Laser Engraving Beach Pebble Stones: Indepth Material Review

I was asked the other day which types of stones come out best using a CNC laser, the answer is generally the finer the particles making up the stone, the better the results. That didn’t ring a bell with a particular client so I headed to the beach and grabbed a sample of beach pebble stones and brought them back to CNCROi.com HQ.

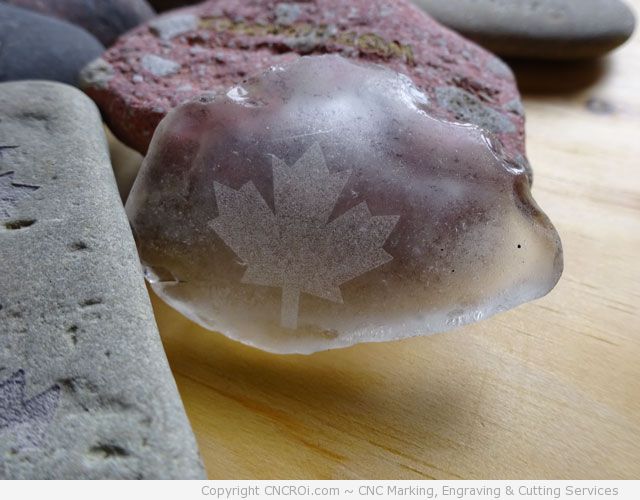

For good measure, I also found a nicely “wave sanded” piece of glass which surprisingly came out awesome! Before we get going though, let’s see how all these stones began before any laser engraving was performed using our Austrian Trotec Speedy 400 flexx!

In this case, we used our powerful and consistent 110 watt CO2 tube… the light was so bright that even with the filter, it was hard to look at the process. Unlike just about any other material out there that I’ve laser marked, etched, cut, annealed or engraved, stone by far is the toughest to observe though it does look cool with sparks shooting all over the place!

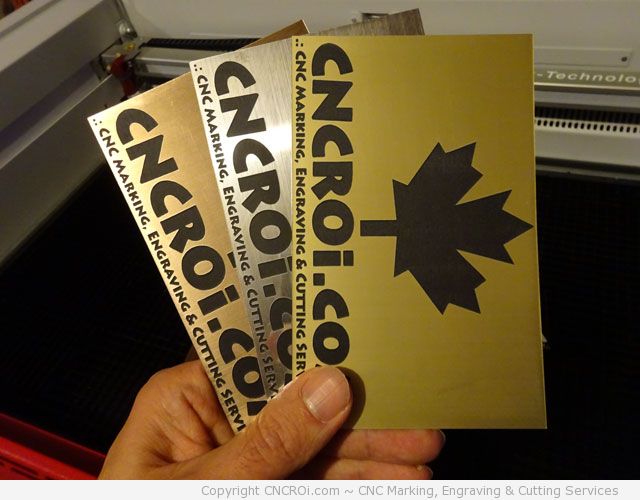

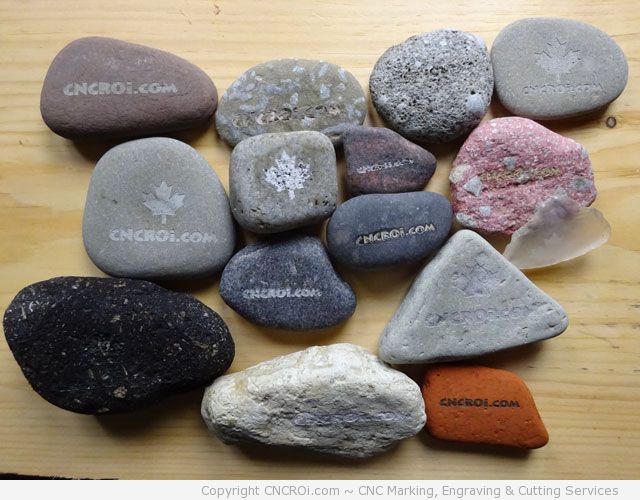

And here is the after shot after these beach pebble stones were blasted with energy! There is a fine powder over the entire bed as you can see more clearly with the business card but some results are already very promising!

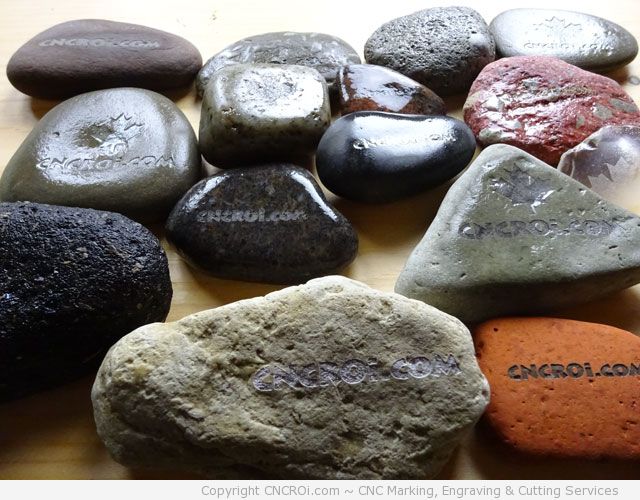

They are still rather dirty in the above image so cleaned them up with some water to remove the debris and the results look pretty cool!

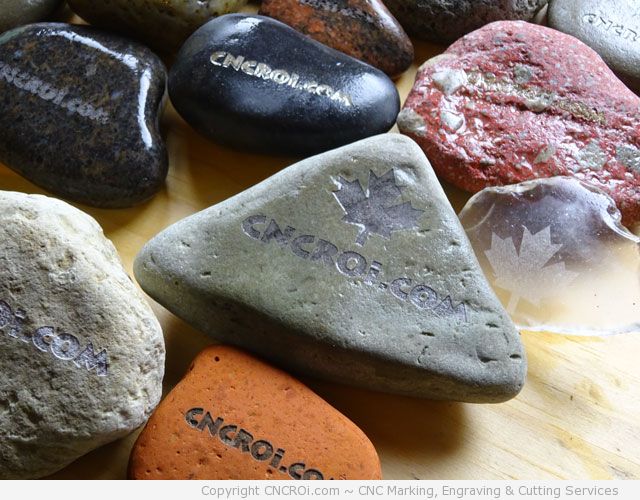

So let’s take a look at them a bit closer to more clearly see what worked and what didn’t… as you can see, the particulate size made a massive difference in the results we achieved as well as material composition and distribution. Color also played a role but not in a way I could have predicted though.

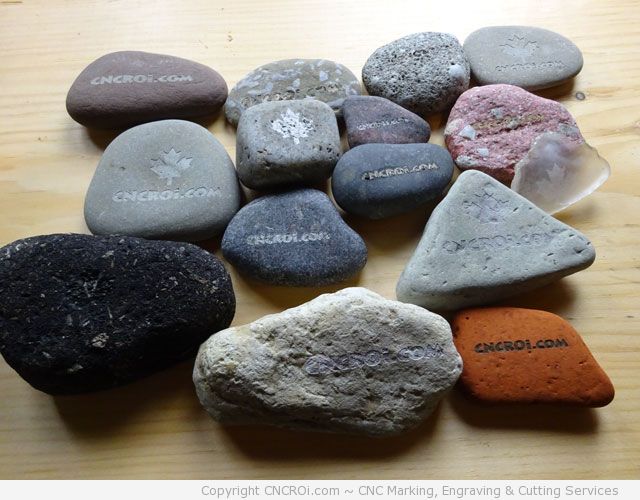

What really stands out from the pack is the more weathered the stone, the better the results. I did not clean them before putting them on the bed to be laser engraved, regardless of how dirty or Sun baked they were, the laser would vaporise that better than any cleaning I could do on my part. What surprised me was the darker stones, many came out fantastic while others look hardly touched.

What I did afterwards is allow them to dry.

Alright, now that we’ve seen this bunch of beach pebble stones wet and dry, let’s take a closeup view of a few notables in the pack in more detail.

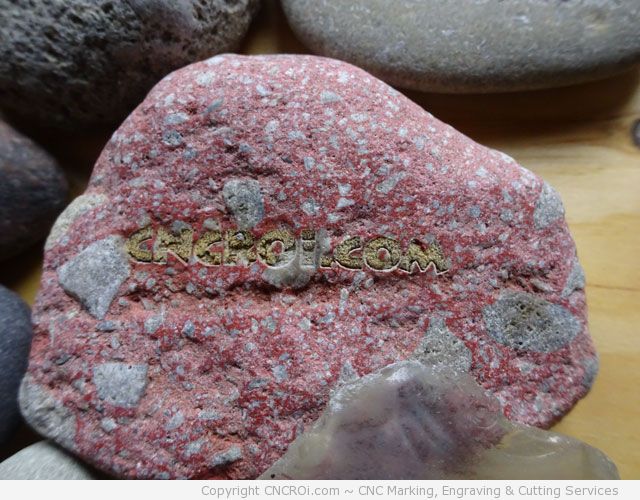

By far my favorite, this red stone that is actually a worn out brick just came out fantastic after being pounded with the CO2 laser. The contrast is awesome, the depth is perfect and the results just look great!

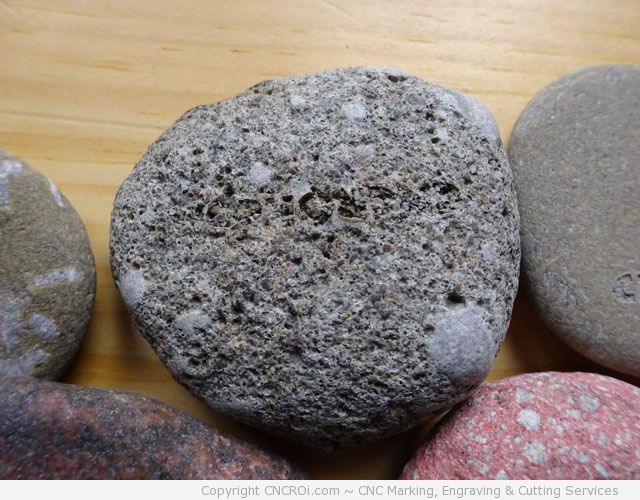

This black stone is actually a worn out piece of asphalt, I don’t know if it’s natural or man-made asphalt but as you can see, the results are far less than spectacular. There is a maple leave on the top middle part (I had plenty of room so got a bit creative) and you can barely make out the CNCROi.com below it. Oddly enough, the detail seems to be easier to pick out from the corner of my eye than looking at it directly, even with just this photograph!

Another stone or beach pebble that’s made up of a bunch of other rocks cemented together over time, you can barely make out my company’s domain (and name) just above the middle. Some particles really like being vaporized by our CNC laser while others, not so much.

Now this one really surprised me, you blast a rock that’s essentially pink and made-up of a bunch of different particulates of different sizes and densities and you end up with something that looks pretty interesting! I guess the surface of this beach pebble stone was coloured after the fact, maybe this is part of an old paving brick!

Looking at some other stones, the results were mixed though predictable, that piece of marble came out interestingly but by far the best was the weathered slate… I’ve done a lot of these kinds of rocks in the past and slate is just a fantastic stone to be laser engraving.

Of course, watch the video to see it all being done yourself!

Incase you missed it, here is another project I did a while back, this time field stone – it had awesome results as you can see that sprung to life after I gave it a bit of water.

You can watch the video of this one being made below as well!