Virtual VS Physical Model Kits

Virtual vs physical is something that comes-up often in our line of business. The vast majority of our projects at CNCROi.com begin as virtual models and CAD documents, we then transform those pixels into physical form.

Virtual VS Physical Model Kits: Scale

In our virtual environment, there is no such thing as scale. A model can be designed to be as big as the entire Earth as easily as the size of a needle, but there always is a practical consideration that must be taken in account.

For instance, if you are building a model kit, it’s no fun making something that’s HUGE that you can’t store it in or has to be broken down into pieces for transportation or due to gravity, too heavy or cumbersome to practically put together.

Generally, I like to make my model kits just big enough to be able to easily hold and carry around.

Virtual VS Physical Model Kits: Material Costs

The 3D animation of our Army Transport Truck at the top of this page is a great case study as to what can be accomplished in the virtual world that would cost a fortune to do in the real one.

It would look amazing to make this model out of glass, it would be heavy and I’m not sure how well it would actually look in the real world when you have such things as glue to content with, which you would see straight through the glass.

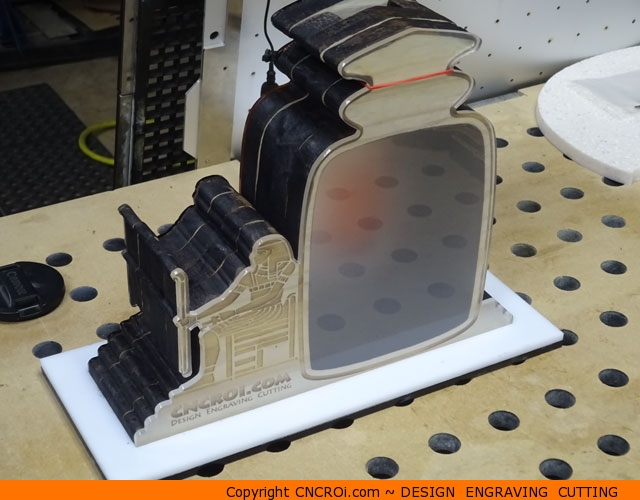

Take a look at the above model as well, I used blue and red polycarbonate, not only would such a thing cost a lot of money but the perfect form and finish would be different and require a lot of work. I use it though to show structure of the model.

The edges of polycarbonate are black when cut with our CNC laser, so all the edges would need to be sanded down, a tremendous amount of work! Building it out of semi-transparent acrylic might be a workaround but it has its own issues when it comes to model making.

Virtual VS Physical Model Kits: Physics

There is such a thing reality that we need to content with when it comes to building real models, some material is stronger than others, some are more durable, some bond very well while others are just a paint to work with due to their very nature.

It’s quite easily to design a model that can’t be made in the real world just as easily as it is to build a model that works perfectly but the client decided upon a material that just won’t work at a given scale.

The structure involved with building a model to be “carry in your hand size” is very different from one the size of a building, even if it’s the same model.

For instance, the Straddle Carrier above works great in plywood at about the size of a typical inkjet printer but if I were commissioned to make it the size of a two-floor building, none of the materials presented would work, the string would have to be aircraft cable, the entire structure would need a metal frame and the tires would probably be far larger and numerous than shown.

Virtual VS Physical Model Kits: Fit

Fit is one of those things that are very much material and design dependent, when CNCROi.com designs something, we need to get an idea of scale and materials in order to design a model that actually “fits”.

There is a lot of variance in material, I’ve NEVER bought quarter-inch plywood that was actually quarter-inch. Acrylic is a bit closer to spec but that has its own issues when model construction.

Metal needs to be welded together, materials vary sheet to sheet and wonderful things such as glues and bonding agents don’t always work the way you intended or was advertised.

This is why the vast majority of my projects found in my books are tested out using wood, it’s by far the easiest material to work with, bonds incredibly well and is easy to modify and “push to fit”.

Virtual VS Physical Model Kits: Budget

By far the biggest issue that we need to resolve with our customers right off the bat is budget.

Budget dictates model size…

Budget dictates material options…

Budget dictates timeline…

And most importantly, budget dictates if your idea is possible, design through build.

For instance, if you want one bank as shown below but you want it made out of 304 stainless steel, all welded together and deep etched with bullet proof glass in front, it will cost significantly more than just using plywood even if it’s the same size.

Volume is also a critical factor to contend with, designing one bank is as easy as designing a thousand but designing a thousand unique banks will cost significantly more than designing one and making it a thousand times.

The options are endless as CNCROi.com is a custom shop where we make everything to spec on-demand. We aren’t an importer of trinkets where we have a range of offerings, we build to what you want and to us, that’s easier than buying mass produced things at the store.