Uncle Raymond’s Custom Urn

My Uncle Raymond was a great woodworker and when ever I’d go back to my family’s hometown, I’d drop by to spend a few hours with him before visiting other relatives nearby.

I was asked by my cousin if I’d like to make a custom urn for him and I told him I’d be honored, so I decided to make it out of solid Maple slabs, the finished piece was roughly 14″ cube and was about 30 pounds.

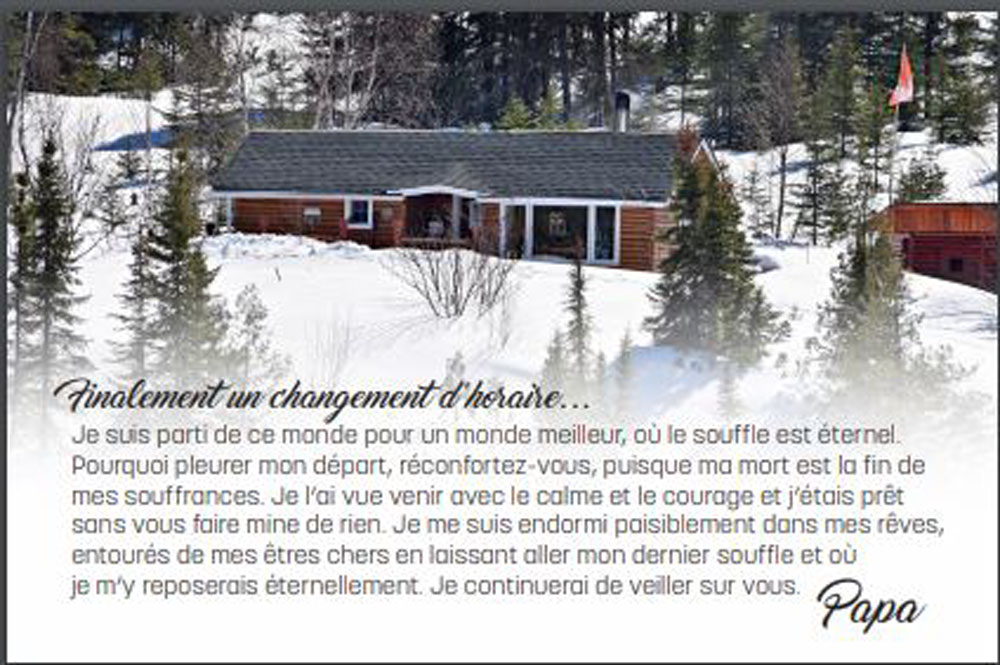

Through the years, I’ve showcased one of his projects he did in his youth, a wonderful cottage that my other Uncle has taken over and made his own.

Hand built using just a few tools over the course of several years, the cottage is a lasting legacy to my Uncle Raymond that everybody appreciates greatly and enjoys year round.

I had a few really big and heavy solid Maple slabs in the shop so I thought it was the perfect material to honor is live with by using this as building material for his custom urn.

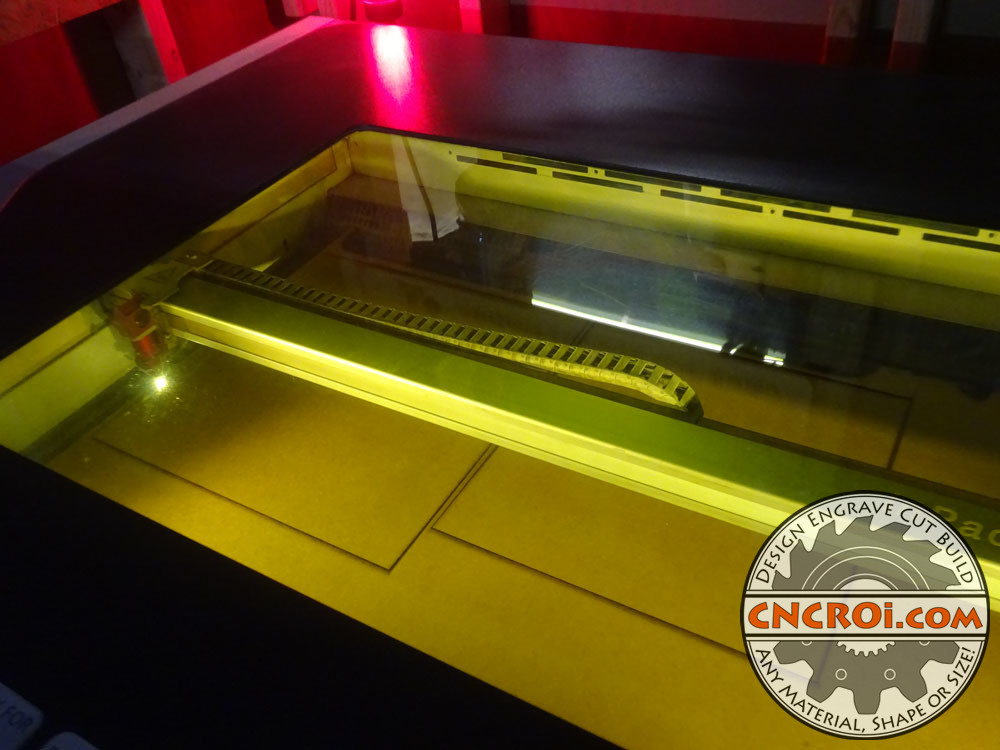

These might look small but this is a 5 x 10 ft table for reference, as it’s live edge, nothing on this wood is straight so I decided to make myself a custom jig to make precise positioning way easier using my CNC laser.

I could have made this custom jig using my CNC router as well but the laser was faster, there were multiple slabs 12″ and 14″ square to cut out of the live edge, as such, making a jig with the XY position being the center was an incredibly efficient way to get precise position quickly and easily across the entire slab.

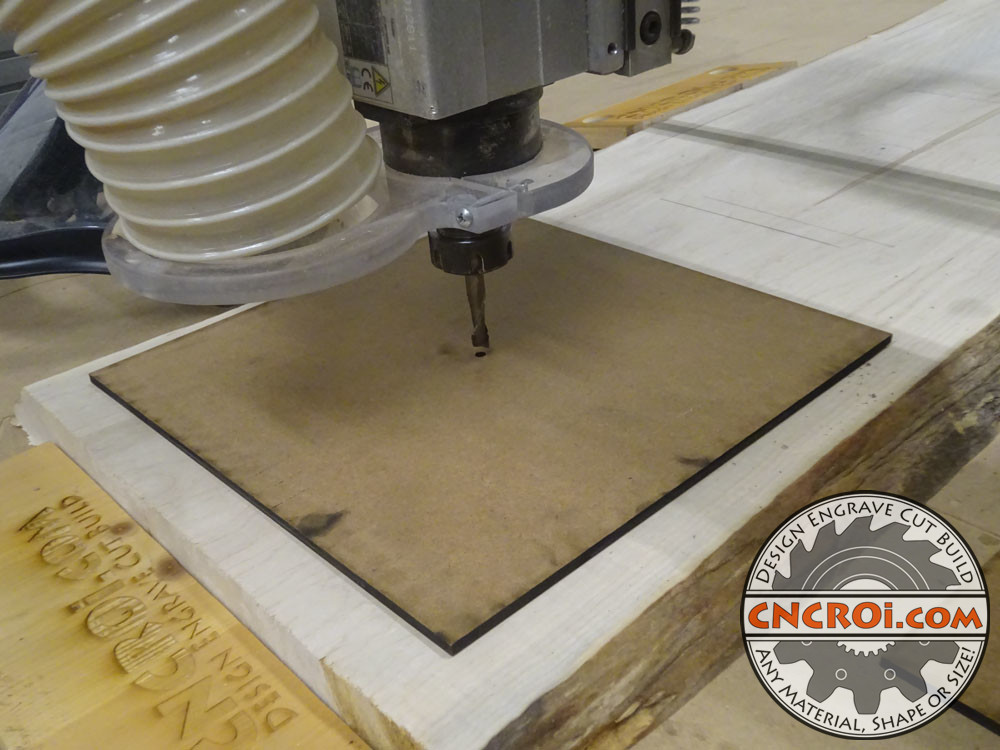

Cutting into solid Maple isn’t the easiest thing but my equipment had no problems doing it, slow and steady, the CNC router would cut out all the pieces required to complete this custom urn.

I’ve never really had to make custom jigs of this sort, the idea to make it just happened and it went so well, I’m surely make more of these as projects come along whether it’s for custom urns or signage using live edge.

I didn’t cut all the way through as live edge is notoriously tough to keep down, just making myself a reference and leaving a little material at the bottom was more than fine, I have other tools as you’ll see in the shop to clean the edges up.

I didn’t have my dust foot on the CNC router either as I was cutting down down to the level of the collar on my machine, the dust shoot would be ripped off, so lots of dust was produced making this custom urn out of thick Maple slabs.

This was yet another great excuse to use my bandsaw, it’s just such a wonderful tool to have in the shop and I use it any chance I get.

As for the inside places, I had to drill a hole for my jigsaw to have room to cut them out, I could have made this box using a lot less wood, just four sides that come together, but I wanted something extra heavy and strong.

The build quality is similar to how I like to make custom corporate awards, extra tough and a nice weight to them in order to give them extra gravitas when carried or given to somebody.

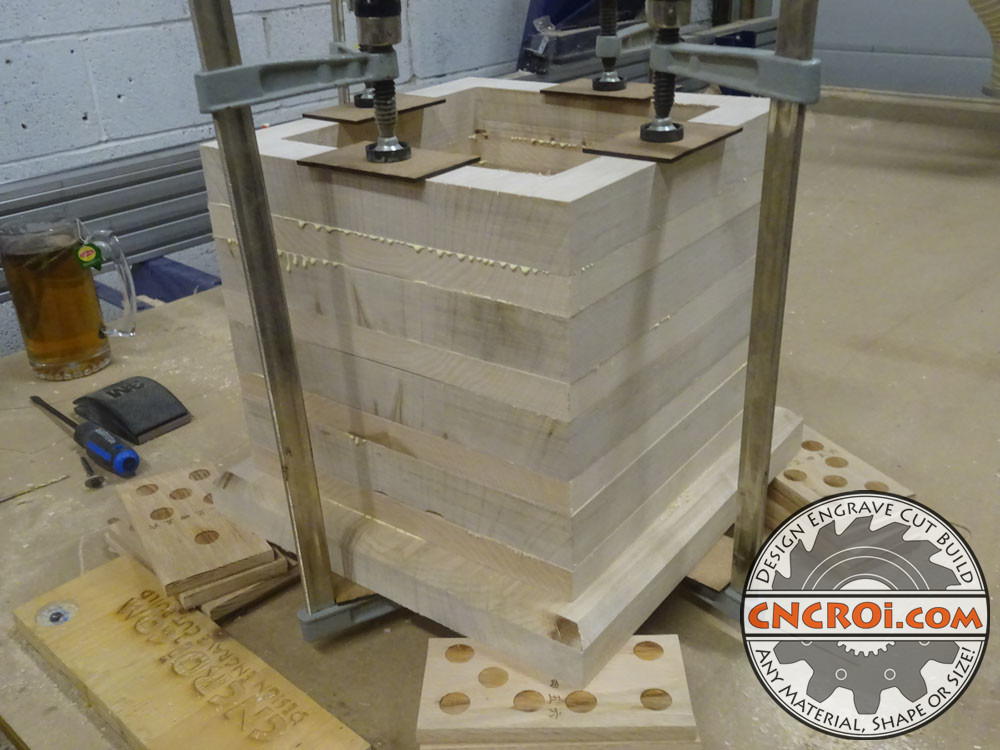

Glueing the custom urn itself required lots of glue, it may not seem like it, but there is a lot of surface area in this Maple that had to be stuck together AND that was even before full panels on each side were glued on it too.

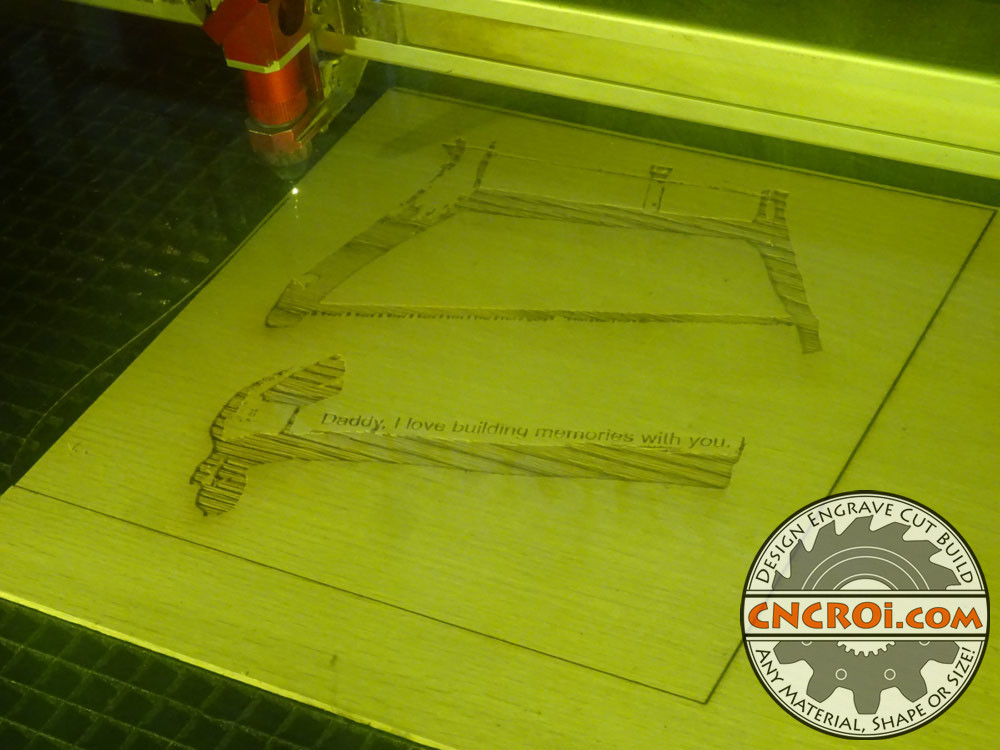

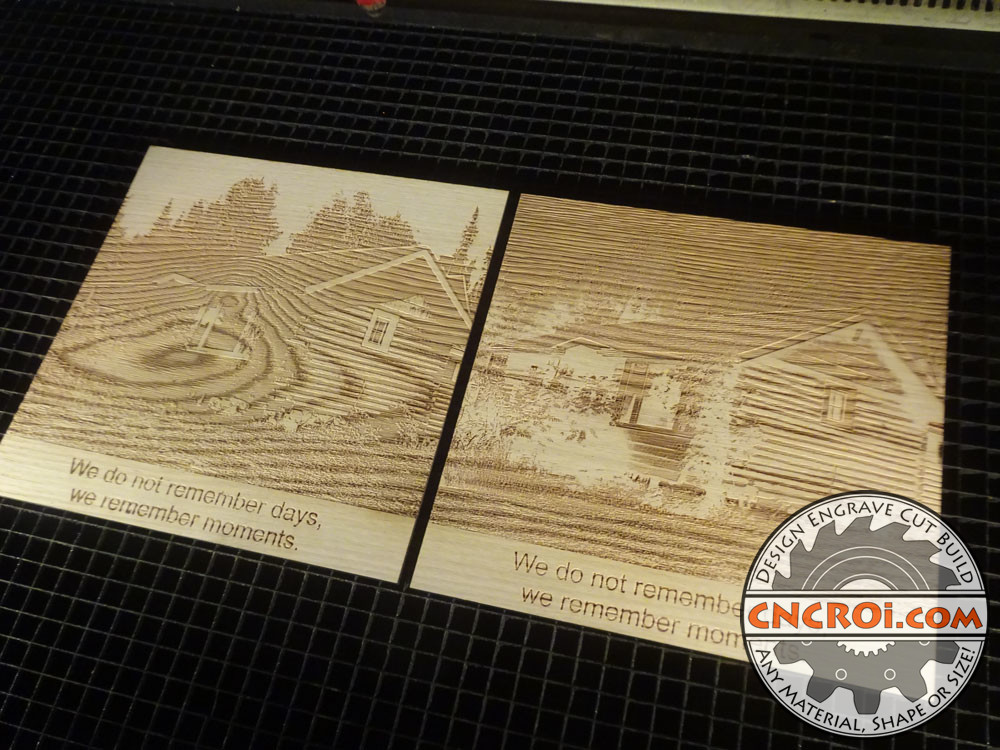

The laser engraving below shows you two of the tools that made the cottage that Uncle Raymond built in his youth.

The reason for making panels was two fold over engraving the urn directly, first, the resolution of the images wasn’t the best overall so a lot of image editing was required and secondly, I didn’t know what “version” would come out best so like the cottage below, the one on the right came out clearer than the one on the left.

It’s really hard to photograph these panels properly, the camera tends to focus too much on the grain and not the engraving, but all of these panels are clearly visible and were stuck on all sides of my Uncle’s custom urn.

Before sticking them on though, this Maple urn needed to be thoroughly sanded, there was glue, there was unevenness and a few other issues that sanding resolved most of.

It’s astonishing how much work went into making this custom live edge Maple urn, it certainly wasn’t an afternoon project but took several days and I only did about half the work as my cousin wanted to finish it.

So the last step for me was to glue the panels onto each side then ship it over to my cousin to add metal brackets, finish the inside and out for his father’s new resting place.

My cousin did a great job of the urn, I’m very proud to have given his memories a place of honor as he did for the whole family when he built that cottage.

My Uncle Raymond had a great sense of humor, if you can’t read French, it basically states that finally his schedule has changed after years of health issues, don’t be sad for him as he’s in a better place now.

If you want a custom urn, any size, material or design, contact me.