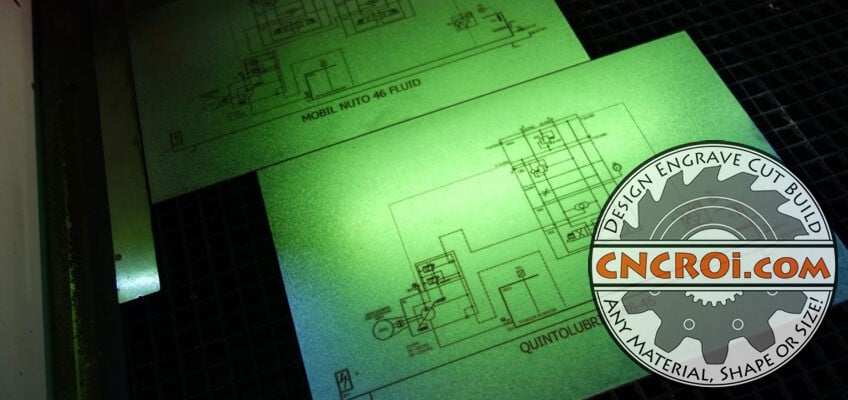

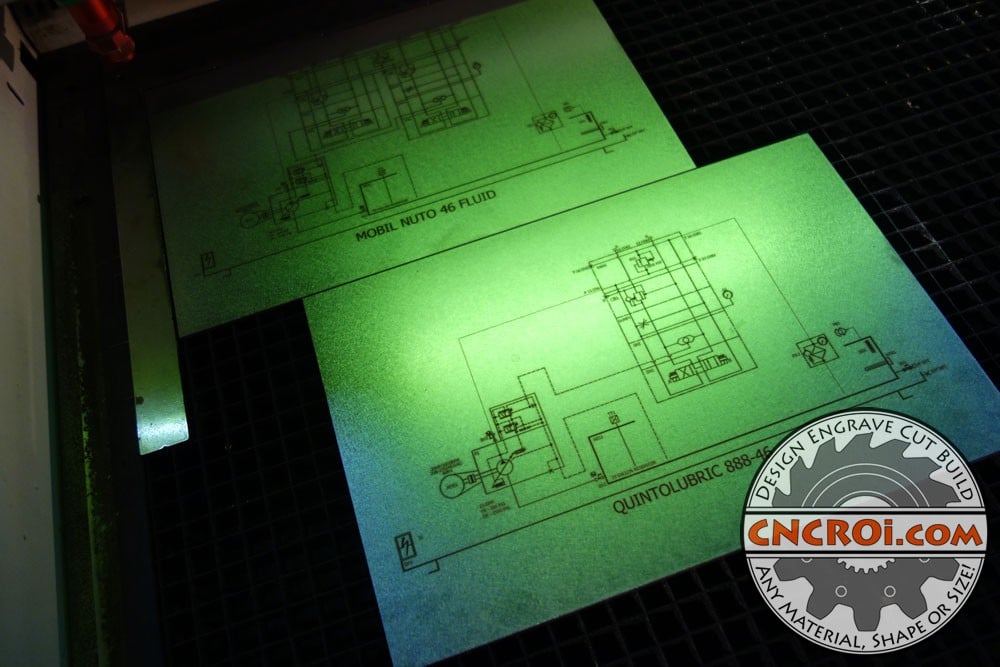

Steel Machine Equipment Plates: Plasma Cut, Fiber Etched

Steel machine equipment plates can be customized however you wish by CNCROi.com, from material type and gauge (thickness) to color, when we make them using anodized aluminium.

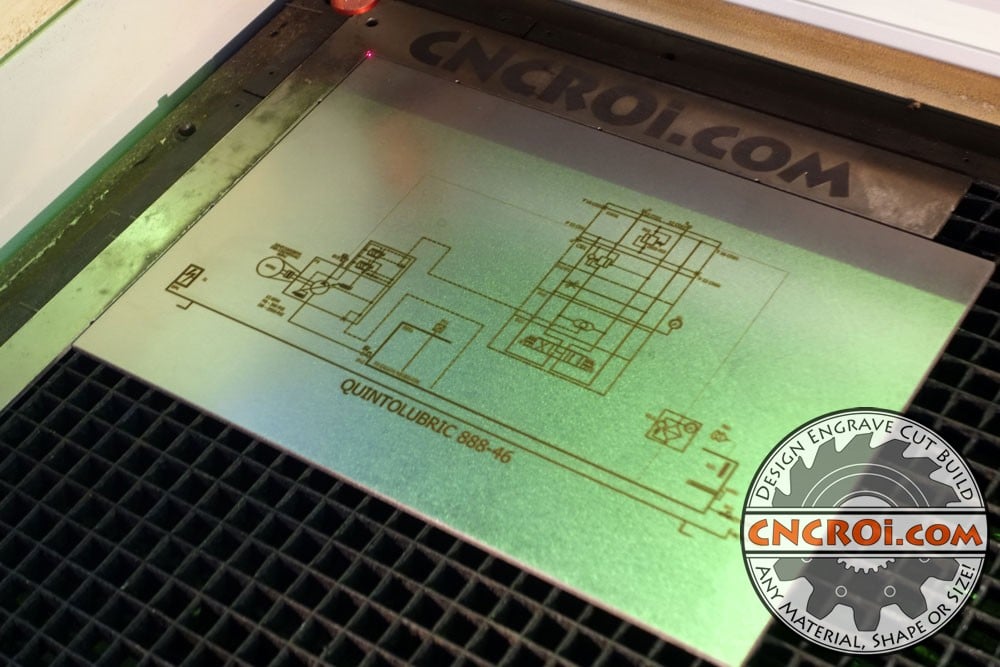

For this project, CNCROi.com used plasma cut 12 ga 304 stainless steel that was then fiber laser etched permanently.

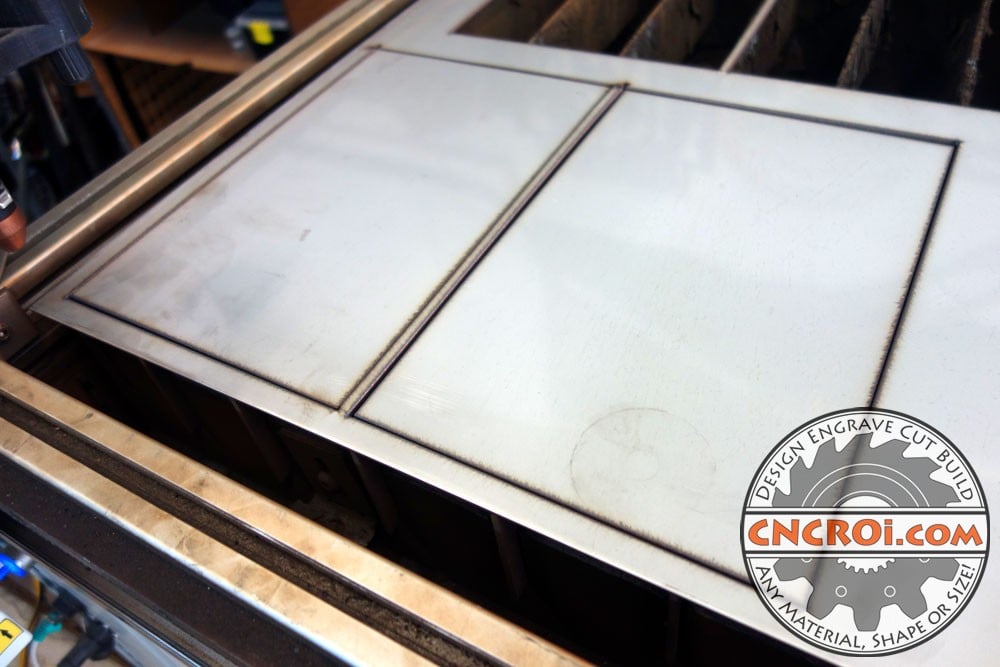

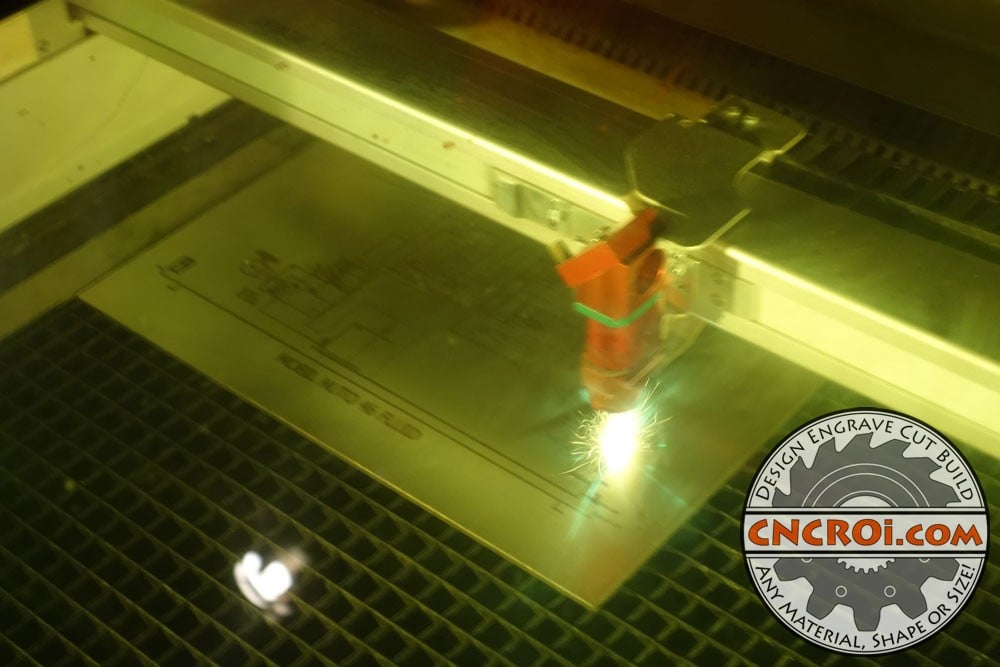

CNCROi.com could have used laser or even our waterjet for this custom steel machine equipment plates project as we were sanding the surface on both sides anyways but the plasma was already warmed-up from a previous project so I threw the sheet of 12 gauge 304 stainless steel 2B and proceeded to cut out two rectangles to the customer’s spec.

There is an absolute synergy between different CNC platforms, as such, a project done on one can be transfered to the other for additional processing, as you see with these custom steel machine equipment plates.

The plasma cutter cuts just as fast as the laser and waterjet at these thicknesses, the advantage of the plasma over waterjet is that it’s a dry process, as with the laser but I prefer the slight rounded kerf you get with the plasma over the absolute straight edges the laser produces when cutting stainless steel.

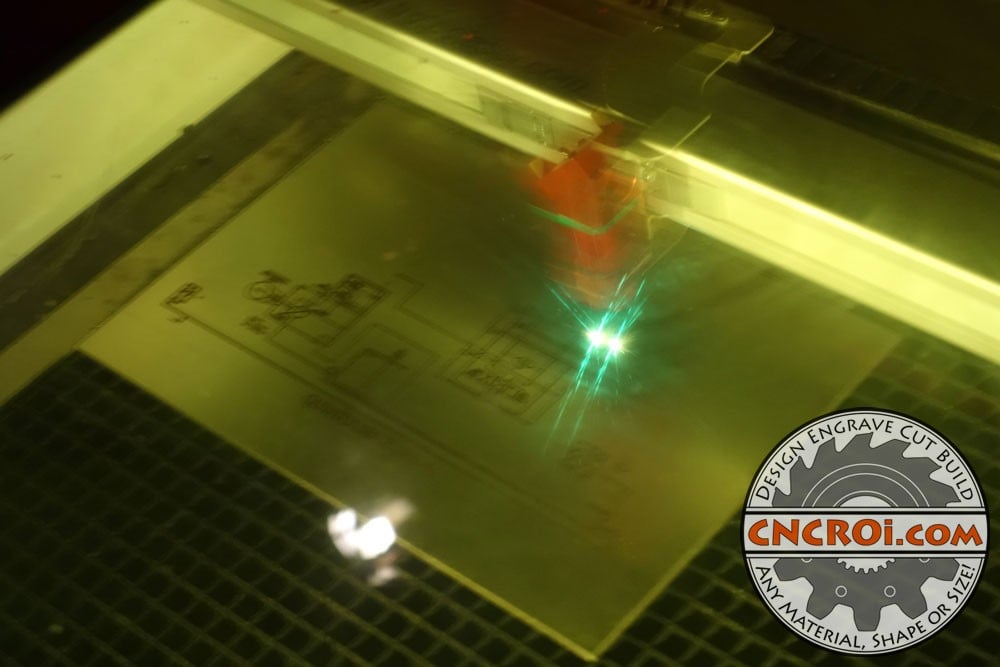

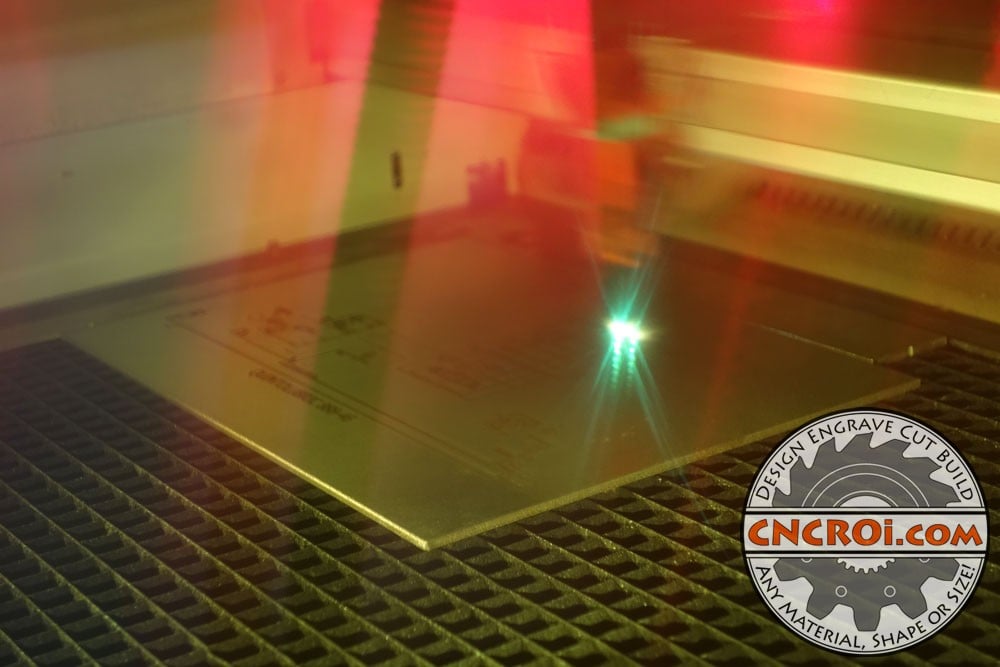

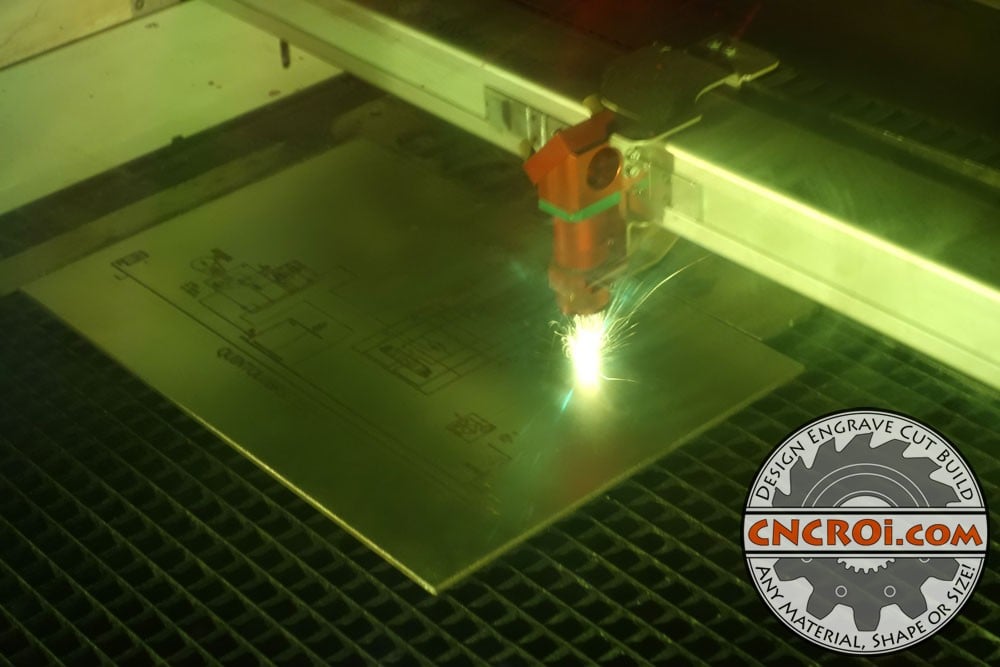

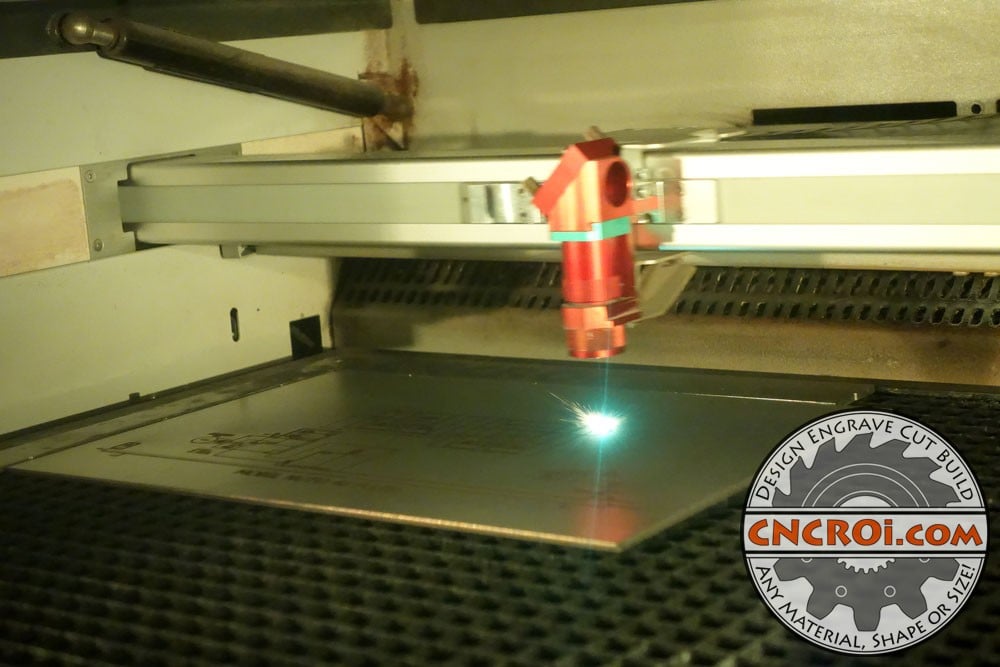

If you are wondering what vaporized stainless steel looks like, the picture above shows you how much is produced, not something you want to be breathing in for an extended period of time, hence why CNCROi.com has a powerful extractions system on the downdraft table to suck it right back down and out of the shop ASAP!

I use CNCROi.com‘s CNC plasma for a wide variety of projects.

Since starting my welding courses at college, I’ve grown to also enjoy cutting metal using oxy/acetalyne which definetely has it’s place for thicker metals though our plasma running off Hypertherm’s Powermax85 can cut through up to two inch thick metal at CNCROi.com.

I also have an additional manual hand plasma cutter and of course, an adaptor if I wanted to use my Powermax 85 for thicker processing but the vast majority of the projecs I do at CNCROi.com involved using CNC equipment to handle this type of work as the edge quality is far superior and the accuracy is second to none using an automated verses manual approach.

While plasma cutting these two custom steel machine equipment plates, the plates absolutely get hot, they’ve been melted along the outer edges, but there is no warping, which is why this is a great mix of material thickness to cost and it’s incredibly resilient when it comes to fiber laser etching as well.

Lasers can do highly detailed cutting into stainless steel.

I use to use the grounding clamp on my plasma cutter on the bed of the plasma cutter itself but I’ve found a better result when I clamp the material itself for grounding, that’s what you see at the top of this sheet of stainless steel in both the video and photos showing the cutting of the two custom steel machine equipment plates.

Plasma cutting these steel machine equipment plates is an efficient process, dramatically better than cutting it by hand or using power tools, that’s the massive advantage of CNC machines, perfect results, everytime.

When it comes to stainless steel, CNCROi.com has a variety of was to cut it but etching is always performed using one of our two fiber laser sources for permanent marking of said material.

Of course, plasma cutting can also do pretty detailed projects as well using mild and stainless steel.

Permanence is important because you don’t want vital information on your steel machine equipment plates to fade, crack or peel over time nor be affected by humitity, temperature or chemicals in a corrosive environment.

There are two finishes available when it comes to stainless steel, 2B, as you see in these photos before running the orbital in the picture above, or #4 which has a nice brushed stainless steel finish.

Etching stainless steel provides a sharp, highly detailed permanent tempering on and to a certain extent, into, the steel.

Anodized aluminium plates are a great way to have a bit more color in your machine, easily riveted or welded in place.

Steel machine equipment plates can be customized however you wish, but generally, they are roughly the size you see in this blog post as it provides tons of space for CNCROi.com clients to put just about any mix of images and text information they want.

Like our plasma cutter, the etching can also be the same spec or different for any volume of required steel machine equipment plates.

The finish you see on these, originally 2B finished stainelss steel, was accomplished using a simple orbital sander, the finish works great and I prefer it to the finish you get from #4 as it’s more interesting visually, to me at least.

Etching can be done quite deep into stainless steel, including other materials, but the costs go up quite a bit the deeper you go.

Etching isn’t limited to any particular thickness of stainless steel, for these steel machine equipment plates, CNCROi.com is using 12 ga, but it could be 4 ga as it can be 22 ga, though thinner than 12 ga, which is roughly 1/8″, the metal tends to warp from the heat of the fiber laser etching process itself.

Although these two steel plates were made one after the other, the rectangles are identical but the etchings are not.

Need steel machine equipment plates? Contact CNCROi.com right now!