Barrel Head Mylar Stencil: Multi-Inserted

CNCROi.com has made many barrel head Mylar stencils, what makes this one special is that it uses different inserts that the customer can use depending on what’s IN the barrel.

https://www.youtube.com/watch?v=r4_RvTRoA0Q/

A lot of our great ideas or unique creations don’t actually come from CNCROi.com but our customers, and this is one of those “why didn’t I think of that” moments that I’m sure many of our other customers will catch onto, both in the distillery business and others from education to construction.

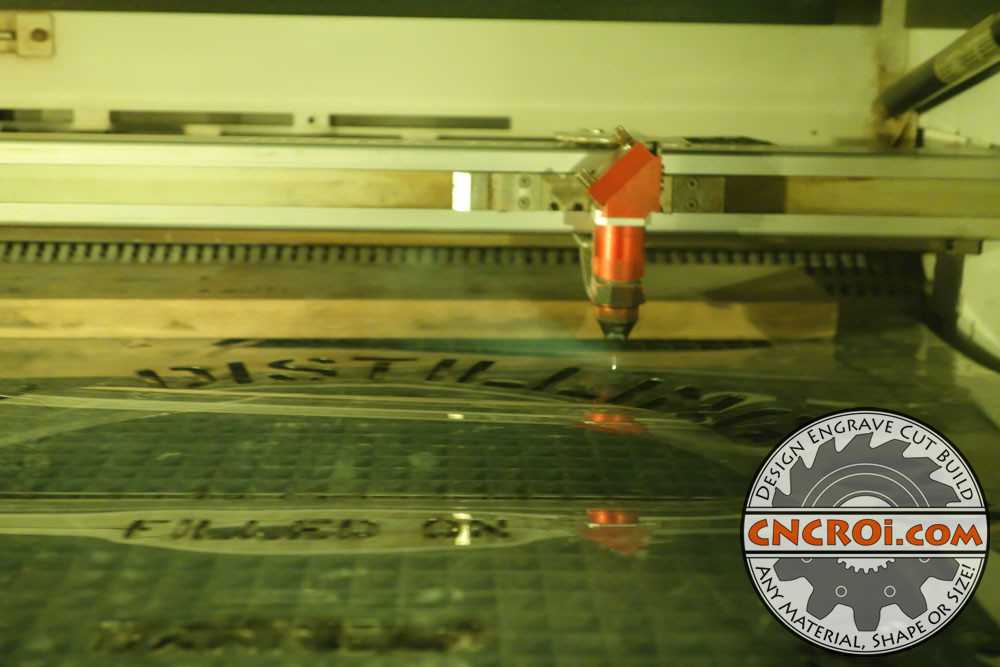

For this specific barrel head Mylar stencil, the inserts go right above the area they’d put in the date of filling the barrel.

The inserts for the barrel head Mylar stencil are Rye Whiskey, Rum and Bourbon Whiskey with a “blank” one added-in if they wish to also write anything else that’s in the barrel not covered by this round of stencils.

We’ve made HUGE stencils and very small ones, whatever you need, CNCROi.com can make it for you!

https://www.youtube.com/watch?v=k5f4JxbzjZM/

CNCROi.com isn’t just limited to Mylar when it comes to making custom stencils, anything from stainless steel to plywood can be converted into a custom stencil for any of your needs and we also aren’t limited by sizing, you want one little one or a thousand big ones, no problem!

Each material has a plus and minus to it, there is no perfect material for making custom stencils from, it all comes down to the application, how many imprints you envision making and your budget and timelines as to which one CNCROi.com uses for your custom stencil requirements.

I have a special place for stainless steel stencils made at CNCROi.com, they just look fantastic!

https://www.youtube.com/watch?v=fhwwm4DgLSA/

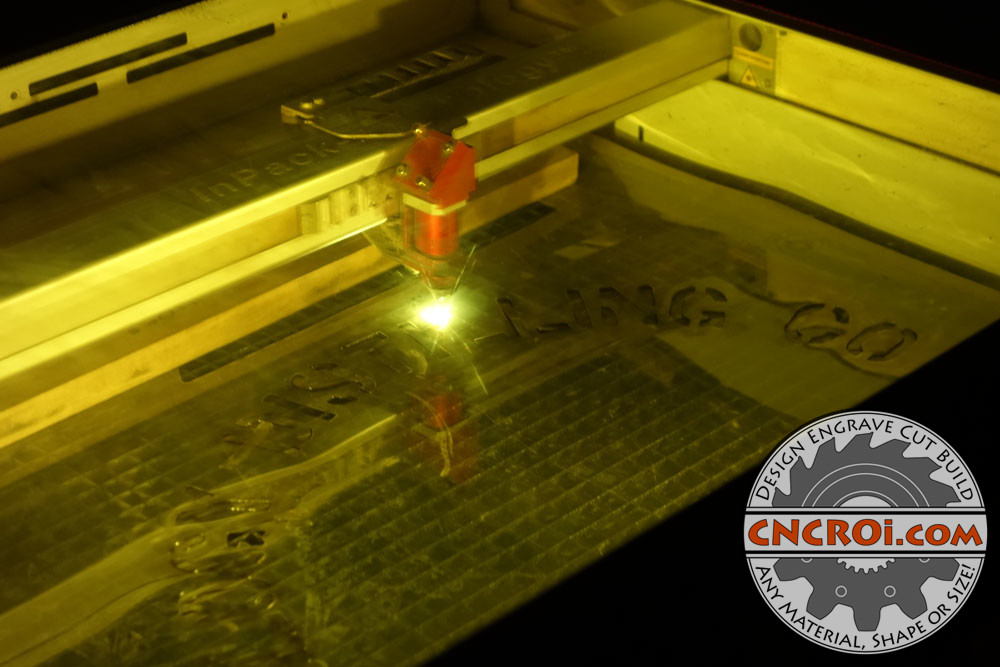

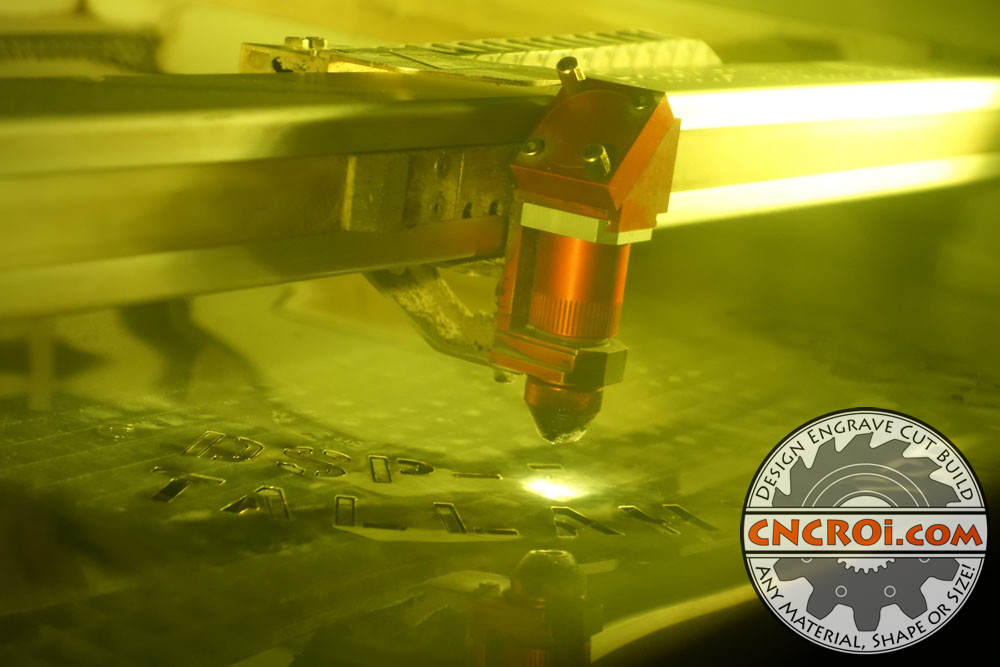

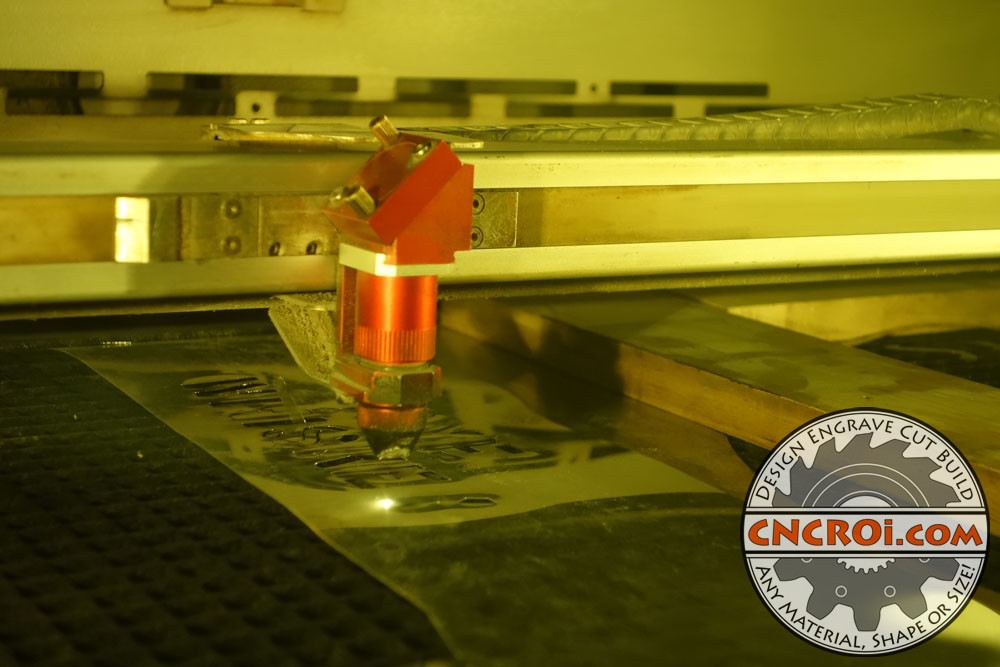

For this specific barrel head Mylar stencil, the laser cutting produces a sharp inner corner, although spray paint will be used for this given application, the edges will still be crisp as long as the customer doesn’t drown the stencil with paint.

Regardless of the material CNCROi.com employs to make your barrel head Mylar stencil with, doing several light passes rather than one drenching one will produce a better result as the paint (if that’s what you are using), has time to dry on the surface and doesn’t need to dry over another layer of paint that’s still wet… it will also dry faster overall.

If fire and flames are what you plan on stenciling with, then a barrel head Mylar stencil is the worse material, plastic will catch fire from a propane torch and then this will make your barrel catch on fire, so in that case, mild steel or stainless steel is probably in your future regarding what material CNCROi.com uses to make your stencil with.

Plywood stencils have their place in the whole stencil food chain, they are especially good for very large scale projects without too many fine details.

https://www.youtube.com/watch?v=dz27x1cdrt8/

How often can a barrel head Mylar stencil be used? I’d say almost endlessly, the problem that will happen without cleaning it between uses once the paint dries, is that the paint will build-up in the holes of the stencil, this is easily chipped away when dry though.

The nice thing about a stainless steel or mild steel custom barrel head stencil is that no cleaning is ever required, and if you do happen to use paint every once in a while, the process of burning itself will remove any paint build-up but this only works with metal, don’t try it with plastics or woods that CNCROi.com can use to make your barrel head stencil.

Whether it’s one or a thousand barrel head Mylar stencil, each one that CNCROi.com produces will be identical to the last, the accuracy in our machine is second to absolutely nothing.

If you are wondering how the same stencil looks like in polycarbonate vs stainless steel at CNCROi.com, here’s your answer!

https://www.youtube.com/watch?v=xgaqYllL5nI/

https://www.youtube.com/watch?v=mEDJyj24G_8/

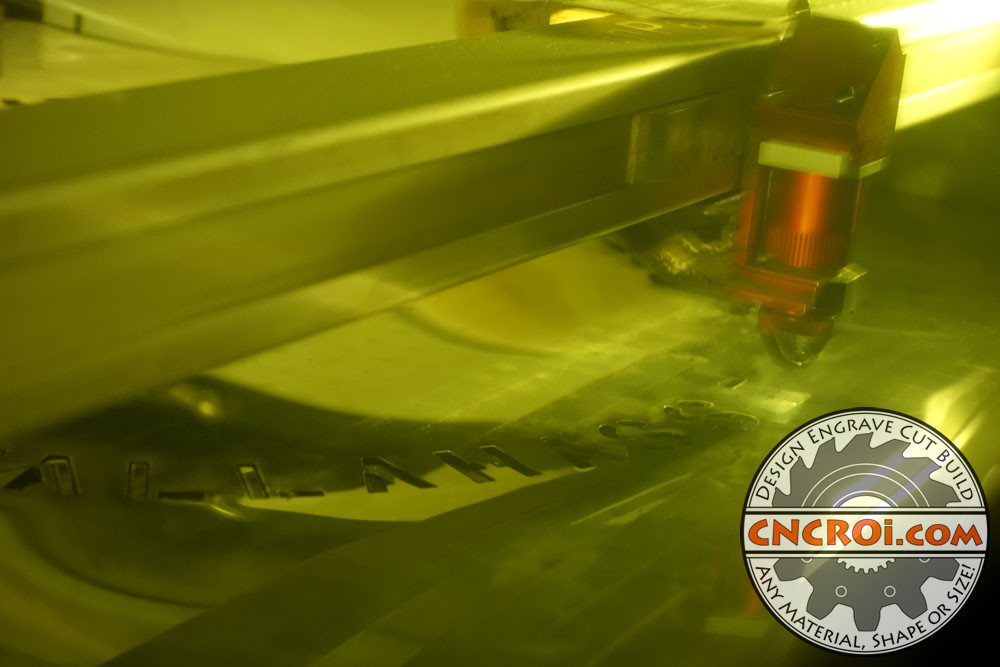

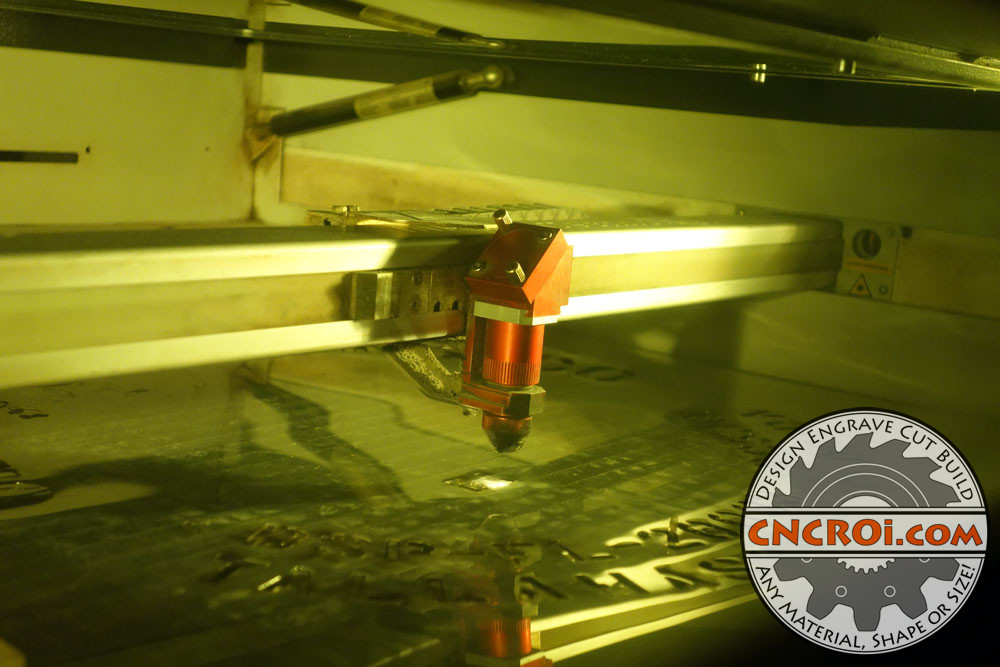

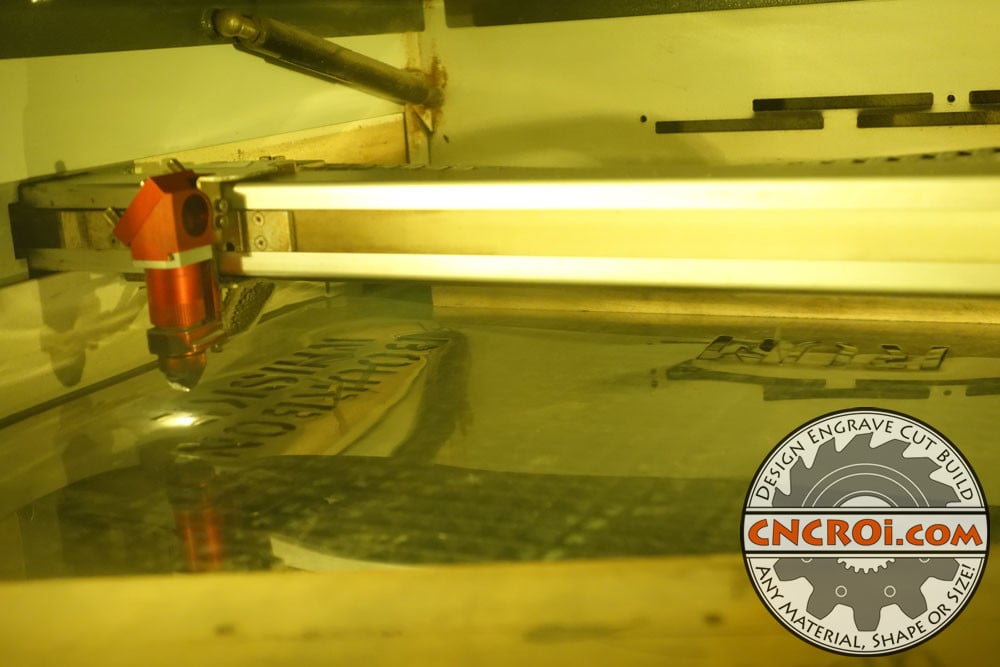

Now that the first part of this barrel head Mylar stencil job is done, the next step is making all the inserts, they will be a little bigger with some inner overlap just to make it easy to spray paint without producing any empty spots where the paint can go onto the barrel inadvertently.

The inside parts of the barrel head Mylar stencil are produced out of the same material and process as the overall stencil, the overlap also gives plenty of room to add masking tape around the perimeter without going over any holes in the stencil itself, producing a professional result every time.

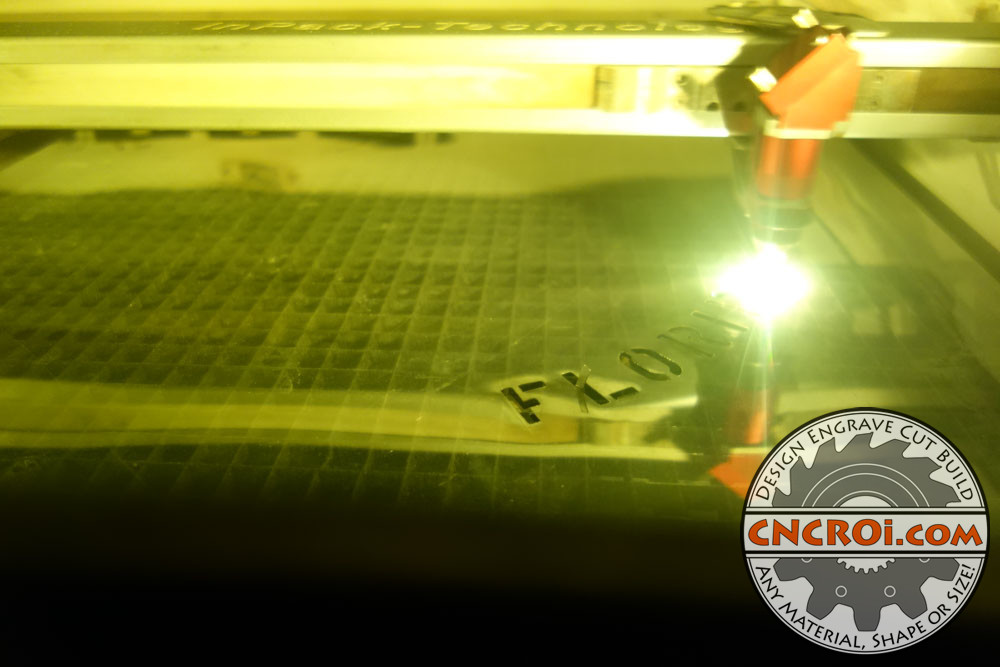

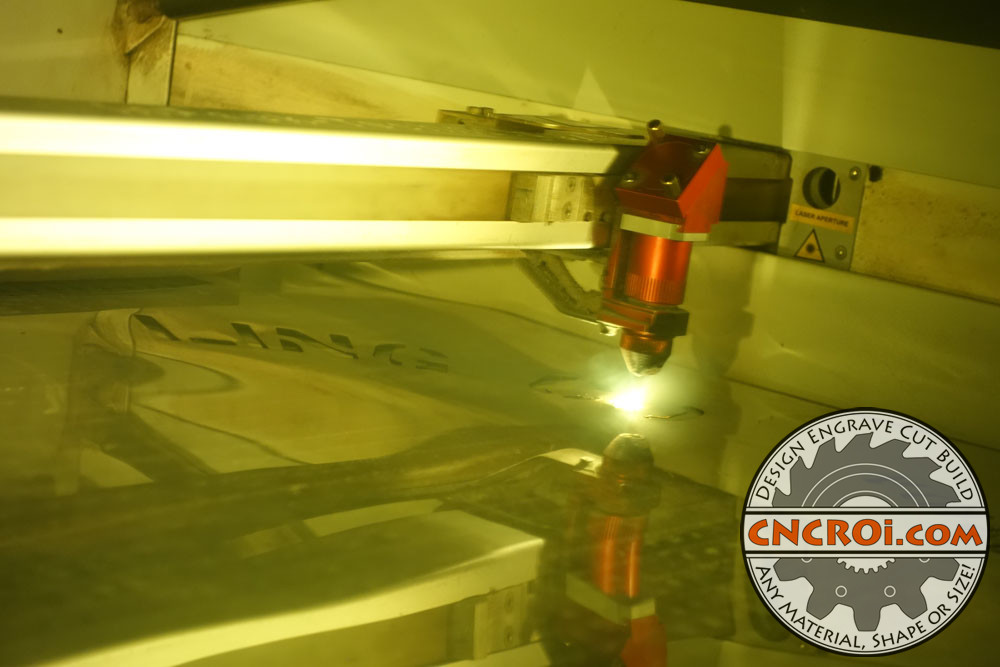

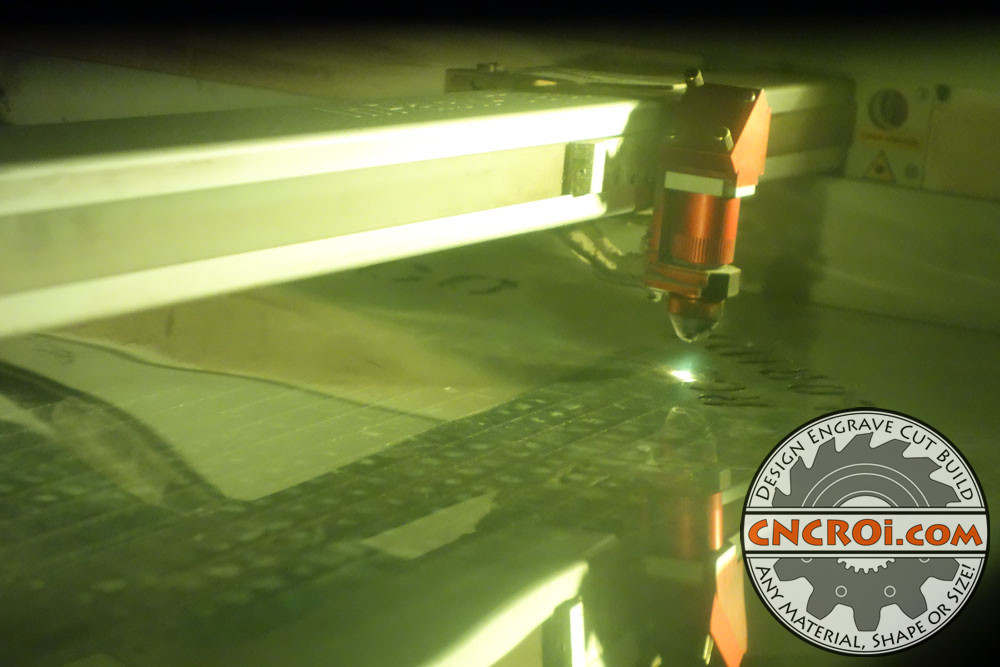

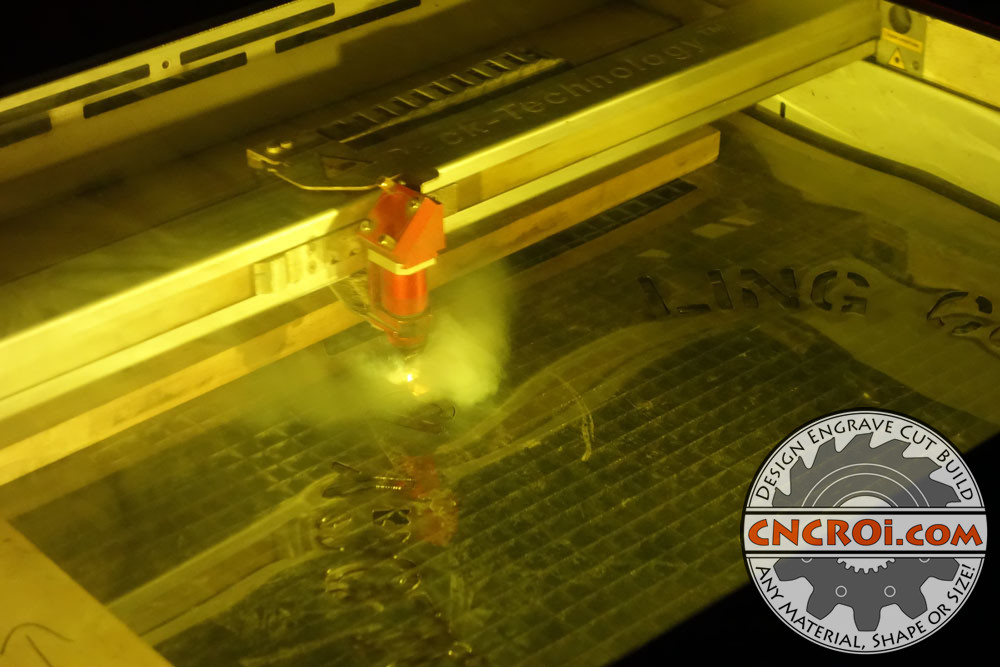

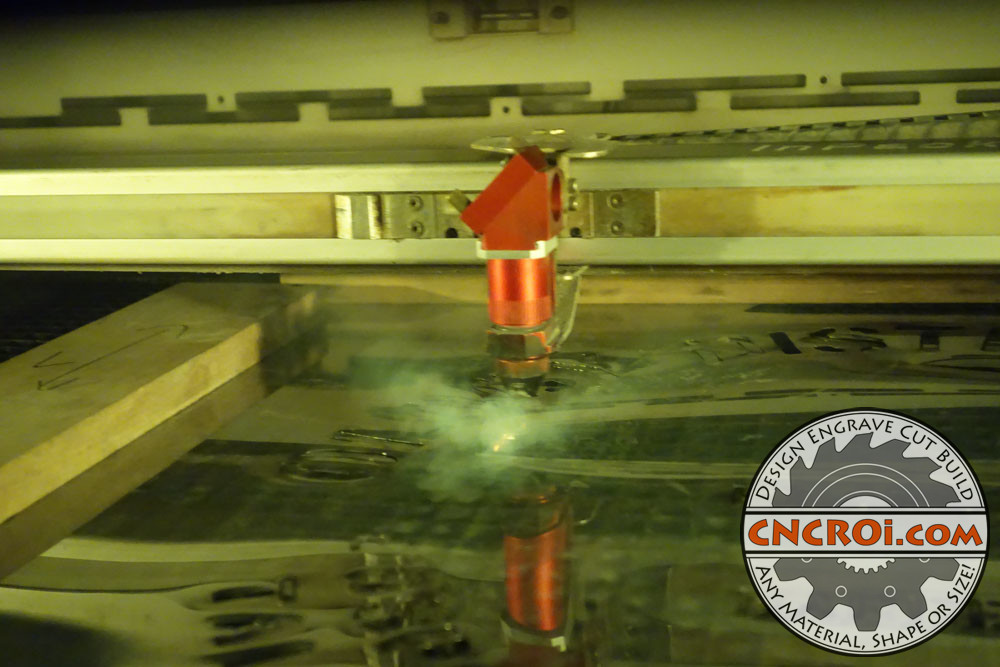

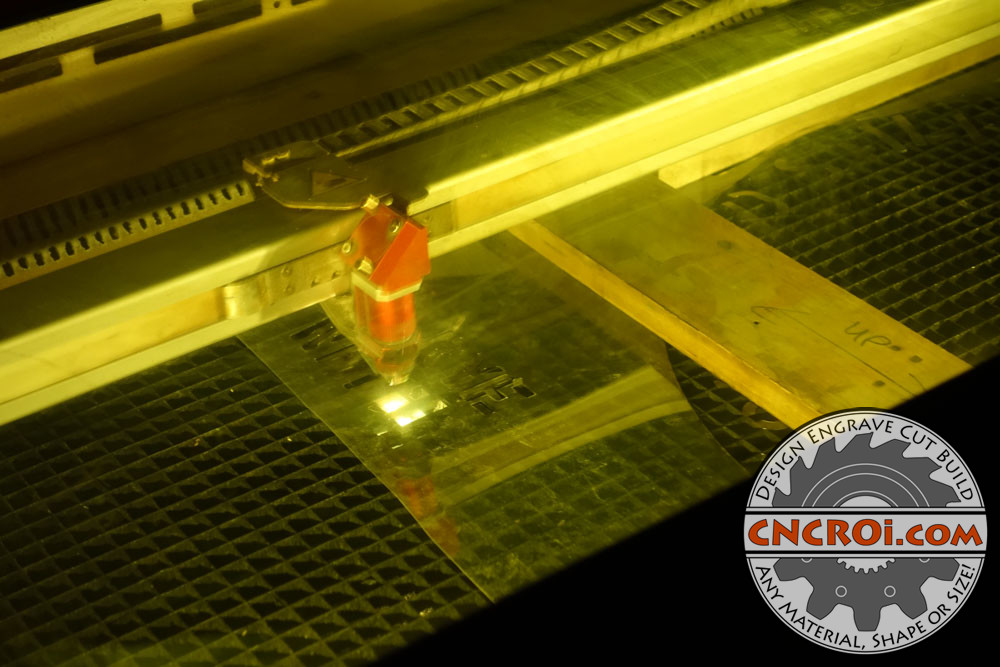

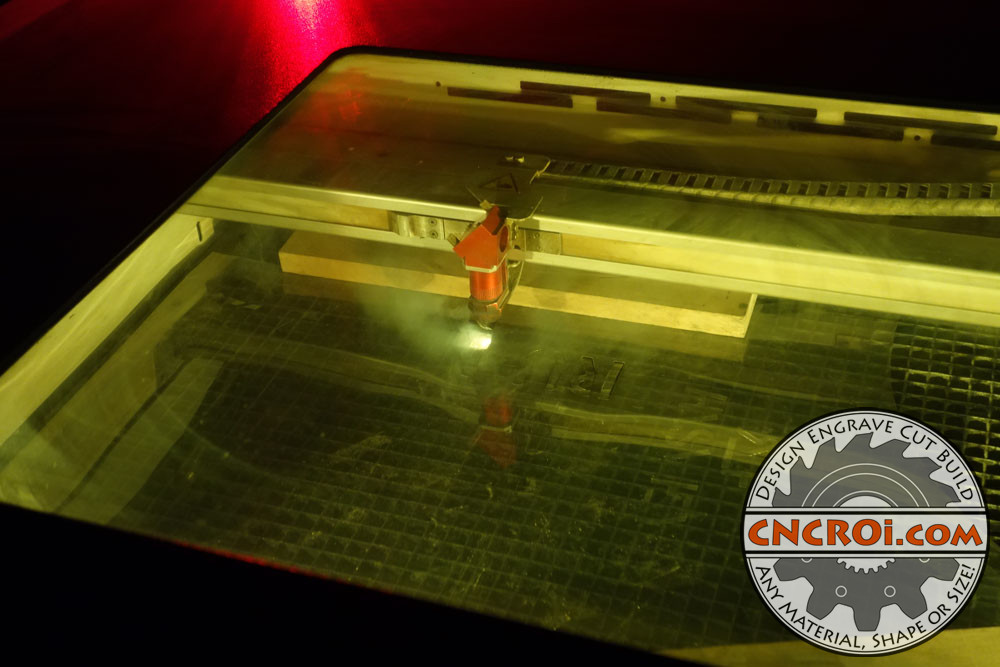

Cutting just about any type of plastic at CNCROi.com using our laser will produce a fire of some type, but the combustible fumes coming from this are quickly removed from the laser and the compressed air shooting down on the custom barrel head Mylar stencil extinguishes it on-site as well, which is why you see flashes of light then it disappears the instant they show-up.

Of course, CNCROi.com makes stencils for other applications than barrel heads, we make custom t-shirt stencils too!

https://www.youtube.com/watch?v=dwEyYkcdJy4/

By far the biggest issue you need to be concerned about when it comes to getting a custom stencil made, regardless of the material it will be in, is to make sure inner parts of letters and design are well supported with bridges, otherwise, they will fall-out.

As for the resolution that’s possible with your stencil, CNCROi.com can make a custom barrel head Mylar stencil with details so fine, even a spay paint can’t get into it, so the only real limitation is making sure everything is well supported.

I’d say the only material that may be of concern with stencils is cardboard or paper, it has a very limited number of uses and although cheaper to produce, can’t be reused or cleaned… and the stencil itself will be very weak and break down rather quickly.

Polycarbonate is a very popular material when it comes to making custom stencils, it’s extremely durable, optically clear and relatively cost-effective compared to making the same stencil using metal.

https://www.youtube.com/watch?v=BrE6GhW6W2A/

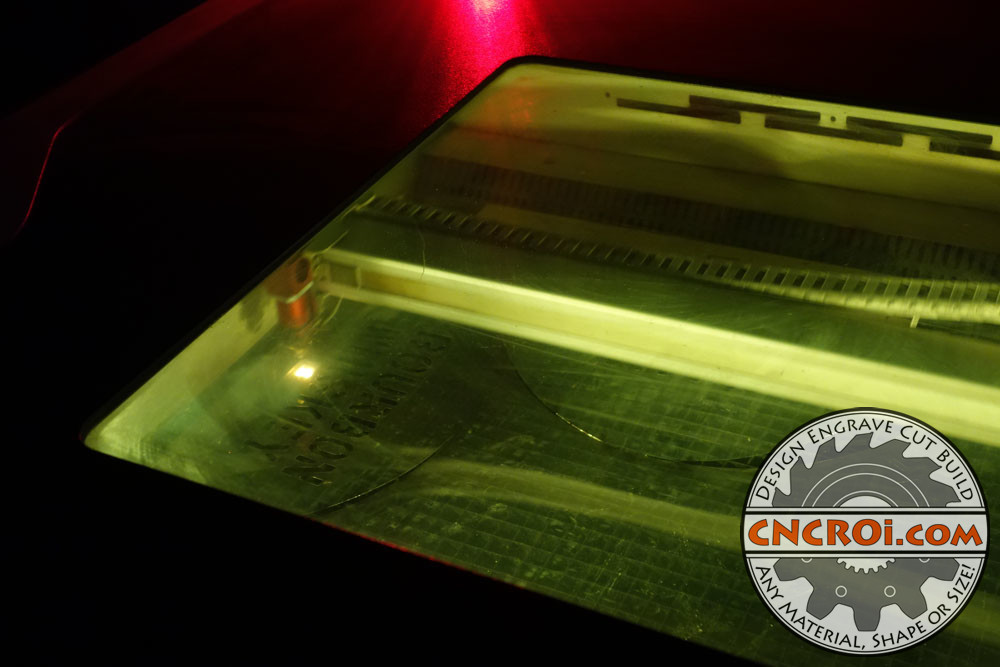

The nice thing about a custom barrel head Mylar stencil or one made out of polycarbonate is the durability, it will easily outlast many other material options and best of all, it’s transparent, so you can see exactly where you are going to have the stencil applied.

The finished results of this custom barrel head Mylar stencil production run made at CNCROi.com look great as always, the sharpness isn’t achievable with any other machine than a laser and a fantastic design provided by the customer.

Looking at it from another angle, you can see everything is sharp, this weighs practically nothing and is incredibly durable for a lot of spray painting.

Need a custom barrel head Mylar stencil? Contact CNCROi.com right now!

https://www.youtube.com/watch?v=0j7SOQVaI4o/