Tale of Two Hard Drives: Fiber vs CO2 Laser Results

Part of the material testing process at CNCROi.com is deciding which laser source works best for any given material. For marking steel it’s always fiber laser source but for wood, CO2 laser source but this isn’t always true with other materials, notably plastic and composites.

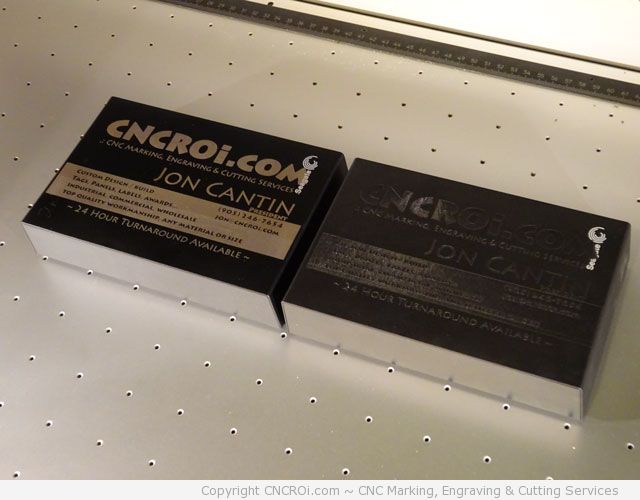

Two identical hard drives, two very different results.

As you can see, the differences between our dual-source Trotec Speedy 400 flexx can be dramatic! Watch the video to see how each was done.

Can you guess which hard drive was done with which laser? (spoiler alert – don’t scroll down until you guessed)

.

.

.

.

.

.

.

.

.

.

.

.

Alright, the one one the left is Fiber laser source and the other by deduction is CO2 laser source! This was an easy one as sometimes the effects are notably more difficult to figure-out even in person. Generally Fiber tends to elevate the surface while CO2 laser source engraves into the material but in this case, running you finger over the lighter coloured fiber to feel the difference is so minute that it’s tough to tell. The color is a giveaway though, generally CO2 laser source tends to melt plastic while Fiber just color changes it. There are more types of plastic out there than humans on the planet so there are always exceptions to these generalities.

As for cost, fiber is generally a slower process than CO2 laser source but again, that’s material dependent – there are some plastics out there that change readily while others will never do a thing no matter how much energy you throw at them. Also the amount of energy coming out of the laser has a different effect on the plastic as well, sometimes a light sprinkling of CO2 laser source power will give better results than a 100% powered fiber laser!

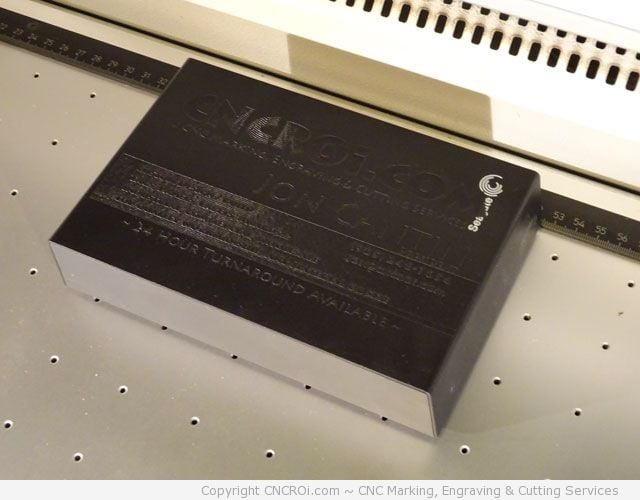

If you look at the hard drive hit with fiber energy, the surface is very nicely polished and consistent.

It’s a really nice finish, almost metallic looking in this photo – there is no steel in this material by the way. Comparing it to the hard drive that was CO2 laser source engraved though, it’s a different story, I SEE the material inconsistencies in their plastic, in most of it, it’s a nice even finish but other places, you end-up with a wavy pattern – looks cool to me but maybe a client wouldn’t be as much with a random pattern appearing on their products.

If I had a thousand of these hard drives to mark or engrave for a school in order to prevent theft, which process do you think I’d go with? Fiber but at the end of the day, it’s the client’s choice. The effects of this are permanent by the way, no amount of scratching or washing will remove these especially on the CO2 laser source where it’s pretty deep into the surface of the material.