Wood Lamacoid Engraving Imagery Options Review

Wood lamacoid engraving is sometimes a wonderful alternative to real wood engraving, today we’ll review the differences between them so you can get an idea of some of the decisions involved with picking which is best for your particular application.

Although the video above starts with the wood lamacoid engraving first then the real wood engraving second, in this blog post CNCROi.com will review the imagery engraving in the reverse order.

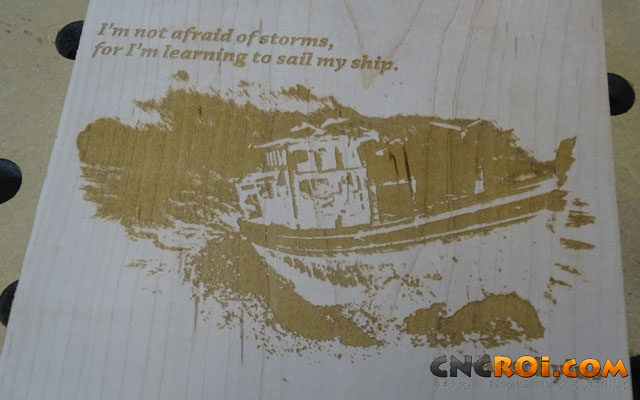

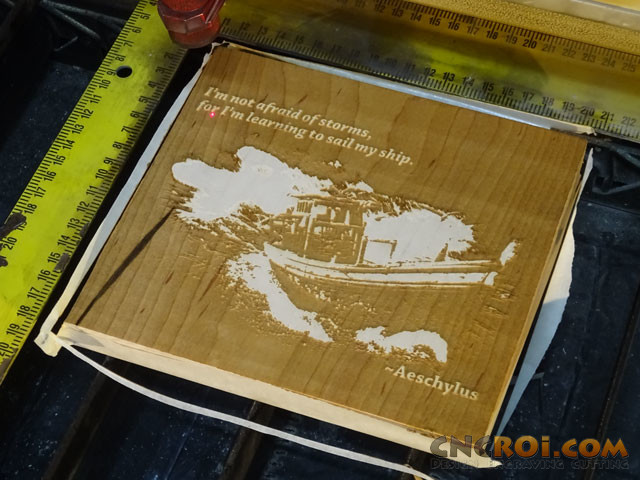

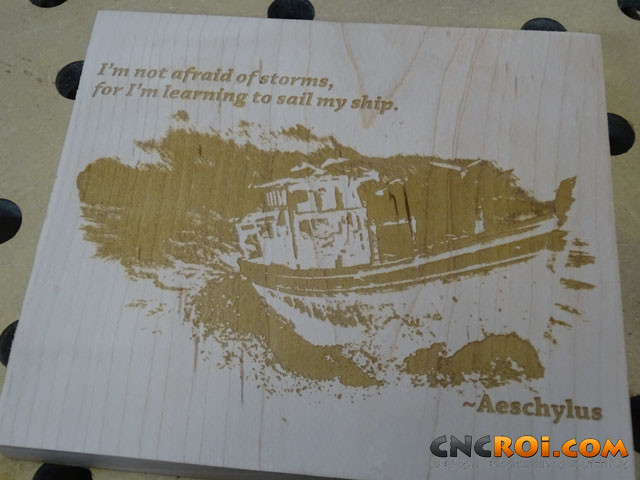

One of the first major differences with wood lamacoid engraving when it compares to real wood is that real wood needs to be masked, although this can be sanded after production, the mask will help a lot to make the clean-up far more efficient.

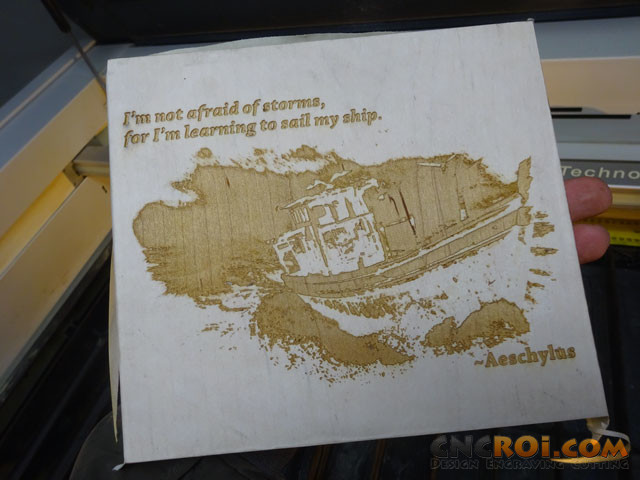

Another difference as you’ll see further in this post relating to wood lamacoid engraving is that here we are burning the wood to be a darker shade while with the lamacoid version, we are just vaporizing off the first layer of the laminate to reveal the white layer underneath.

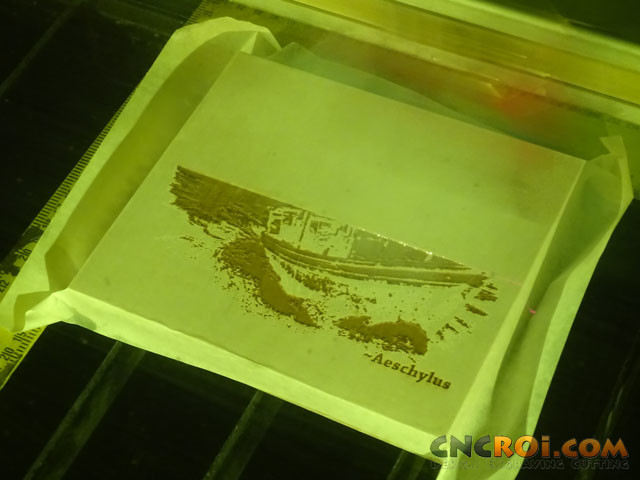

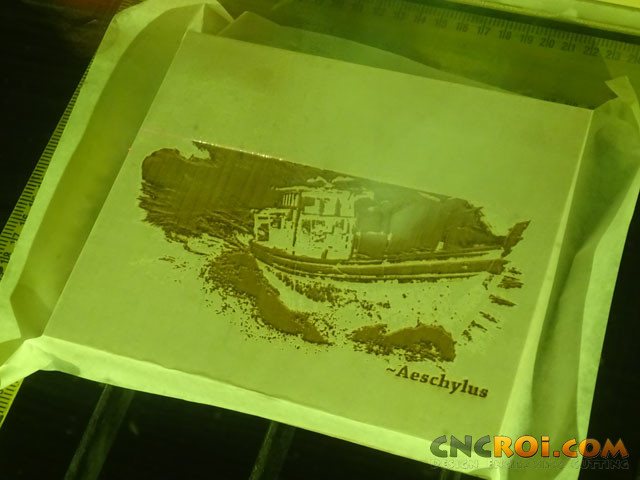

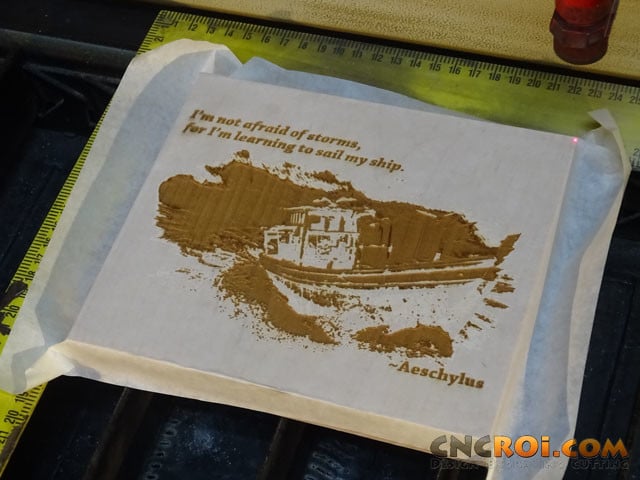

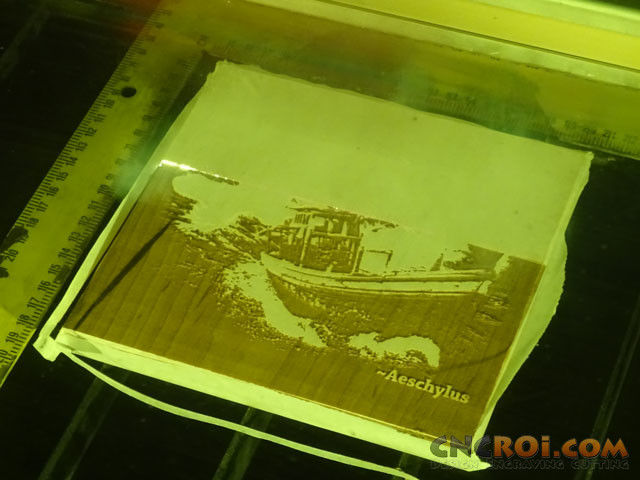

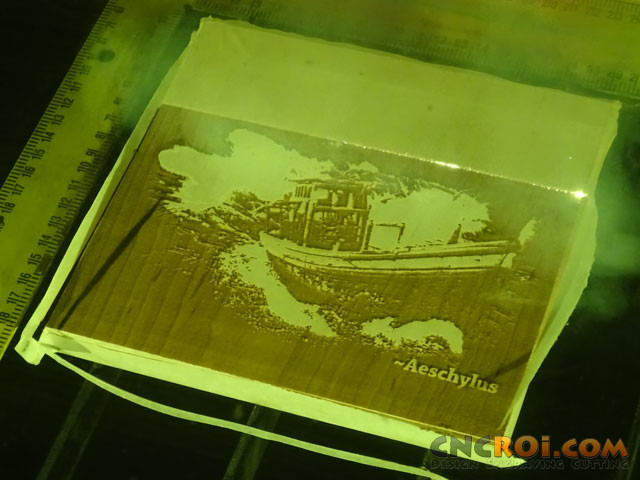

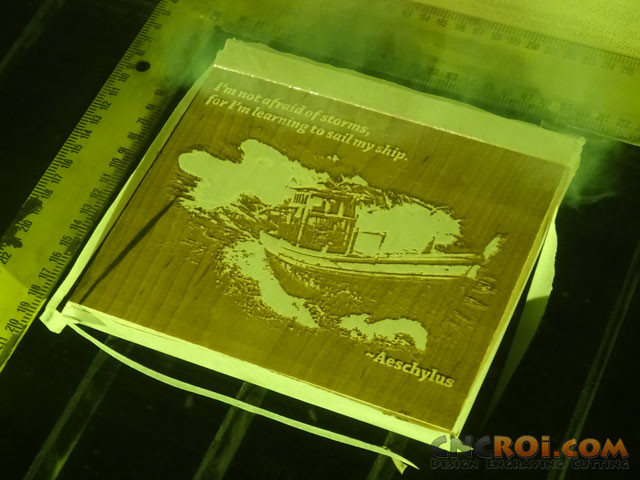

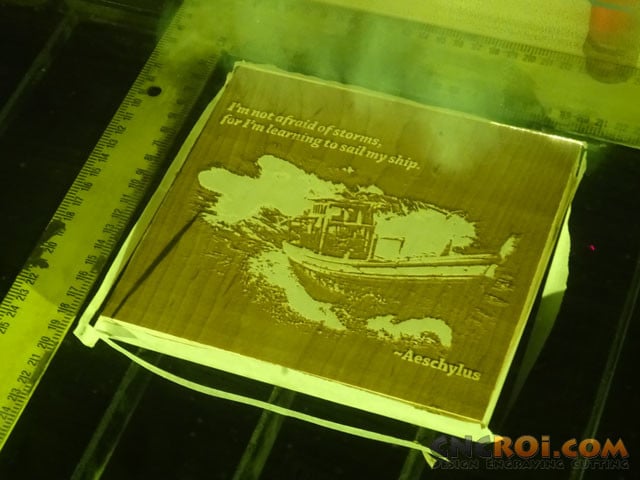

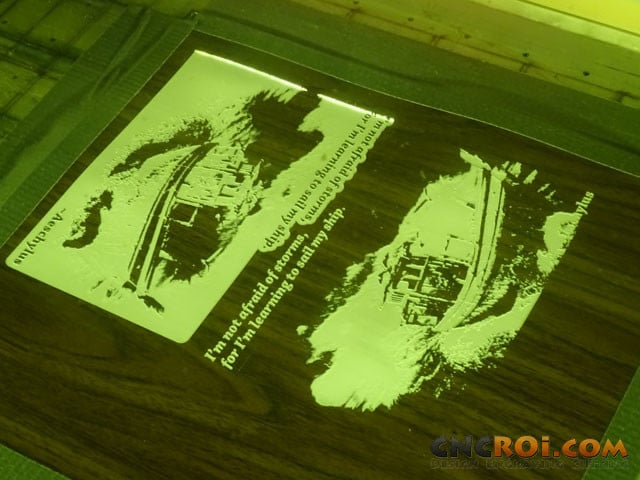

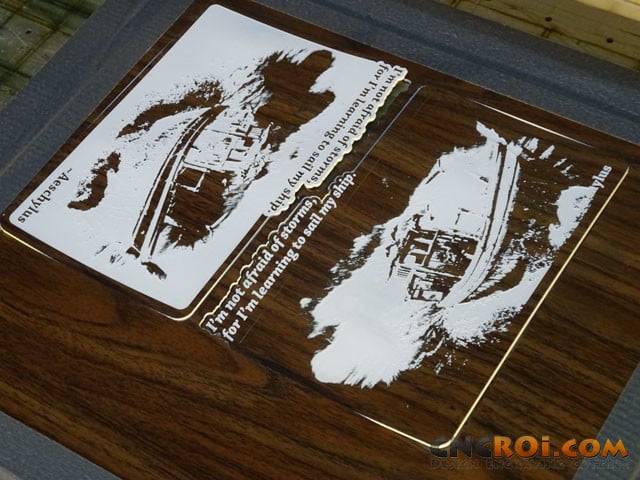

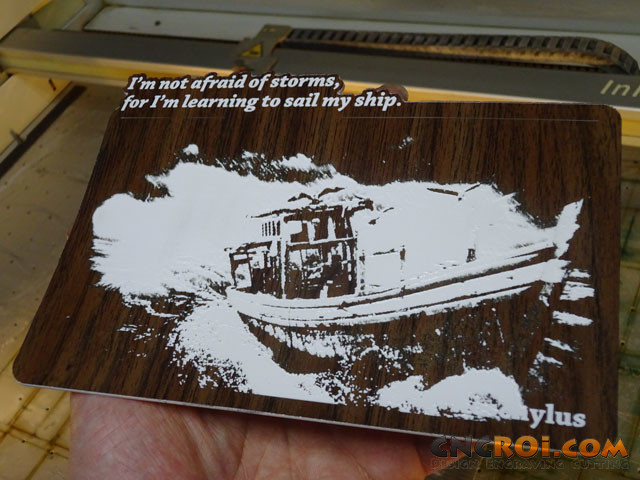

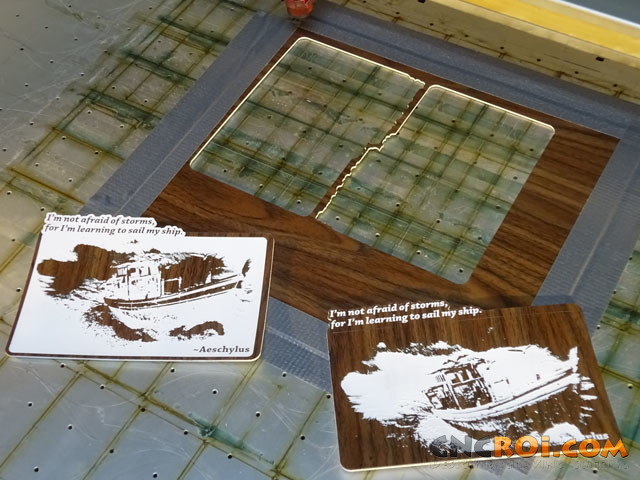

In this blog post, we are wood lamacoid engraving two versions of the same photo, one a positive image and the other the “negative”, sometimes it’s difficult to tell which will show best for our clients so what we do this exactly as you see here, we do both and let them decide which we use.

Generally, we do this on some cheap plywood or MDF before moving to the more expensive wood lamacoid engraving, for instance, the live edge wood plank was tested this way on a piece of plywood first before we did the piece for the client.

The text was easy, that was a given that it would be engraved into the live edge wood plank you see in the above video but like this image of a ship in a storm, we nor the client were sure if it would look best as a positive or negative image (with a few design modifications to make it work of course either way).

For this wood lamacoid engraving, no changes were done to the image to accentuate details, it was as/is as I wanted this demo to be more ambiguous on purpose.

We don’t live in a perfect world where every image fits amazingly on a given material, I hope this blog post gives you a glimpse into some of the decision-making process behind the custom work CNCROi.com does on a daily basis.

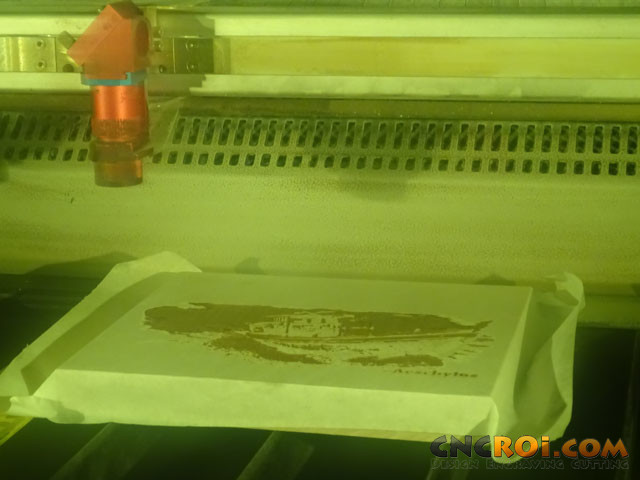

As you can see, we have plenty of clearance when it comes to wood lamacoid engraving, solid wood or lamacoid, the distance between the material being engraved and the head of our laser is 4 inches.

CNCROi.com also has a variety of other lenses, as short as 1.5 inches and other specialized for other materials, such as fiber laser specific lenses for optimal annealing and metal etching results for our clients.

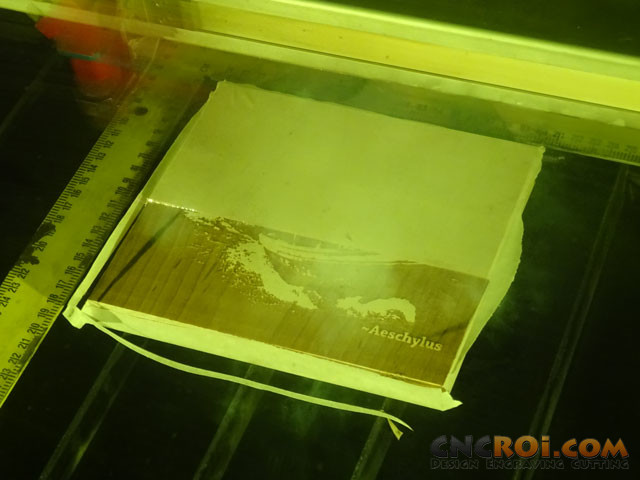

Personally, of all four examples of wood lamacoid engraving shown in this blog post, the version that’s being produced right now, I believe, is the best looking and with a little more image manipulation such as making the boat with a stronger outline, would come out perfect if this was a client project.

As this is the same piece of maple being CNC laser engraved on both sides, I kept the masking on and flipped the board.

This was done to protect the board as the slots can sometimes have sticky resin on them and to make this a quick turnaround production video for you, the website visitor and soon to be CNCROi.com customer!

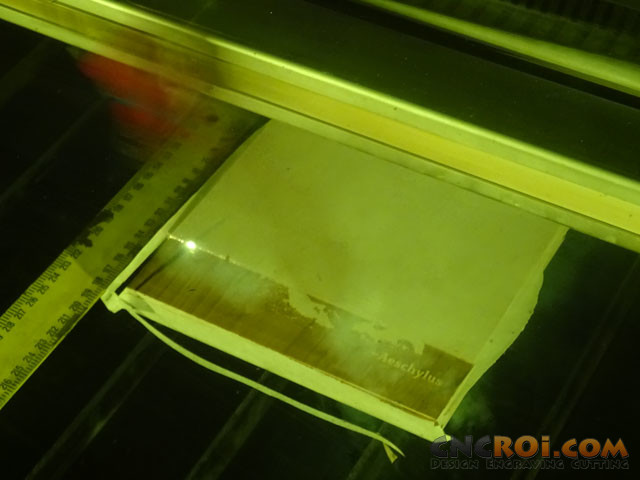

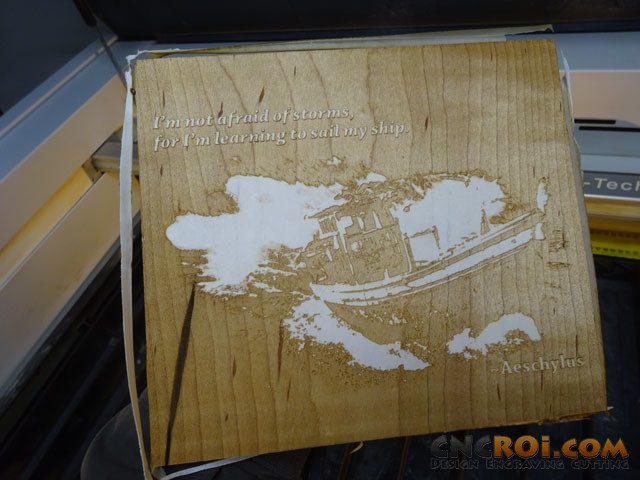

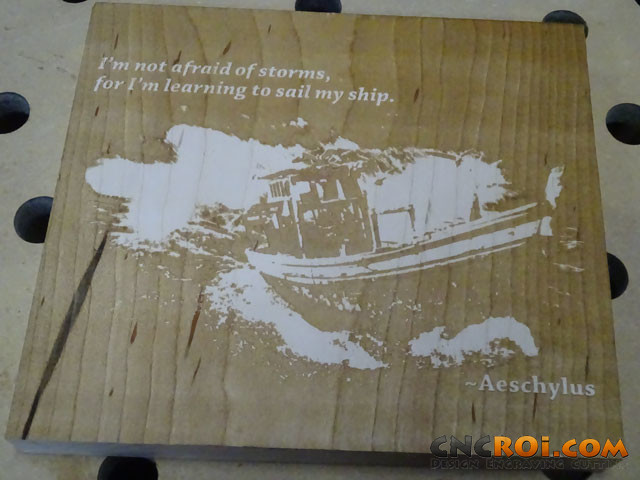

Reverse engraving or negative engraving takes longer to produce as we are vaporizing everything BUT the image, so the entire surface is engraved rather than just the imagery.

The same is true with the wood lamacoid engraving but it’s a bit more challenging as the heat build-up tends to warp plastic while with wood, my favorite material for this application, is no problem though this poses challenges when it comes to sanding the finished piece.

You’ll notice the first major difference i this maple wood engraving is that there is a lot more smoke being produced, the same holds true, of course with the wood lamacoid engraving.

Why? Well, we are essentially vaporizing the entire surface of the material, on some images we’ve done at CNCROi.com, the difference was hardly noticeable but as this is a demo, I wanted to emphasize the differences.

It has been a very long time since I made a “quote” piece of work here so that’s where the boat and the saying came into being, it was just a matter of picking an image that went well with the saying and then putting the two together.

There are plenty of royalty free and lists of quote website out there to choose from, so the process of coming-up with something is actually pretty easy.

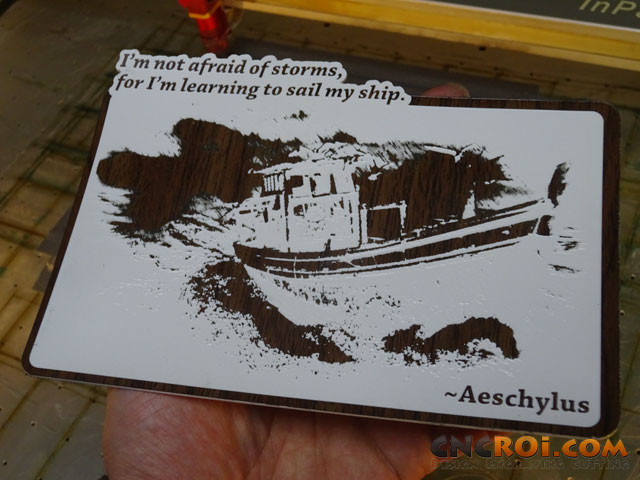

The quote in this case is from Aeschylus and states “I’m not afraid of storms, for I’m learning to sail my ship.”

I’m fully aware that the ship in the picture being engraved into the solid piece of maple off-cut isn’t a sail boat but the image fit so perfectly with the quote otherwise, I just had to put both together.

CNCROi.com has done a lot of work on various woods, we have over 20 species of woods in the shop at any given time beyond what we can find readily available at the lumber store and a bunch of equipment to make what we can’t find to meet our customer’s specs.

Wood lamacoid engraving is only one of hundreds of options when it comes to lamacoids alone, there are a ton of different laminate color options out there and then we have metals, acrylics and other materials to choose from such as leather.

Like the previous ship engraved into this maple but on the reverse side, it’s just about done, the focus isn’t to go DEEP but to darken the wood for this demonstration of wood lamacoid engraving.

One thing that REAL wood does that lamacoids and laminates can’t is the grain, for real wood, it follows through from the engraved to un-engraved parts while in lamacoids, it doesn’t.

I believe that’s why REAL wood looks better for signage than lamacoids for many applications where wood is the favorite, it’s the esthetic beauty of a natural imperfect material that adds a lot of character to a piece that’s just missing from their plastic man-made cousins.

Like my experience in 3D animation for industrial customers around the world, when we made a machine too perfect, it actually made it look weird while adding small indents and imperfections actually made it look more natural and real.

And there we go, a reverse engraved real maple boat and quote.

Burning emphasizes the grain but as you saw, it’s the same wood, just done differently design wise.

Before moving onto the wood lamacoid engraving, let’s take another look at the finished piece, with the protect wrap on the surface, so you can see how different the same image can look in two different ways.

The first, maple engraved only where the boat image is found.

The second, everything is engraved except where the image is found.

Some people call this reverse engraving, I call it positive and negative based on how film works.

Now we are going to deal with a very different monster, plastic laminate.

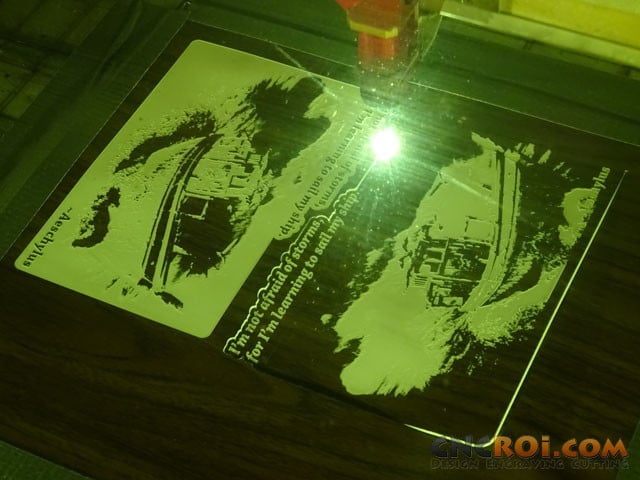

You can already see the set-up is very different, this wood laminate needs to be held down as it will bubble up and warp due to the heat produced by the laser.

There is double-sided tape under the wood lamacoid in addition to duct tape all around, to keep it from moving during production.

This is a little extreme to what we typically do because we are engraving both a positive and negative image, so a lot of heat will be involved over a large surface area.

This is one reason why I prefer to do lamacoids with a solid backing if possible, for instance, this plaque of another famous saying by one of the world’s richest people looks great using a metal lamacoid at the top with black plastic underneath.

And here’s another version of the same thing, lamacoid with a solid backing, this time plywood, again, to keep everything flat and add strength to the final piece.

In this case, CNCROi.com is using wood lamacoid engraving but again, that lamacoid laminate can be made-up of hundreds of options, red on black like the bull sign above, gold and black like the video above it.

Lamacoids have their place when it comes to custom production, especially where material alternatives are too expensive or just not possible or produce a sub-par result.

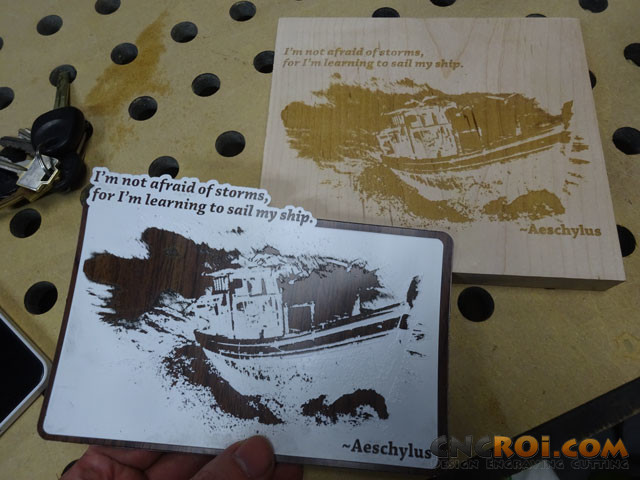

The advantage with wood lamacoid engraving over regular REAL wood is the result, notice how brilliant the white is, this would be next to impossible in real wood, for big details and letters, it’s possible but for fine details, it would be incredibly difficult to achieve and far more labor intensive.

This is why, for some applications, it’s best to use a lamacoid over a piece of wood then engraving right into the wood, using our Austrian CNC laser or American CNC router.

Regardless of how much prep is done, there is always some slight bleeding along the grain when using real wood with paint, it’s just the nature of the two processes when sanding and wear and tear are present.

The issue with wood lamacoid engraving material though, a with all the other laminates, is that when it comes to durability, nothing beats using REAL steel or REAL wood.

Wood is naturally resistant to UV degradation, it actually looks better over time while lamacoids and laminates tend to break apart, dry off and fade.

This is why I often tell customers that when it comes to custom applications, the environment will dictate more than material as to which should go where.

If this was an applications where the wood laminate engraving was to stay inside where there aren’t any real variations in temperature or humidity, this would be a great options while for outdoor use, the real thing is far superior.

I know this blog post is focused on wood lamacoid engraving but another options to consider is Corian using paint filling.

It has some of the positives of both materials with none of the negatives but it does cost a lot more though it’s incredibly tough to beat durability wise.

Although Corian is a man-made material, just like the lamacoid or laminate options out there, it machines and sands just like high density wood.

Corian is compressed and heated acrylic but is available in a massive variety of color schemes and is solid all the way through, just like grain is with real wood.

CNCROi.com works with the best material for the given applications, we can work across many of them and have extensive experience with many optimal processes, which means that with us, we make what you want to spec using the best for your given applications.

There are always compromises as there is no perfect material that fills all the possible niches our customers come-up with, but at least we have the equipment, experience and expertise to produce the best result for you.

As laminates are generally very thin, they are easily cut, CNCROi.com has a full binder of material options, the thicker the lamacoid, the more prone it is to bending but there is some extremely thin laminates as well.

In this case, our Austrian CNC laser is done wood lamacoid engraving both the positive and negative image so then we just need to cut it out.

Unlike REAL wood, wood lamacoid engraving only works on one side which is probably a good thing due to warping and hold down issues that need to be dealt with when melting plastic inside of a machine.

You can already see how, when the laser is cutting away at this relatively thin lamacoid, how warping is happening.

Again, I’m doing this wood lamacoid engraving demo using extremes, there are ways around some of the issues like warping, during the process of engraving and cutting this laminate but I want to emphasize material differences so they were not done or documented here.

You can already see how sharper the contrast and brilliance is between these two pieces of wood lamacoid engravings are, that’s a general characteristics of these laminates, which is why they are fantastic for high visibility signage as well.

But keep in mind that you can’t have dimensional results like this Corian piece (same with wood) so again, each material is optimally used for a given application.

Wood lamacoid engraving has its place, mostly for interior uses or where tight budgets are concerned where for instance, doing this in real walnut with white paint filling just wouldn’t look as good as using the plastic alternative at such a small-scale.

There are a ton of options when it comes to materials, this is why one of the first questions I ask our customers is what material they would like to use and what the application is for.

This will pinpoint, along with budget and volume, whether to use REAL wood or Corian or wood lamacoid engraving or dimensional cutting.

Although I really like the hyped-up contrast produced by the wood lamacoid engraving, I’m still very much partial to using the real wood if this was a customer application.

If this was to be stuck on a wall, I’d go with a thin veneer of real wood with double-sided tape on the back but if the client absolutely wanted the high contrast, lamacoids is the only way to accomplish this at this size.

You can now more directly compare the two image results, both the positive and negative wood lamacoid engravings.

This is why CNCROi.com sometimes does testing like this before going into production, so our customers can pick which they prefer.

Now, let’s compare the wood lamacoid engraving more directly with the REAL wood version, again, application dependent, one might be better than the other.

For instance, the real wood has slight grain imperfections which you can see in the dark marks in the maple image below.

Some customers like this, some don’t, it’s a matter of personal taste but this is some of the real issues that do come up, along with knots and other imperfections, when going into full production.

And here’s the other boat with the quote, wood lamacoid engraving on the bottom right, real maple wood engraving top right, after it’s been sanded a bit and the mask taken off.

And a closer looks at the engraved maple, again, the grain pattern is different because wood is wonderfully inconsistent, which is what makes it beautiful and unique.

If you have a custom project, lamacoid, laminate, wood, steel, Corian or anything else, contact CNCROi.com right now and give us the opportunity to make it for you!