316 Stainless Steel Machine Tags

Let’s see how CNCROi.com makes custom 316 stainless steel machine tags in this blog post.

Being able to start custom jobs from sheet material is a massive advantage for CNCROi.com because it gives us endless opportunities for our customers to have whatever they want, in any quantity using any design profile they can think of produced efficiently and shipped right to their door.

In this case, we had a small piece of 316 stainless steel that was perfect to be cut-up in pieces for a custom fiber etching job we undertook shortly thereafter, though now documented online due to NDAs involved, so I just etched my logo into one of the extra plates for fun instead.

CNCROi.com can both etch and anneal, both at depth and just on the surface of stainless steel.

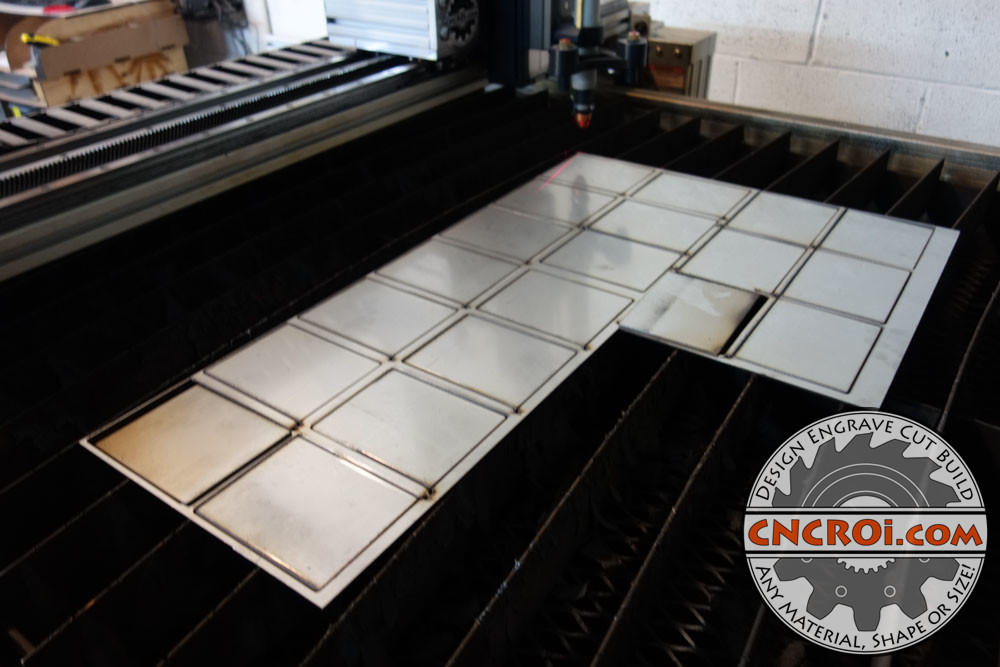

The plasma arc from CNCROi.com‘s CNC is 5x hotter than the Sun and the material being cut is 12 ga or roughly 1/8″ thick 316 stainless steel, very much a staple at the shop though we process more 304 than 316 at this point.

Why make custom 316 stainless steel machine tags using this higher-end material? Durability, as it’s a bit more corrosion resistant than 304 stainless steel and for this application, every little bit helps.

You’ll see some of the custom 316 stainless steel machine tags fall down into the table, that isn’t a problem, it’s when they stick-up that an issue arises but in this case, we were fine.

CNCROi.com can also mix and match equipment for optimal results, sometimes tight tolerances call for the precision of waterjet cutting, though it’s a much slower machine which means it costs more than plasma but if you want sharp inner corners in metal, it’s the best out there!

What happens with parts that stick-up? They can be picked-up and dragged by the plasma cutter, CNCROi.com makes lots of tags, so we’ve had this happen before when making custom 316 stainless steel machine tags.

Cutting our stainless steel is a fun process, the arc melts the metal like it was butter and the results look great, I’ve grown to really enjoy the edge quality that CNCROi.com‘s plasma cutter produces, it isn’t as sharp as what a laser cutter would produce and that means I’m not cutting myself on the kerf.

You can see how this round of custom 316 stainless steel machine tags are coming to an end, but remember, this is only the plasma cutting process, there is a lot more to be done, drilling holes, clean-up then fiber laser etching.

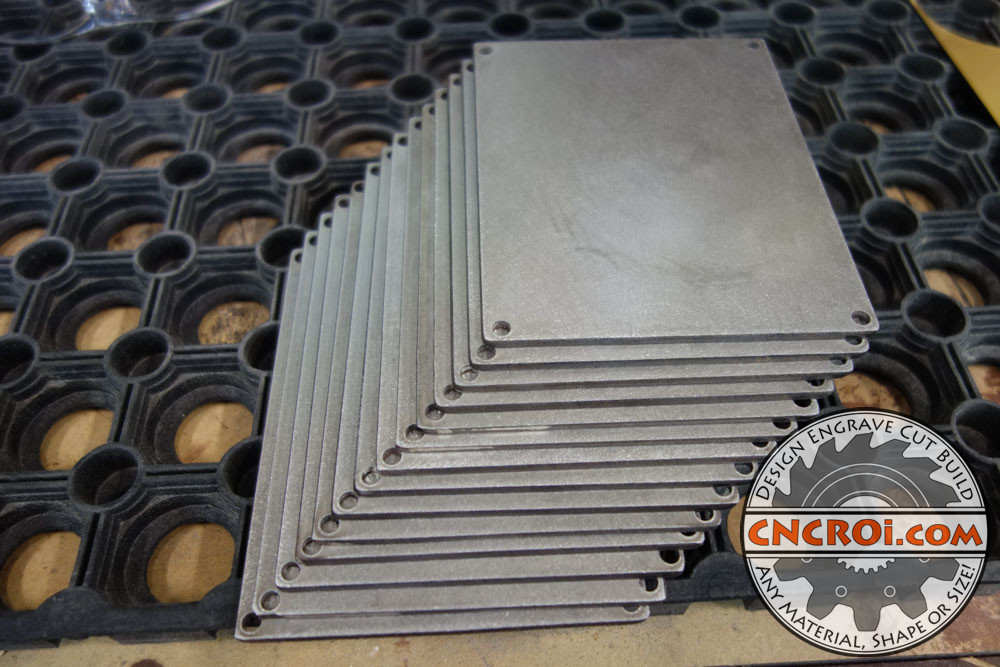

At least the first step of the custom 316 stainless steel machine tags is finished now, the rest is a piece of cake, though a little repetitive.

Fiber etching is a permanent process, it’s always neat seeing what can be done permanently on stainless steel, this won’t fade, crack or peel over time.

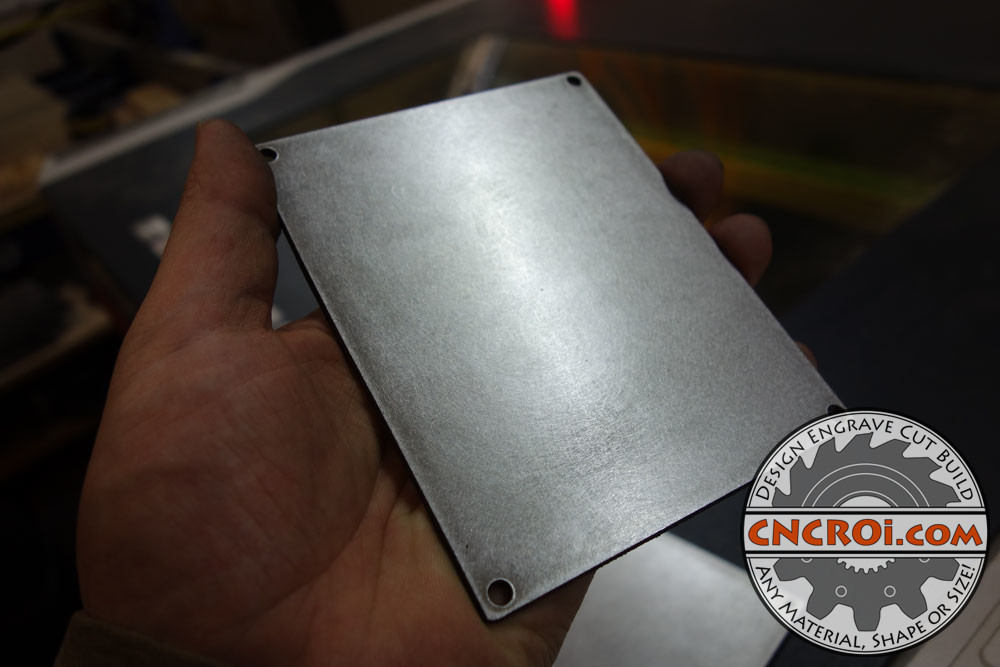

As the plasma needs a lead-in and lead-out, it’s best to just drill the holes out of the custom 316 stainless steel machine tags manually using a way too expensive drill press using a DVR motor, this produces fantastic results, sharp and perfect to spec for this customer’s job.

After all the holes are cut out, the next step is sanding both sides to have a nice finish on them after angle grinding off the burr on the backside of each of the custom 316 stainless steel machine tags.

You can see how fantastic these look in the picture below, they are 4″ x 5″ tags by the way, the fiber etching CNCROi.com does fills-out most of that space, the customer rivets them to their machines.

Notice how the edge looks fantastic and the holes look amazing, it’s the best of both worlds coming together for the customer’s benefit.

Each custom 316 stainless steel machine tag was made one at a time, but you’ll notice they are all identical in every way, which means that when it comes to etching them out at CNCROi.com, we have absolute repeatability across the production run.

CNCROi.com has made big jobs, and little jobs, whatever you need, we can make and ship right to your door!

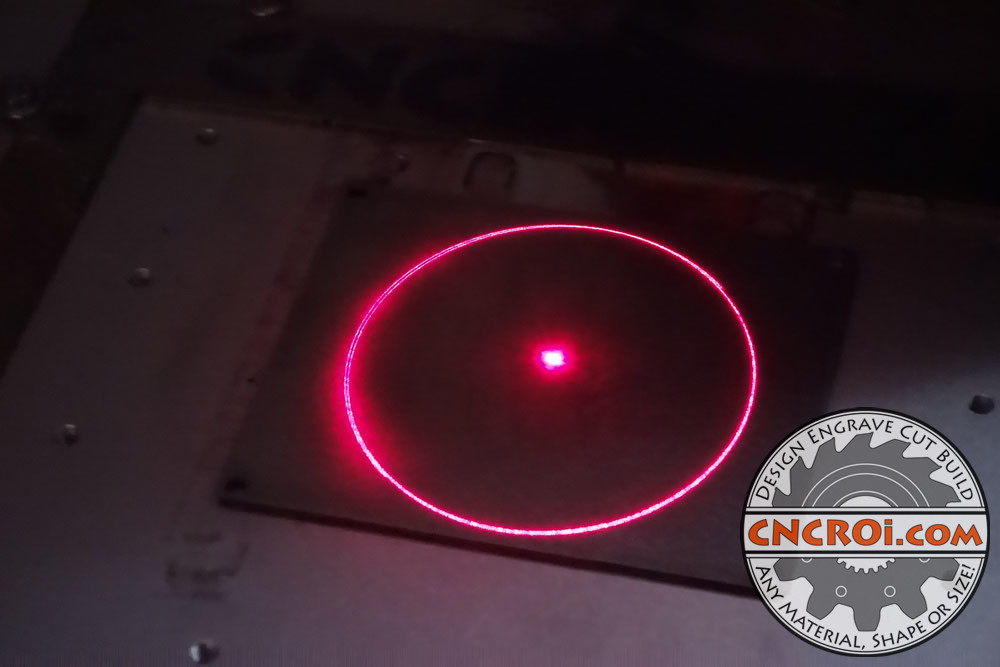

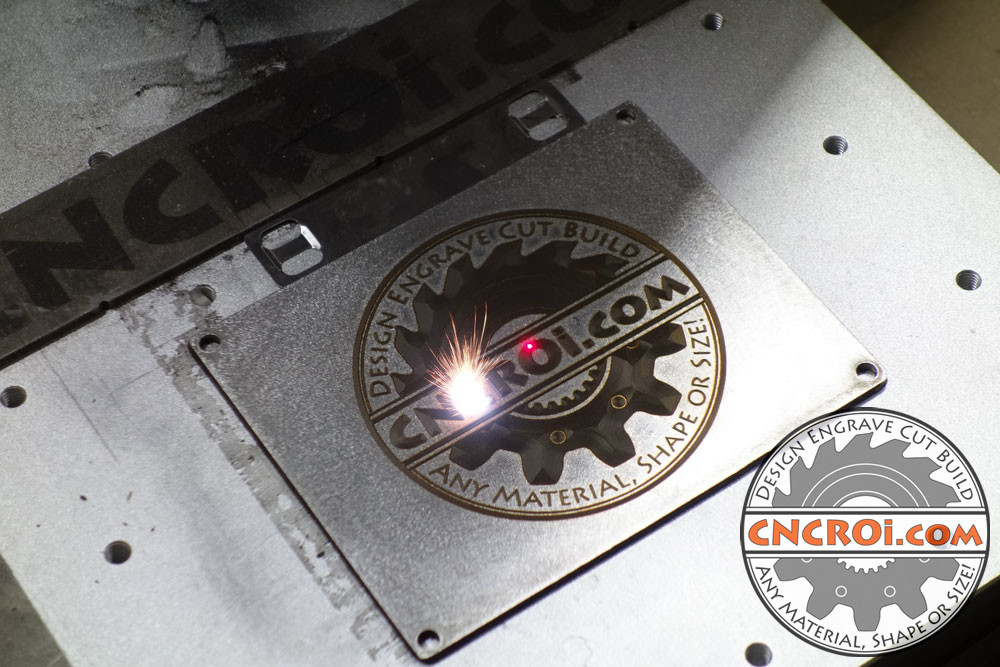

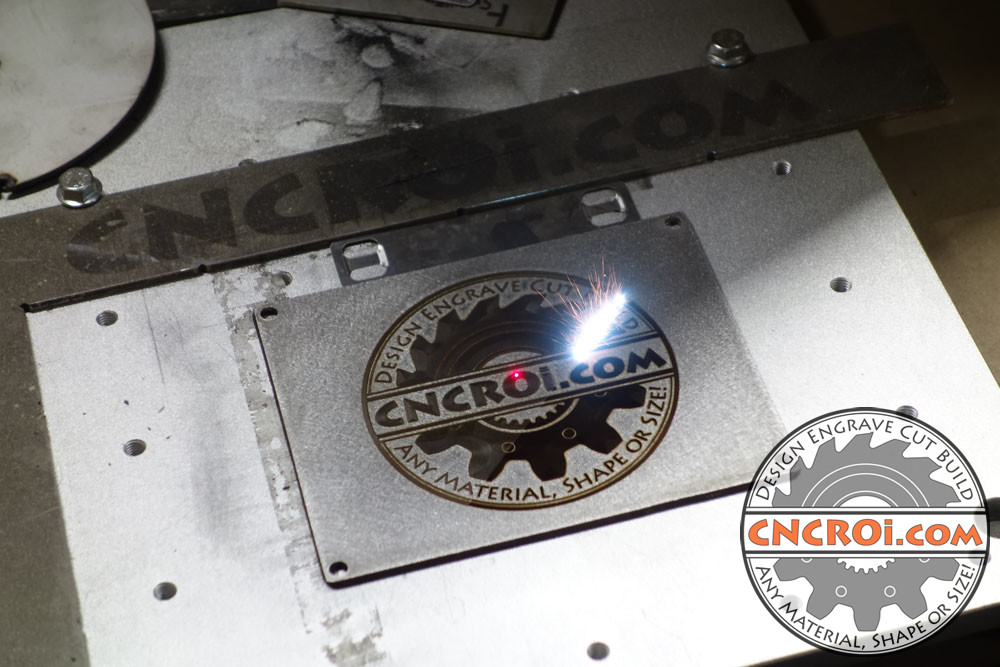

The nice thing about using our galvo laser is we can actively preview what we are about to do on the custom 316 stainless steel machine tags before actually doing the work.

Most of the jobs CNCROi.com does involve etching tags ONCE, rarely do we do anything at depth, it’s a very slow process, especially for such a big logo, and thus, time equals money.

I’ve put my logo on everything, so why not use one of the custom 316 stainless steel machine tags to put my logo on and just let the machine run hour after hour to create some cool depth!

I ran our galvo several hours a day over several days and the results were perfect until the last hour where the plate actually bent, causing it to slightly shift.

Shapes and designs don’t matter to us, we’ve done lots of wonderful jobs across a huge variety of applications.

Regardless, the results of depth fiber etching the custom 316 stainless steel machine tag was fantastic, again, most of the etching we do is nowhere near this size and nowhere near this depth so it’s fun to try things.

You can get an idea of the depth that CNCROi.com achieved on this tag by the various pictures I took.

Keep in mind, we can do the same regardless of size, material (wood, acrylic or metals) or design.

Need custom 316 stainless steel machine tags? Contact CNCROi.com right now!