Top 10 Questions I Get @ Networking Events

For now, most of the people I meet at networking events have never heard about the services we provide. Here are some of the top 10 questions I get as I show people what we do here at CNCROi.com.

10) What is CNC?

Watch this video I made a while back – it will make you an expert by the time it’s done.

9) How did you learn how to CNC and get into the field?

Although a bit dated – I hadn’t started CNCROi.com when this video was done, you can see a clear projection that it was basically the only direction I had left to go. I filmed this video while I was in Perth, Australia – I’m now back in North America where I established this company more than two years ago. Essentially, self-taught passion.

How do you start a custom CNC shop? It’s easy, you START.

8) Can you engrave, cut or etch XYZ material?

Short answer is anything short of vinyl as it releases chlorine gas though I can do it with our CNC router as it isn’t vaporizing / melting material but just cutting it. As such, we can cut, for instance, dibond which is made-up of PVC sandwiched between sheets of aluminium.

It really depends on the application, once I have an idea of what you want, the next step is figuring-out the most efficient method of making it happen. So yes, technically our CNC laser, for instance, can cut through stone but it’s more efficient to do so using a diamond blade or if it’s flat, we could do it with our CNC router but if all you want is a mark on it, it can be accomplished any number of ways from having us produce a custom stamp or stencil through to actually engraving or etching it within our equipment.

7) Can I get a tour?

Generally it’s by invitation only, the reason being is that our shop isn’t listed anywhere (on purpose) and the work we do is highly specialized for clients – we have signed lots of NDA (non-disclosure agreements) and respect the privacy our clients with to maintain. Most of our work involves us being a cog in a larger wheel production wise.

What I find interesting is that some of our clients have an open invitation but have never come here… it’s really nothing special if you are in the CNC field yourself. We have no public access to the building nor any signage so in reality, nobody knows where we really are… which suits us and our clients just fine.

6) How much is it to do XYZ?

It’s amazing to me how many quote requests we get in the shop, two years ago, it would be weekly (we just started!) and now it’s borderline hourly from across North America. I can tell a mile away the clients who have thought a bit deeper about what they want done and those that are just kicking the can. How?

Clients who know what they want actually have files or sketches and are open to discussion regarding how to best help them with a specific application. Those who have no idea just grab a random image from our site and say “how much for something like this”.

CNCROi.com is a custom production and design shop, by its very definition, everything we do is CUSTOM which means we don’t know how much it will cost to do something until we understand what you want using which materials. Make both our lives easier and just be upfront and send us what you want (text file, image etc.) with volume, budget and preferred materials. We’ll be able to give you a ballpark quote within 10 minutes generally. At the very least, we’ll be able to tell you if your budget is reasonable or not.

Being organized goes a very long way and will save both of us a lot of time.

5) Can you get this done for me by tomorrow?

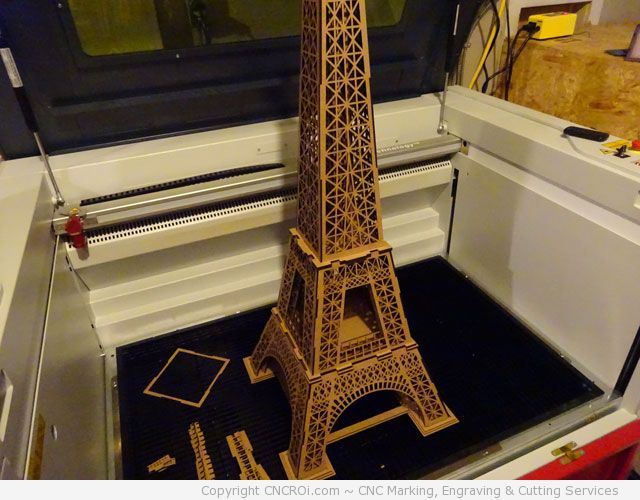

If you are organized (have digital files), we have the material in stock and budget accordingly, generally the answer is YES. For instance, if you want a custom rubber stamp, the shipping will cost you through the nose but 24 hours is plenty of time for us production wise to get it done and out the door.Our Austrian CNC laser and our American CNC router are able to really make a lot of very good work fast and efficiently, the hold-up for projects generally comes from two sources, first, we are blasted with work and just can’t fit you in with such short notice and the second is materials take a day or two to arrive. Having your files ready to go is a great start, but without materials or “time” your project will be delayed.Don’t worry, we always give an ETA and updates about our production cycle so you aren’t in the dark when it comes to making your project. 4) How much do your machines cost?This comes-up quite a bit, my answer is always the same, more than your car and possibly your house depending on where you live. Running a custom CNC shop isn’t cheap, the equipment is only part of our overhead and as such, costs of machines just isn’t worth answering to be honest.What I can tell you is that we invested HEAVILY in top of the line equipment, sure, we could have bought a Chinese CNC laser but instead, we got the best model with all the bells and whistles and dual tubes (CO2 and fiber) money can buy. Not cheap, but that’s the quality we want for our clients.When you consider just a generic bit for our CNC router along can easily cost more than a hundred dollars and the electricity bill required to keep a full complement of 220/240 plugs happy, machine costs are the least of our concern.

4) How much do your machines cost?This comes-up quite a bit, my answer is always the same, more than your car and possibly your house depending on where you live. Running a custom CNC shop isn’t cheap, the equipment is only part of our overhead and as such, costs of machines just isn’t worth answering to be honest.What I can tell you is that we invested HEAVILY in top of the line equipment, sure, we could have bought a Chinese CNC laser but instead, we got the best model with all the bells and whistles and dual tubes (CO2 and fiber) money can buy. Not cheap, but that’s the quality we want for our clients.When you consider just a generic bit for our CNC router along can easily cost more than a hundred dollars and the electricity bill required to keep a full complement of 220/240 plugs happy, machine costs are the least of our concern. 3) How do you get so many videos etc. done?Some of our clients visiting our website and chatting online with me ask how we get so much online content done weekly? The answer is simple, we are EFFICIENT! Generally after a production run, we have a few extra odds and ends, instead of chucking those out, I think of an application it could be used for and make a quick video with photos. Voila, blog post, YouTube video and lots of images.I think it’s important to show our clients that the process behind what we do is just as much fun, if not more so, than the project we are doing for them. It’s a black box that gets opened and helps our clients realize just how much work is involved with some of their work. I really enjoy sharing this knowledge and practice so it isn’t work – just having fun after hours.

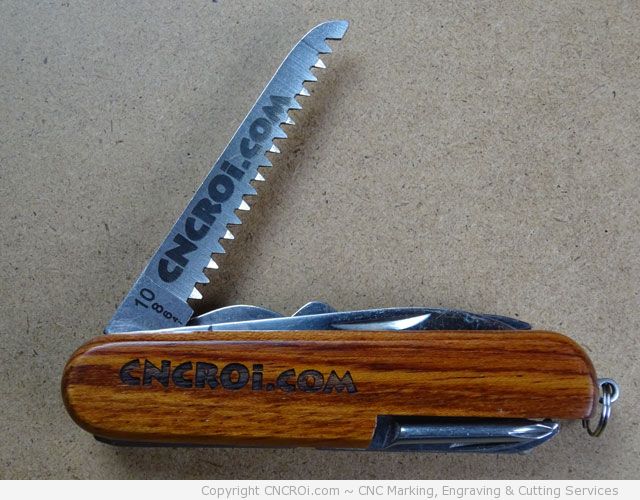

3) How do you get so many videos etc. done?Some of our clients visiting our website and chatting online with me ask how we get so much online content done weekly? The answer is simple, we are EFFICIENT! Generally after a production run, we have a few extra odds and ends, instead of chucking those out, I think of an application it could be used for and make a quick video with photos. Voila, blog post, YouTube video and lots of images.I think it’s important to show our clients that the process behind what we do is just as much fun, if not more so, than the project we are doing for them. It’s a black box that gets opened and helps our clients realize just how much work is involved with some of their work. I really enjoy sharing this knowledge and practice so it isn’t work – just having fun after hours.

2) Can you beat XYZ price?

It depends on the application, materials and expectations. Our goal isn’t to be the cheapest custom CNC shop in the world but the best. As such, we pay a hefty premium on everything in CNCROi.com so that we have as few production problems and customer headaches as possible.

About once a week, I get a customer quote request which I fulfill and the response I get back is along the lines of “this guy’s cheaper” and what I find fascinating about this is that, if you think about it, half the time this “other guy” is working below costs! Just TODAY I had a potential customer being quoted on a project and the price they got per unit was actually BELOW MATERIAL COST, which means, not only is this other guy doing the project, but he’s doing it for free AND not even covering material costs! It makes no sense.

Although I agree that price is important, QUALITY IS MORE IMPORTANT. You want to get some name badges done, you want them to LAST and be STRAIGHT! Sure, I could make your beautiful corporate wall plaque using a jigsaw out of MDF and then engraving it with a chisel but you know what, it will look like crap and the person getting it will probably leave it in the paper bag it came from.

1) Do you offer discounts?

It depends on the volumes you want, material and sizing flexibility you are. Generally, the more stringent the project specs, the less room there is to offer discounts on our work. Take for instance stencils, there are A LOT of options from polycarbonate to cardboard, acrylic to plywood – each has their + and – but if you only want one-off, regardless of which you pick – there won’t be any discounts.

If on the other hand, you had a thousand custom 1/8th thick (3 mm) business cards out of red oak wood veneer, we can of course give you a better rate then you’ll find at our e-commerce site (Buy Online heading). The higher the volume, the bigger discount we can make as it becomes, more or less, a volume game for us as well. The materials cost less, time spent per unit drops and production efficiencies play a huge role as well.

My question to you, the reader

Need something custom? Contact us, we’ll make something to the best of our ability using top of the line equipment and passion to boot. Could you ask for anything more?