Two Custom Carbide Saw Clocks

There are endless ways to brand real custom carbide saw clocks at CNCROi.com using our fiber laser system.

https://www.youtube.com/watch?v=Ia-wS8eUBeg/

The advantage of the fiber laser etching process is that the results are PERMANENT, they will not fade, crack or peel overtime, unlike the vinyl or screen printing most saw blades have on them when you get them at the hardware store.

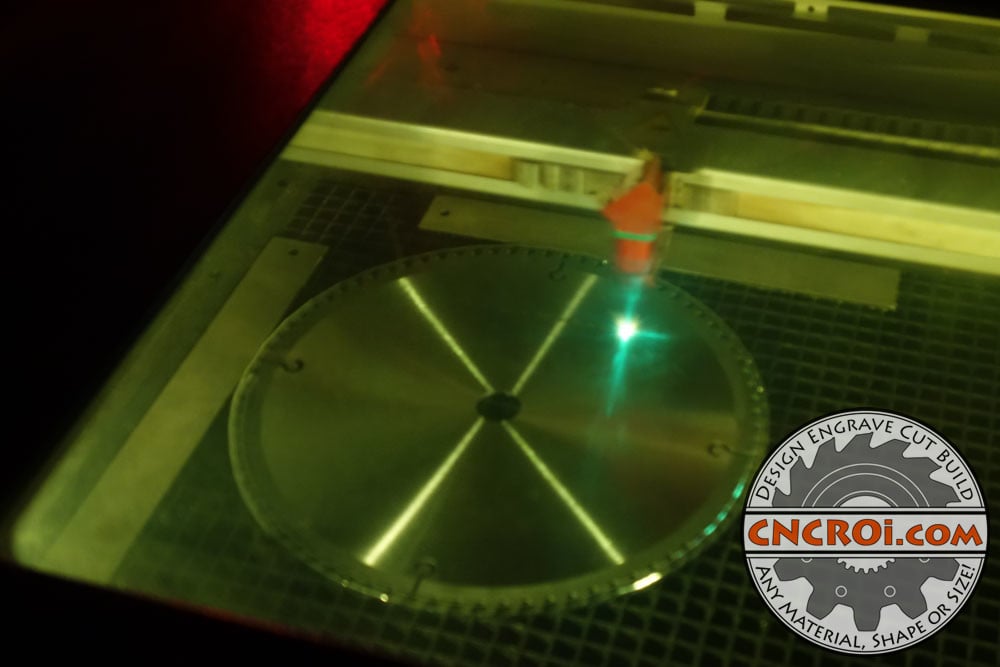

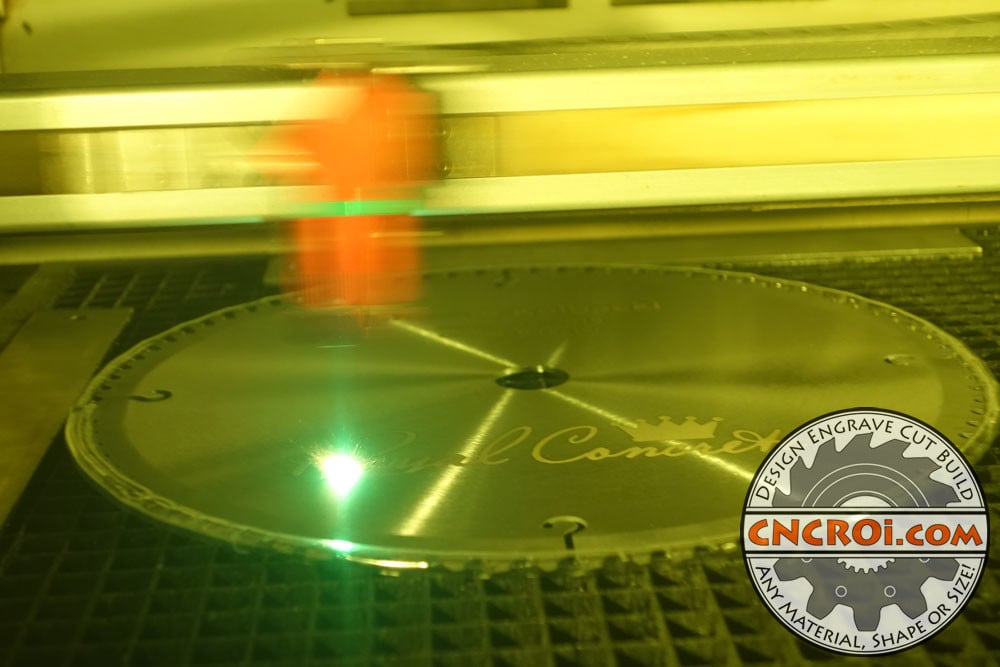

For this specific set of custom carbide saw clocks, the fiber etching branding was of a font and an image, the image is clear because it’s a vector format and the font is clear for the same reason.

Fiber laser etching only involves heat and photons, there are no chemicals, dyes or magical powers involved with branding the custom carbide saw clocks by CNCROi.com.

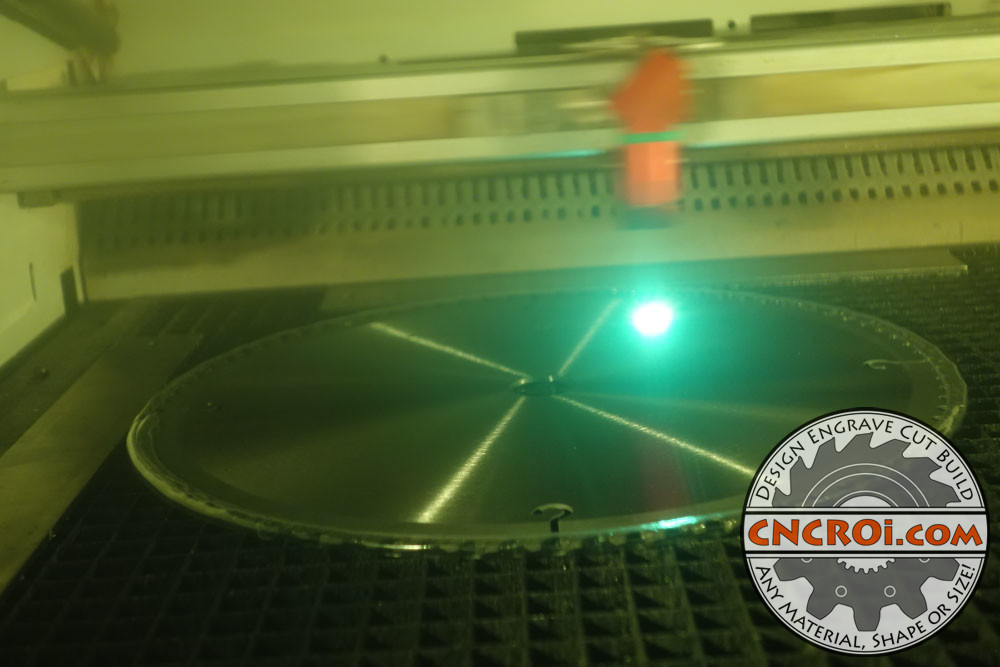

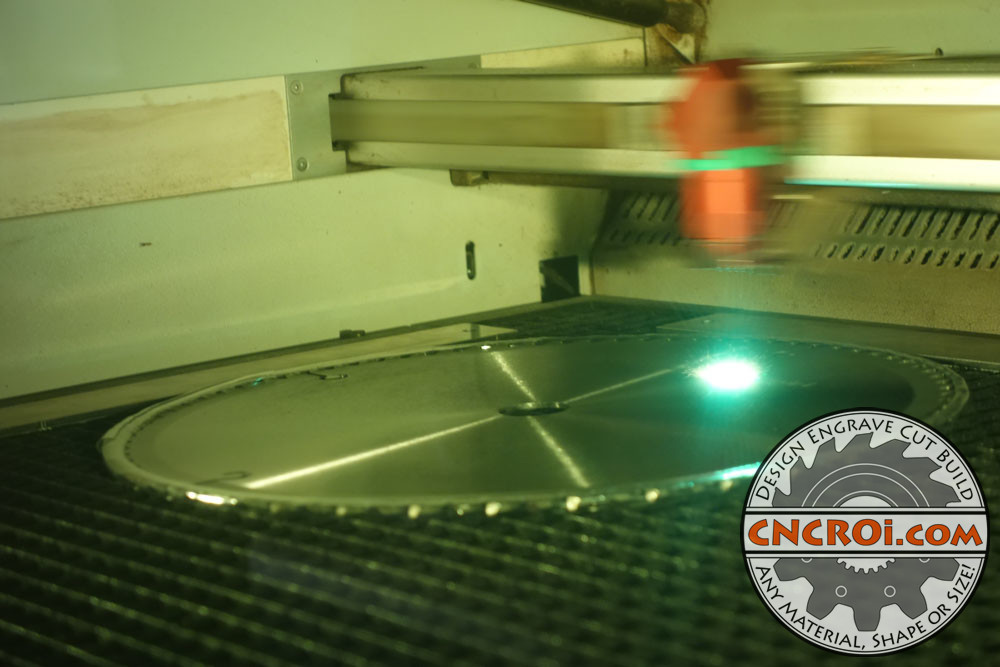

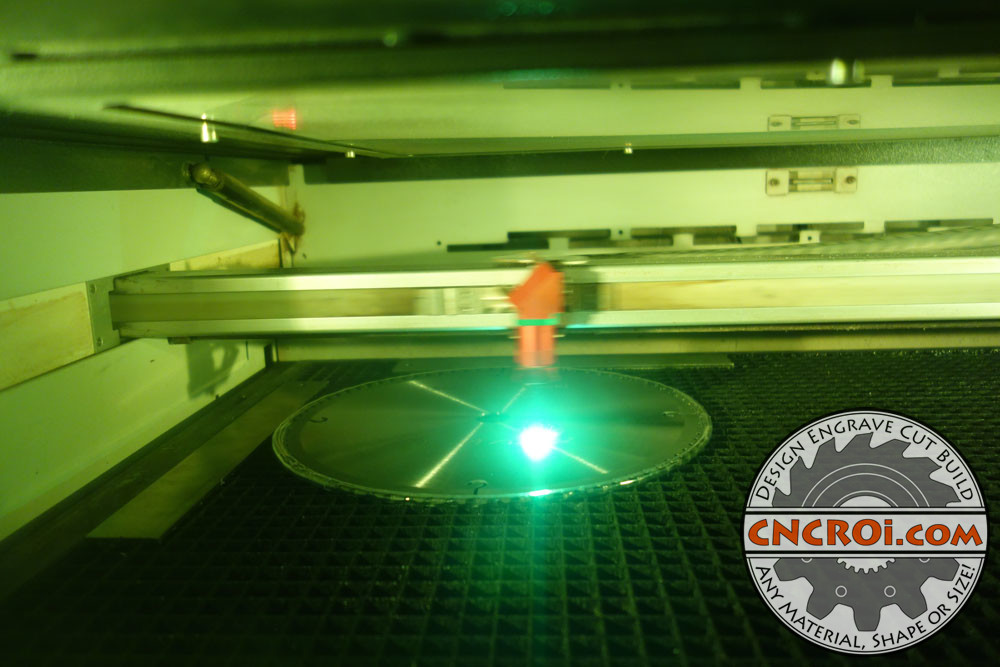

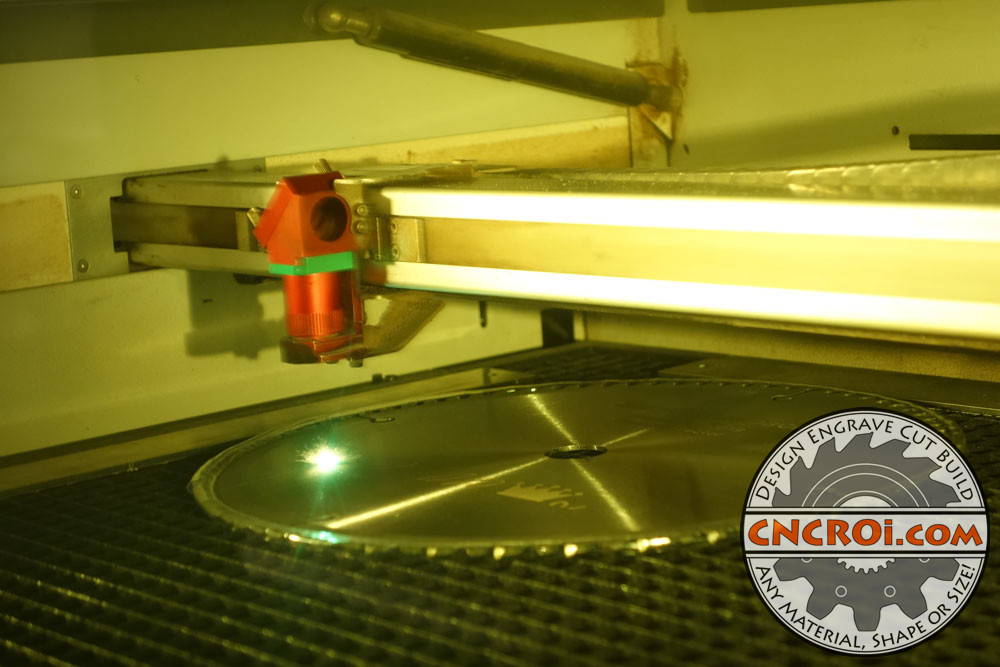

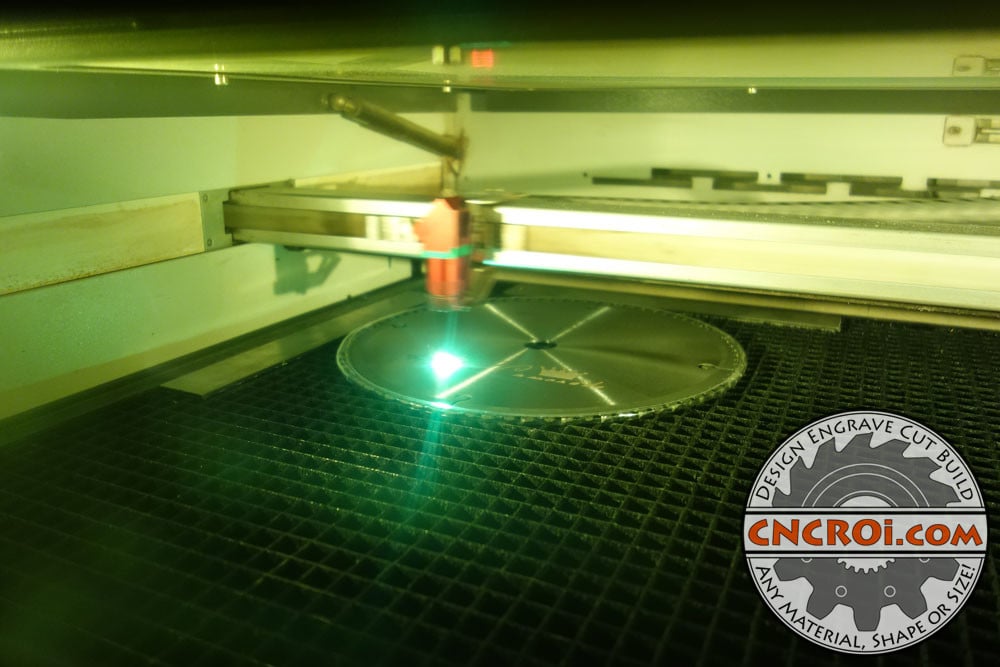

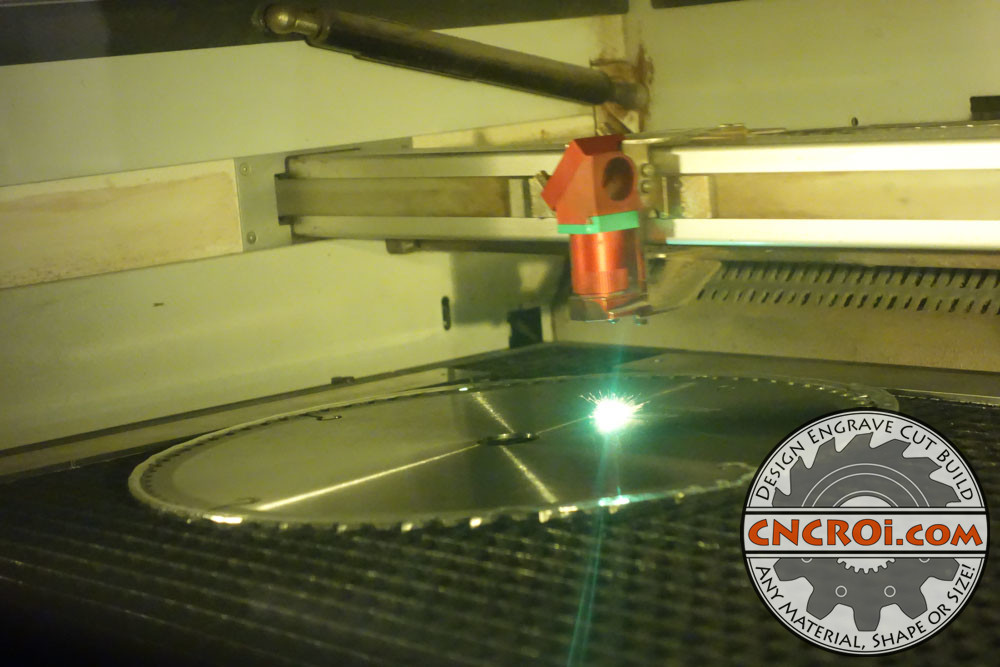

Having multiple fiber etching platforms at CNCROi.com means we can optimize the machine to the process, in this case, the surface area was just out of range for our galvo fiber laser etching machine, so the gantry system works just as well, fiber is fiber, regardless of the machine behind it generating the laser.

You can see how much of a different look just changing the clock handles can have on these custom carbide clocks.

https://www.youtube.com/watch?v=n56CCFPCMbE/

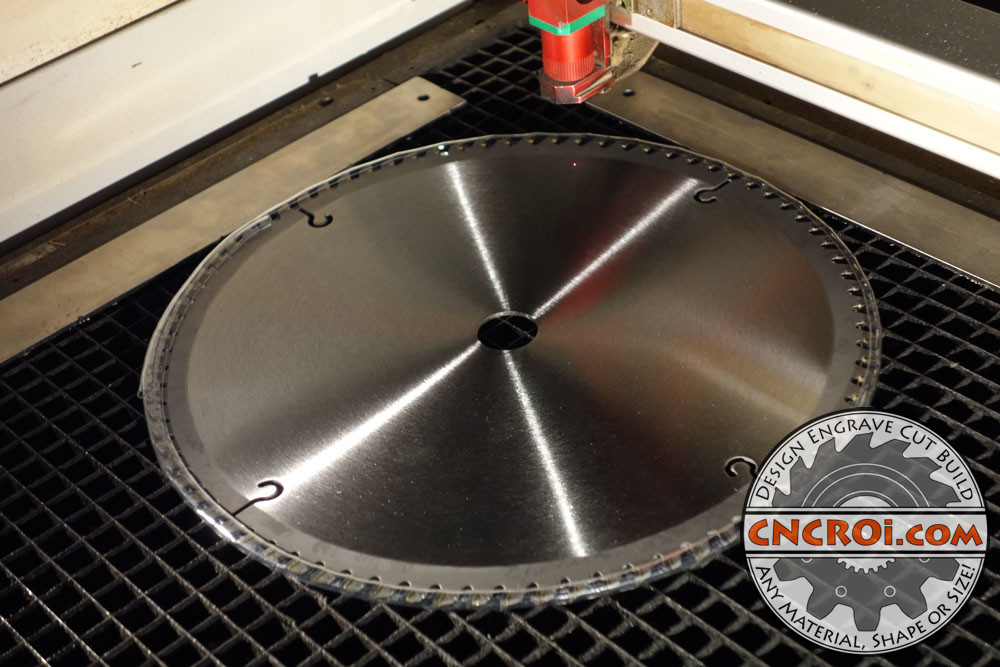

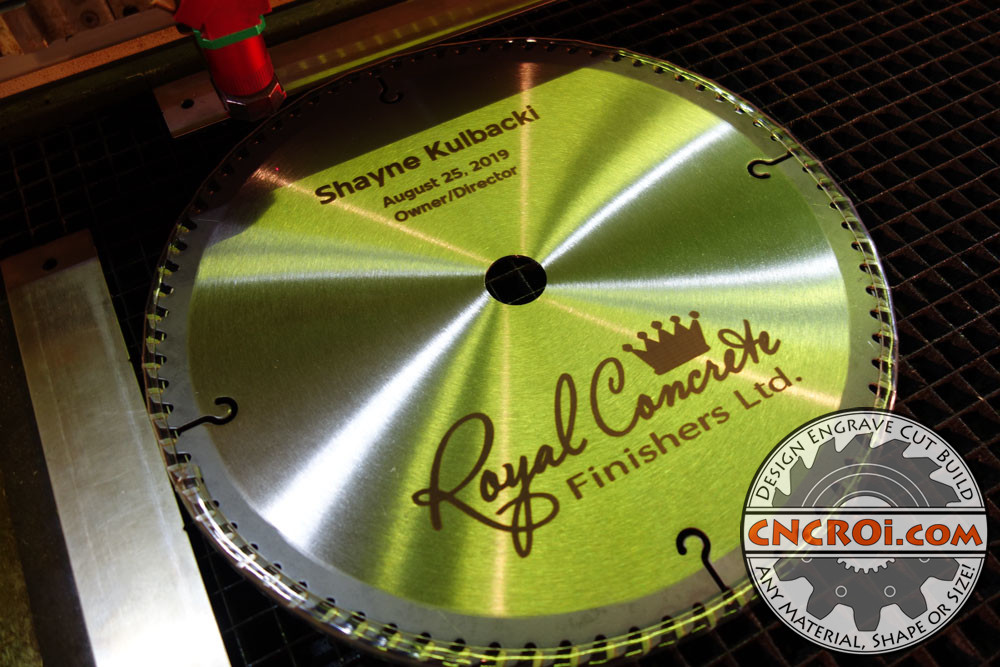

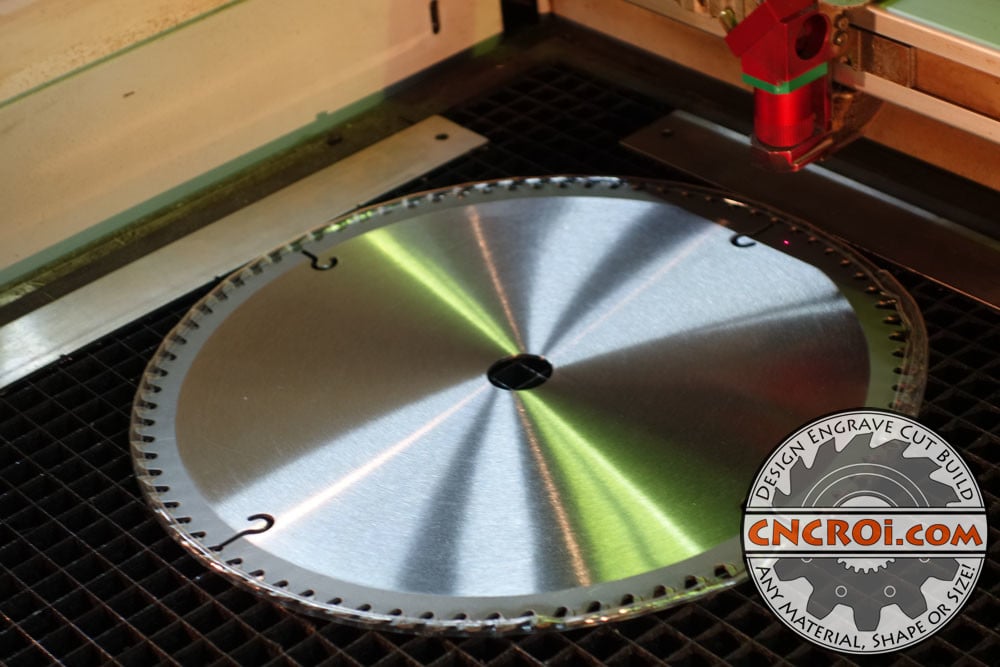

Keep in mind these are REAL carbide blades, measuring 12″ in diameter, even after the fiber laser etching process, if you are in a bind, they can very much still be used in a limited fashion for their intended purpose, so these aren’t just custom carbide saw clocks but actual functional emergency items that can be used in a real shop to cut that last piece of Pine shelving.

Like annealing, which takes the same amount of time and power to achieve as the etching, the entire process is caused by heat, just at a different focal length from the stainless steel.

When it comes to fiber laser etching, as long as the image and text is black and white in a native vector format, the results will be crisp and sharp without any jagged edges or unresolved lines.

Annealing and etching only works on stainless steel, if we are working with anodized aluminium or other metal combinations, CNCROi.com would generally use our CO2 laser source over our fiber laser source for speed, though both laser beams produce the same amount of accuracy and reliability on the source material.

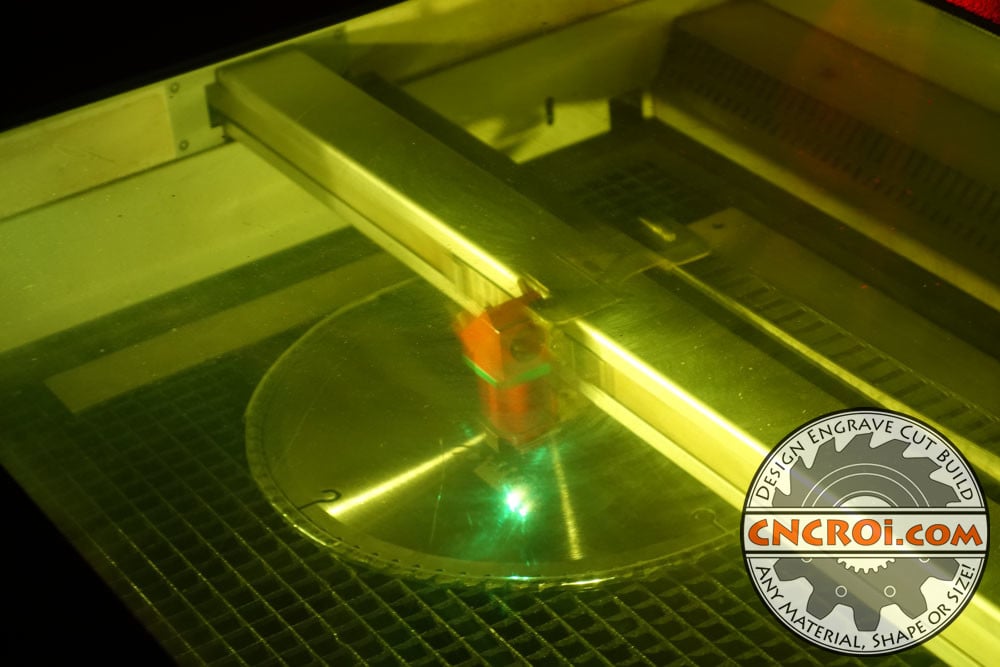

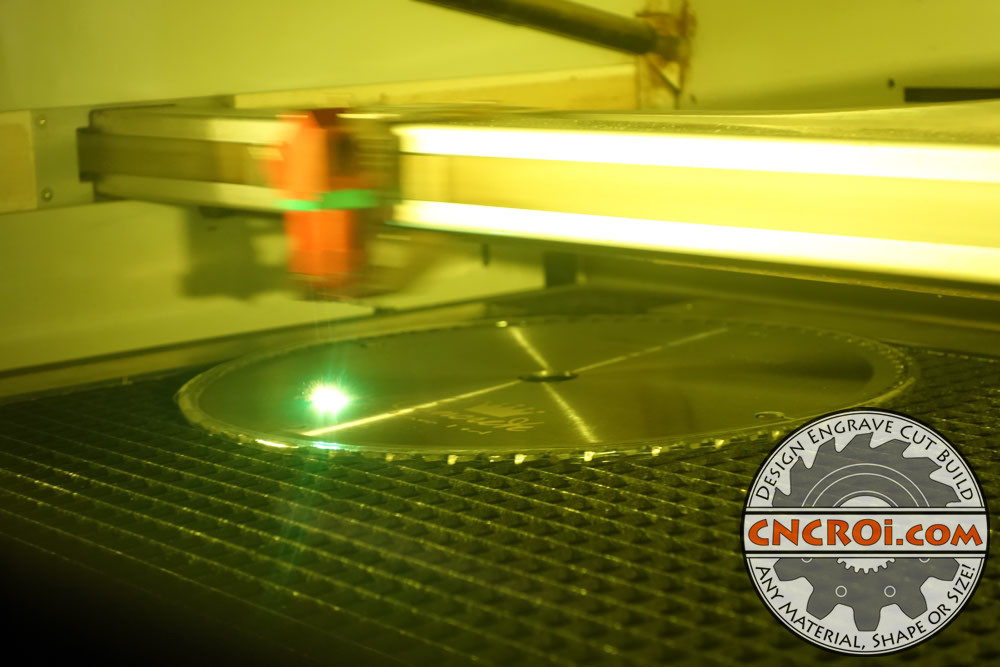

Both of these custom carbide saw clocks are identical, except for the name we etched onto them, the reason for the plastic gasket going around the blade is because carbide is sharp and I don’t want to cut myself yet again on these blades loading and unloading them into the CNCROi.com laser etching machine.

Of course, if you wanted a bigger clock or using a different shape or design, literally anything can be made into a clock, here’s how CNCROi.com cuts most of its metal.

https://www.youtube.com/watch?v=Ln9EXslzc04/

For both of these custom carbide saw clocks, the mechanics were also the same, there is a little variety in that regard but generally what works best are just black handles because they contrast nicely with the stainless steel surface with a little back reflection to boot.

In all these custom carbide saw clock videos, you only see me etching one side as the other side is against the wall, but if you wanted CNCROi.com to add a message to the back, the process is the same and entirely possible as well.

You can see below what the custom carbide saw clock looks like right out of the machine, a little clean-up is required and then sealing but it’s pretty close to the finished product.

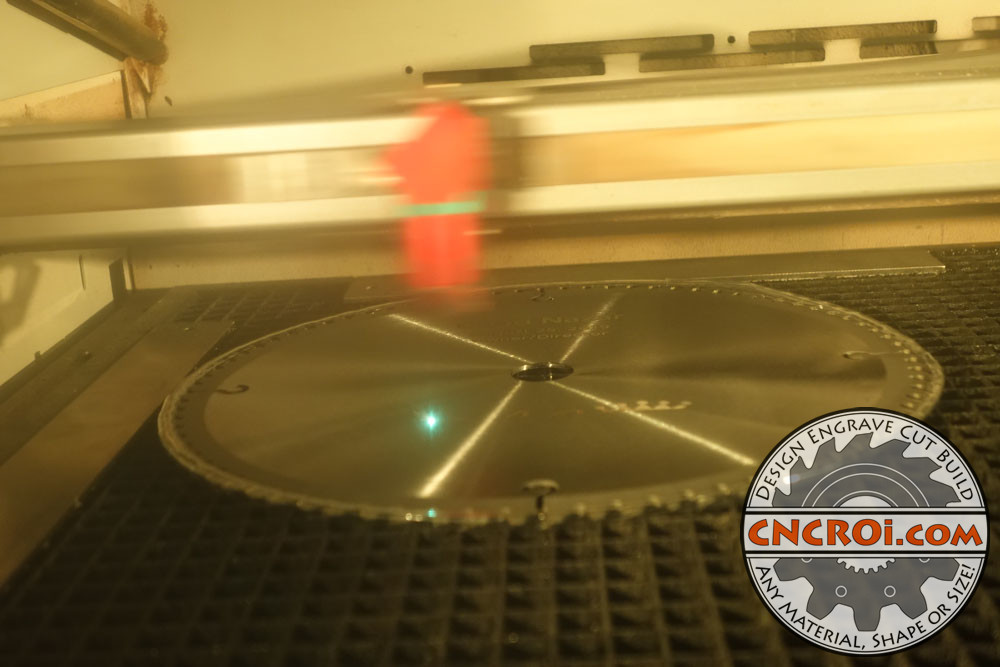

After the first of the custom carbide saw clocks is made, time to load-up the next design file and do the same on the other clock, our laser is just as accurate on the first clock and it will be on the last.

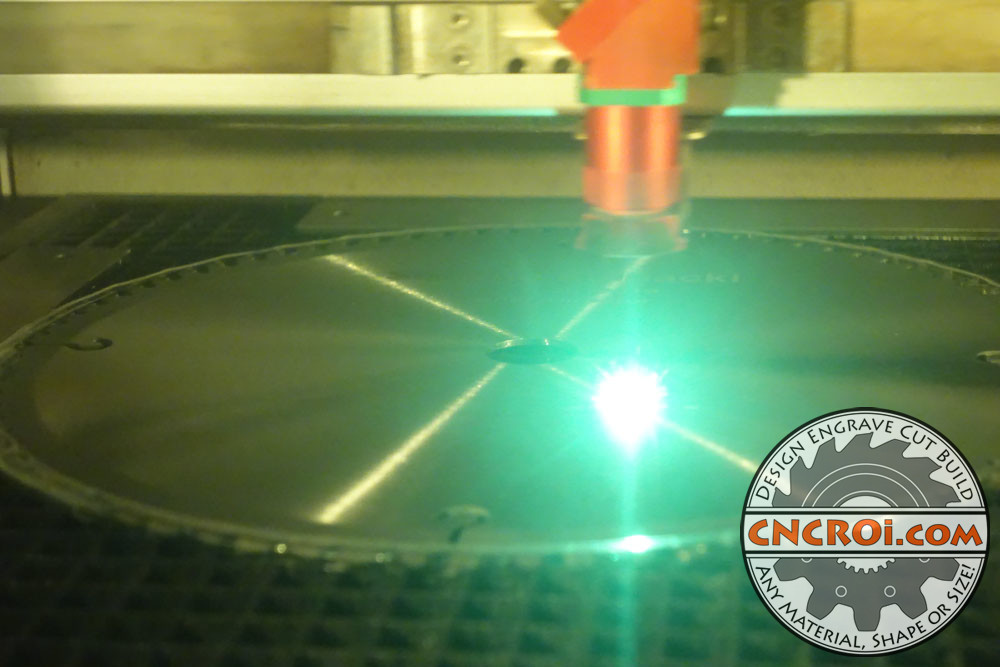

You can see the sparks generated by the fiber laser etching process, the laser light is invisible which is why you only see the results and not the light going from the right to the bottom of the head producing the etching itself.

Fiber etching can also be performed at depth, it isn’t just a surface method of branding.

https://www.youtube.com/watch?v=rWeM9-VUOII/

Fiber laser etching is a non-contact printing method, meaning the machine never directly touches the custom carbide saw clocks to produce the finished result, unlike our CNC router which has a bit in direct physical contact with the clock.

You can see both of the custom carbide saw clocks below, they look great, the brown color you see is flash rusting during the fiber laser etching process, this is next going to be cleaned-up and sealed to give it a black etching esthetic.

It’s quite a contrast, just cleaning off the rust, you can clearly see how great and sharp the fiber etching process is, no bleeding like you’d get with inks and no issues with cracking or peeling like you’d typically get just trying to print on stainless steel itself.

Before the clock mechanisms are added by CNCROi.com to the custom carbide saw clocks, they are sealed, you can see the color goes from a rusty brown to a nice deep dark color that contrasts great with the stainless steel.

We allow you to be as creative as you want when it comes to custom clock making.

https://www.youtube.com/watch?v=vqiPA6lVGN0/

Generally CNCROi.com ships out these custom carbide saw clocks with the hands taken off so they don’t bend during the shipping process, they are easily place on without applying glue or any other type of adhesives.

You can see the nice reflection of the back of the clock hands, it really produces a whole other level of coolness to these custom carbide saw clocks.

You can now compare the finished custom carbide saw clocks in the image below, they look great and the customer will really enjoy having these on their walls.

Need custom carbide saw clocks? Contact CNCROi.com right now!

https://www.youtube.com/watch?v=gbrSZMquitg/