Acadia Cutting Board: CNC Laser Engraved Wood

An Acadia cutting board will last a very long time, CNCROi.com can also make cutting boards out of any other material and in this case, laser engrave it too.

https://www.youtube.com/watch?v=CCGj3ib3eA8/

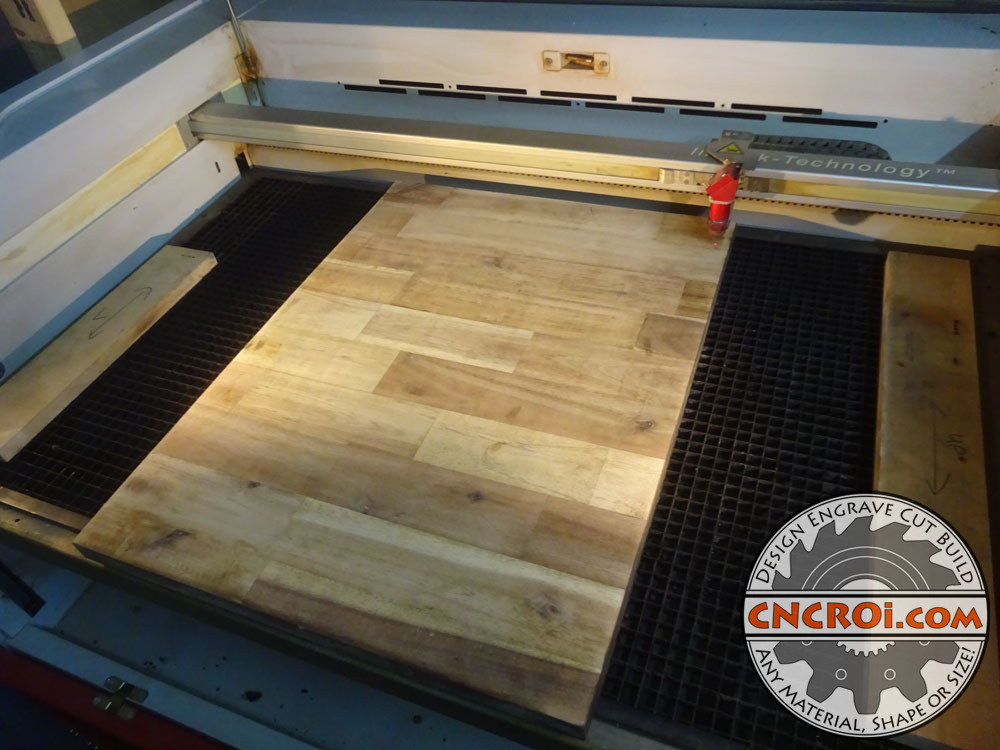

For this specific project, the customer wanted hardwood but the spec didn’t match material availability so I suggested we go with Acadia as it’s incredibly durable, easy to maintain and at an inch thick, very sturdy as a cutting board.

When it comes to material selection for cutting boards, CNCROi.com can machine anything, from HDPE to steel, so your options, as long as material is available, are endless.

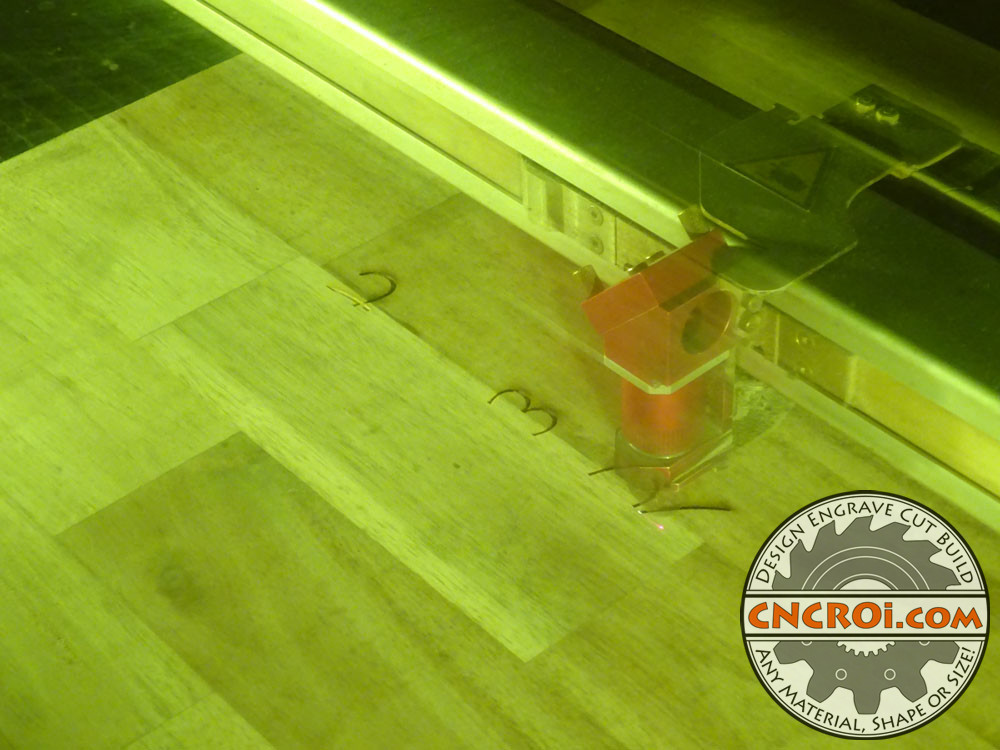

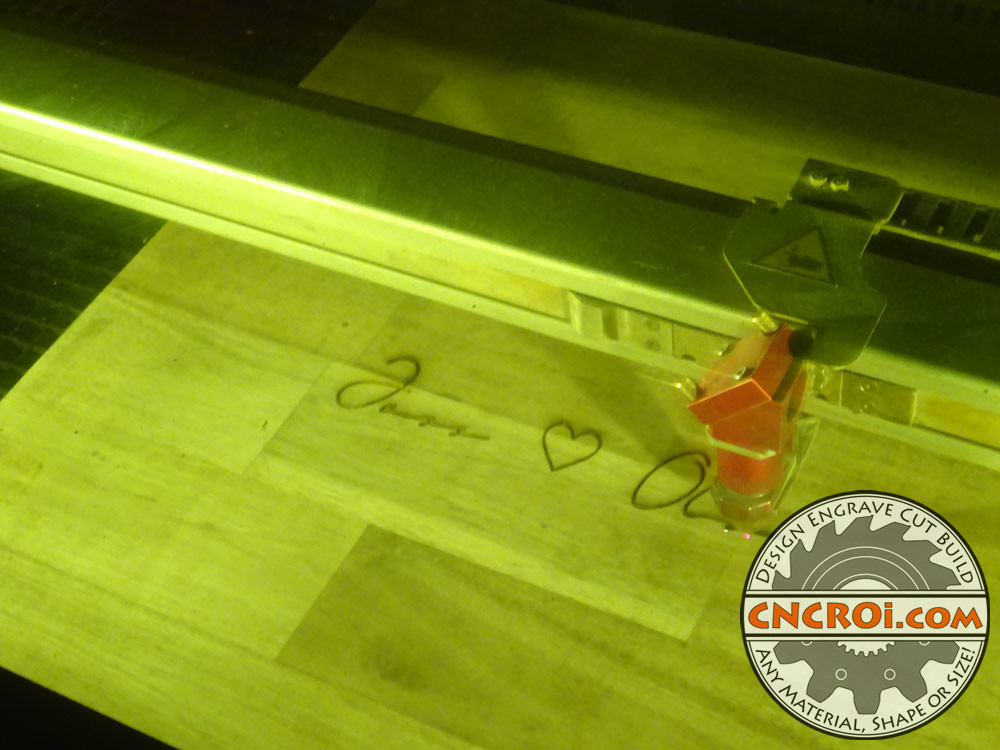

When it comes to your branding options, in this case we used our CO2 laser source, they are equally as endless, literally any vector font works fine, and vector based black and white imagery as well and the nice thing about wood is that there is a lot of give to the material, so if your images aren’t perfect, nobody will notice.

CNCROi.com has extensive experience working with wood, we have both a full metal workshop and wood workshop, so there is endless possibilities when it comes to further customization of your own Acadia cutting board.

If you want a cutting board that can also hold the juices of meats and fruits, we can machine that into it.

https://www.youtube.com/watch?v=Z4PnfHZWRqY/

For instance, if you wanted your Acadia cutting board to have a bevel along the edges or a taper, you wanted pockets carved out of it or even some 3D imagery carved right into the board, that’s no problem for CNCROi.com.

Wood is by far the favorite material when it comes to custom cutting boards, it looks great, easy to clean, has anti-bacterial properties built right into it and best of all, it feels “warm” to a kitchen.

When it comes to laser engraving, the goal on this Acadia cutting board was to create contrast and a little depth, you don’t want to go too deep as food and juices might get trapped and you don’t want to go too wide with the font thickness for the same reason.

Just to give you an idea of what deep engraving looks like imagery wise when performed on a laser, check out this key holder I made a while back, still have it to this day.

https://www.youtube.com/watch?v=dlHqdyxTabI/

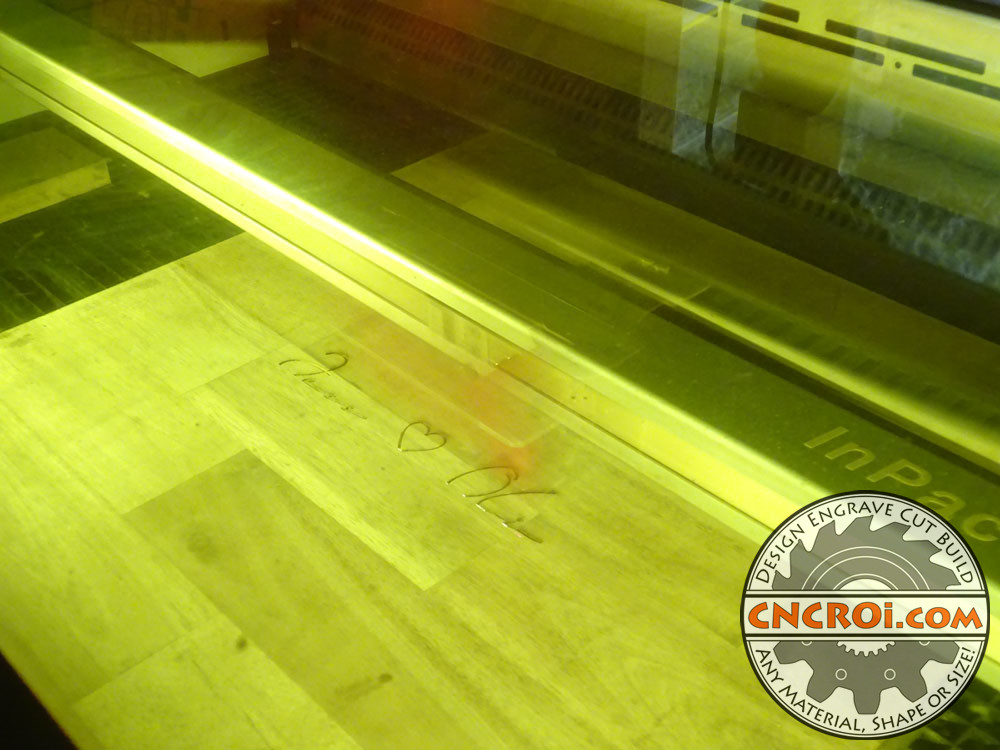

CNCROi.com could have laser engraved this Acadia cutting board anywhere as well, you aren’t stuck with only one area, it can be at the top, on the sides, on the edges of the board itself or anywhere else you want in any orientation.

I performed several passes on this custom Acadia cutting board laser engraving just to create a bit more contrast with the charcoal I was producing in the wood, but always keeping in mind not to make it too wide or deep.

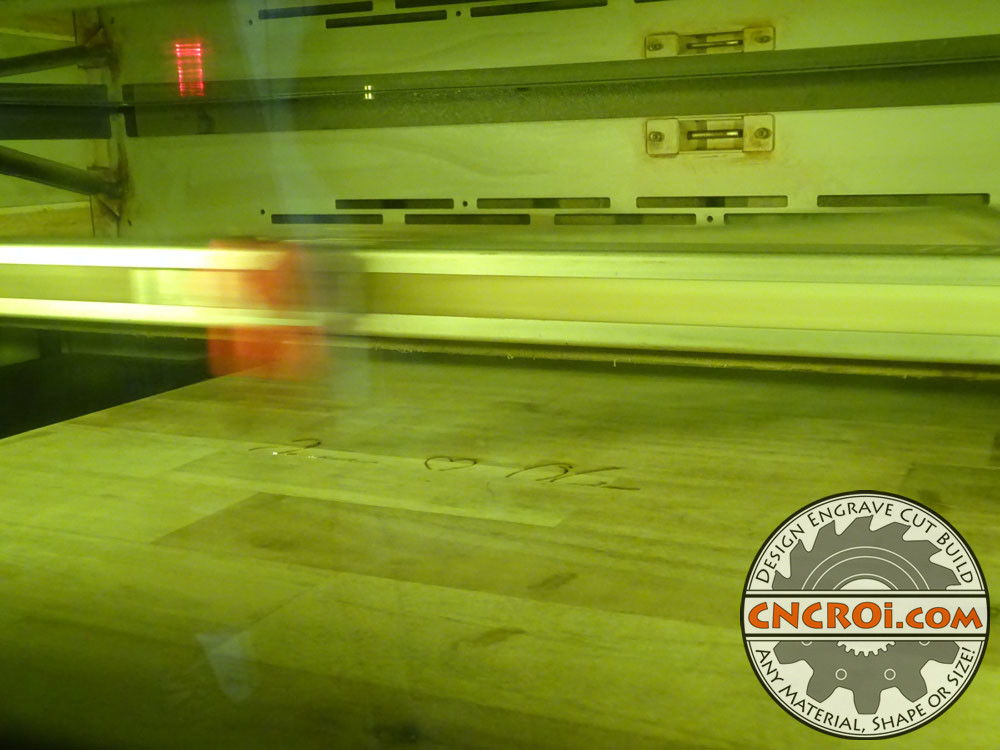

Now that this custom Acadia cutting board is just about done, the next step in the process is to use the laser itself to give me the cut lines, the material is too big so it needs to be cut down a bit on the bottom and the right side to be within spec.

You can see the cut lines in the image below, I might as well use the laser to make the reference lines, saves me from having to measure it out and the laser will always be more accurate than a tape measure.

When it comes to live edge cutting boards, we have stock but there are certainly some sizing limits as the bigger trees are harder to come by.

I have a table saw at CNCROi.com but I like to mix things up and thus, decided to use my skill saw instead, it does just as good of a job, using my spoil board from my full sheet CNC router to do the work while using my hand as a guide for a straighter cut.

I’m so happy to be born at a time where batteries are replacing power cords on machinery, it just makes things so much more efficient at CNCROi.com for so many jobs we do.

The custom Acadia cutting board is now laser engraved and cut to size, time to sand the edges then the top and bottom before doing the finishing using mineral oil.

Cutting boards can be as imaginative as you want, there are no design limits when it comes to what CNCROi.com can produce for you.

https://www.youtube.com/watch?v=yAZEWjgNfXM/

Sanding the edges is more of a clean-up job to make all the edges consistent, both those that were cut with the skill saw and those that weren’t, the edge quality on this custom Acadia cutting board is already very good.

Once every surface of this custom Acadia cutting board is up to spec at CNCROi.com, it’s time to add some mineral oil to every surface, front and back, and all the sides to help preserve the wood, make clean-up easier and to give it a lot more esthetic appeal.

It’s quite a contrast from the above picture to the one below, mineral oil is amazing, it’s almost like a finishing using tung oil except it’s food safe and easy for anybody to re-apply down the line using just a rag.

Here’s a straight-on shot to show you the finished custom Acadia cutting board, I’m very proud of how well this turned-out!

Want a custom cutting board? Any size, shape, material or engraving combination… contact CNCROi.com right now!

https://www.youtube.com/watch?v=Wyofm2-pJ3o/