Solid Oak Domino Set: Reclaimed Wood to High End Game

Making something as “simple” as a solid oak Domino set doesn’t seem complex but It’s astonishing how many steps are involved with making a custom set using nothing but a few tools, a laser and some reclaimed wood that’s been outside for the better part of a year.

Interestingly, when CNCROi.com makes custom corporate awards out of wood, reclaimed or just typical lumber, the steps are almost identical and sometimes even more complex as they involve multiple pieces glued or nailed together.

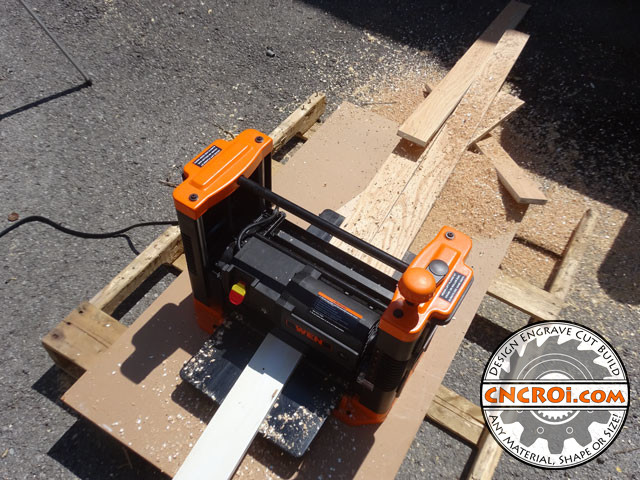

As you can see from the above picture, this isn’t the “best” wood out there, it was water, sun and ice damage with a bit of mud thrown in for good keeping, no worries, our planner transforms those upper layers into WOW in no time.

This solid oak, which was sadly painted on one side white too on one side, comes to CNCROi.com via a home renovation and if the steps look familiar, it’s very close to the same procedure we used when making pyrography using broken-up pallet boards.

Regardless of source, CNCROi.com has the equipment, expertise and experience to pull it off.

We are able to transform just about anything into something that’s amazing.

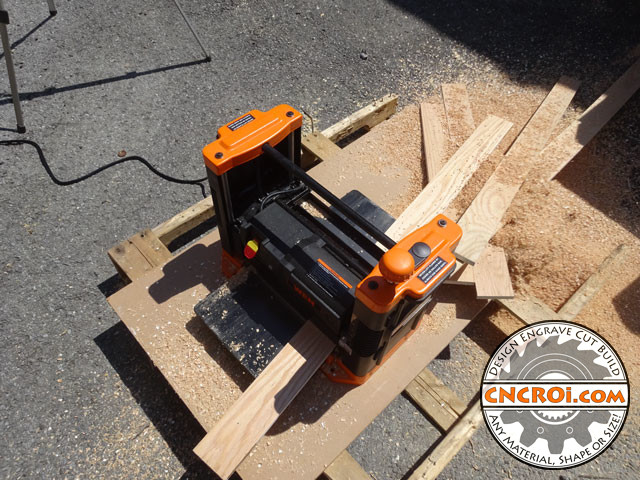

After one side of this worn out solid oak soon-to-be domino set pieces, it’s time to plane the other, and this leaves us with absolutely amazing looking oak at a fraction of the price of getting this at the local lumber store.

The process of cleaning-up worn out oak planks does produce a very substantial amount of wood chips, great for fire pit operations at CNCROi.com at night after a hard day at work!

The CNCROi.com planer does an amazing job, but we aren’t done cleaning this wood up, next step is to clean-up the sides.

I could have bunched-up all the boards and planed all the edges but we have a fantastic woodworking bandsaw that’s faster and at the same time, gives CNCROi.com a good view of the newly refreshed boards we are using to make this custom solid oak domino set.

Like pallet wood, this reclaimed renovation oak does have nail holes, so during this clean-up process, we’ll work around them to have as few of them visible on our finished custom solid oak domino set.

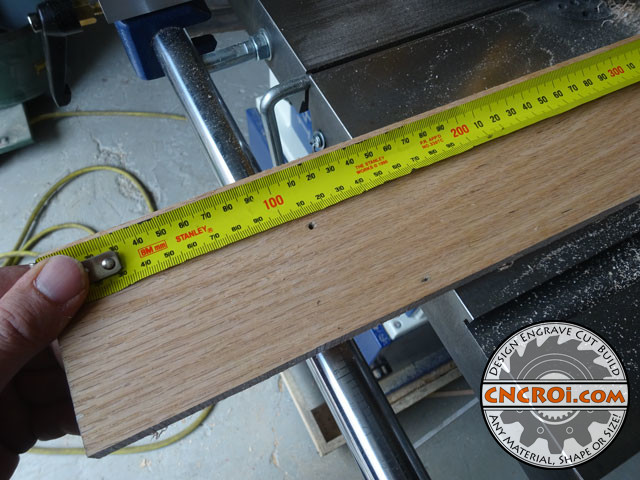

After all the edges are cut off, it’s time to cut the domino set pieces to size.

This is just so much like making custom corporate awards, here’s a simple design we made for a CNCROi.com customer that involves two pieces nailed together.

After the roughly 6.5 inch x 3.5″ solid oak domino set pieces are cut out, they are reviewed for any flaws, of course, these all came-up awesome and at the end, only 3 pieces ended-up having nail holes which were hardly noticeable.

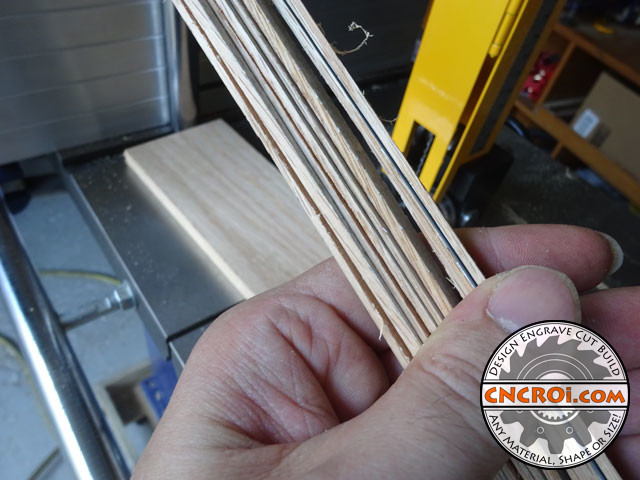

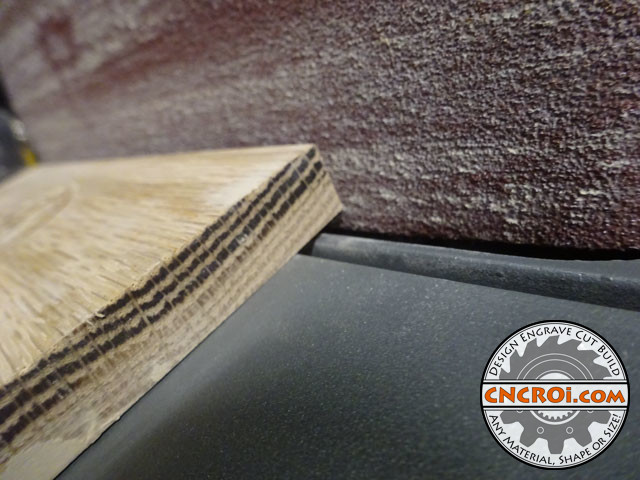

Here are what the edges look like after they were removed from the long planks, this would be great for other applications but I decided they were ready for the CNCROi.com fire pit instead.

These solid oak domino set pieces will require sanding but the bandsaw made quick work of this solid oak, it’s faster to cut these with a bandsaw than a laser though it does require sanding but I wanted the edges to not be burned, hence bandsaw over just straight into the CNCROi.com Austrian wide-format industrial laser.

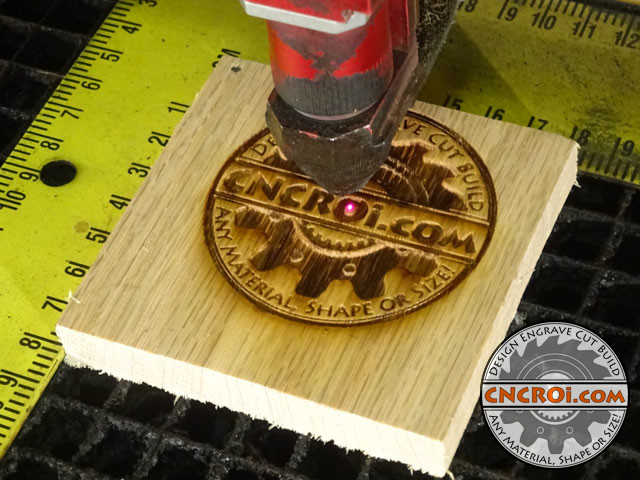

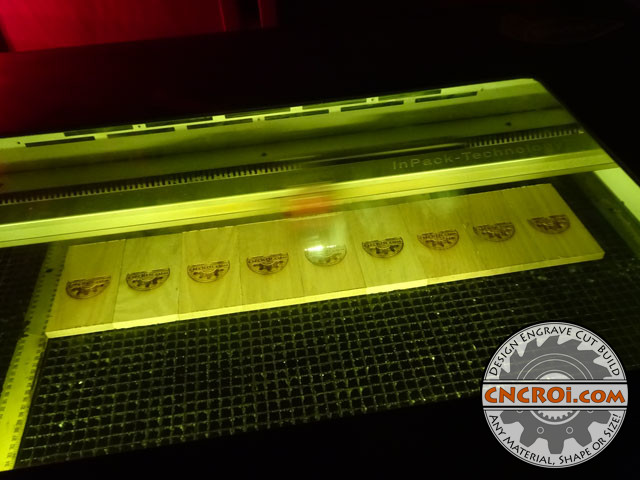

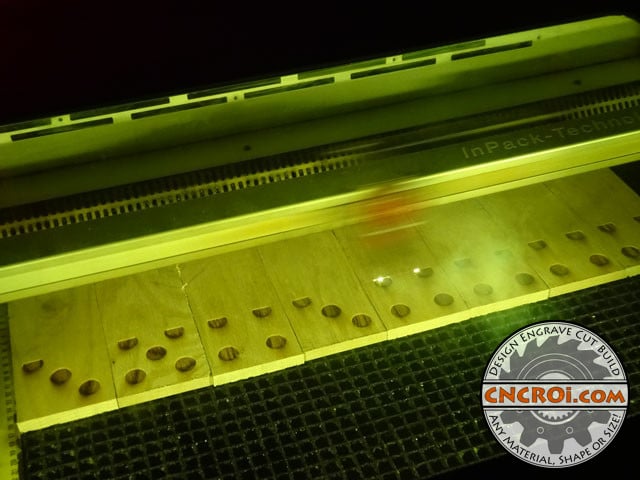

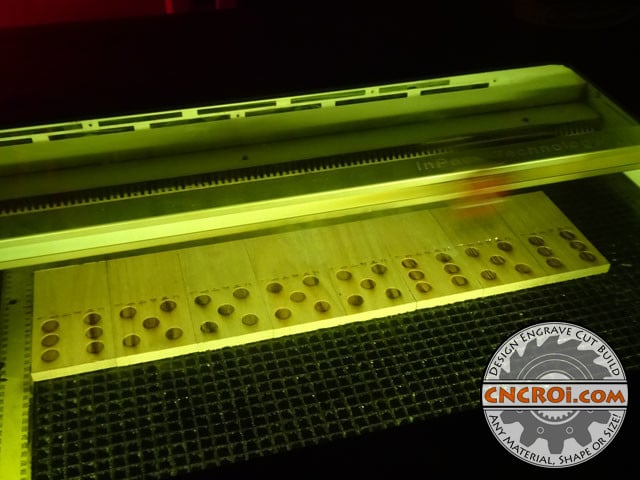

Before going ahead and engraving the whole lot, front and back, I did some test on a piece of scrap to make sure all the settings would work.

I ended-up engraving the solid oak domino set pieces a little deeper as I knew there would be extensive sanding required on all surfaces.

I decided not to mask them either, the simple reason being I wanted to see just how much work would be involved as it’s been a while since I did a production run using only oak and the laser without any masking.

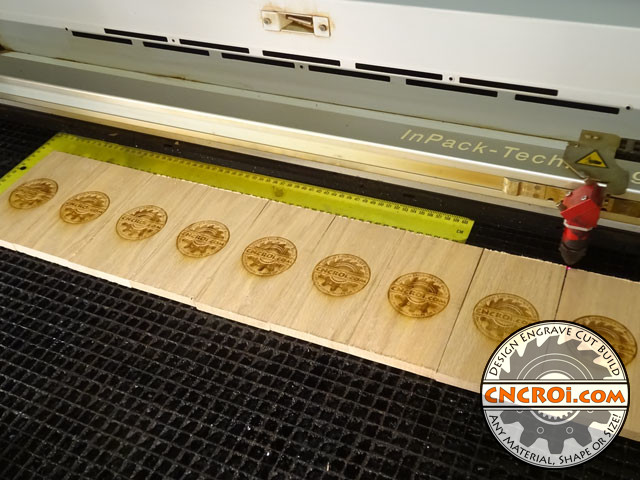

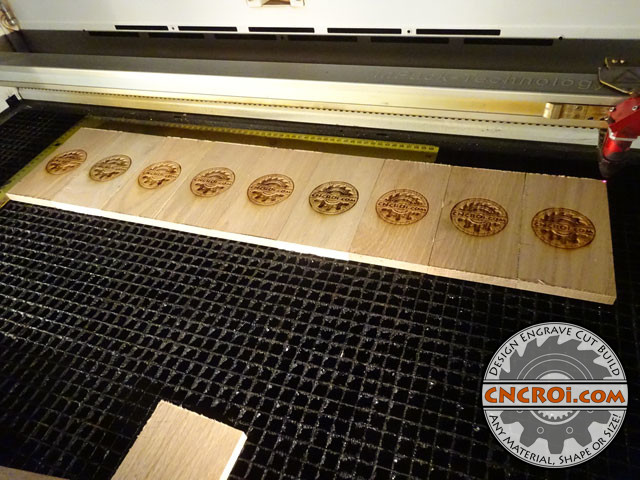

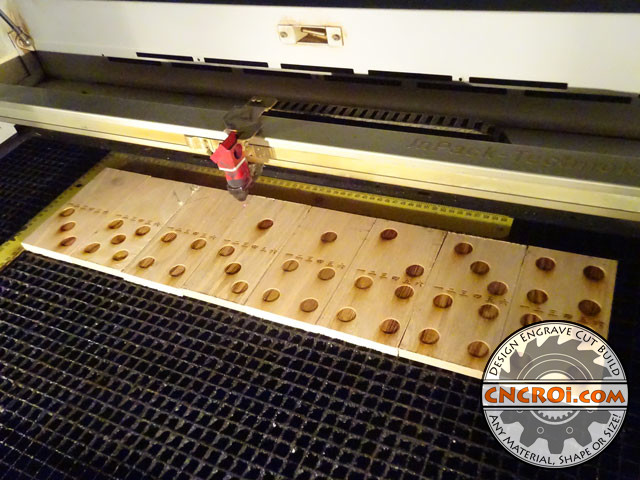

The results look amazing, each solid oak domino set piece has my corporate logo on one side then a unique dot matrix on the other.

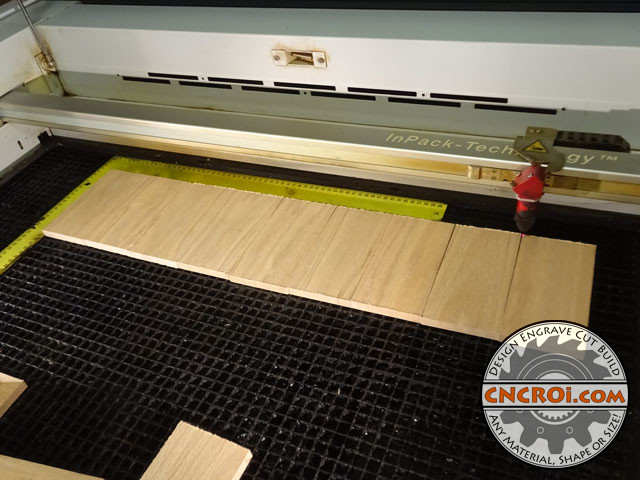

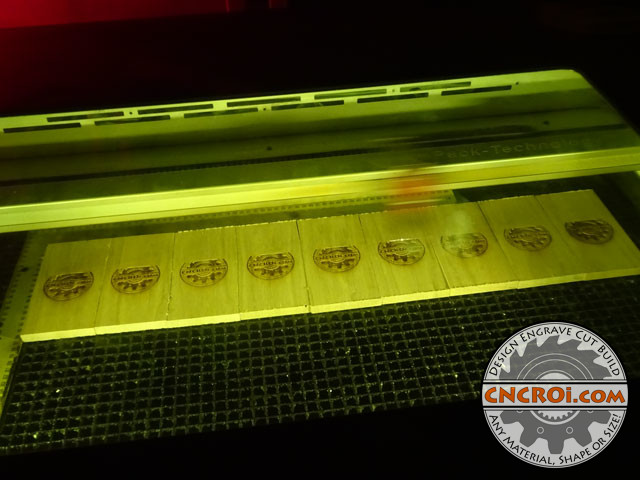

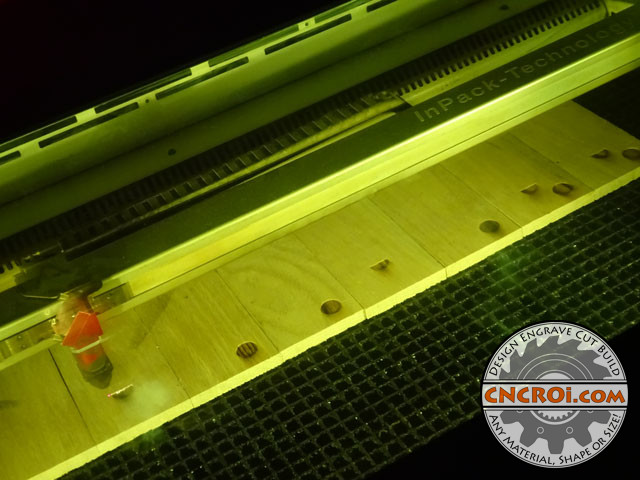

I could have easily filled the CNCROi.com Trotec Laser Speedy 400 flexx with all the pieces at once but I was in no rush and doing things piecemeal between other work was more efficient as these solid oak domino set pieces were done over the course of a week.

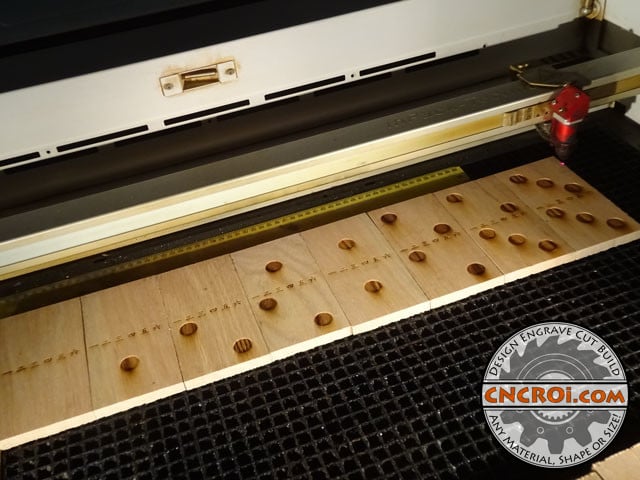

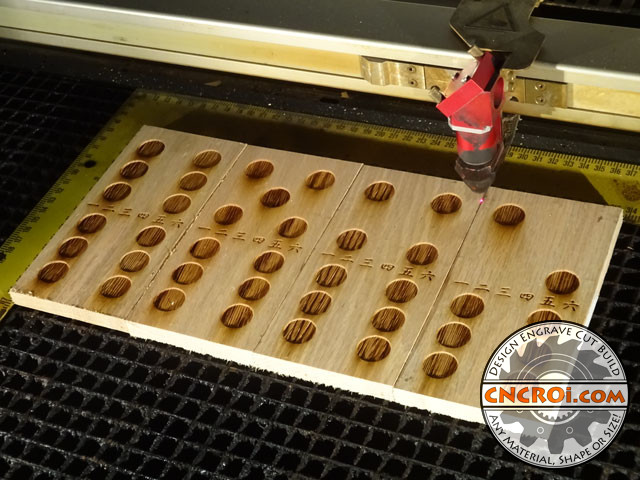

This was the final batch of logo branded solid oak domino set pieces, it was then time to flip it around and CNC laser engrave the other side.

What’s fantastic about CNCROi.com is that everything is made on-demand, what this means is that if these were custom corporate awards, each one could have a unique name, wording, logo(s) and even shape as our laser would cut each one out, one at a time.

Rectangles are easy but as you saw in the above videos, these could have been any shape using any combination of materials.

Engraving the front of the custom solid oak domino set is the same as branding the back.

There are some very slight height differences between them but it’s no big deal, the sanding will take care of that.

Due to all the engraving patterns of the dots, it took significantly longer to laser engrave the dots than the branding on the back as the logo was always at the same place on the custom solid oak domino set pieces.

CNCROi.com did a very nice custom set of solid table number stands and the steps involved here were also the same, when ever we do production runs, the materials and branding may be different along with the design but the steps are generally the same.

And the final four custom solid oak domino set pieces are not finished at CNCROi.com!

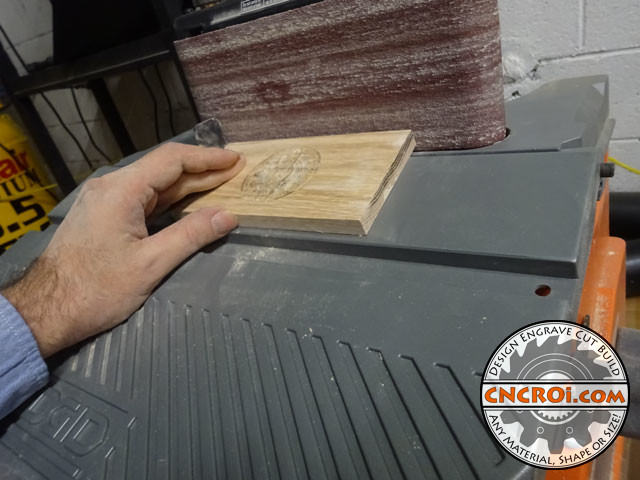

Now for the fun part, sanding each and every custom solid oak domino set piece on every side… and then some as you’ll see shortly.

The before and after are incredible, all that gunk from the natural oak is sanded off, it comes from the laser engraving process.

The branding on the back is the same, a mix of resins, smoke and natural wood stuff all settle and are sticky on the surface, nothing the CNCROi.com belt sander can’t fix!

Again, before and after sanding makes a huge difference!

I see a lot of laser work and rarely is it sanded, I don’t quite know why, CNCROi.com does A LOT OF SANDING regardless of the tools and processes we use to make our customer’s work really pop.

Although I didn’t have to use our custom downdraft table for this process, the belt sander was more efficient, it still served me very well as just a regular CNCROi.com table!

After sanding, I cleaned-up a piece to show you the incredible transformation this reclaimed solid oak took, from garbage to amazing within just a few processes!

But that wasn’t enough, I wanted the edges of these solid oak domino set pieces to be angled as well, it just fits better in the hand than a sharp 90 degree angle.

CNCROi.com does have a table router and a bunch of other tools to make this happen but sometimes the simplest tool in the shop is staring you right in the face and in this case, the sander did a wonderful job rounding the edges and sanding in one step!

After all the surfaces were sanded on these oak domino set pieces, you can see the amount of dust that they had acquired, rounded the edges surely added to the dust as well!

A quick spray using compressed air quickly cleaned up the domino set pieces though, they went from rough to amazing within seconds!

This magic trick also worked wonders on the custom CNCROi.com branding as well, after and before air spray is like night and day on these amazing custom solid oak domino pieces!

After everything was sanded and cleaned-up, it was time to review to make sure we got all of the pieces done to spec.

Originally I was going to finish these but I decided against that for now, I really like just the feel of the natural wood and as it’s wood, I can always give the domino set a quick sanding and finish them at a later date.

There you have it, an amazing set of custom solid oak domino pieces ready for endless games and as its solid oak, this will last a VERY LONG TIME!

Need something custom? You know who to contact… CNCROi.com!

and yes… CNCROi.com could have just as easily made this entire set using solid stainless steel too!