Bird House Prototype: CNC Routering 3/4″ Maple Plywood

A custom bird house is a great way to lessen the number of bugs in your yard and provide a welcome shelter for the local bird population.

One of the first projects I did a long time ago when I sold design files around the world was actually a birdhouse, here’s that early animation.

A few years later, I continued to refine my ideas when it came to custom bird houses, knowledge I’ve used the last few days to make something even better at CNCROi.com.

Suffice it to say, I’ve designed a lot of these so when it came time to add a custom bird house to my backyard garden, I wanted to make something DIFFERENT with a bit more esthetics to it and heavy-duty build.

Another great use of wood are custom rustic stamps, in this case, I did a comparison of different options available and the result.

https://www.youtube.com/watch?v=B_G1p4djcCI/

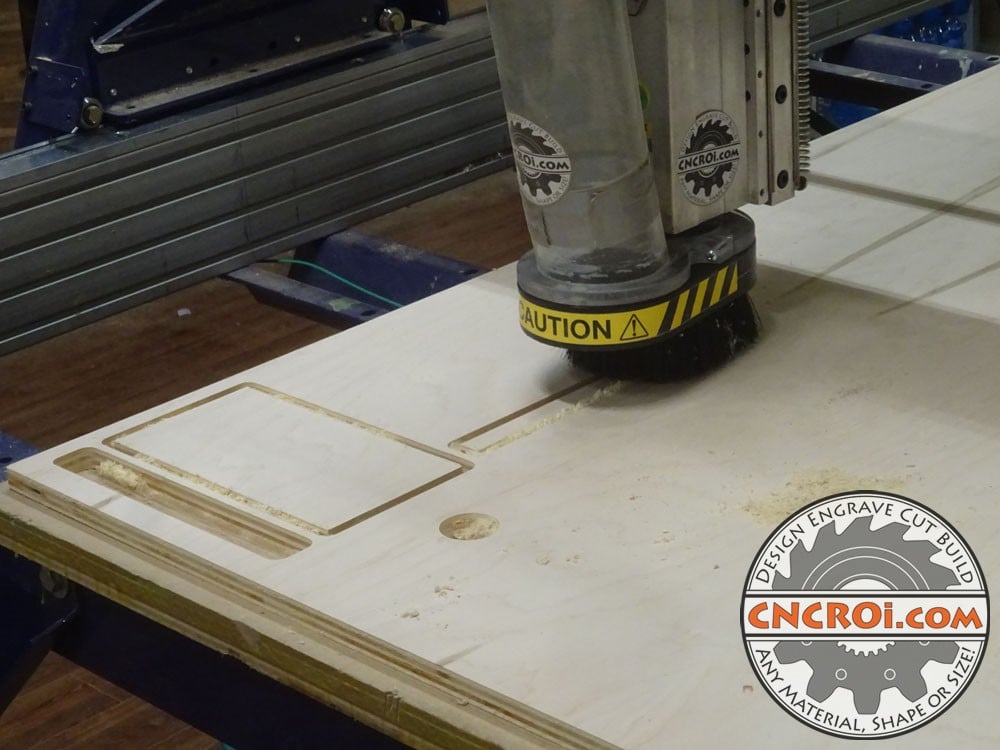

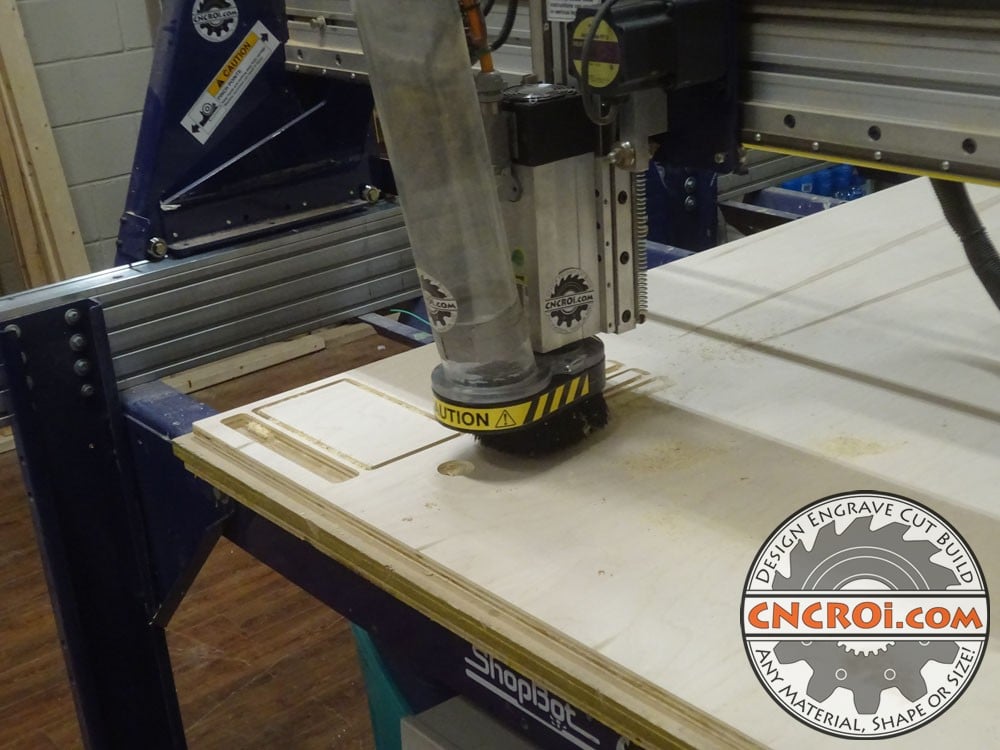

I looked online for some inspiration and found a lot of woodworkers making log home looking bird houses, so I thought I’d make my own but instead of using power tools, I’d design it to be CNC router cut using 3/4″ furniture grade Maple plywood.

Before making half a dozen of these custom bird houses though, I wanted to make a bird house prototype to refine ideas I had and further improve on the overall design aspect of my bird house design before making a wack of them at CNCROi.com.

I’m happy I did a prototype, I found some parts not necessary, some parts needed further refinement and other parts needed to be replaced – that’s the fun part about prototyping, you can fiddle around to your heart’s content until you have exactly what you want.

I also make odds and ends things for CNCROi.com customers who want something a little better than what can be purchased at the store.

https://www.youtube.com/watch?v=gu-NKOjWP8A/

The reason I went with heavy duty quality plywood over much cheaper options was that I wanted a bird house that was both insulated, same idea as a log cabin, and tough to last many many years.

This bird house was built in a log cabin style, it also gives it fantastic strength due to the nail and glue construction so overall, this custom bird house is strong enough to survive 4 seasons and a hurricane no problem.

CNCROi.com uses it’s CNC router for a whole bunch of different jobs, including doug bones using solid Maple.

https://www.youtube.com/watch?v=67DOfMCacBk/

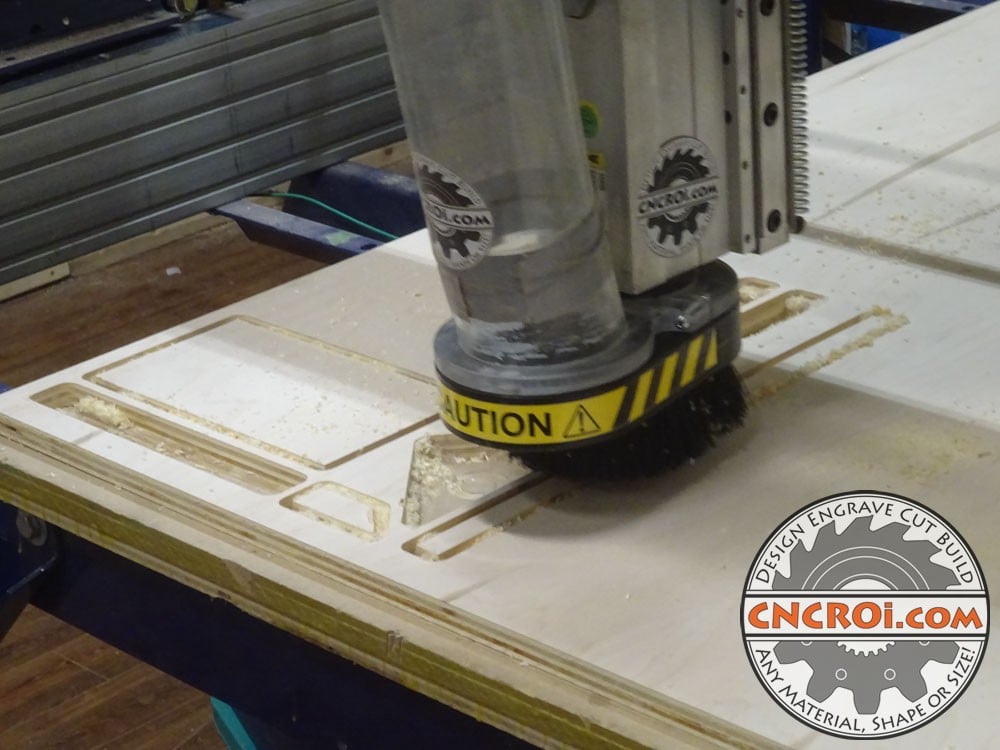

One of the parts I had to redesign for when I make a batch of these custom bird houses was the front door, I ended-up cutting another one after the router exploded it as the hole was too big without enough supporting material, it vibrated itself apart.

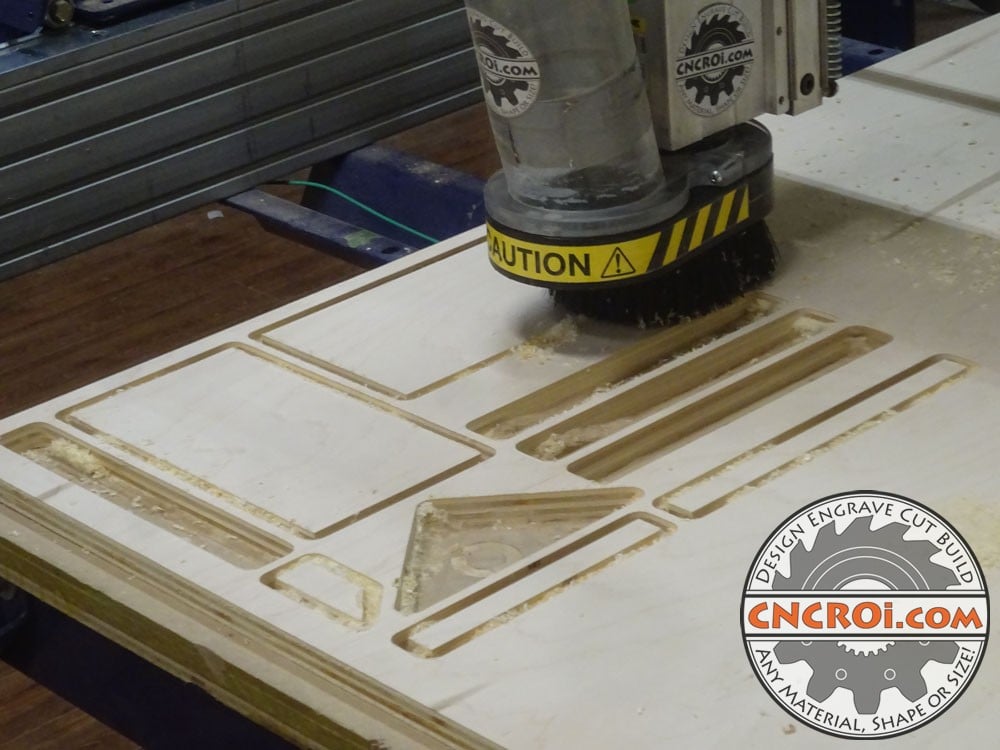

Otherwise, all the small log parts you see missing in the plywood sheet below flew away, again, hold down issues without enough of them, but I’ve done thousands of jobs with my CNC router, I know how to fix these design wise down the line.

Regardless of how many jobs I’ve done across my CNC equipment at the CNCROi.com shop, there is always something new to learn and have fun with.

One of my favorite woodworking projects thus far was a simple desktop business card holder, not a lot of CNC involved here but a great finished result that CNCROi.com‘s customer loved!

https://www.youtube.com/watch?v=N3a1sBNi_H8/

I updated the design on the fly, which is why you don’t see any other parts flying off the CNC router during the cutting process – of course, that also played a role in the initial triangle door breaking apart as well.

Once all the parts of the log cabin custom bird house prototype are finished being CNC routered out of the plywood, it’s time to take an inventory of all the parts, you can see the broken piece in the image below but otherwise, everything survived.

I’ve also used wood to make my own Uncle’s urn, not a fun project due to the reason it had to be built but was a great send-off I had the honor of making for the family.

Taking the sawdust away, you can see the tabs I mentioned, they were doubled in length and thickness, and that did the trick to hold them in place until all the parts were cut out at CNCROi.com.

Tabs are a double edged sword, great for holding parts in place but the better they are at that job, the harder it is to remove them from the wood after, so you want to use the bare minimum you can get away with and still allow easy removal by hand.

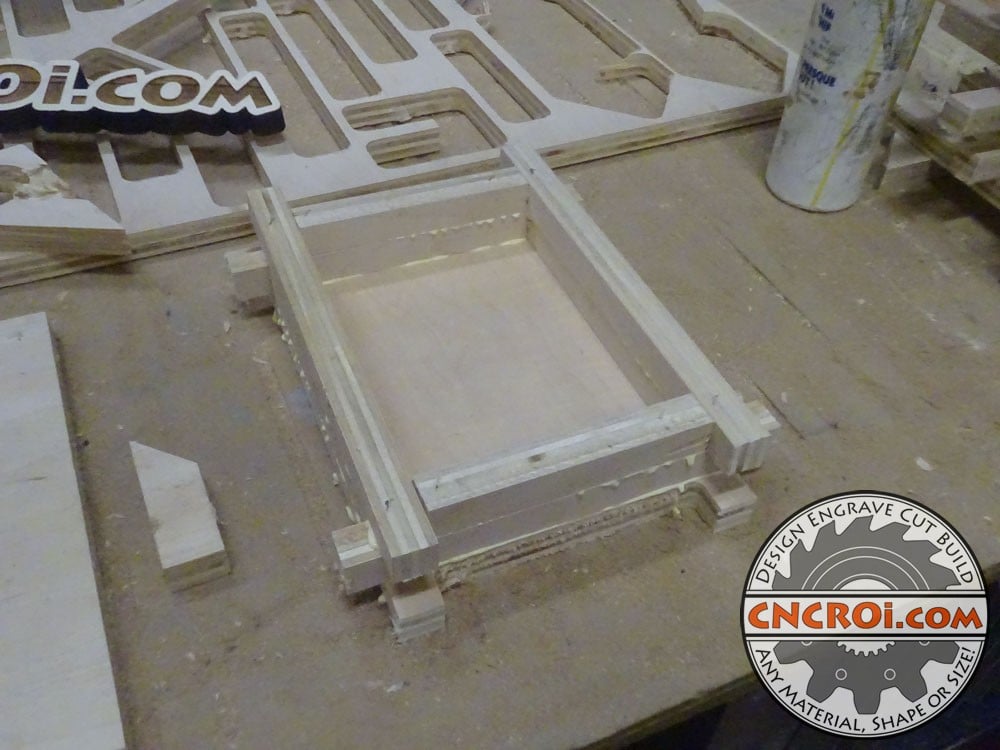

Skipping ahead a few steps, I sanded off the tab remnants on all the custom bird house parts and did a dry fit, didn’t see any real problems here but decided during assembly to put it “sanded side out” rather than what you see below, stacked.

CNCROi.com makes custom woodworking jobs but also house number signs, we work with whatever you want when it comes to wood production.

https://www.youtube.com/watch?v=RVIYUnOMUyE/

I think this approach gave the bird house better esthetics and weathering characteristics, you can see I already glued two levels and used my pneumatic nailer to further make sure nothing moved.

Once the custom bird house was built, it was time to add some tung oil to the entire surface to preserve it.

But first, I sanded off and removed excess glue, the tung oil isn’t absorbed by glue.

If you wanted some metal elements added to your own personal house, CNCROi.com can produce those as well, check out what I did on my house.

https://www.youtube.com/watch?v=DxHyaObcZjs/

Once I was done the entire build process of this custom log cabin inspired bird house, it was time to get it ready for the tree in my backyard it would live in well into the future.

I found-out that this design is wonderful for “hold” in the tree, the extruded parts of the log cabin really give it a log of grabbing power so that it sticks in the tree solidly without needing nails or screws to hold it in place.

This custom bird house is now available for rent, will make my production run of a ton more in the coming days at CNCROi.com!

Need something made out of wood, contact CNCROi.com to make it for you… and yes, I can also design bird house castles.