we’d make these out of 316 stainless steel instead of 304 like the one below.

Now that this thick stainless steel round metal coaster is done being annealed, it’s still a little dirty from the oxidation of the metal that settles on the surface.

But after a quick cleaning, you can clearly see the result, the surface is smooth and the CNCROi.com branding and entire logo are nice and sharp.

The branding would be darker and more “in focus” if the surface was brushed, hence why we generally do this by default unless asked by a CNCROi.com customer not to.

And here are the round metal coasters branding options, thin stainless steel on the left, anodized aluminium in the middle then the thicker stainless steel on the right in a custom round maple coaster.

By comparison, here’s how anodized aluminium round metal coasters look like production wise.

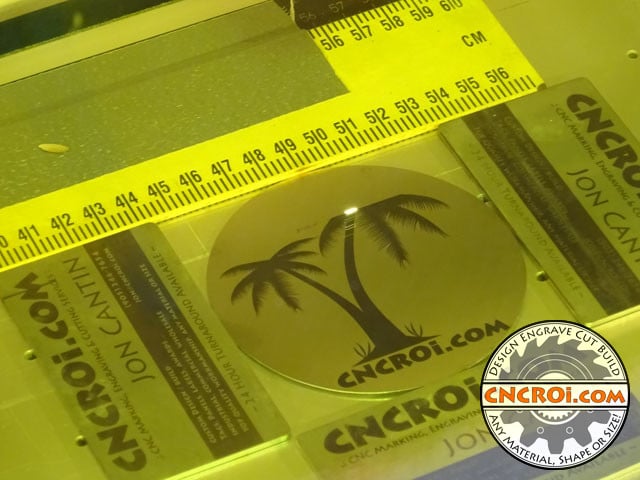

Just to show you how you can literally have any design on our round metal coasters, let’s do another using just a palm tree and some light branding.

The clarity and precision of CNCROi.com‘s industrial wide-format Austrian laser is great, the fine details come out perfect.

Unlike stainless steel, custom round metal coasters made out of anodized aluminium can be made in a variety of colors but the engraving is always an off-white.

Now for comparison when it comes to custom round metal coasters, let’s do the same design but this time onto a thin plate of 304 stainless steel.

Of course, the coaster doesn’t need to be round, we also make lots of custom metal business cards and gifting ideas too at CNCROi.com!

Notice the bottom edge of the stainless steel coaster, it’s RAISED!

That’s from the annealing heat and it would be dramatically more if I did my CNCROi.com logo onto such a thin plate as the annealing (in this case) would be all the way around and inside.

There are a variety of ways to “hold down” the stainless steel but at the end of the day, to make production efficient, it’s best to just go with thicker plate, especially when it comes to round metal coasters.

Whether you need some custom round metal coaster or anything else across a variety of materials, contact CNCROi.com right now!