Small Custom Fire Rescue Marshal Plaque: Poplar (Part 1 of 3)

After completing the larger custom fire rescue marschal plaque, the customer wanted a smaller one.

The most obvious course of action was for CNCROi.com to just scale the entire drawing down to roughly half the length, width and height to create the smaller version of the custom fire rescue marschal plaque.

The above video shows you the “original” size of the plaque so you have an easy comparison.

So, the same steps were applied, just at a smaller scale, the lamination was from smaller bits of poplar as well.

Poplar is sometimes very hard to see what was skimmed off and what was not, so a bit of pencil marking provides me with the contrast needed to make sure there are no low points that have been missed, the reason is, I want to make sure everything is dead flat for the laser engraving.

At this point, I still haven’t glued anything up, I’m just cleaning-up two sides of four on these pieces of poplar so that when I do the glue-up, there is an almost seamless look to it – this is the power of doing glueups this way at CNCROi.com using our CNC router.

Of course, if you wanted a custom plaque using another material, more suited to outdoor use for instance, Corian is a great choice.

After one side is cleaned-up using our router at CNCROi.com, I just flip the sticks over and do the same process, though this time, it’s more obvious what is shaved vs what isn’t.

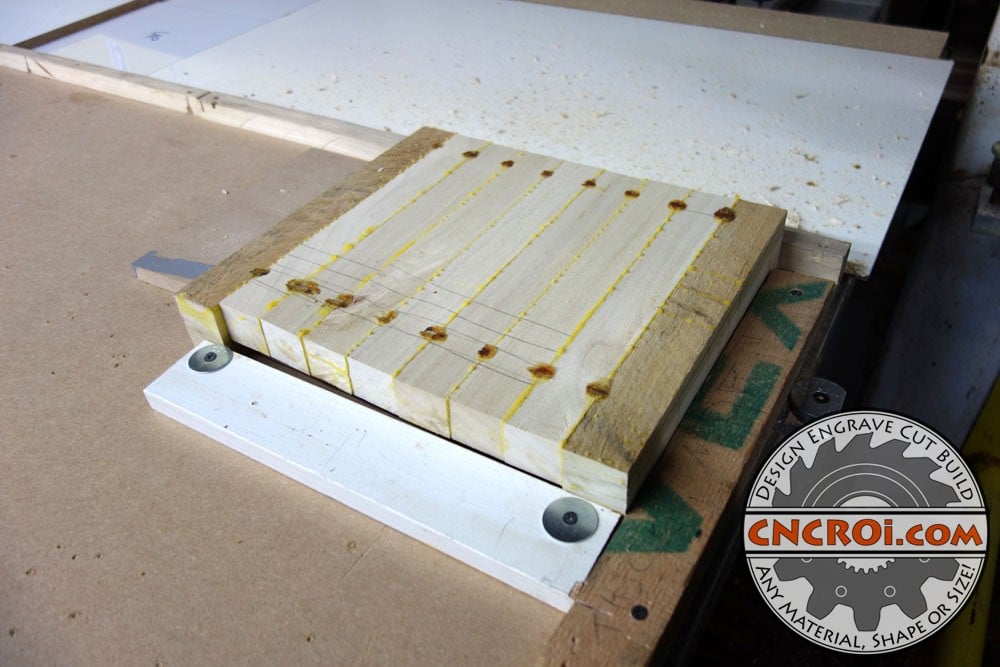

After the two sides are shaved, it’s time to stick it all together, laminate the poplar, in order to produce the blank that I require to make the custom fire rescue marschal plaque.

I generally give the wood a few days to fully cure in this state, I find this assures that everything is dry, although the glue bottle says everything should be cured within 24 hours, there isn’t much atmosphere getting into the full seam, so the middle takes a lot longer to cure than the edges.

If you wanted other things incorporated into your custom plaque, CNCROi.com can make that very much possible as well.

After everything is dry, it’s time to yet again, flatten the front and the back of the custom fire rescue marschal plaque blank so make sure everything is flat, parallel and PERFECT at CNCROi.com!

I’m happy I have such a fantastic CNC router, it allows me to quickly and easily make really good blanks for further processing at CNCROi.com with the best results possible.

I found the original blank needed a little more width to it for holding it down during production, so I glued two other pieces at either side, these will never be or meant to be part of the finished custom fire rescue marschal plaque so their color and texture doesn’t matter.

We have years of experience making custom plaques of all sizes and shapes out of just about any material.

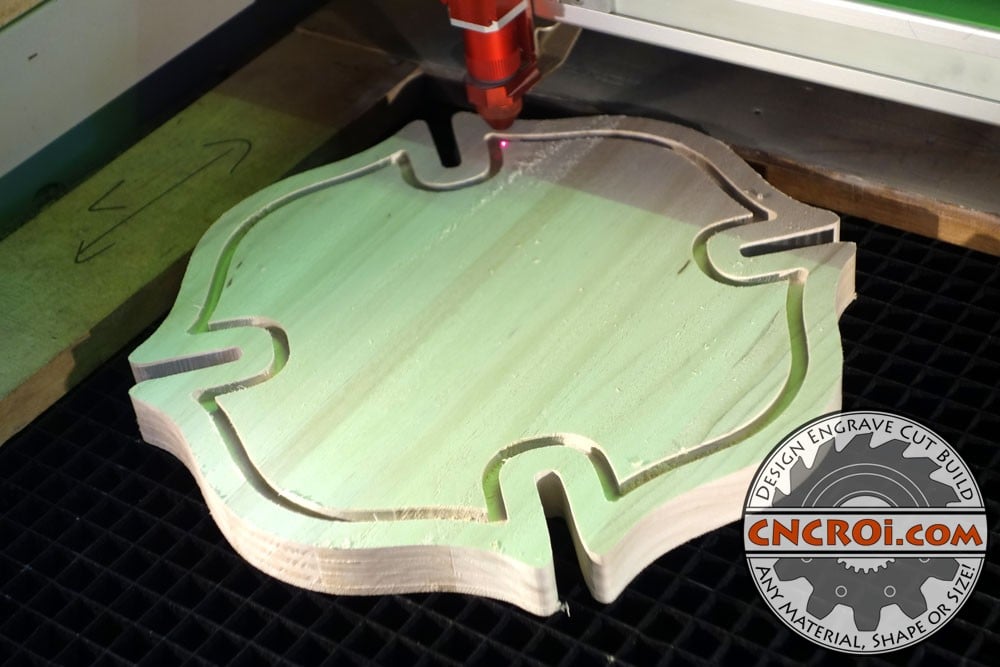

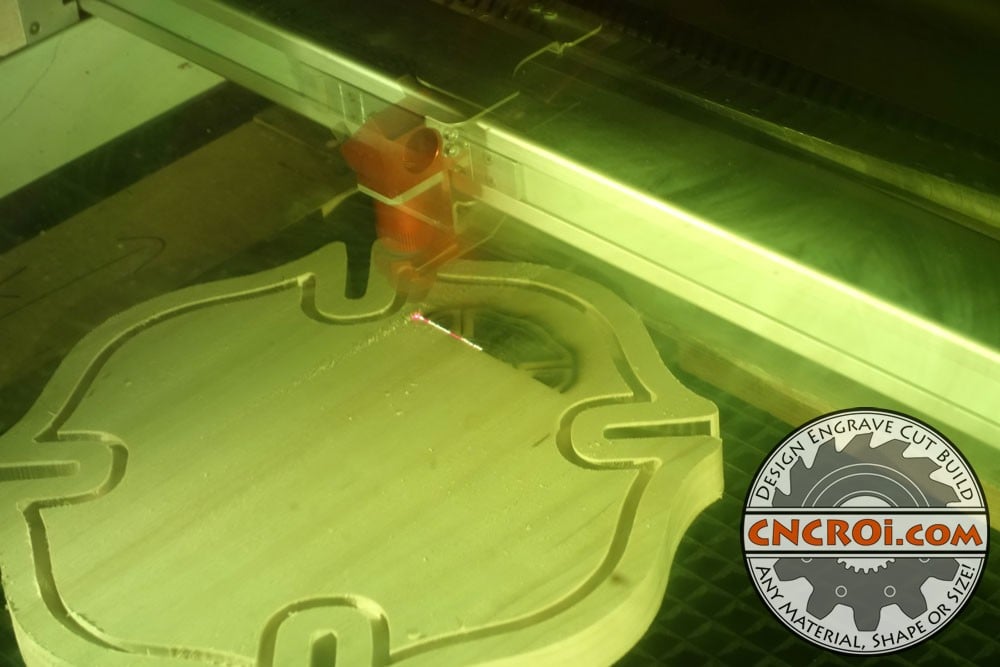

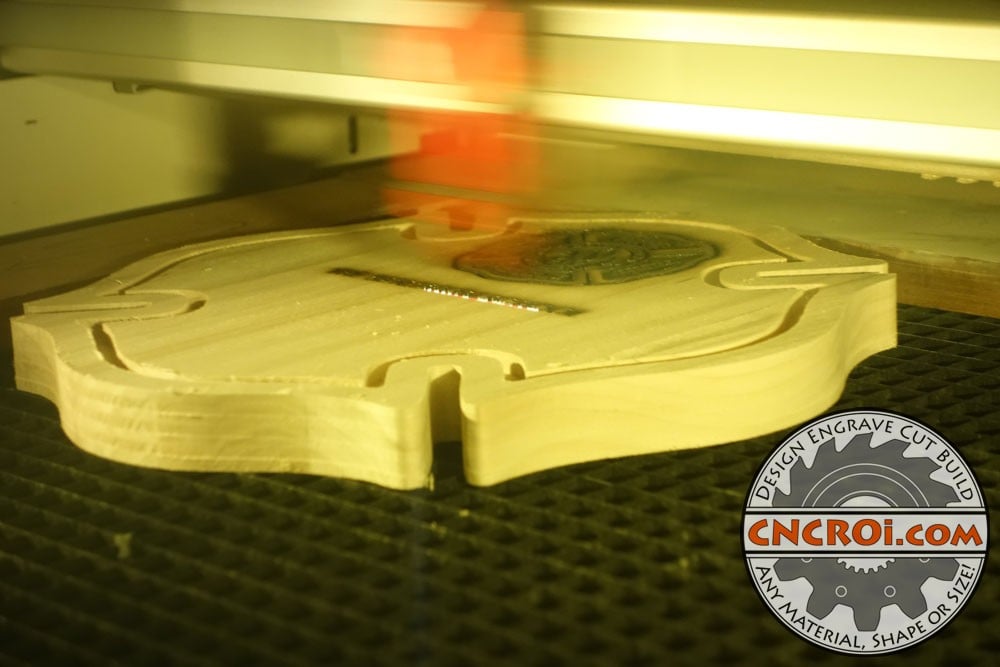

After making sure everything was flat, it was time to start carving out the custom fire rescue marschal plaque from the poplar blank I made.

Although I don’t use a lot of different tools for this custom fire rescue marschal plaque, it’s still wonderful having the option of many different tools for efficient and repeatable production.

Although the lamination process is a time consuming process, I still very much enjoy doing because the results are so spectacular, the glue seams are just perfect without any gaps or pockets and although you can tell it’s a glue-up based on the differences in grain patterns, the overall custom fire rescue marschal plaque is very much consistent.

Firefighting plaques using a similar design to the one you see here can be made using any wood species you want at any size you require.

After cutting out the plaque, the “scrap” is removed and will be found a new home in the firepit – something I’ll be custom fabricating shortly at CNCROi.com as well.

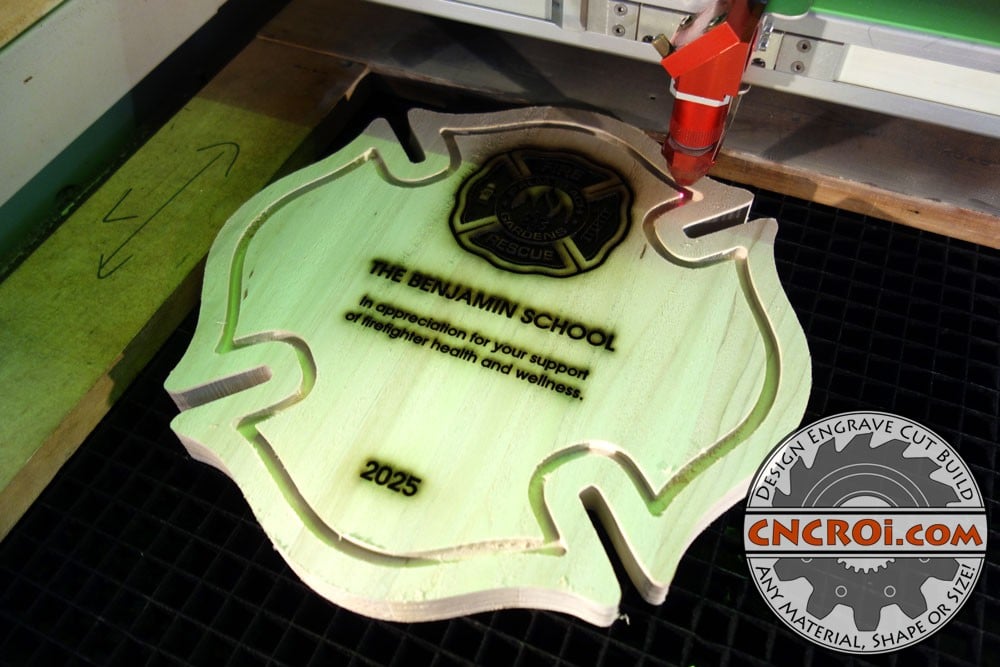

Although technically I could very much CNC router the logo and other details onto this plaque, the laser is a more finer process with a narrow beam, so it produces sharper results at this size.

The challenge with scalling down a drawing and overall project isn’t that our equipment can’t do the job properly, it’s that sometimes the material can’t handle the tight resolution of what we make at CNCROi.com and this ended-up being a fine example of that.

Although the results from the laser engraving process onto this custom fire rescue marschal plaque was very good, we found out that afterwards that small parts of the logo were breaking off.

Whether you want a more traditional plaque design or something more fancy, CNCROi.com can fabricate it just for you!

The contrast produced by poplar is fantastic though, there is quite a bit of sanding and finishing required after the router did it’s job but I really like working with poplar, it’s a “soft” hardwood that has so many wonderful applications.

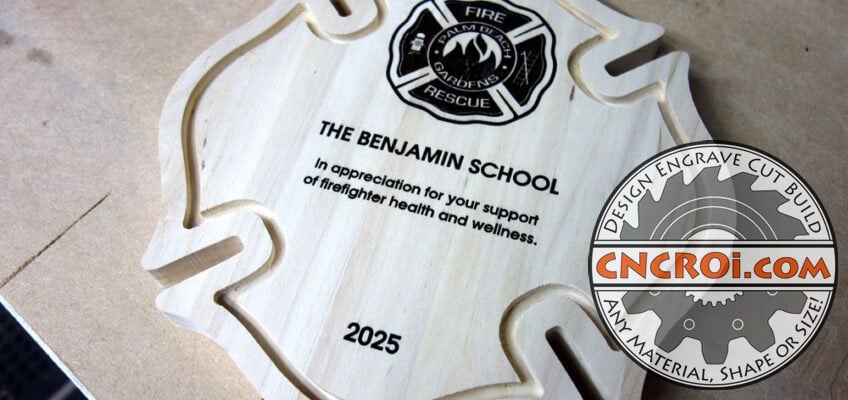

After laser engraving and finishing, you can see how awesome this custom fire rescue marschal plaque looks!

Everything is nice and sharp, the logo looks great and the overall plaque looks incredible, there is nothing cookie-cutter in this!

After shipping this to the customer, some of the inner logo parts were starting to break-off, hence why this is part 1 of 3, the second part will be next time as we look at other options when it comes to making these smaller custom fire rescue marschal plaques.

Need a custom plaque? Contact CNCROi.com right now!