Two Sided Pick Prototype Jig: Tight Tolerances for UV Printing!

Let’s make a two sided pick prototype jig for a client that requires very tight tolerances for their UV printing business at CNCROi.com.

When it comes to making UV jigs, CNCROi.com has made them from just about any and every material out there, from high-end Delrin to MDF and everywhen inbetween.

As this is a prototype, we didn’t want to do the testing using an expensive material, hence using MDF to check tolerances and processes at the customer’s business for their own two sided pick jig.

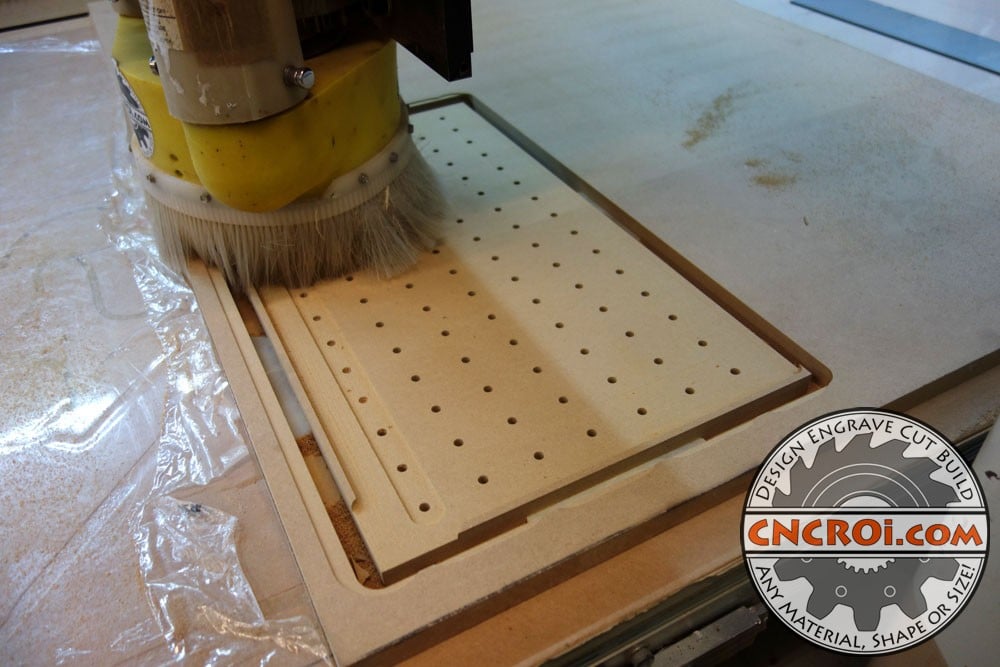

The CNC router you see here is actually our old machine, we’ve since upgraded to a bigger and more recent one but the tolerances between both are the same, our new machine just has a lot more tooling options, which is why I upgraded to it to make bigger and more complex projects at CNCROi.com easier and more cost-effective when lots of tools are required.

Some jigs are so big, they need to be made as multi-parted ones.

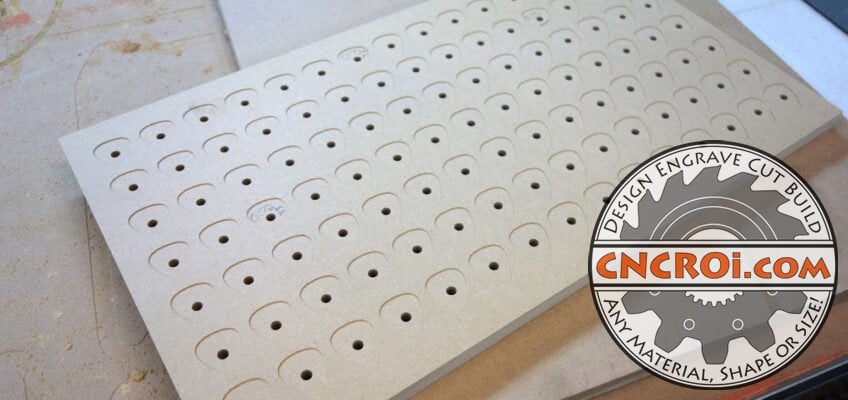

This two sided pick prototype jig has two sides, the first, are these pick indentations, which is made to a specific 0.73 mm (yes, mm, not inches) recess, so that the customer can easily load and unload them between production runs.

As guitar picks are relatively thin plastic, the addition of holes for vacuum suction is also required, as such, the customer can unload, then reload and the picks stay in place while the overhead UV printer head moves back and forth.

When it comes to making UV printer jigs, where possible, color coded inserts work very well to make sure things are totally emptied and filled without any thinking required.

One of my biggest concerns with making this two sided pick prototype jig is hold down, this is a 5ft x 10 ft table (same as our new machine) with a very powerful vacuum system but even with everything blocked-off, you begin to lose suction exponentially as holes are made.

As such, careful attention is done to ensure nothing moves during production, from start to finished production on this two sided pick prototype jig at CNCROi.com.

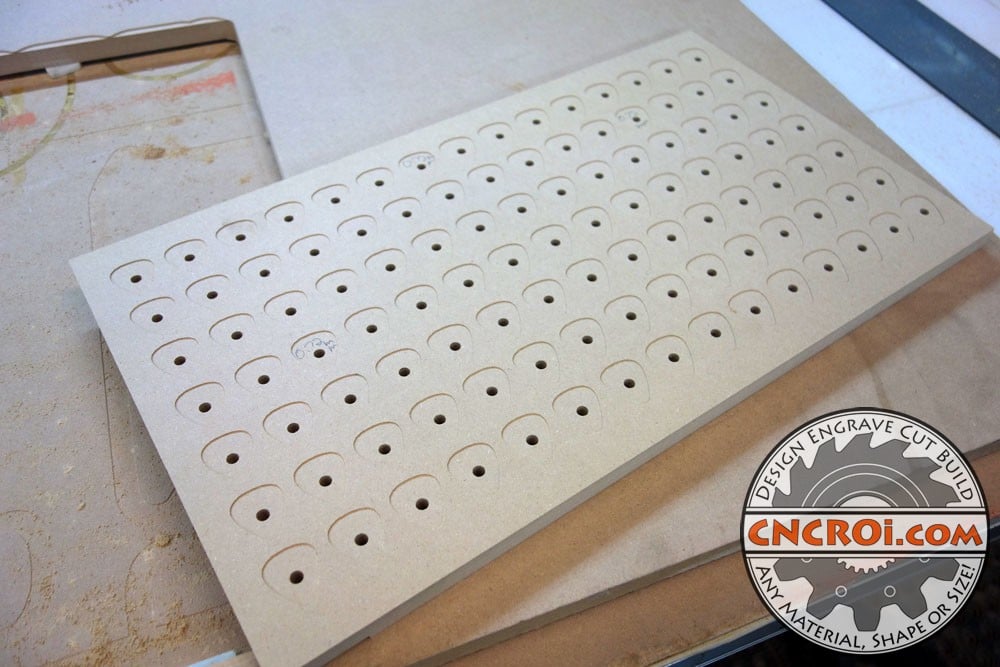

Once the inside parts are all sorted, the jig is cut-out and this is where the magic happens, because the diameter of the bit cutting this out is exactly half an inch, thus the carving out is half an inch, thus, flipping the jig around and putting half-inch blocks provides perfect positioning for the backside, as long as the overall board is not moved.

Most of our UV jigs require nowhere near the level of precision of this one for picks, so tolerances of +/- a few mm here and there aren’t an issue.

The jig recesses are all sorted out and look great, now the real issue of hold-down comes into being for the backside as now I have a jig that’s full of holes that will be revealed when I shave off the backside of this two sided pick prototype jig and make the vacuum recesses.

If you are wondering what I’m using for my spacing to hold the jig in place firmly, it’s just welding chalk, which is exactly half an inch thick.

You can now see all the holes I made on the front being revealed on the back of this two sided pick prototype jig.

The back of the jig is carved out as the front was, but with a little more give due to the hard stops, as long as those are consistent, we are fine as it’s shaved again, meaning everything is dead-flat and parallel.

This material was going to be made delrin for the finished prototype but the pricing for that is stratospheric at the moment, so most likely it will be made out of HDPE, which is a little less resilient but for this application, totally fine.

And there we have it, a two sided pick prototype jig made out of MDF with precision built-in.

MDF is a wonderful material to make jigs from, especially prototyping, as the material is readitly available, easy to work with maching wise and very cost-effective while being available in endless quantities for CNCROi.com customers.

MDF would have been a perfect material for this finished jig but the production requirements would be all day everyday, and as such, it won’t hold-up, hence this being a two sided pick prototype jig and not a final jig, that will be made using more resilient material by CNCROi.com.

As MDF is just sawdust and resin, the results we get from it with our CNC router are spectacular, you don’t have chip-out and other issues you’d see with regular hardwood or even softwood.

Even the lego jig came out pretty clean and that was a very tough one to get done well.

You have to keep in mind that the level of precision on these jigs is required to not be 1 mm but 0.01 mm +/- as little as possible, as such, we are out of the tolerances I can measure in the at CNCROi.com easily, so I bought two different types of digital calipers and they were within 0.01 mm of each other, which is fine for this two sided pick prototype jig and this will follow-through with the finished actual plastic jig thereafter as the coding and tooling is basically the same.

Just for re-enforcement, I did a few measurements here and ther on the jig that I sent to the customer to double check once they receive this two sided pick prototype jig to make sure we are getting the same measurements in our respective shops.

Precision is required on both the front and the back of of this two sided pick prototype jig, we’ve since gone to another design for various reasons.

Looking for a custom UV printing jig? Contact CNCROi.com right now!