Laser + Aggregate: What REALLY happens?

Among my favorite materials to work with in the CNCROi.com shop, aggregate such as stone, granite or marble are up there!

What our CO2 laser does to these materials is no different from what a chisel or mill does except we never actually touch it as lasers are a contactless technology. Unlike our fiber laser source, CO2 also gives you a lot more tolerance to play with which means we can engrave the surfaces of rocks even if they aren’t level or perfectly flat!

The type of resolution we can get on these aggregates is very depending on the density and composition. Some of these are full of organics which means they are instantly vaporized while others have tougher particles or strata which require more work to pop out due to extreme heating or vaporise all the same. Generally, natural aggregates come out better than some of the man-made versions of these such as tile where the under-surface may leave a less than desired finish.

But this also leads to a new opportunity, where wood absorbs paint and most finishes, aggregates generally don’t, which means we can paint fill them for better contrast. The nice things about aggregate is that’s easily found just about anywhere and the cost is essentially free for the more natural stuff. Other things that may not come to mind immediately are things like bricks.

Depending on the manufacturing process and their makeup, they can be easily engraved (not cut) using our Austrian industrial CNC Trotec Laser with a high degree of precision, producing results that will last a lifetime and then some if well maintained.

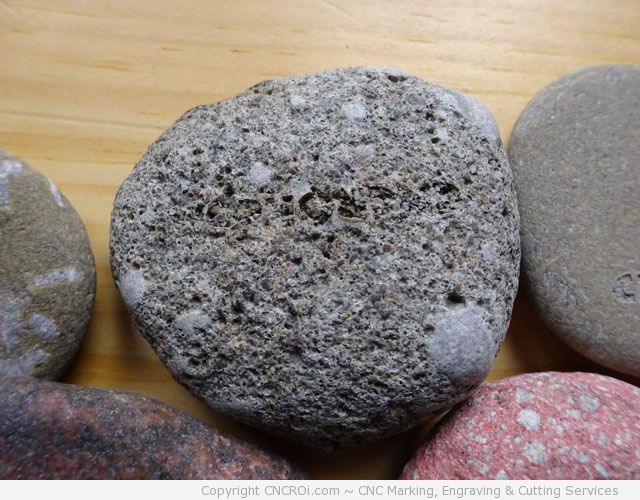

This field stone took thousands if not millions of years to form, we just came in around the end of the production line to brand it.

Firestone is also a very nice material to work with, depending on the aggregate it’s made from. We are able to engrave pretty deep into these materials using our CO2 laser source with several passes which makes them ideal for architectural or industrial applications. As for speed, it completely depends on the density and material properties of the aggregate, the denser it is, the longer it takes to achieve depth while some materials in these stones simply doesn’t react at all to our CNC laser.

Looking at the above field stone at high-resolution, you can see the edges and inner corners are nice and sharp, the material was extremely flat and homogeneous which produces a spectacular result. The smaller particulate the better the result as well. Compare that to the beach stone below and you can see it’s very difficult to workout that CNCROi.com is engraved into it!

Material Testing is Important!

This is why material testing is so important as part of the job quoting process regardless of material… some results come out great with little work while others require a lot more work pre and post CNC laser time. If you had a great aggregate, we can produce amazing results using our CNC laser like the stone below but sometimes we also get results like the above. Sometimes this is fixable using other processes but other times, it isn’t… and we won’t know unless we do testing!