WATERJET VS LASER: Cost Effective Metal Prototyping

As CNCROi.com does more and more CNC waterjet work, we are always trying to think of more efficient ways to move projects forward, and one concept that seems to work very well for our customers is using MDF for metal prototyping.

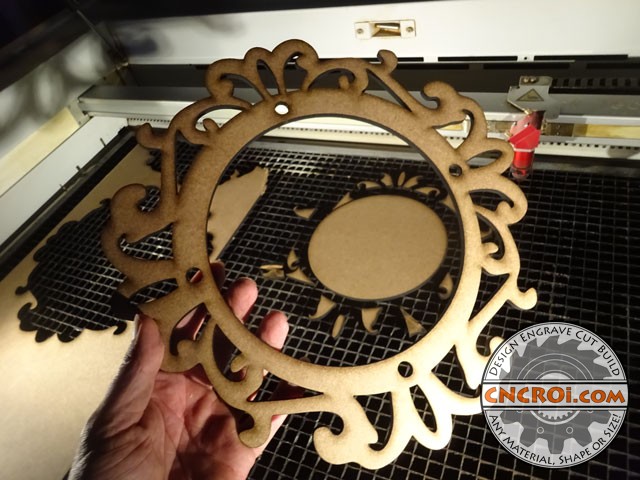

If the designs above look familiar, it’s the same flowery design concept I used for an earlier wooden fretwork example I did for CNCROi.com using, you guessed it, MDF.

This is 20 gauge cold-rolled steel, which is great for this application and the design is complex enough that it’s a very valid comparison to show what we produce with our Austrian CNC laser vs CNC waterjet, showcasing our metal prototyping capabilities before going full-bore into actual volume production.

What I really like about metal compared to just about any other material CNCROi.com uses to make our customer’s projects is just how strong it is, but that does come with a cost and as such, when it comes to metal prototyping, it’s more cost-effective to make test using that to refine a design before jumping right into production and finding an error down the line.

The “problem” with metal is that there is no going back, with other materials, if you are a bit “off” due to design issues, you can adapt and work around it, but with metal, you just don’t have that flexibility and there is a difference between a CAD design and the actual REAL design in the physical world.

For some of our simpler projects, jumping right to metal makes total sense, like this shop sign for instance, even if the customer’s design has a few issues, it doesn’t matter as there isn’t anything interlocking with it.

But when it comes to complex welded assemblies, it’s always a good idea to do a rough test to make sure the design is sound before jumping into thick metal and then finding-out once you receive all the parts from CNCROi.com that your holes don’t line up properly which requires you to waste a lot of time at the job site trying to fix an avoidable problem.

I’ve designed a lot of stuff, just think of this Big Wheels I designed, it could totally be made out of metal, but it’s great to prototype something first using an easier and more cost-effective material just to make sure that everything you want to work actually does as it’s always that one little part that can screw-up a design.

As this design is just about done being cut out, you can notice that the tool pathing is almost identical to that of our Austrian CNC laser, the tolerances are slightly different but it’s so minor that it isn’t even a variable when it comes to metal prototyping, which is why it makes for such a wonderful combination for our customers!

I really enjoy waterjet cutting, it’s just another way to accurately and repeatedly cut out design using materials that aren’t suited to other equipment like our CNC router or laser for specific applications, though for larger volume plates, we use a 6kw fiber laser.

Another thing I really like about metal prototyping is that experience with the waterjet helps me isolate issues that just aren’t present with other CNC equipment we have, as a result, the overall designing process is improved to take into account not just one machine, but 4!

From custom metal stencils to assemblies and shop signage, CNCROi.com can do it all for you and having an industrial sand blaster also helps greatly cleaning-up the parts after they’ve gone through the various processes we can use across a whole host of materials.

If you look closely, you can see the sand that has deposited on the surface of the material, this is the abrasive that allows the water to cut through the cold-rolled steel, no sand means, quite literally, no cutting AT ALL.

Straight off the CNC waterjet table, you can see some sand has stuck to the surface, this is easily washed off but the edge quality is a little rough and there is a lip on the underside, but at this point, it hasn’t had the opportunity to flash rust yet, don’t worry, it happens fast…

And this is why we stick it in our industrial sand blaster, to remove all the crud and give the surface a wonderful 120 grit sand paper texture which works wonders with enamel or clear or powder coating to protect the surface from rusting in the future.

Now that this flowery ornamental design is cut out of cold-rolled steel and about to be cleaned using our sand blaster, let’s compare it to the laser process using our CO2 laser source.

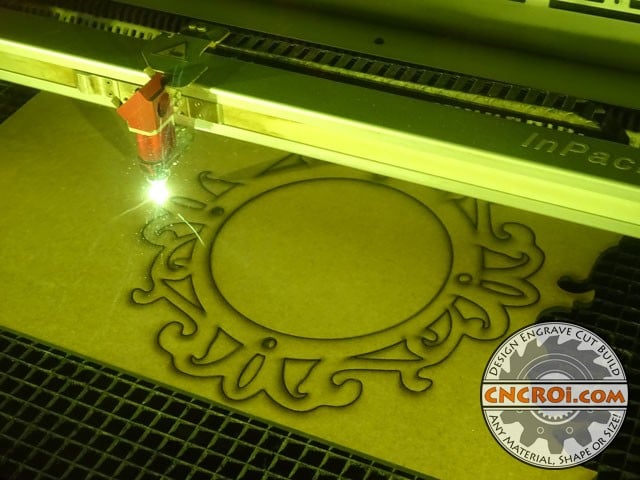

The cold-rolled steel used for the metal prototyping demonstration above is roughly 1 mm or 1/20th or 20 gauge thickness while this MDF is 3x thicker but it makes no real difference, using material this thin with the laser is no problem but I needed something a little stronger, hence thicker, in order to make this work on camera.

Right away, you’ll notice that we are using light and fire to cut out this ornamental design that would be used for metal prototyping instead of sand and water, one isn’t better than the other, it’s just different.

In this case, CNCROi.com is just cutting a sample of each but for larger production runs, the process is the exact same, whether it’s metal, plastic, wood or anything else our customers want us to manufacture and fabricate for them.

Of course, if you want engraving as well, something that we can’t do with the CNC waterjet, that’s possible as well.

But having both machines means CNCROi.com can mix and match, so if you wanted your metal part to be labeled permanently, we can use the waterjet or CNC laser to cut and then anneal or etch the surface, with us, your options are really and truly endless!

For applications ranging from custom corporate awards, coasters, key chain holders etc… we work with what you want within your budget and timeline, that’s the incredible flexibility and power CNCROi.com offers it’s customers around the world!

Alright, back to cutting 1/8th” or 3 mm thick MDF!

If you are wondering, we could have just as easily cut this out using our CNC router as well, the choice of one machine over the other really depends on the material, the design and timeline.

As soon as you jump into metal, the costs go up quite a bit compared to wood for a host of reasons from raw material to production volumes, this is yet another reason why being able to offer MDF prototyping before jumping into metal prototyping followed by volume production works so well for us and our customers.

Turnaround time is generally a few days to get the metal to spec, by that time, CNCROi.com could have already CNC laser cut the MDF and shipped it out and it would just be within a day or two of arrival, if everything checks out to your spec, then we can jump right into the next phase of the project.

Here’s a comparison of the two identical designs cut out using different CNC machines and materials, you can guess that the metal costs more than the MDF but keep in mind that, quite literally, they are just about the same in every way.

Here’s an edge-on example and yes, we can cut out of thin metal and then put a backing using thicker material which saves you another King’s Ransom, just another advantage CNCROi.com can offer you!

Custom metal prototyping has endless applications and benefits for a whole host of custom applications that we specialize in offering.

Need custom metal, wood, plastic or anything else cut to size, shape and thickness? Contact CNCROi.com right now!