A bit about our beginnings...

.

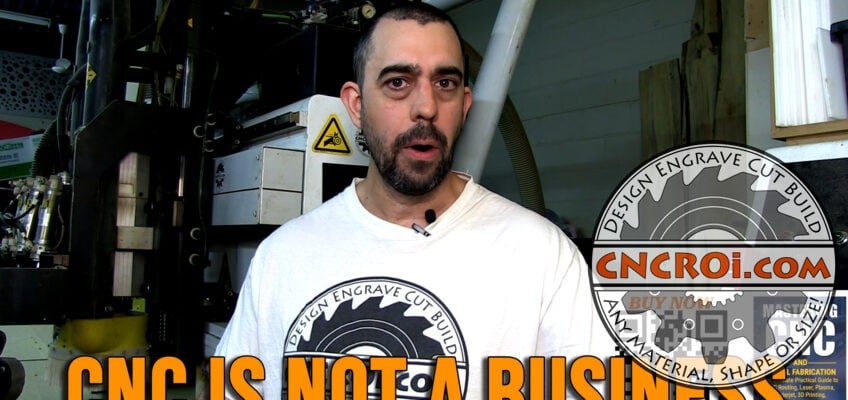

Jon is a self-taught designer who wrote a whole series of how to make custom projects using CNC equipment while traveling around the world for almost a decade.

During that time, he ran one of the most creative CNC digital marketplace websites in the world, CNCKing.com to help people who bought these powerful machines produce designs that would get the attention of their clients.

He began CNCROi.com upon his return to North America a few years ago with a passion towards bringing the incredible possibilities that my creativity can offer government, manufacturers and institutions around the world.

He’s been featured in endless publications, from Make Magazine (issue to the right, Volume 40: Page 19) to radio interviews and podcasts. He’s also the guy you see in all the videos across this site.

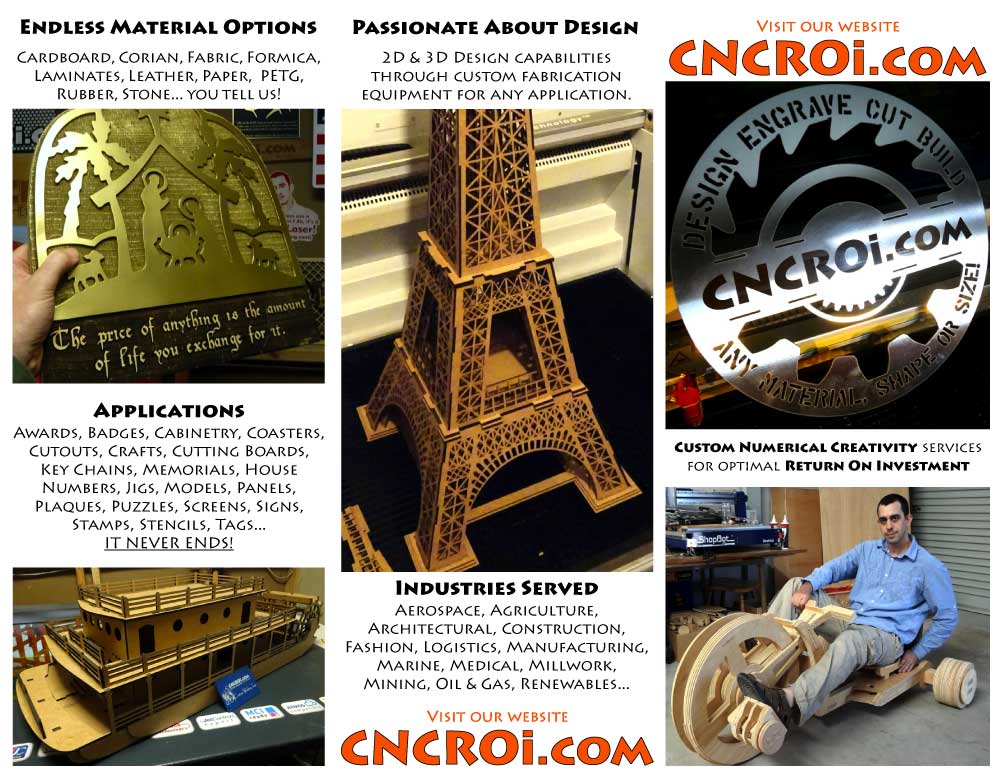

CNCROi.com began with an idea, to bring a little custom to people’s lives. From manufacturers looking for some custom PERMANENT branding on their widgets to marketing agencies offering custom on-demand production of promotional items to their clients.

If you want to get a quick rundown of what we can make,

visit our blog post Custom Cottage & Home Options or Custom Business & Institutional Options.

.

Read Our Blog For Inspiration

CNCROi.com is a custom solutions provider with more than two decades of experience across a huge variety of materials and production processes.

We make what you want, to your specs, on time and within budget… and we work “by the project” so you always know how much you’ll pay and we know how much we’ll get.

We generally work as a cog in your production wheel, providing our unique services and skill set to your applications, when and how you need it.

.

Carving Masterpiece Tables

CNC is NOT a Business

Glue-ups NOT Screw-ups

Five Truths of CNC Life

I CNC Engraved, YouTube AI Hallucinated

Become a BETTER Designer

Customers Dictate Growth

Laser + Rubber = Custom Stamps!

CNCROi.com on Instagram

You must be logged in to post a comment.