Stainless Steel Metal Tags: Annealing vs Marking

What is the difference between stainless steel metal tag marking vs annealing? Today at CNCROi.com we’ll find-out!

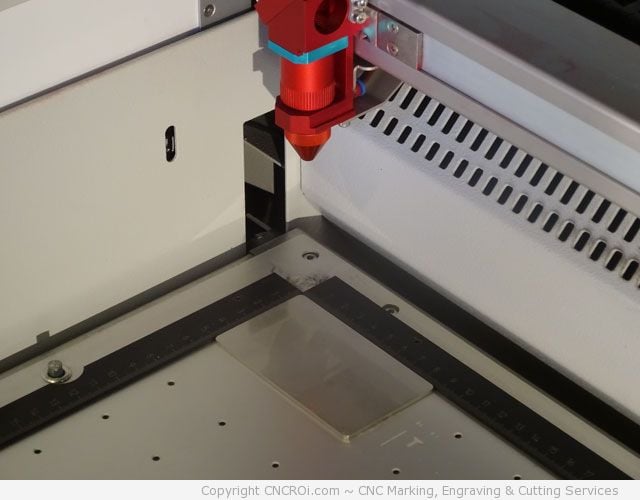

Placing a plane on our Austrian CNC laser for scale.

Metal is one of my favorite materials to work with here at CNCROi.com. It’s incredibly strong, relatively easy to work with and produces very consistent results with our Austrian CNC laser. At the shop, we do a lot of steel tag laser marking and annealing so I thought it would be fun to cover the differences between these two distinctive processes but first, let’s take a look as a physical sample of each.

CNC fiber annealing on the left, CNC fiber marking on the right.

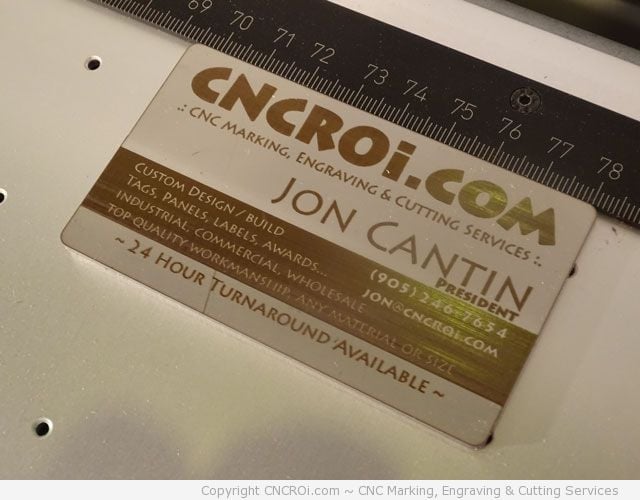

Just looking at the cards, you can see right away what was laser marked vs annealed. Annealing gives a rich black finish on 304 stainless steel (light reflection is making it look non-black in the photos) while marking doesn’t – it can vary from dark brown to an almost light grey polished look.

Depending on the settings I use for certain applications, either process can produce a smooth or abrasive result so that’s why I focused on color rather than surface qualities. Now that you’ve seen the results, lets take a look at the production of each of these samples in our laser. I want you to notice we aren’t applying any special pastes or pre-post processes to this metal, that’s because our laser has both a CO2 and fiber laser source.

For stainless steel, I use almost exclusively our fiber laser source while for softer metals like aluminium, CO2 is generally used. Having this flexibility allows CNCROi.com to efficiently process metal projects without wasted time applying and removing materials – the results are also superior in both color, surface qualities and durability.

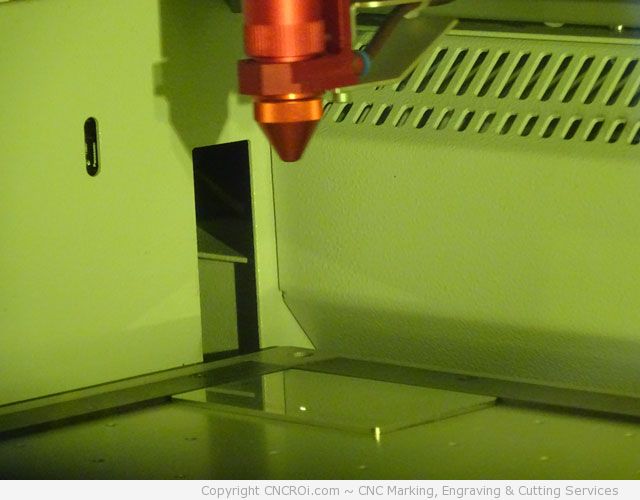

CNC annealing action shot!

Taking a closer look at the annealed plate I have here, what you see in black has been heat-treated with our fiber laser source, the color depends on the temperature achieved during the melting and reforming process, it creates oxide layers on the surface whose composition determines the color, in this case, black.

If I have my settings not hot enough, you end-up with a lighter color (otherwise known as marking) and if they are too high, I begin vaporizing the metal itself leading to abrasion.

Finished product from CNC laser annealing onto 304 stainless steel.

Now, let’s take a look at laser marking.

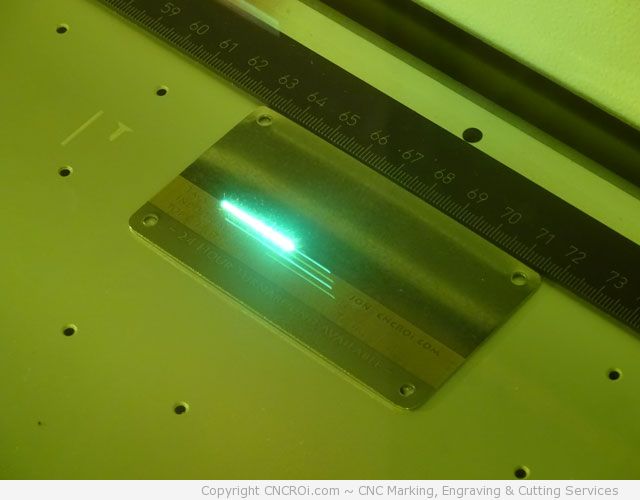

CNC fiber marking action shot.

Finished product from CNC laser marking onto 304 stainless steel machine tag.

As you can see, laser marking produces a non-black result, the tolerances for marking vs annealing are significantly higher meaning I have a lot more play marking metals with my fiber lens even if the surface is uneven, something that’s incredibly challenging annealing.

Marking is also significantly faster and can be done with either our CO2 and fiber laser source while annealing can only be done with our fiber laser source.

There you have it, the differences between laser marking and annealing. Now, let’s take a look at a video of both processes.