Vision is more important than a business plan

When I set-up CNCROi.com, my vision was clear, I wanted my company to be a Custom CNC Shop.

While I was in Australia learning the ropes of the CNC laser and corporate award industry over at Evright.com, I realized what I was passionate and wasn’t passionate about. Evright.com is an awesome company, they taught me so much, their people are fantastic and as is their passion for customer service. This is why Evright.com has become a brand known across Australia and the lessons I learned there have had a direct positive impact on how my company is succeeding even during a global recession.

For CNCROi.com, I wanted my company to become a global brand for Custom CNC Solutions and Production. While Evright.com’s tag line is “if it’s worth winning, it’s from Evright.com” (or something along those lines), my focus was going to be on custom solutions to companies across a wide spectrum.

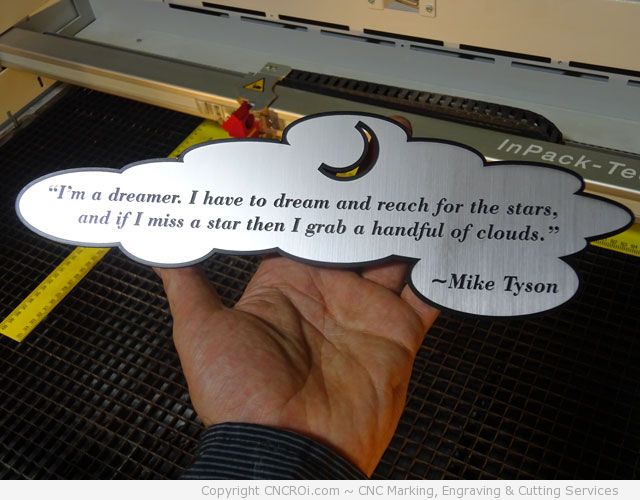

I wanted to focus on the corporate, industrial, aerospace, military and mill working industries, the reason is simple. They have the volume, they have the budgets and they require things to be perfect the first time and every time. The specs are far more demanding, which is what makes it fun! No two days are the same here in the shop!

Yes, we’ve recently branched out into custom CNC solutions for individuals getting married and a few other verticals, the demands are different – instead of making hundreds of unique foam inserts for toolboxes, we are making custom designed cake toppers and other small promotional items on-demand – but the passion is still there and it’s great to be given the opportunity to people to benefit from our industrial expertise. It’s a nice change of pace and demographics.

Why we aren’t a trophy shop

The one thing I wanted to make clear from the onset is that CNCROi.com IS NOT A TROPHY SHOP. Not that there is anything wrong with it, I worked in the most successful one in Australia over at Evright.com for two years!

Most trophy shops are really import companies, meaning they get their wares from third parties and resell them with some personalization (like a tag with your name). They don’t actually design or do much custom work in-house, you pick a resin award from the shelf and your choice of fonts on the tag that’s about as custom as it gets. The reason for this is simple, they don’t have the equipment that can handle production quantities across a variety of materials in a precise manner (this is where Evright.com excelled as they had the custom capabilities that most shops didn’t).

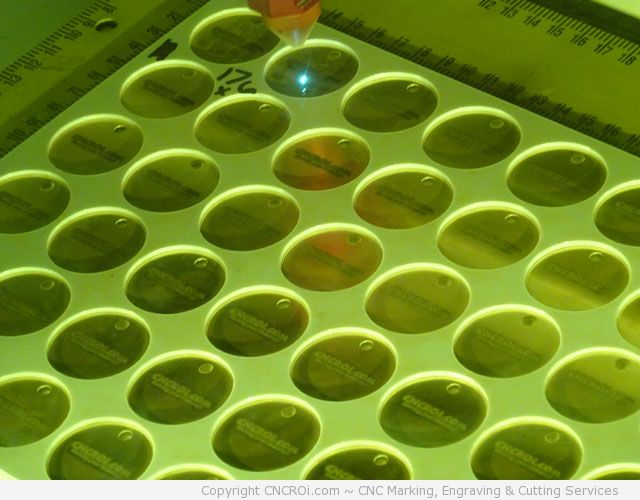

Look online at trophy shops and you’ll notice a few things, first, they generally don’t tell people what kind of laser or equipment they have (mostly small format Chinese ones), they are heavy on displaying the work they have done in the past which honestly, looks like stuff done a thousand times over and at the end of the day, their business model is order comes in, import, put a tag, ship out. I’ve had a client tell me in a meeting that if they see ONE MORE OVAL CRYSTAL AWARD they are going to retire for their sanity.

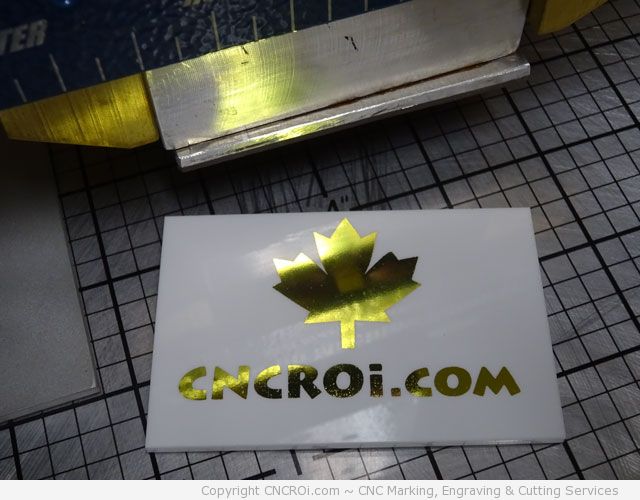

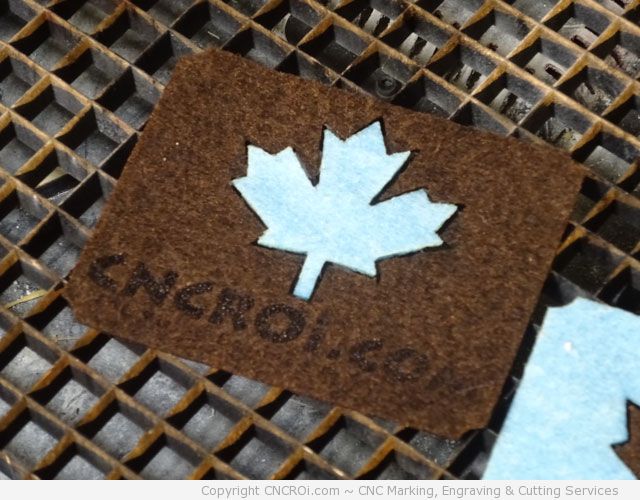

CNCROi.com is very different. Our catalog of products is whatever we come-up with. Your material selection is endless as are the customization options you have available to you. You want a coaster? Well, let’s make it in the shape of your corporate logo and make it in such a way that we can actually incorporate some of your products inside or around it and hey, while we are at it, let’s randomize the colors so no two coaster is the same… and make a few hundred of them… you get the idea. That is where the true challenge is and the fun begins!

There is no import of finished product we brand with a tag, it’s designed FOR YOU to YOUR SPEC and delivered to you ON TIME and ON BUDGET. It would be tremendously EASY to import, tag and ship… there is good money in that industry, but that just isn’t where my passions are, doing something CUSTOM is just so much more enjoyable for both my clients and myself… there is absolutely no need to import anything!

Custom is where we begin, not end

Of course, many of our customers… and the list keeps getting longer… enjoy the creative process behind our offerings but we also do specific spec work as well. For instance, color changing polycarbonate tags for avionics (fiber laser work) or working with other custom providers to create a supply chains that benefit our customers so, we can do both the custom creative stuff and the regular industrial spec work.

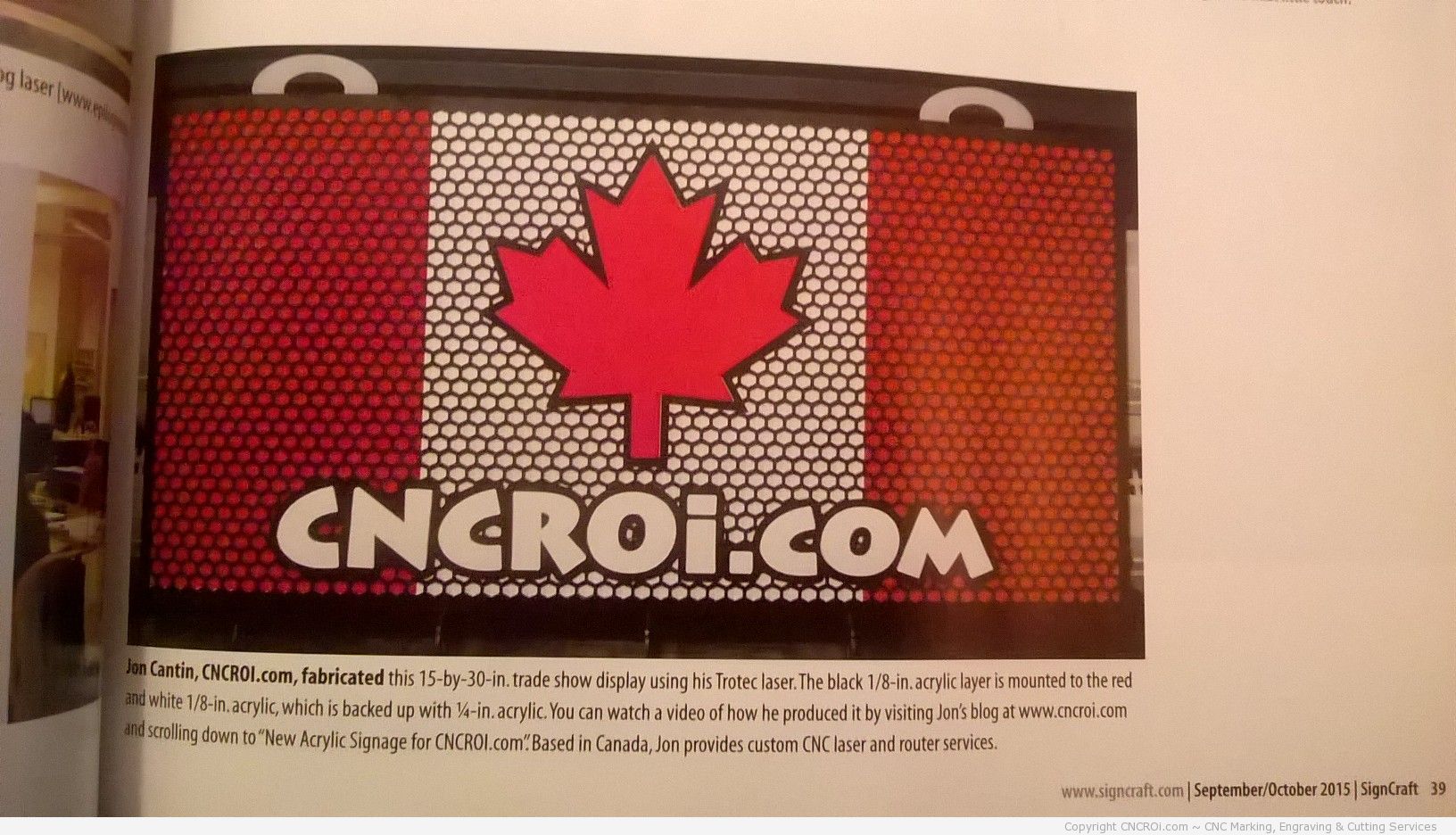

The other aspect that differentiates us is our equipment, it’s an Austrian wide format industrial dual-sourced Trotec Speedy 400 flexx with vacuum table, gas kit, easy change tables, powerful extraction etc… basically, the top of the line machine that’s made for heavy-duty production requirements 24/7/365. This is massive overkill for trophy shops but for us, it’s the perfect machine for our customer’s applications.

Oh yeah, my vision was so strong that I was the first in Canada to acquire this machine! How’s that for trail blazing a path for others to follow… including Tony Stark… we got a better machine than Ironman! He has a Speedy 300 flexx (pictured below), we have a 400 flexx (pictured above)!

CNCROi.com, as a result, has you covered across the custom virtual design through to final physical product. We also work with a growing list of elite graphic designers who require, like our other clients, things to be perfect, on budget, on time. It’s a different market but the specs are just as stringent once they realize what we are capable of producing for their clients.

What does the future hold for CNCROi.com

I really enjoy the challenge that comes from finding solutions to our clients issues, whether it’s custom marketing or industrial spec work or corporate branding a custom showroom so that’s the direction the company will increasingly specialize in. Of course, this benefits our other verticals like weddings, birthdays etc. that also want some custom for their special moment in life.

Right now, we have the world’s best industrial engraving machine that can also cut everything and anything but metal… so we do a lot of custom stamping of tags of all types but it would be great to be able to offer customers the same ability we have on acrylic or wood as with metal in incredibly short runs and within our 24 hour goal.

We already make custom heat press molds and have a heat press machine for testing in house before things go out but it would be great to offer more custom solutions in the plastics department as well so a plastic injection machine would be fun! We do have a CNC router (awesome ShopBot Desktop) that helps us with small production runs and a 3D printer that does the same. Plastics are an interesting tangent because we have both a CO2 and fiber laser source in our industrial CNC laser, which means we can color change it quite easily.

There is always “one more CNC” that can find its place in our shop as we grow and expand in capabilities to, at the end of the day, produce even more awesome products for our clients and help them with their spec work.

One thing is for sure, the more clients and expertise we acquire along the way, the more ALL our clients benefit, it’s an endless cycle of precision, commitment and passion!