Anodized Aluminium FAQ: Custom CNC Production & Options

It’s time for an Anodized Aluminium FAQ where we review what’s possible using this process and the costs and benefits of various production methods involved with its use.

I had a project come-up a few days ago where the customer needed a very small run of custom anodized aluminium plates, not enough volume for an actual production run (cost effectively).

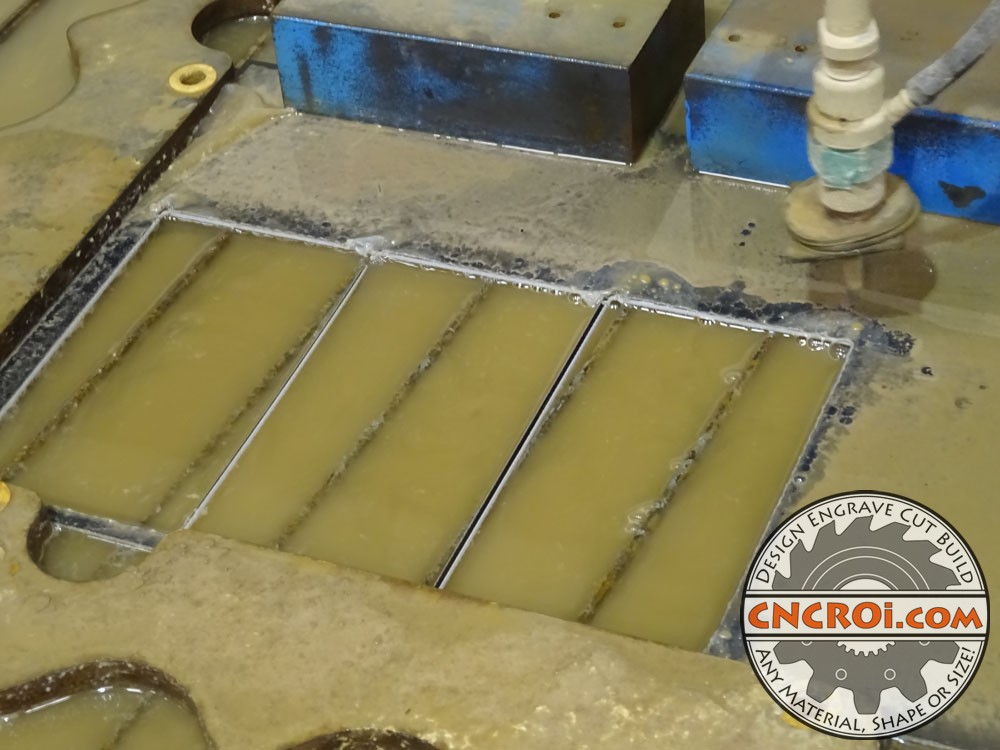

In that case, CNCROi.com did something we’ve done many times before, just boot-up the CNC waterjet and start cutting the plates to spec.

Waterjet also has limits regarding sizing unless tabs are used which then must be sanded or grinded-off… we’ve done both on projects here at CNCROi.com and it does add to costs which are best avoided.

For big and small production runs, a CNC waterjet is extremely cost-effective, when compared to high-powered lasers, it has just the right mechanics to make very low volume custom anodized aluminium plates (in this case).

The “problem” with large industrial lasers cutting very small volumes of product is that they are so fast that quite literally, the cost to cut one plate or several dozen end-up being the same and as such, when all you need is two, there isn’t much point unless a whole production run of various sizes and pieces are slated to be done at the same time.

Even more cost-effectively, stamping is a great method to make custom anodized aluminium plates but the issue there is costs involved with making the die AND each plates must be identical (as per the die).

Of course, CNCROi.com does have equipment to manually shear and hole punches to make a custom plate too, but it’s nowhere as accurate as a CNC machine so typically, I reserve that process for prototyping before going into a production run with a CNC or stamping.

Like every material, there is no perfect machine, each and costs and benefits and that’s especially true when you start to tie material to a process such as this anodized aluminium plate.

You see, CNC waterjet is great for production runs of all sizes actually but it does use an abrasive to cut and when working with anodized aluminium, high pressure sand with water isn’t generally a great mix.

Due to the blow-outs (sand shooting in an unexpected direction at high-speed), there are always additional plates needed to be made and then triage through, it isn’t as bad as it sounds, but it is an issue.

When it comes to laser cutting custom anodized plates, there is now possibility of blowout, the plates are all basically perfect in every way but in small quantities, the production costs per plate is cost prohibitive for most applications.

We could also use our CNC router to cut out these plates but again, the set-up time and “things that could go wrong” is far higher with that technology on extremely small production runs than what’s possible using a CNC waterjet.

So, as you see, CNCROi.com‘s role here is to produce the best plate in the most cost-effective manner for our client in the production volumes they require, and that’s why we went with CNC waterjet cut anodized aluminium plate from sheet stock we keep in the shop.

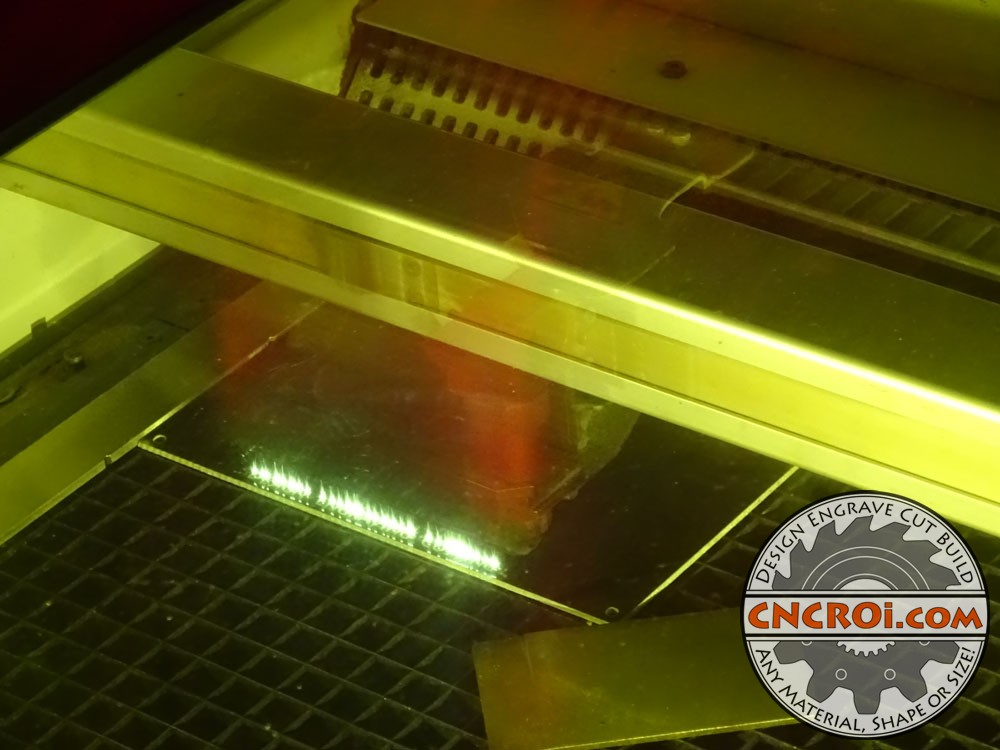

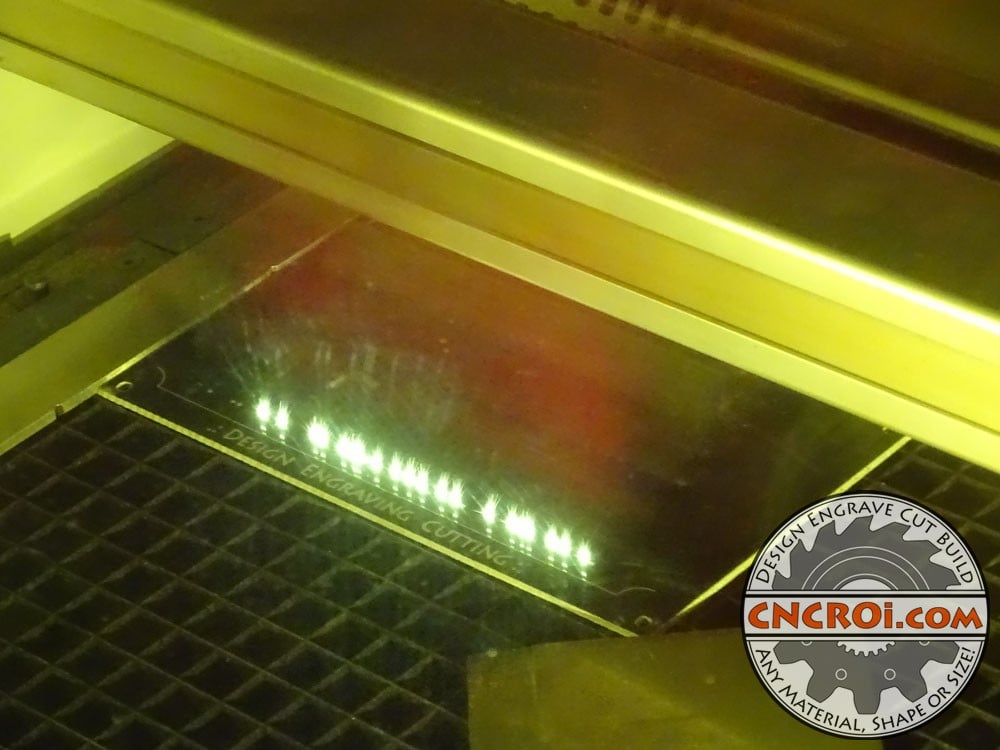

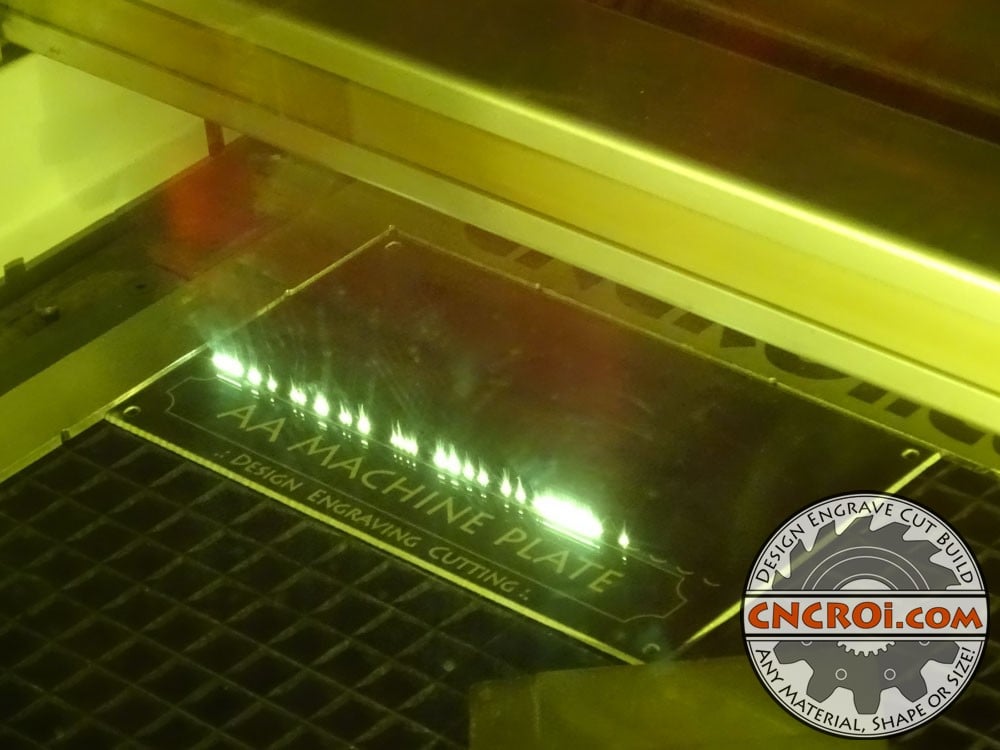

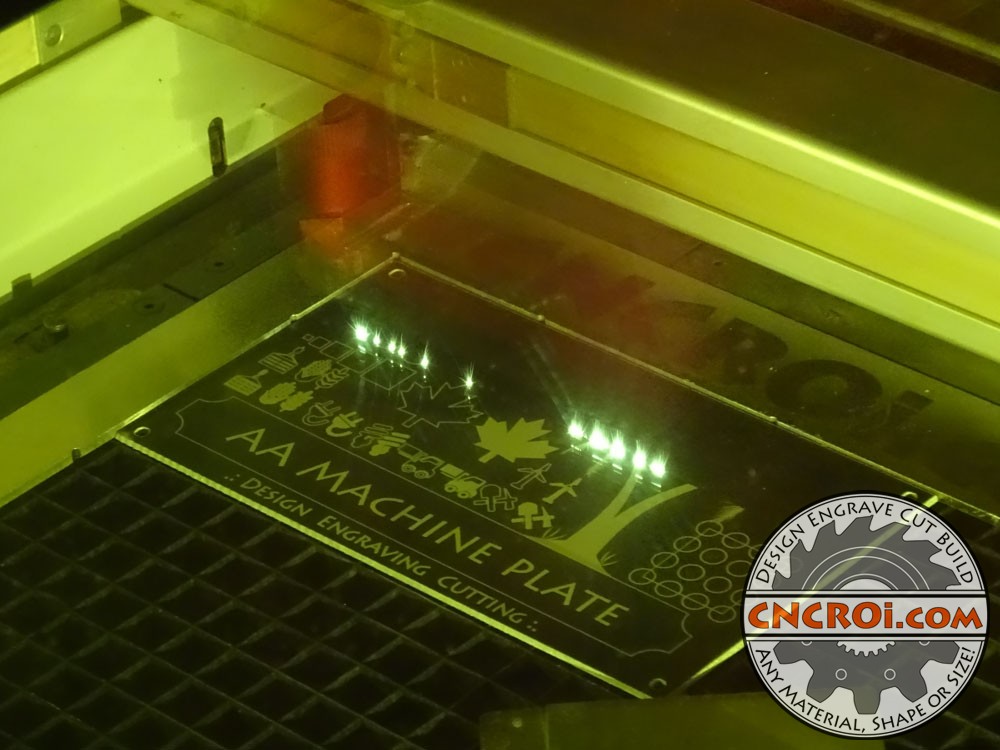

CNCROi.com has a large industrial Austrian wide-format CNC laser and with this piece of technology, we are able to vaporize the anodizing with incredible precision with pin-point accuracy.

The light you see is the vaporizing of the anodizing along with a little aluminium underneath.

When it comes to anodized aluminium, there are an endless variety of applications where it’s a wonderful choice across a whole host of spec requirements.

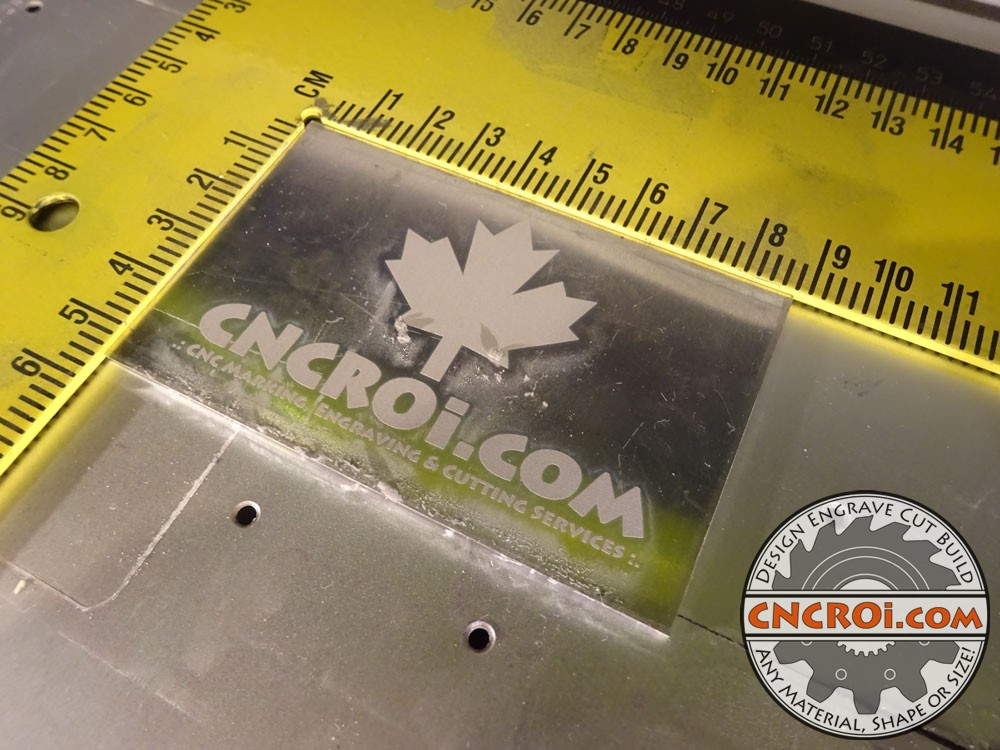

CNCROi.com can also work with raw aluminium, the results aren’t as spectacular as anodized aluminium nor as durable, which is why aluminium is anodized (or powder coated) to begin with.

Endless color varieties re possible too but the engraving is always an off-white.

The bonus with anodized aluminium is that it’s great at dissipating heat, where a piece of metal at similar specs will roast under the Sun and be prone to warping, this isn’t an issue with anodized aluminium and I’d argue, it’s just as durable.

CNCROi.com pushes through a lot of anodized aluminium in the shop, like every other material we work with, it’s my favorite to work with.

Alright, time for some CNCROi.com anodized aluminium FAQ’s answering!

Anodized Aluminium FAQ: Colors & Pantone Matching

I often get contacted regarding making a widget, call it a series of corporate awards or pet tags or whatever and the customer tells me the most evil word in my industry, what’s that word? PANTONE

I understand the reason for this word and it’s application, but from what I’ve found through the years, not only is this standard totally useless but it’s mostly unworkable in an industrial context.

Industrial processes by their very nature have variation involved with them, what Pantone tries to do is standardize color and that just isn’t possible unless we deal with a lot of wasted product.

You want dark red, light red, red with speckles, fine… you want PANTONE Red 032 U, go take a hike as it’s not worth the trouble 12 times out of 10 for something that I’d bet most people wouldn’t notice.

“Wow, look at this award, they used Pantone Red 032 U, aren’t they cool!” Something I’ve NEVER HEARD EVER.

Anodized Aluminium FAQ: CNC Waterjet VS CNC Router vs CNC Laser vs Stamping

CNC waterjet is cost-effective in slow volumes but as those volumes increase, the speed (and finish) of a CNC laser beats it out and if you want something in very high volume, nothing beats making a die to stamp out the various anodized aluminium “things” you want.

The advantage of CNC router is that we can make edges at an angle which is harder to do with stamping and impossible with waterjet or laser unless you do a secondary (tertiary) process.

CNC routers are also great when it comes to dimensional work, think of the old type plates they used when newspapers where all the rage a century ago, so each machine has its place.

Anodized Aluminium FAQ: Sizing and Volume

Technically speaking, anything is possible given an unlimited budget but as with most things, there is a specific requirement and a budget attached to it that must be adhered to and anodized aluminium or metal generally, is one of the tighter commodities out there to work with.

The advantage of CNCROi.com is that if you wanted half a dozen plates, different sizes using the same color, that’s not a problem, if you wanted them all at a different color expecting to pay the same, well, the costs have gone up dramatically.

Good news is, for most applications, CNCROi.com does stock common plate sizes from off-cuts and over-runs meaning when a customer asks us for 50 plates of something, we generally get a few more made because I KNOW SOMEBODY ELSE WILL WANT IT TOO.

Anodized Aluminium FAQ: Engraving “Colors”

Like the old Model-T, you can have any color you want engraved onto custom anodized aluminium plate as long as it’s off-white.

There are technologies and processes that allow a black but short of getting a MOPA laser which we are investigating, they aren’t permanent solutions to branding, and CNCROi.com specializes in PERMANENT BRANDING.

Anodized Aluminium FAQ: Why Anodized Aluminium Over Steel?

Steel is a wonderful material, the reason why we do things out of steel is because the customer wants other to KNOW IT’S STEEL so covering it with paint just doesn’t make sense as if that’s what you want, best to go with aluminium.

CNCROi.com does lots of work with steel, it’s a wonderful material for the right application, it’s heavy, stronger and more durable than aluminium but generally, it’s also more expensive to work with, engraving is a far slower process too.

Anodized Aluminium FAQ: Speed of Fiber VS CO2 (we have both)

Our Trotec Speedy 400 flexx has both a fiber and CO2 laser source, they both vaporize anodized aluminium but fiber takes a lot longer to produce a similar effect.

Generally, vaporizing is vaporizing and I’ve yet to find a real reason to do a multi-sourced card using our laser, as the results are interchangeable in the best of times.

Anodized Aluminium FAQ: How durable is anodized aluminum?

I made a video just for you using our industrial sand blaster, so don’t just take my word for it, here’s documented proof of how anodized aluminium holds-up to other options CNCROi.com offers it’s customers.

Anodized Aluminium FAQ: What are some applications for anodized aluminium?

There are an endless assortment of uses for anodized aluminium, it’s incredible durable, it’s easy to keep clean nor does it stain.

CNCROi.com uses anodized aluminium plates for machine identification, pet identification, mine shaft valve tags, tube identification tags and the list is literally a mile long.

If you aren’t sure what works best with your application, CNCROi.com can help you pinpoint the best process for us to make your production a reality.

Anodized Aluminium FAQ: Possible Resolution?

CNCROi.com is able to engrave at incredible resolutions, down to a thousand DPI (dots per inch) so things like bar codes and even highly detailed imagery is no problem for us.

This is important when it comes to permanent part identification and serialization but also for more fun things as vineyard locators and security badges.

This concludes our anodized aluminium FAQ, if you have any other questions regarding your application, contact us at CNCROi.com.