Custom Formica Template & Inlay Pieces

CNCROi.com has been using Formica template and inlay pieces almost since we started, it’s a very hardy material, wonderful for a whole bunch of different applications.

For this specific job, the customer wanted to do a Formica inlay on a piece of furniture, so the first thing CNCROi.com had to do is make the Formica template that they can use their hand router to carve out easily what will then be filled with Formica using glue as the adhesive.

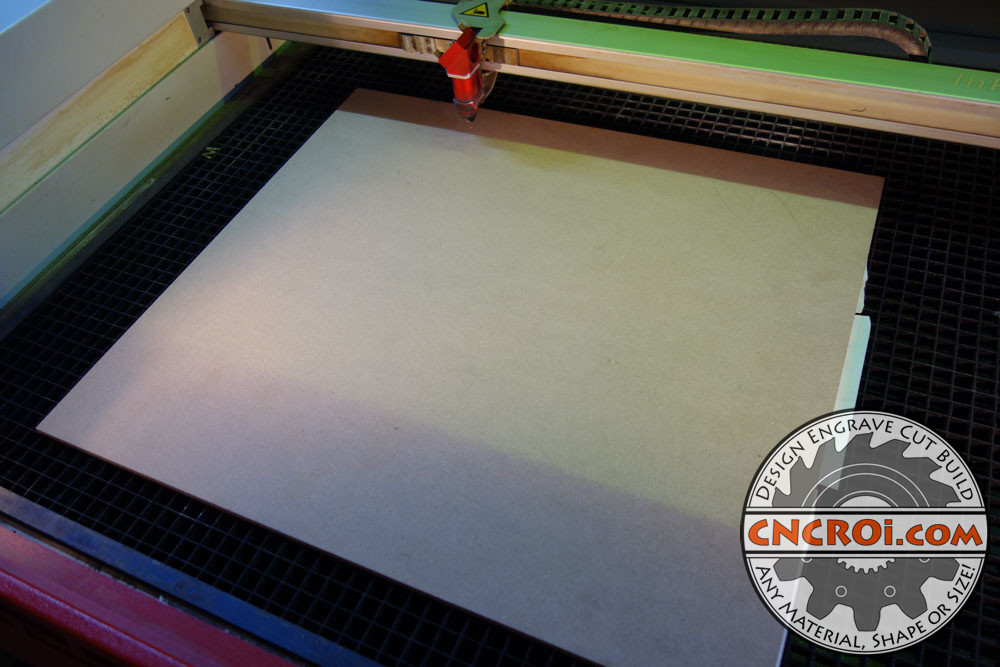

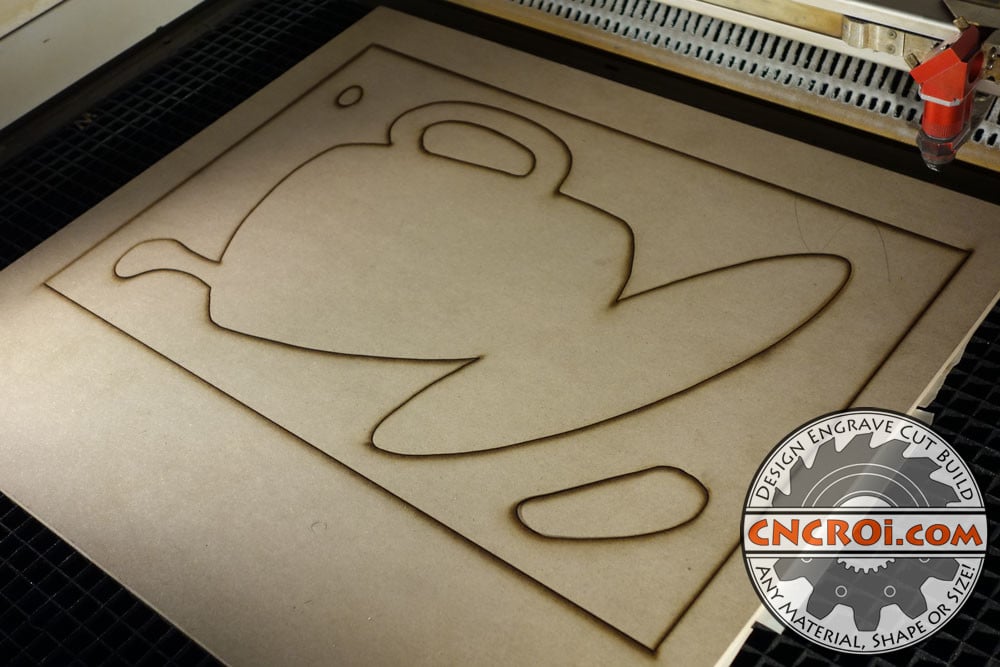

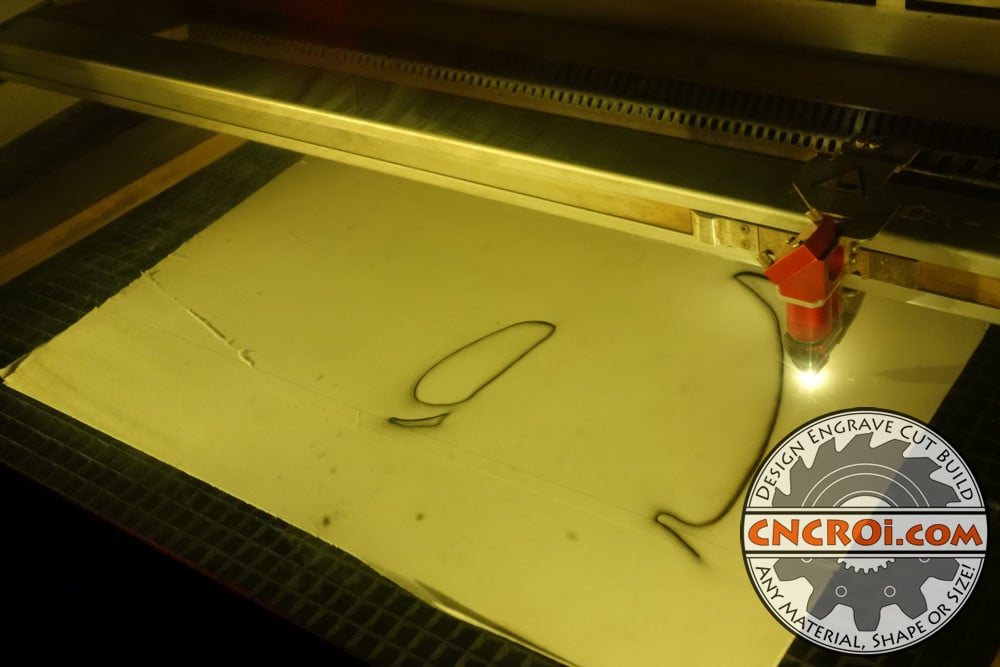

The Formica template is just regular quarter inch MDF with double sided tape applied to the back, this way, the customer has an easy way to non-permanently bond the template to the furniture top and then remove it after the routing is done.

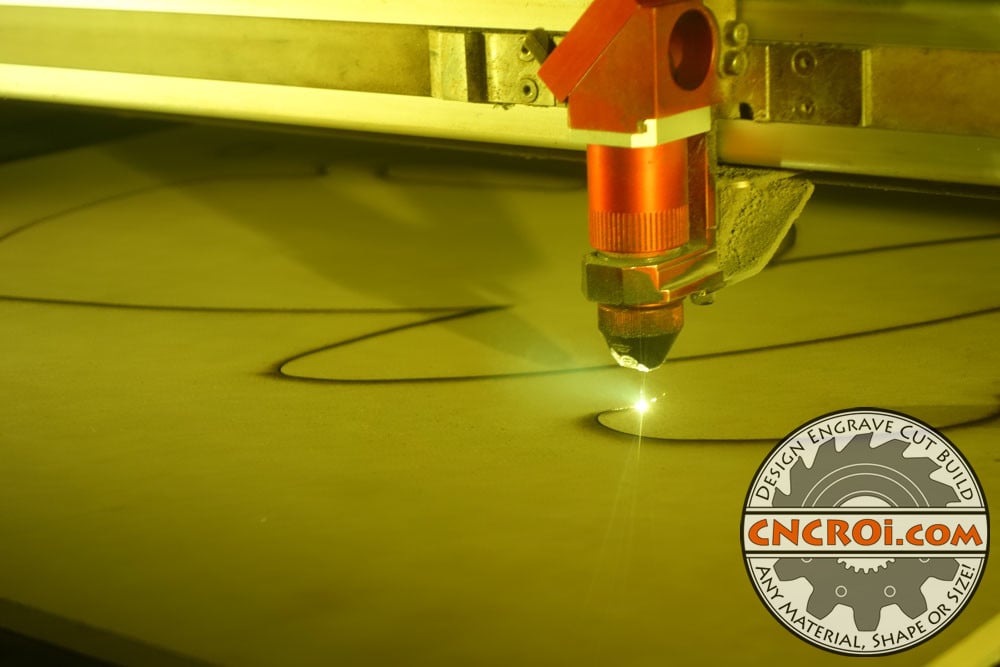

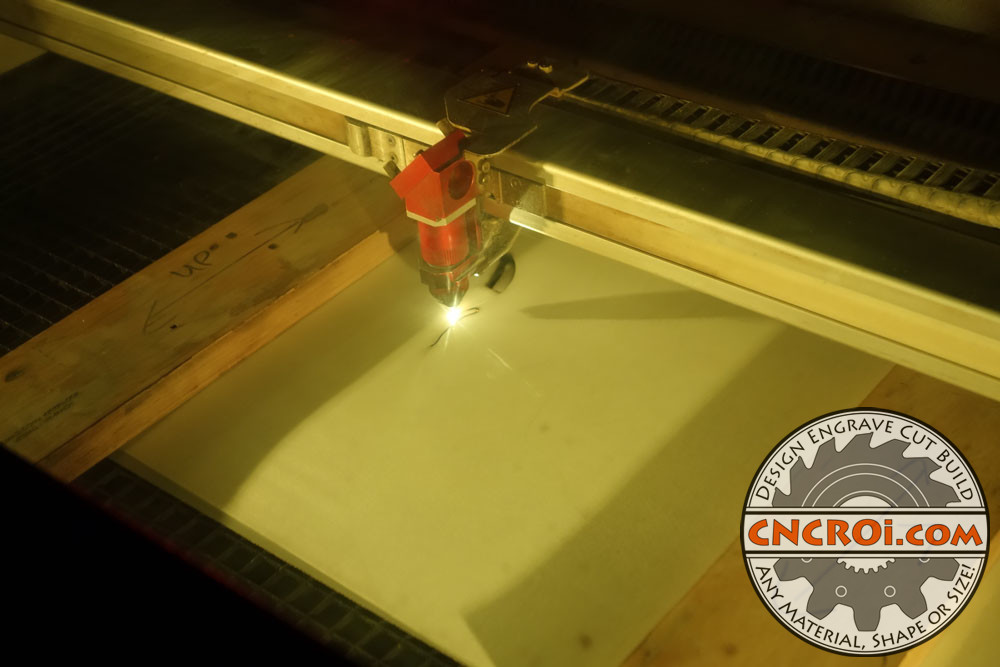

CNCROi.com can easily cut far thicker MDF, we’ve done thousands of jobs though the years using this material, in this case, the Formica template is being laser cut because the laser is already going to work on the Formica pieces, so might as well use the same machine for everything, otherwise, this entire job could have just as easily been made using any of our CNC routers as well as there weren’t any sharp inner corners to contend with.

CNCROi.com has made thousands of custom Christmas ornaments using Formica, the durability is fantastic and the color options endless.

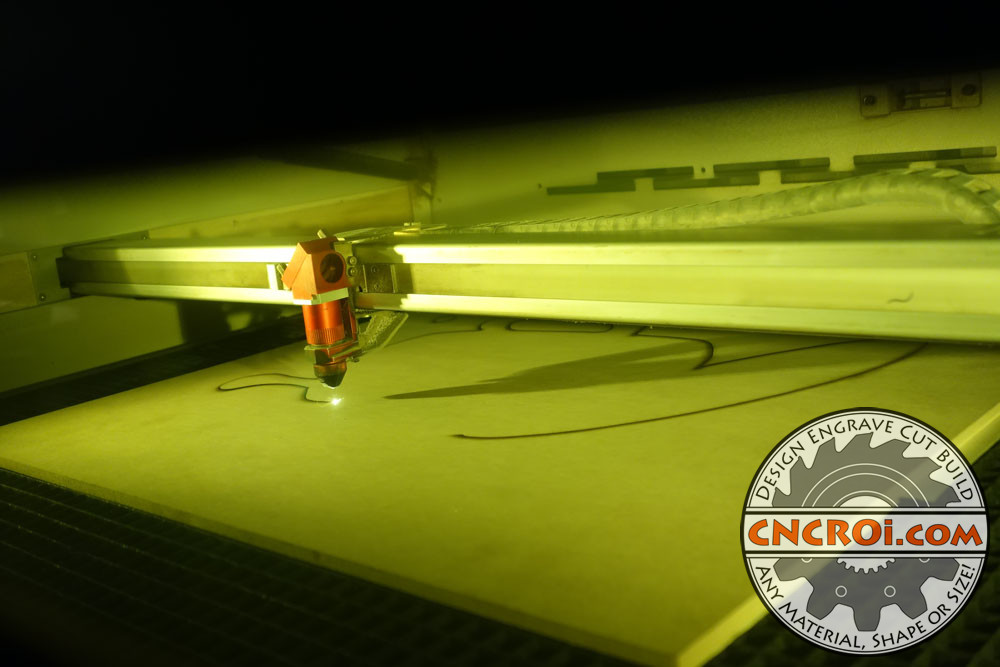

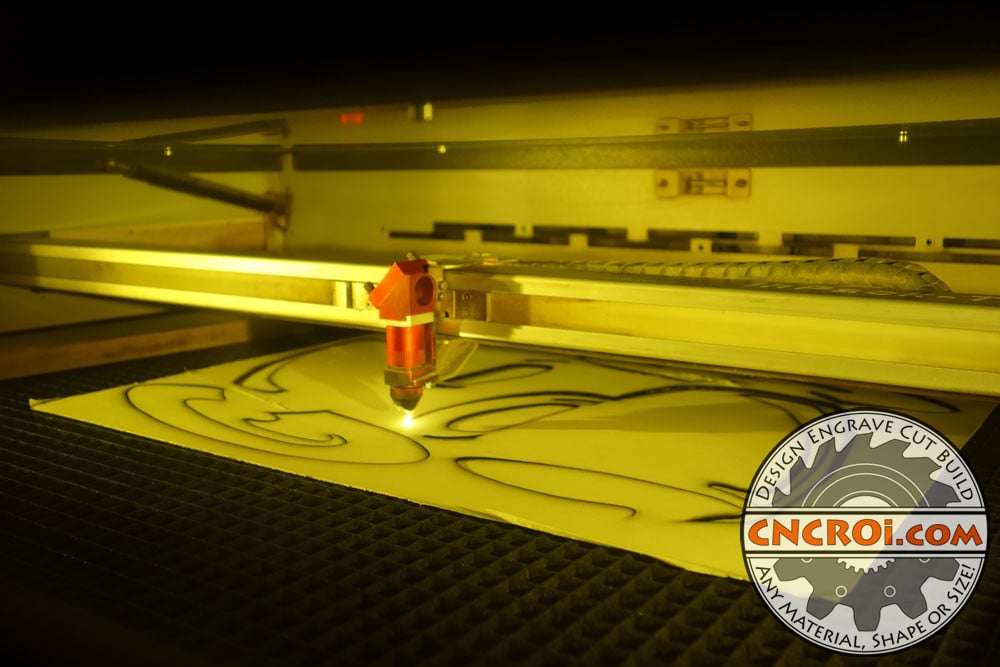

The advantage to laser cutting the Formica template and inlay pieces over the router was that there wasn’t any need for a hold-down system as the laser is a non-contact cutting method, verses a laser pushing and pulling through the material.

Oddly enough, the MDF cuts faster than the Formica that is a fraction of the thickness, the reason being that Formica is an incredibly dense and hard material, while MDF has more air in it than wood dust, that’s why we can use it as a spoil board on our routers because air literally goes right through it!

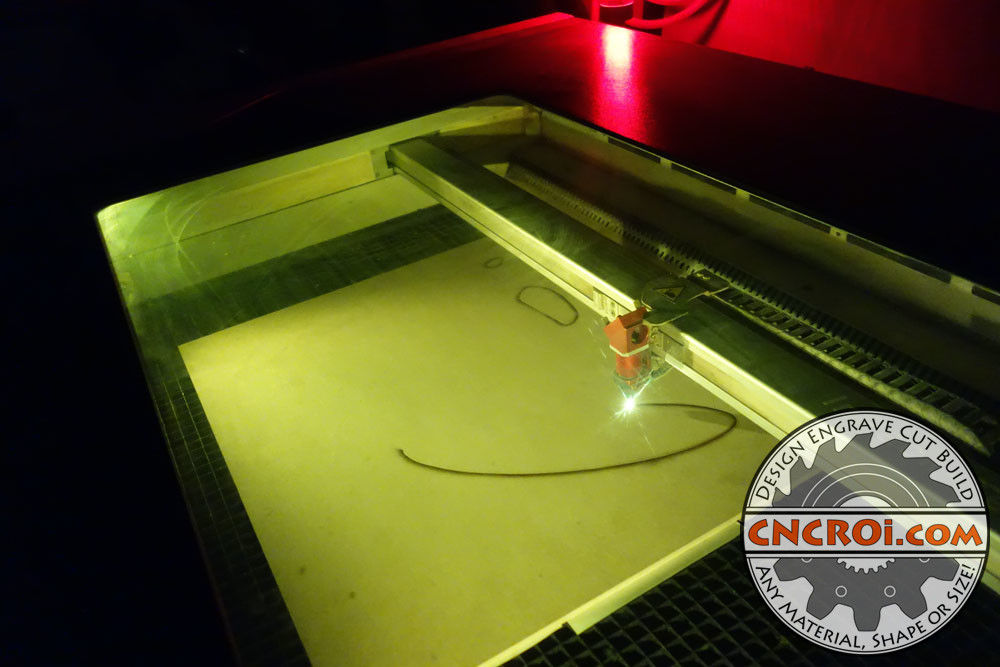

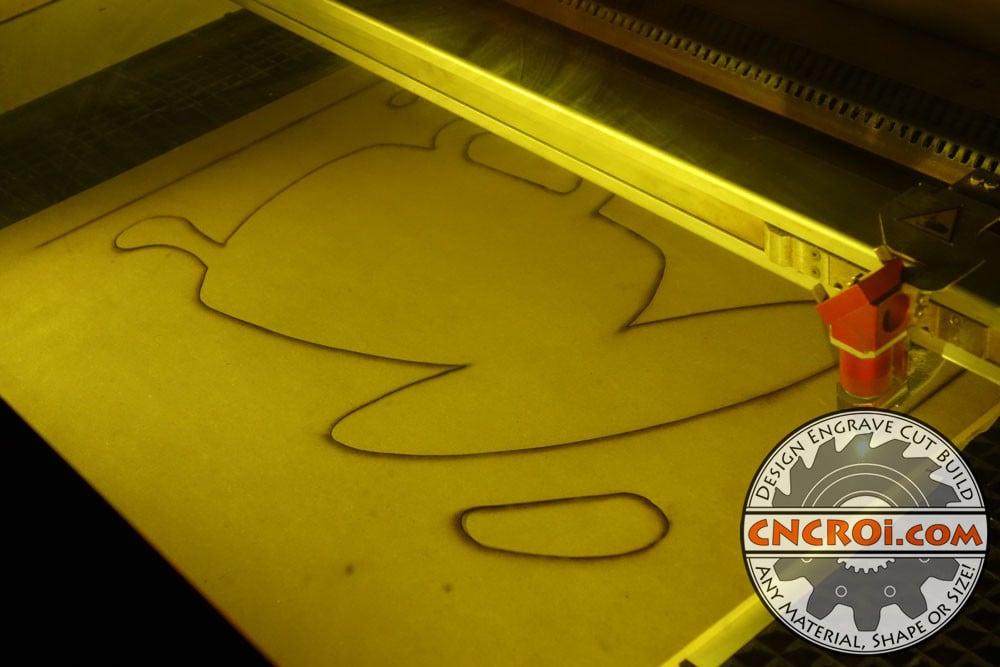

The Formica template is just about done, the inner parts are cut out before the outer ones so everything is accurate, probably overkill for a job like this but if something can be made at a high standard at CNCROi.com, that’s what we’ll do!

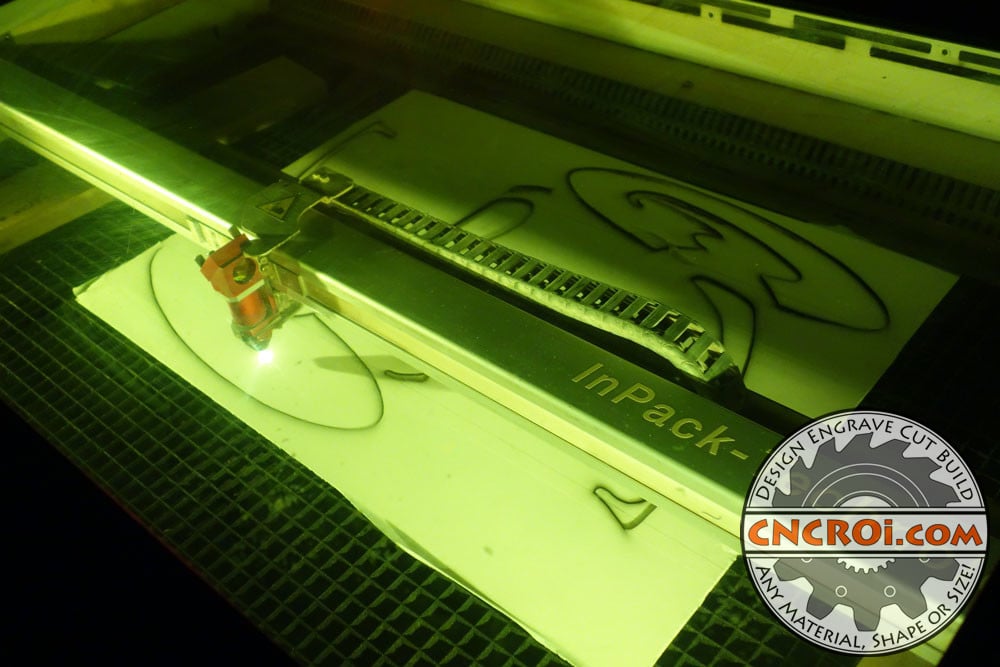

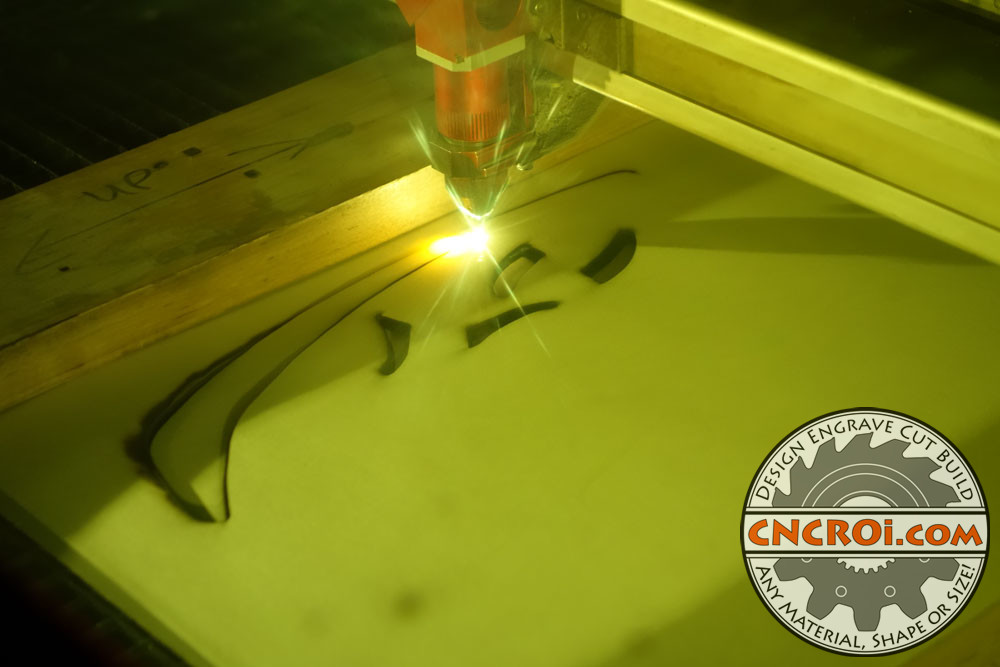

This Formica template is looking great, now it’s time to take out the inner parts – which were shipped to the customer as well as the template.

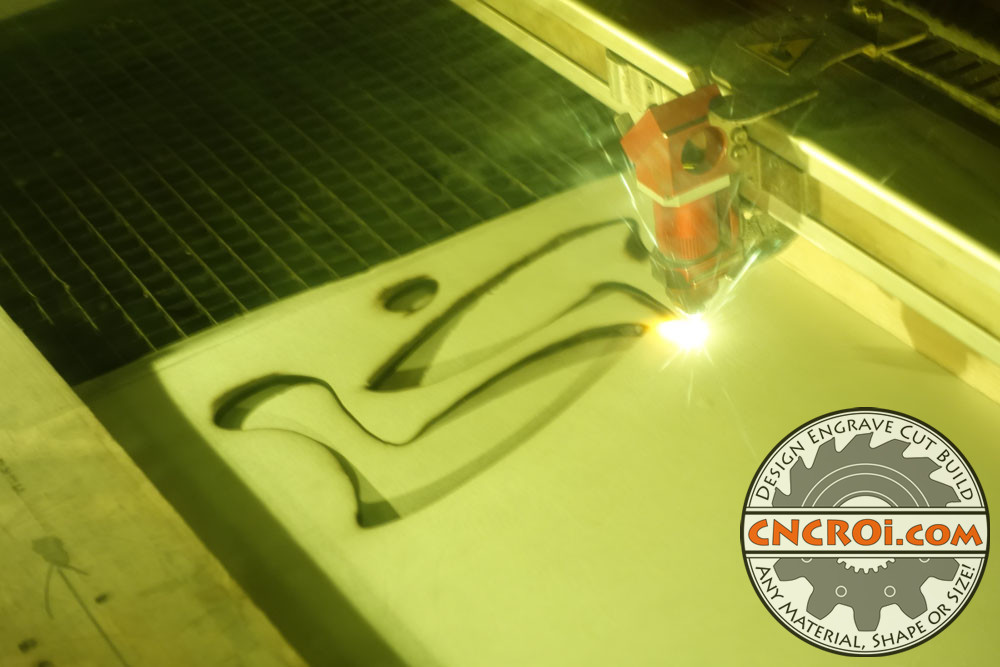

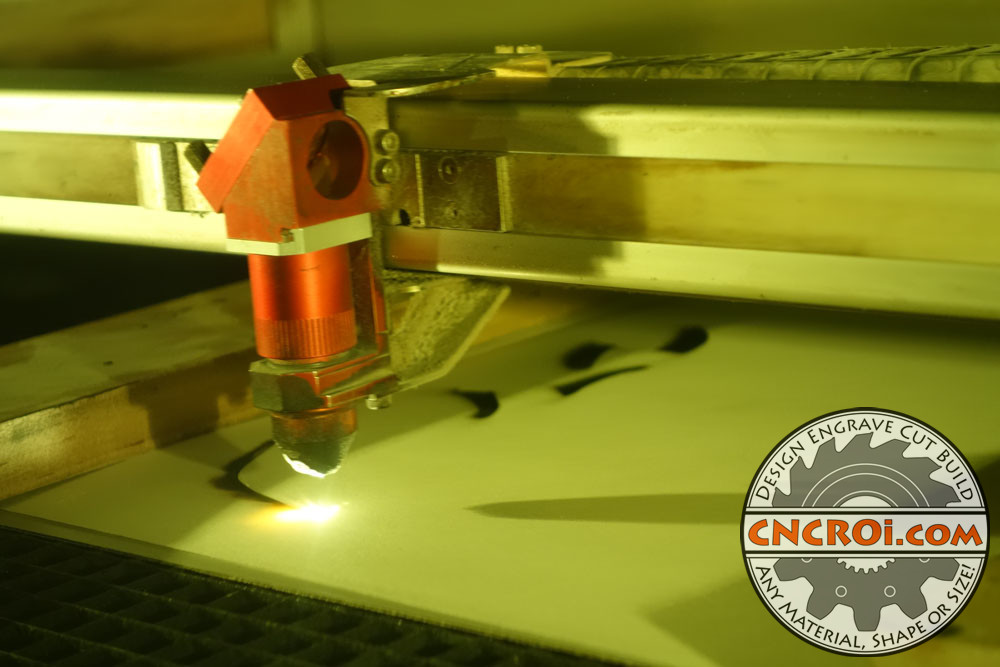

As you saw in the finished picture that I took at CNCROi.com, the Formica inlays are made-up of different colors but as mentioned in the video, everything has heavy masking on it to make sure the burning happens on the masking rather than the top surface of the Formica.

We’ve also been known to make templates using Formica itself, it all depends on the spec that the customer has in mind when it’s time to make awesome stuff.

Cutting Formica is like cutting thin wedges of stone, it’s hard on router bits and the laser goes super slow to cut it out as well, this is a great feature of Formica because this is why it’s such a durable material for countertops all around the world!

The advantage to do this entire project with the router is that it would be a lot faster, but it’s a fine line because of the time needed to set-up a proper hold-down method to keep it dead flat, Formica ships as rolls, at least in the limited quantities that CNCROi.com uses for project, as such, it keeps this curvature until it’s glued or something or given time to let gravity put it back flat, something that we rarely have time to wait for at the shop.

There is some soot being created along the edges of these Formica pieces, the same is also true with the MDF Formica template, lasers essentially cut by burning, and there isn’t anyway around that fact, regardless of the material employed.

Sometimes we use the laser to make custom Formica projects, other times, it’s the laser, the thickness of the material and sharpness required are what tell CNCROi.com which machine to use for the given job at hand.

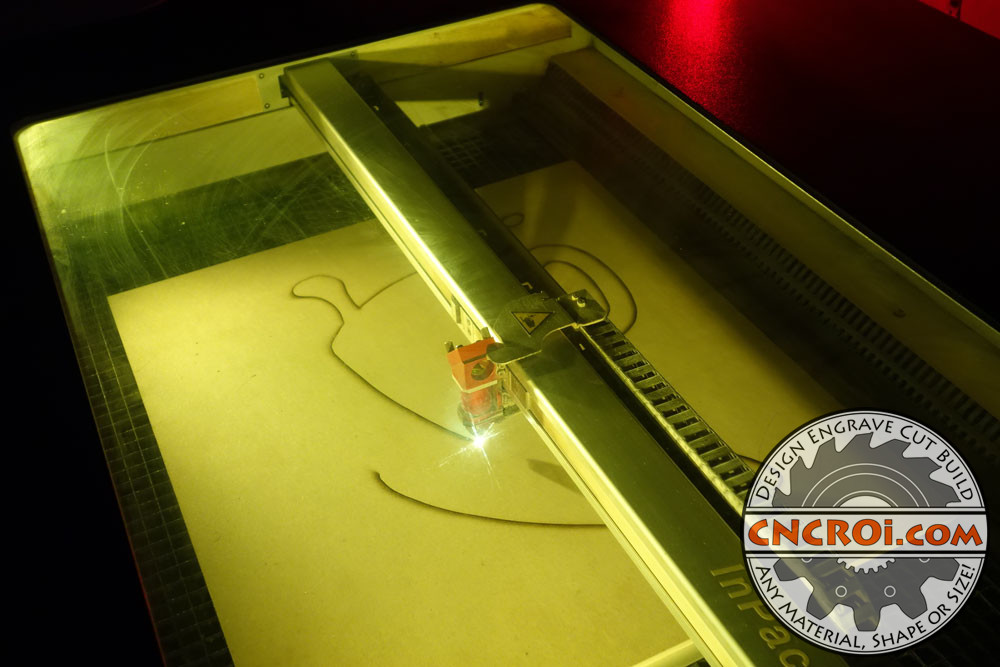

As each one of these Formica pieces as being cut, I was putting them in the MDF template to make sure I wasn’t missing any pieces and to verify the cut quality and fit before shipping this project from CNCROi.com to the customer who was going to use all of this for their master creation.

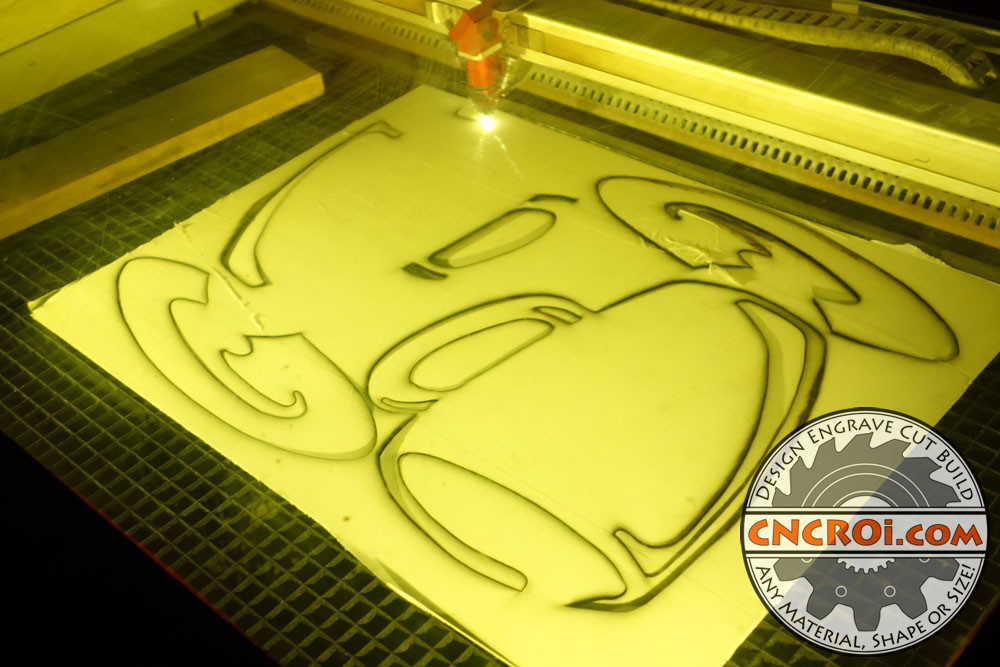

Formica templates can be any shape, size or thickness, just like the Formica pieces that are being laser cut – and there is an endless variety of Formica options out there as well to match pretty much any color scheme you require for your project.

The other advantage of the laser over the router when it comes to making custom Formica pieces is that I can get away with making smaller pieces because again, I don’t have a full-contact router bit pushing and pulling through the material, of course, sharp inner corners which aren’t possible using a round bit also helps.

When it comes to laser cutting Formica, it works only up to a certain thickness, then the heat builds-up in the material, just like stainless steel, and more burning than cutting is produced by CNCROi.com‘s laser, this is why we often employ our router to do these types of jobs.

If you are wondering what laser engraving looks like with Formica, here’s a quick video showing that.

As each of the Formica pieces are cut at CNCROi.com, they are checked to see how the burning has affected the surface, as such, doubles of everything are made as one may be rejected and it’s easier to cut two with a tight nesting rather than one and then try to nest it perfectly on the left-over piece of Formica.

Formica that’s only one layer thick cuts very well with CNCROi.com‘s laser, the only real limitations are making sure it’s relatively flat to ensure that the cut quality is top notch throughout the process, if it’s too far off the height, then again, we get more burning than cutting.

The reason you don’t see any smoke during the MDF Formica template cutting and all these smaller inlay pieces is because we have a powerful extraction system with air shooting down from the laser head, so the smoke shoots down and out of the machine almost as soon as it’s made.

If it comes to creating branding on Formica, I prefer to use scoring than engraving.

Can Formica be laser engraved as well? Sure, but you can’t have much depth to it, and generally, it’s better to cut out the pieces that you want rather than trying to engrave it as it’s faster and a cleaner result.

Taking a look at the final Formica template and inlay pieces, you can see how great everything fits, you really couldn’t produce a better results by trying to cut this stuff by hand or with power tools.

Taking a look at the entire job, you can see how everything fits together, of course, these pieces aren’t dead flat, this will only happen when the customer applies glue to the back and pressing down with it for proper adhesion, that’s why you see slight spaces in certain areas.

Have a Formica job? Contact CNCROi.com right now!