Sample MDF Texture Plates

At CNCROi.com, we recently created a unique series of custom tile samples to address a very practical challenge: getting on the same page with clients when it comes to choosing MDF texture plates.

Often, clients come to us with vague ideas like “make it sort of like this,” or “a little like that,” which introduces too much interpretation into a precision-driven process.

That’s not our style. We prefer clarity and shared understanding. So we decided to speak a universal language—design.

These texture tiles were created to give clients physical references. Instead of guessing what “sort of like this” means, we now offer a range of samples they can literally hold, feel, and point at. MDF texture plates are incredibly versatile, and having a common design vocabulary makes communication dramatically smoother.

For instance, a client can now say, “I like this V-carved texture,” and we’ll know exactly what tool to use, what shape the groove will have, and what result to expect.

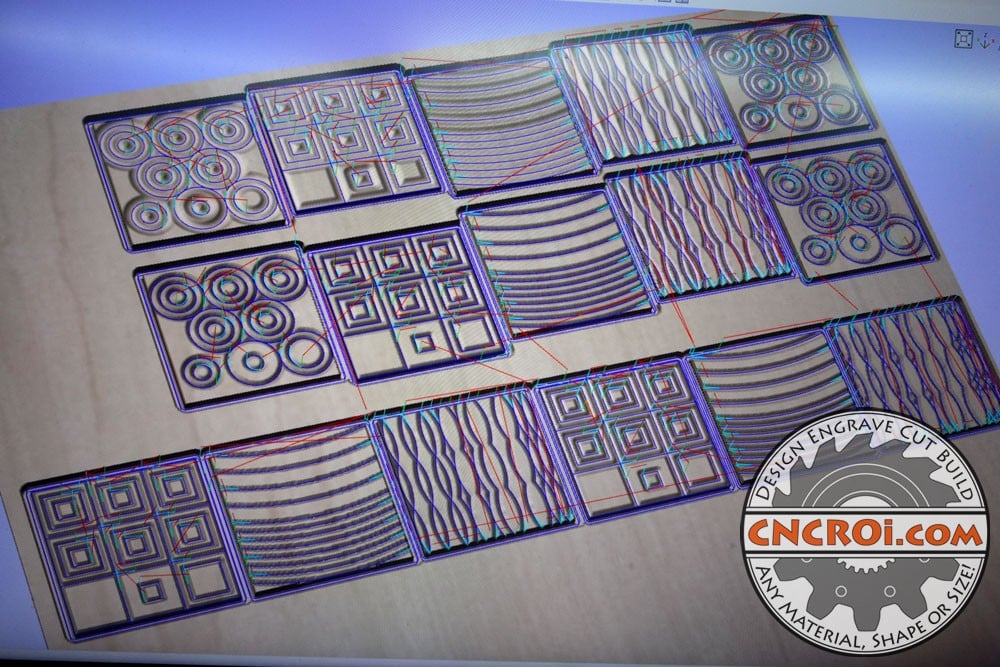

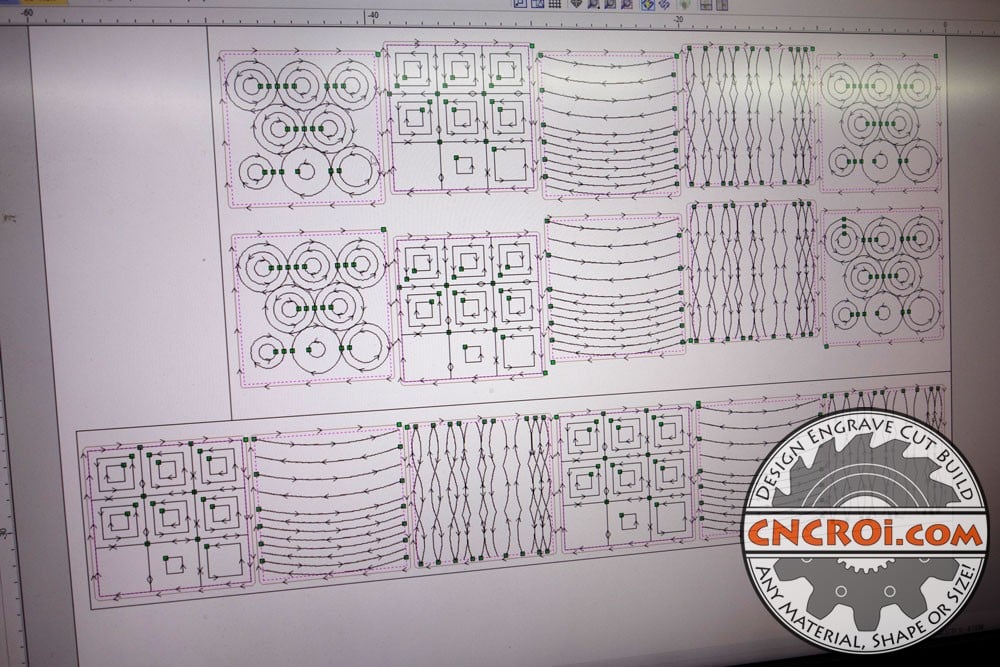

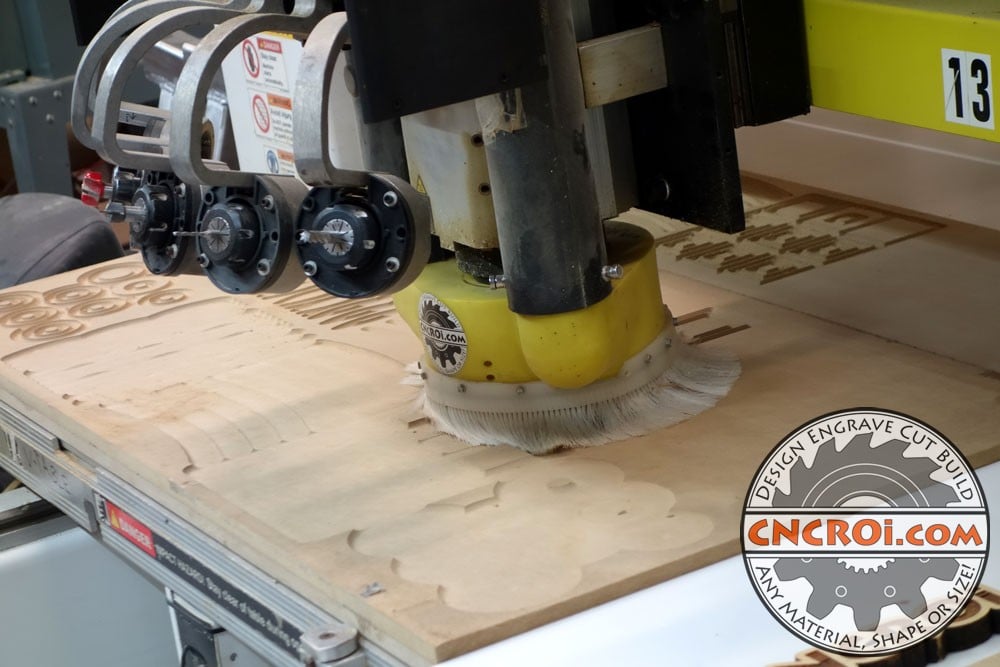

For this prototype run, we used four different CNC router bits: a ¼ inch (6.35 mm) straight bit, a 3/8 inch (9.5 mm) bonus bit, a 90° V-carving bit, and a ball-nose bit. Some bits were too wide for the spacing in our test design, which demonstrated exactly what doesn’t work—a handy outcome when refining production.

When a client tells us, “I want a ⅛ inch (3.175 mm) wide and deep cut with a straight profile,” we know exactly what they mean, and they know exactly what they’ll get. No guesswork. No surprises.

MDF (Medium-Density Fiberboard) is a dream to work with from a machining perspective. Sure, it’s hard on tools due to its high resin content—it’s a bit like sanding concrete with a foam brush—but its consistency and finish potential are unmatched. MDF texture plates can be sanded smooth effortlessly, painted beautifully, and finished to perfection. That’s why they’re the backbone of cabinetry, wall panels, and museum displays across North America and beyond.

These sample tiles might be small, but they represent enormous possibilities. Each design could scale into a massive wall feature, custom mold, or sculptural display.

CNCROi.com can carve these same textures onto full-size 5×10 ft (1.52 x 3.05 m) MDF sheets with ease. Need a seamless look across a 6×9 m (20×30 ft) wall? We’ll slice and tile matching MDF sheets that align perfectly. Any minor seams left behind vanish with a bit of sanding and a skilled finish.

What makes MDF texture plates so useful isn’t just the material—it’s the design control. By mixing and matching cuts from different bits, you get an infinite array of patterns and tactile surfaces.

Want something elegant and subtle? Use a ball-nose bit. Need a bold, architectural look? V-carving is your best friend. All of these styles are available from CNCROi.com, custom-designed, custom-cut, and shipped directly to your location.

There’s no such thing as a universal material, but MDF comes dangerously close for most interior applications. It’s relatively lightweight, very strong when used properly, and dimensionally stable—key for long-term installations.

As long as you don’t try to hang an anvil from it, MDF texture plates hold up like champs. That’s exactly why kitchen cabinets, store fixtures, and commercial wall displays are built with this dependable fiberboard.

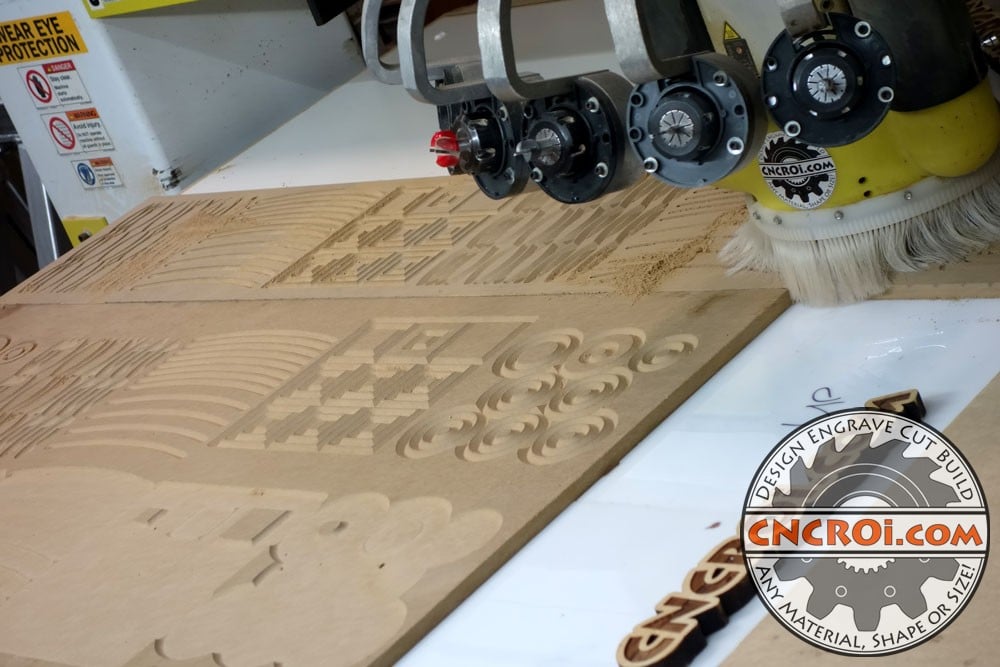

Let’s dig into some visual differences using our tile prototypes. Each tile used the exact same pattern, but different bits. That alone produced drastically different outcomes. A straight bit gives sharp, clean lines with a flat bottom.

A ball-nose adds a soft, rounded depth that plays with light and shadow. A V-carving bit slices deep and tapers dramatically, giving textures a pronounced, graphic feel. Even dust patterns help highlight these differences.

Next up: a square tile design with repeated line spacing. Again, the same pattern was applied using different bits, and the results speak for themselves. The V-carve version looks aggressive and crisp. The straight bit makes for more architectural, boxy impressions.

The ball-nose softens everything into gentle contours. This is how CNCROi.com ensures clients choose exactly what fits their brand, space, or product line.

The point of all these samples isn’t to overwhelm—it’s to empower. Once a customer says, “I want the look of this tile, but scaled up,” we handle the rest. And thanks to the size of our industrial CNC router, we can run full sheets without blinking. We’ll even let the machines hum overnight if that’s what the job needs. We know texture. We know scale. And we know MDF.

Custom MDF texture plates open up endless creative opportunities, whether you’re building a trade show booth, a retail storefront, or a corporate headquarters wall feature. Want something modern and geometric? Done. Prefer organic and flowing? No problem. Need every single tile to look the same across 50 sheets? We’ve got you. CNCROi.com lives for this kind of challenge.

And once you have your CNC-cut MDF texture plates in hand, finishing is where the real magic happens. Sanding smooths out any tool marks or rough edges, especially across seams. Priming and painting bring out the detail, while staining adds a natural, earthy finish if you’re working with veneered MDF. These little steps transform a machined board into a design centerpiece.

Let’s not forget about the tactile quality. MDF texture plates aren’t just for visual flair—they’re meant to be touched. V-carved grooves invite your fingertips. Rounded profiles from a ball-nose bit create surfaces that beg to be run across. Even small changes in bit size or spacing completely alter the way a panel feels, and that’s something no photograph can quite capture.

It’s also worth mentioning how practical these plates are for iterative design. Trying out ten different styles on small sample tiles lets clients choose favorites without wasting full sheets. Once they’ve picked a texture, scaling up is easy. CNCROi.com stores files, tools, and settings, so every piece in your large-scale project matches flawlessly, from start to finish.

Another hidden benefit? Mixing bit types. You’re not locked into a single look. Combine V-carves and ball-nose cuts on the same sheet for contrast. Use straight bits to create framing lines. Vary depth across your design to create a 3D effect. You’re only limited by imagination—and we’ve got plenty of that to spare.

For museum designers, retail planners, architects, and fabricators, this level of flexibility is game-changing. You can simulate stone, wood, tile, or even abstract textures on simple MDF. It cuts down on cost, weight, and installation time—without compromising appearance or quality. Want your MDF texture plates to look like chiseled marble? Just ask.

Because everything we do is custom, your brand identity stays front and center. Whether your project involves hundreds of repeating tiles or one dramatic feature wall, CNCROi.com can make it happen. We can even integrate signage, logos, and functional elements right into the paneling. It’s not just texture—it’s storytelling in 3D.

Now, to be clear, not all MDF is created equal. There are denser grades for more robust applications and lighter ones for ease of handling. CNCROi.com can help you choose the right material for the job, based on finish, application, and environment. We’re happy to make recommendations, especially if humidity or mounting is a concern.

And yes, we understand that MDF has its limits. It’s not going to survive a monsoon or hold up outside without help. But inside? MDF texture plates thrive. And thanks to our precision tools and design expertise, they’ll last longer and look better than you’d expect from any off-the-shelf panel.

Want to get funky with lighting? These plates work brilliantly with LEDs and spotlights. Shadows play off the grooves and contours in dramatic ways. Whether you’re highlighting a retail product or setting a mood in a gallery, MDF texture plates become part of the lighting design—not just the background.

If you need to run wires, embed sensors, or build layered displays, we can accommodate that too. CNCROi.com isn’t just about cutting—it’s about full integration. We’ve built backdrops with hidden cabling, wall features with embedded magnets, and even panels that pop off for easy service access. All with precision-cut MDF texture plates.

The takeaway here is simple: communication, customization, and quality. These tiles are more than just pretty samples—they’re conversation starters. They eliminate confusion, speed up the approval process, and make sure the client gets exactly what they imagined. Sometimes better. And once they’re in place, nobody’s going to guess they started as raw MDF.

So whether you’re outfitting a conference room, designing a boutique, or building an immersive space, MDF texture plates are your new best friend. And CNCROi.com is the one to call when you’re ready to bring them to life. We’ve got the tools, the materials, and the enthusiasm to turn your idea into reality—one groove at a time.

Reach out to CNCROi.com today. Don’t settle for generic. Let’s make your MDF texture plates as unique as your vision.

And if you’re thinking, “This all sounds great, but my project’s a little… weird,” all the more reason to contact CNCROi.com. Whether it’s a funky-shaped panel, an interactive installation, or MDF texture plates shaped like a map of your grandma’s backyard, we’re in.

We thrive on the unusual, the ambitious, and the “nobody’s done that before.” So don’t just imagine it—get in touch and let’s CNC it into reality.