Steel Blade Clock: CNC Fiber Laser Etching

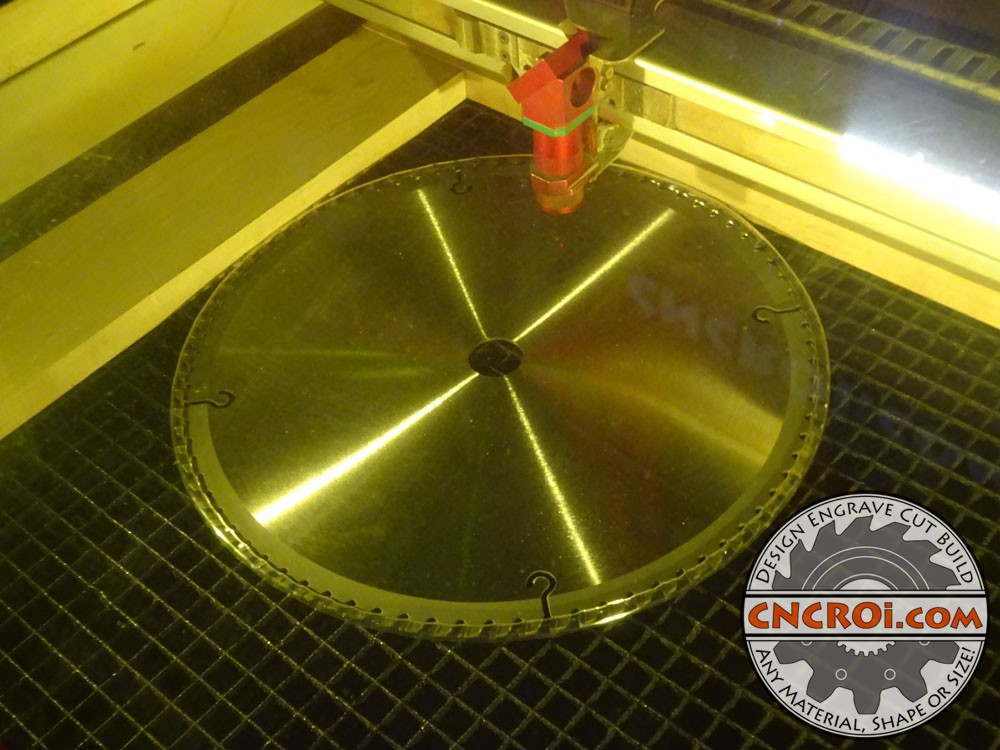

Having a fiber laser means CNCROi.com can make a custom steel blade clock that’s etched permanently with whatever information you want, in this case, it’s a 12″ blade that was transformed into a custom clock.

https://www.youtube.com/watch?v=a5JdXkAFz1M/

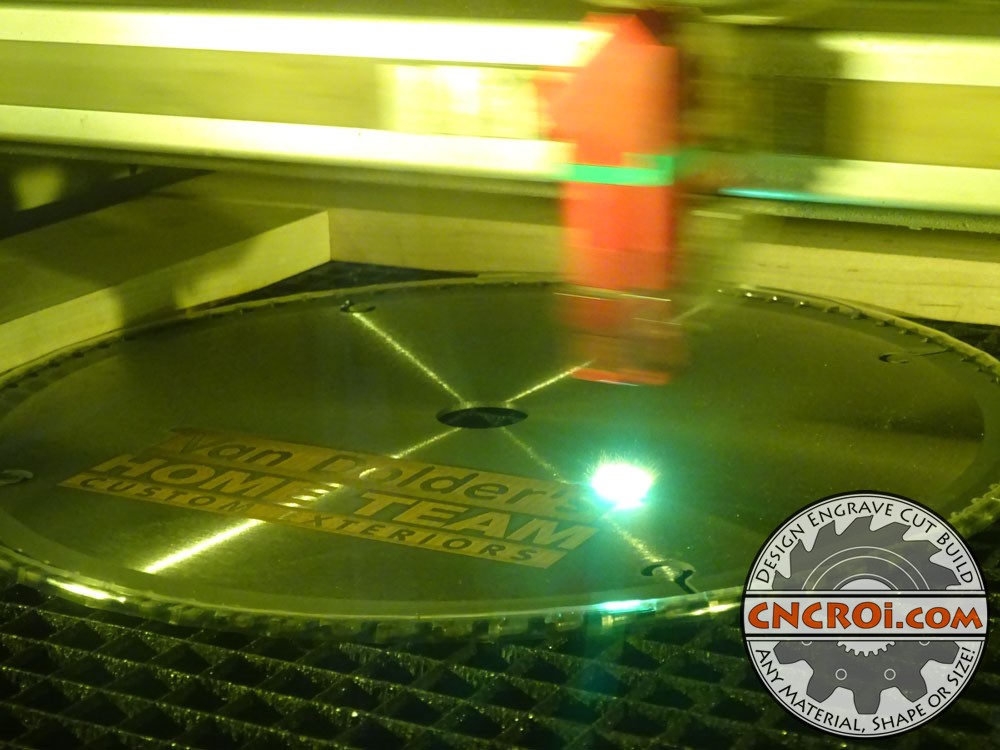

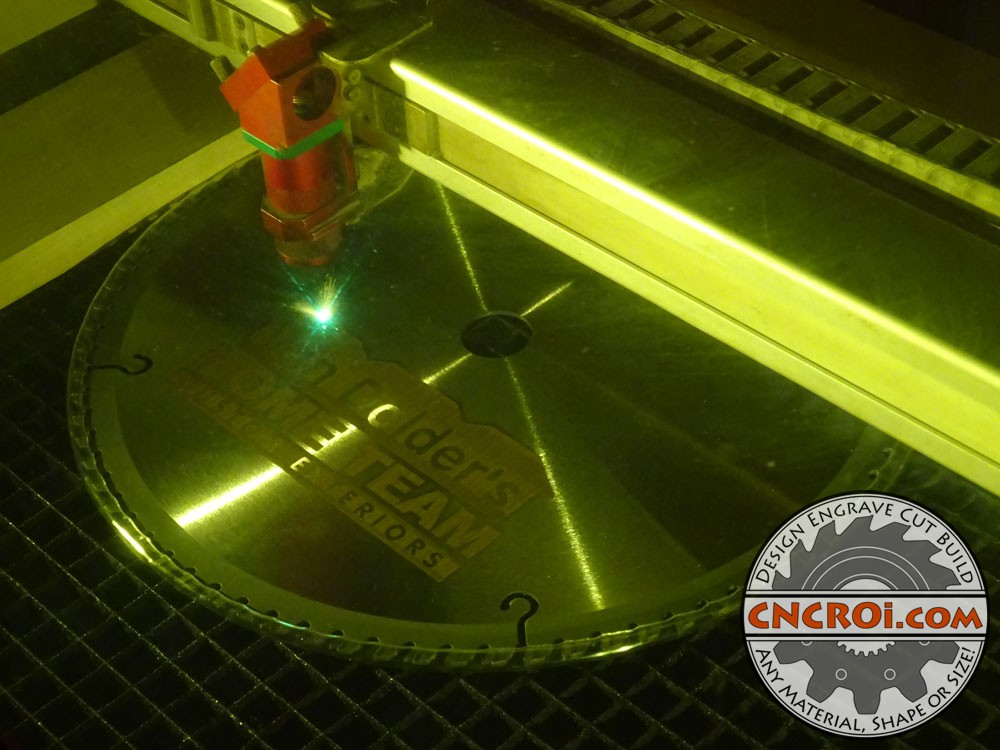

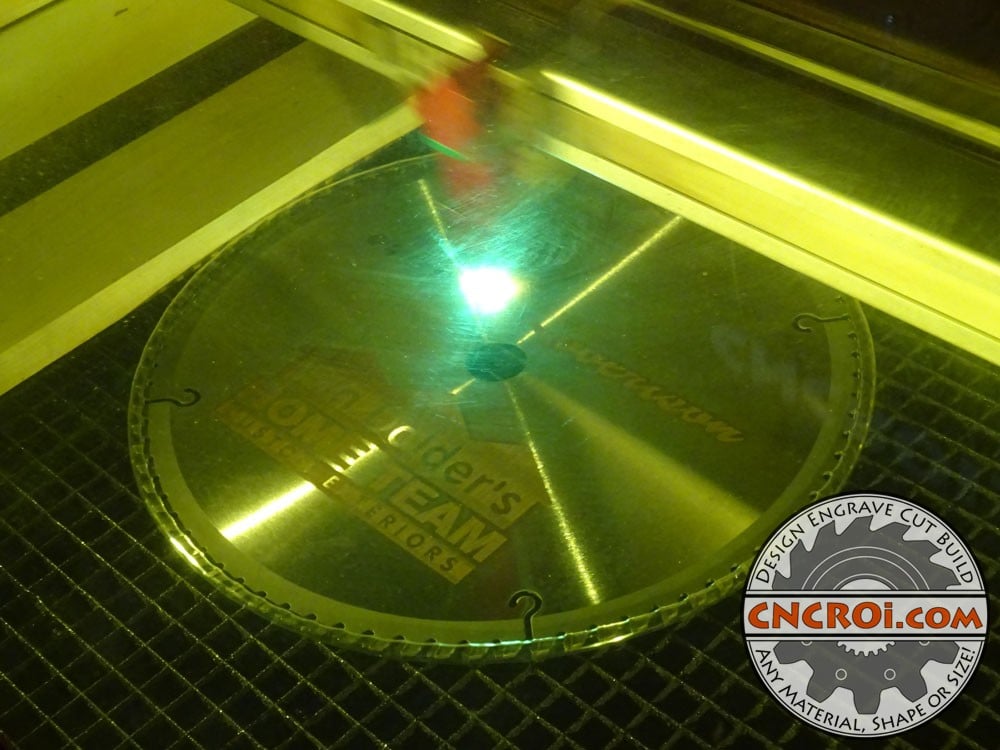

A steel blade clock is fun to make, of course, using a REAL 12″ blade is very sharp so you can see the protective plastic coating going around the clock helps to keep it from ripping my skin during production and handling.

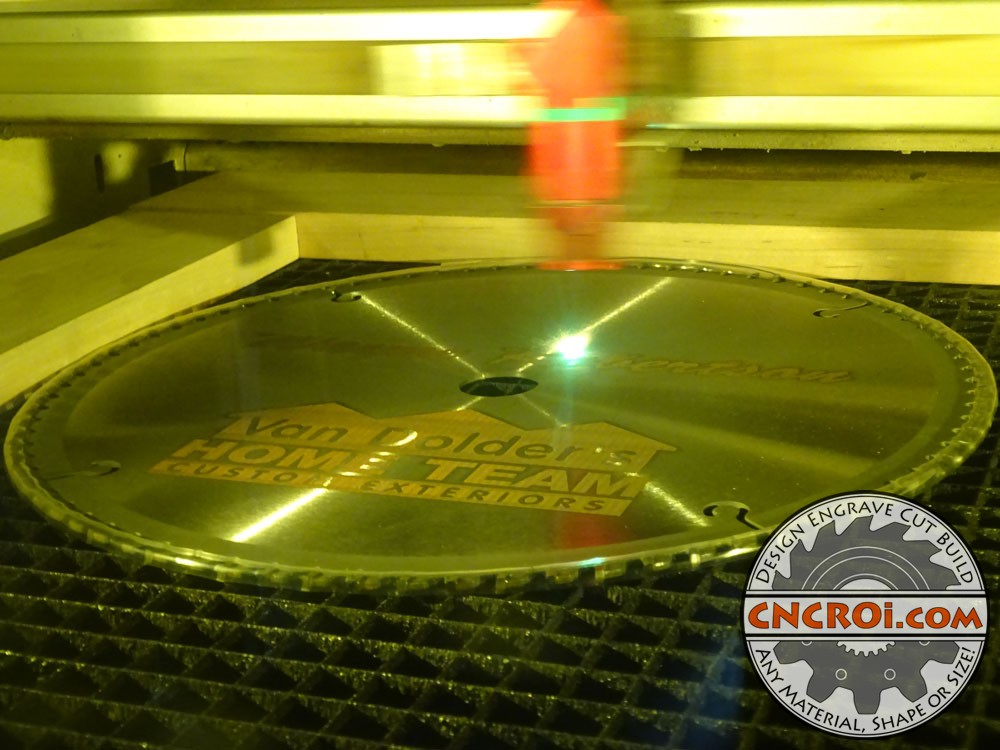

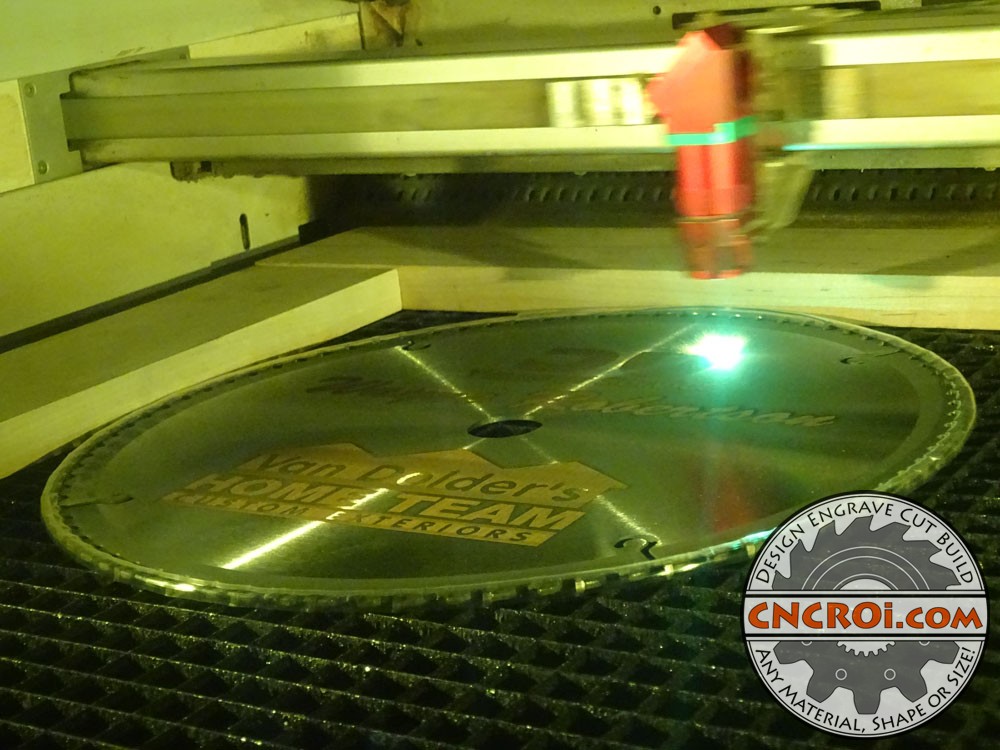

Throughout this video and photographs, you’ll see the same blade in various shades of grey and blue, that’s what makes stainless steel such a wonderful material, and also very hard to document, it changes colors based on reflectivity in the shop and the fiber laser etching work CNCROi.com does on it.

CNCROi.com isn’t limited to stock metal pieces to etch either, here’s a tool we fabricate to give you an idea of what’s possible using our industrial laser.

https://www.youtube.com/watch?v=ObgxYj3yoLM/

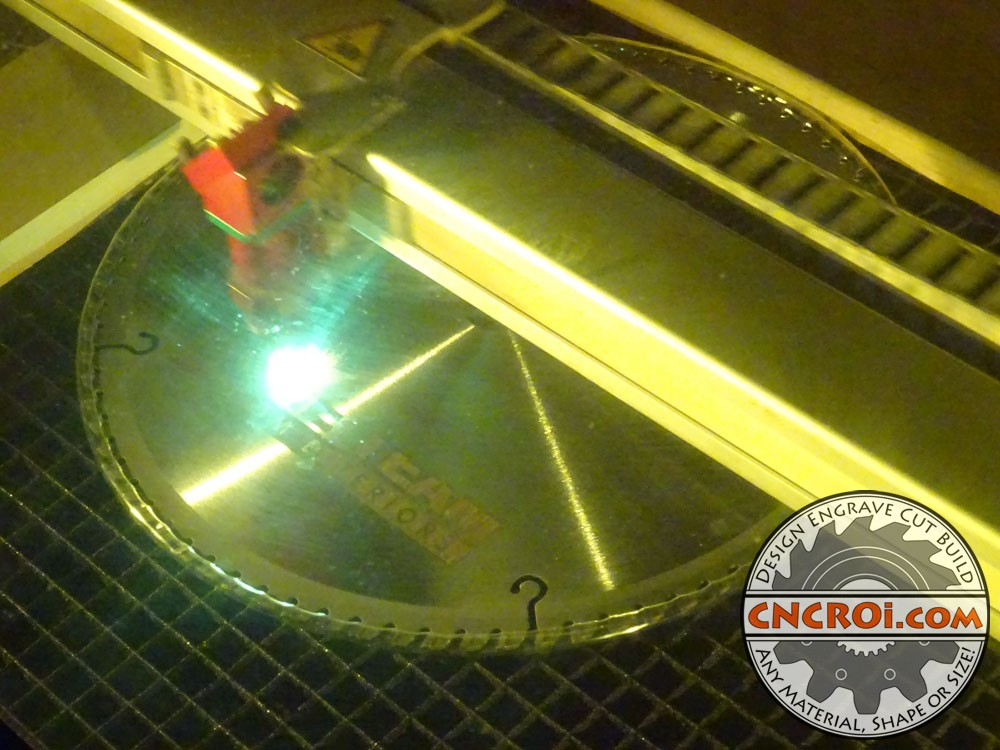

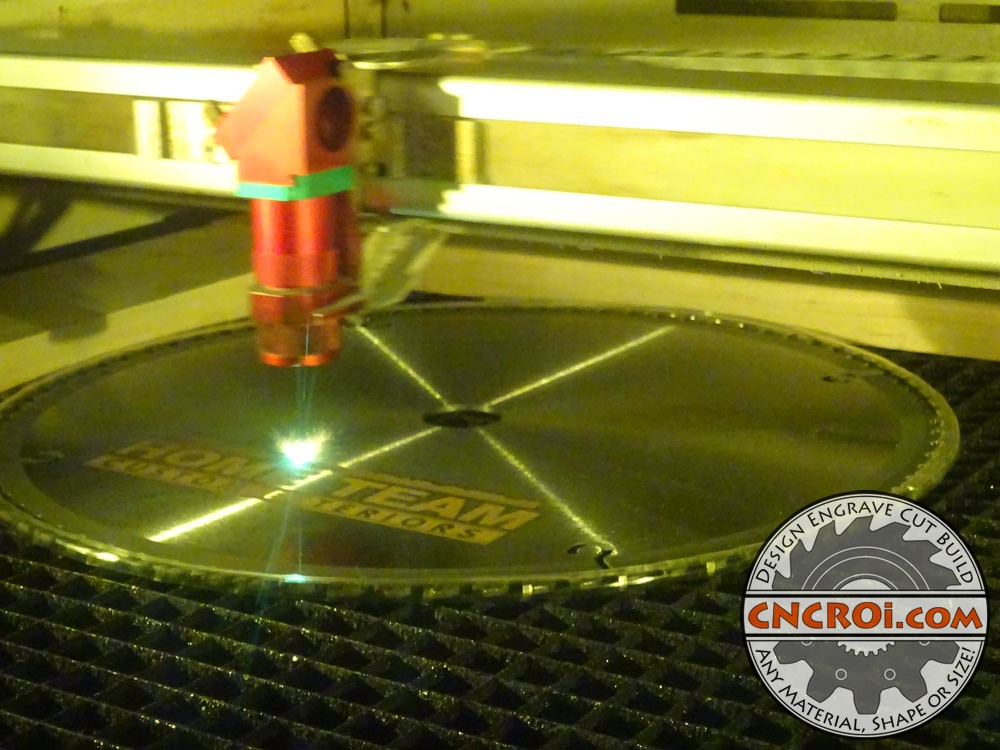

Etching is really a magical process, whether it’s a stainless steel blade clock or machine plates because nothing actually touches the metal, it’s just highly concentrated light that hits the blade and instantly, it goes to work doing whatever is assigned to it, be it fonts or graphics – it’s a contactless process that never gets old or boring.

Fiber laser etching can be done by CNCROi.com up to a thousand DPI, so even very find imagery and font styles can be etched into any type of metal, unlike screen, uv or vinyl printing, fiber laser etching is a permanent process that will not fade, crack or peel over time.

Different stainless steel “items” have different compositions, in this case, the pan has a mix that causes a jet black result without requiring an additional industrial coating.

https://www.youtube.com/watch?v=UUUCUlNA6dI/

This steel blade clock is about 1/16″ or 2 mm thick, the edges have carbide tips so even if down the line the customer wanted to actually use this for production work, it could easily cut a 2×4 no problem though the etching does cut into the surface so this is not recommended as CNCROi.com has changed the surface dynamics of the carbide saw blade.

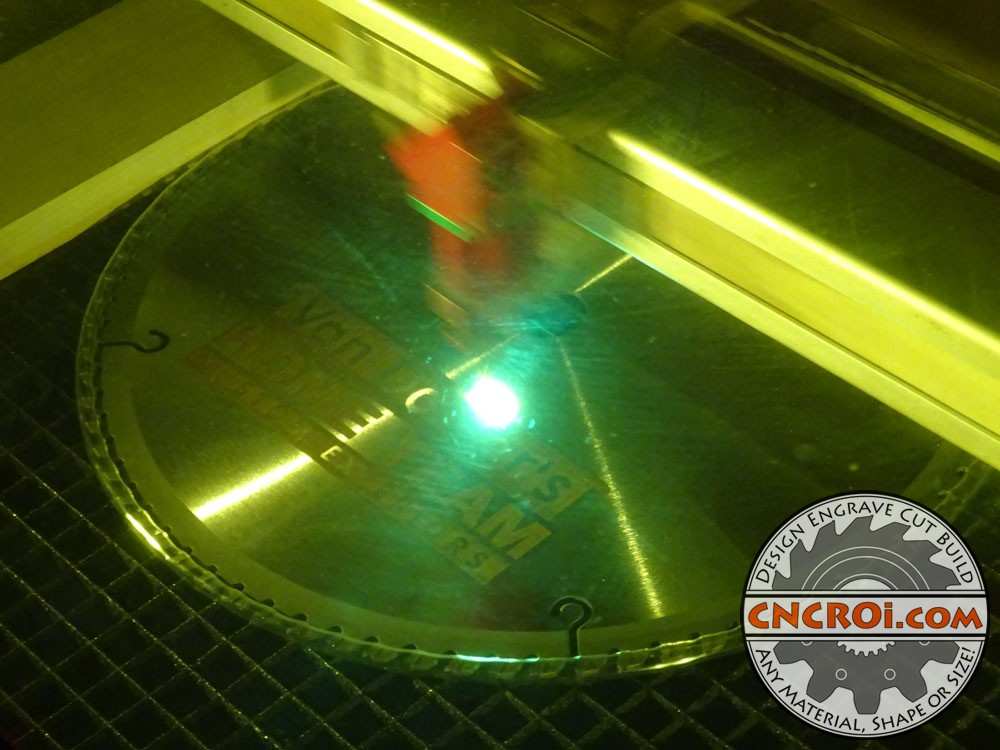

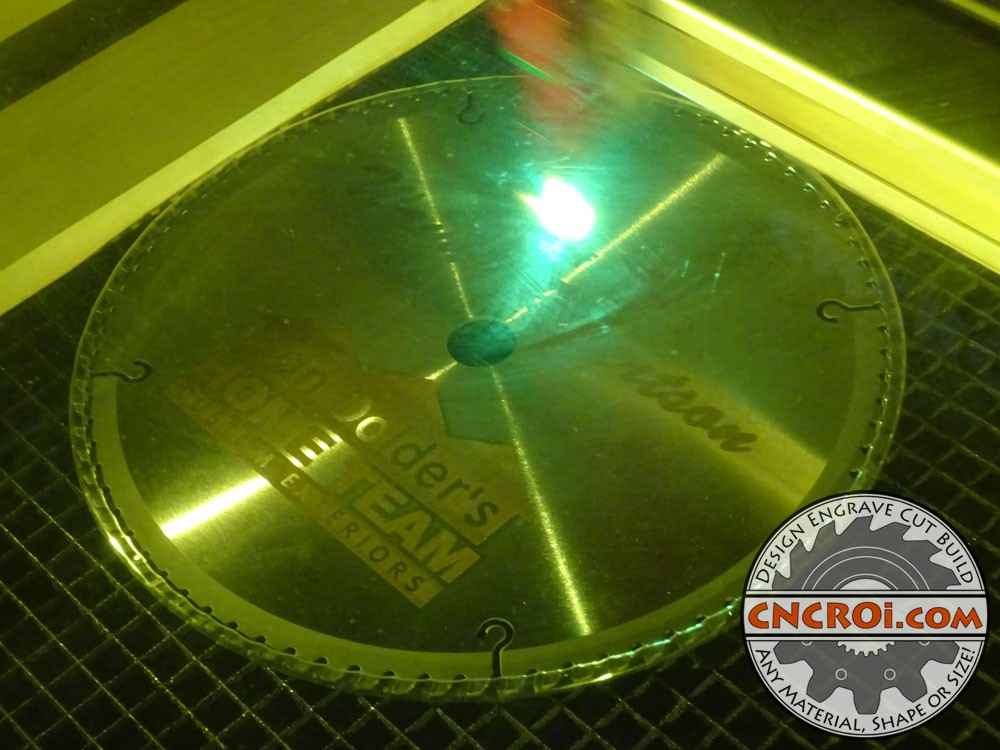

The bright light you see coming from the carbide tipped steel blade saw is just the reaction of the fiber laser beam vaporizing the metal, it’s a similar spark to what you see when welding except it’s far smaller and more precise an area.

How durable is laser etching? Here’s a comparison to other metal items we do in the shop.

https://www.youtube.com/watch?v=w2fhPBwSEMs/

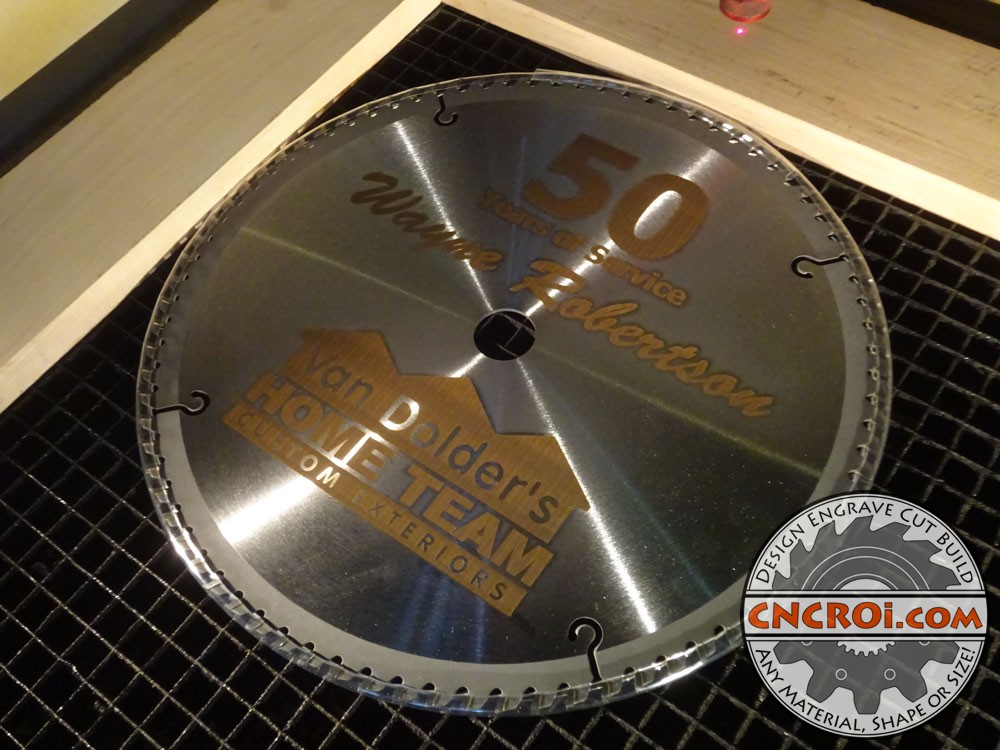

As for the etching color, it’s a light to dark brown depending on the composition of the carbide blade itself, but CNCROi.com applies an industrial coating on the surface to darken the etching and protect it for eons to come.

Literally any font, any size, any graphic, anything you can think of, can be etched permanently into stainless steel or other metals at CNCROi.com using a variety of laser sources, we have both CO2 and fiber at our disposal.

As for clocks, we aren’t just limited to metal, we can make custom wooden ones as well.

https://www.youtube.com/watch?v=gbrSZMquitg/

Fiber laser etching is a slow process, especially when compared to the non-permanent alternatives from screen and vinyl to uv, but the results won’t come off, so it’s a trade-off in more ways than one.

Unlike other print methods, the etching will always be a dark brow to light black, there is no color capability on steel.

As for why CNCROi.com is etching rather than annealing this steel blade clock, it’s due to the viewing angle, annealing maintains the blade’s reflectivity while the etching cuts it right out, it makes a massive difference when you hang this on a wall.

https://www.youtube.com/watch?v=EdEIRd9_c4w/

I’d say the vast majority of our jobs at CNCROi.com involve etching over annealing for this vary reason, easier to see at various angles.

How does heat affect etching and other materials we etch or engrave in the shop? We’ve tested that too!

https://www.youtube.com/watch?v=N4AQRyrI6CA/

What you see in the image below on the steel blade clock is a light sprinkle of brown, this is from the etching into the stainless steel carbide blade, it needs to be washed off and then we apply an industrial coating to increase the contrast of the etching itself.

Here’s the steel blade clock before washing the etching remnants from the surface.

Here’s the carbide tipped stainless steel blade after washing.

Here’s the blade after an industrial coating is applied and the clock mechanism is added to the steel blade clock – ready to go!

If you want a custom blade etched with whatever you want, for use as a clock or novelty gift, contact CNCROi.com right now!

https://www.youtube.com/watch?v=QpmehwehCt4/