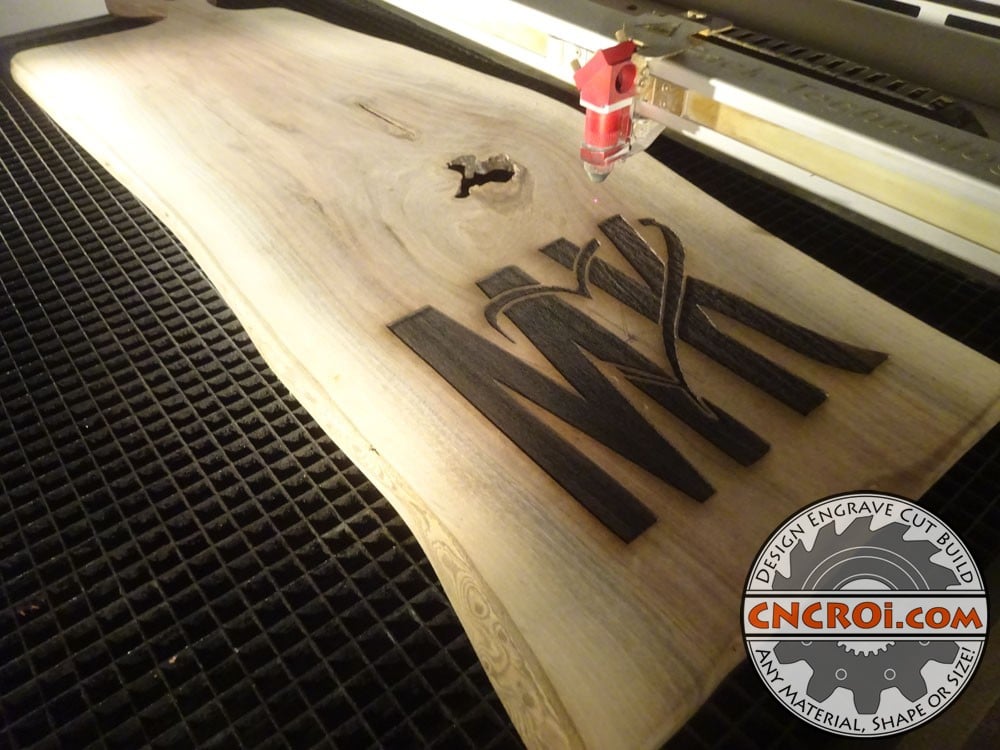

Black Walnut Engraving: Making Room for Epoxy Fill

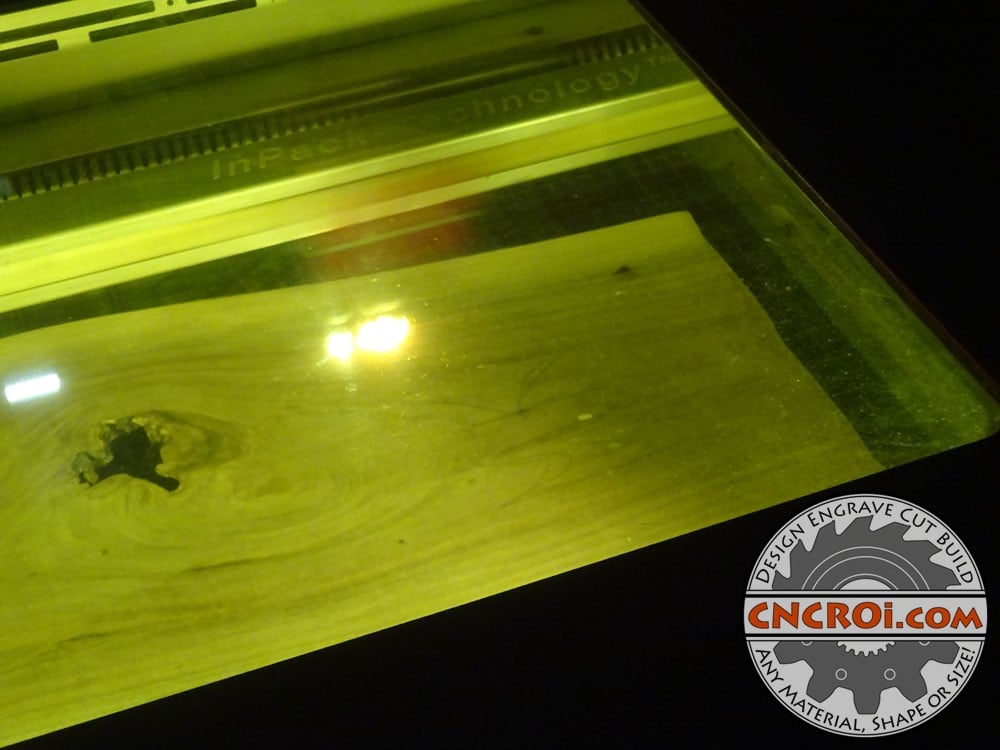

Black Walnut engraving is done for a variety of branding purposes but this is the first time a customer will use what I do to perform an epoxy fill at their end to add color and wow to this finished live edge board.

https://www.youtube.com/watch?v=QB9oqr_M2Kw/

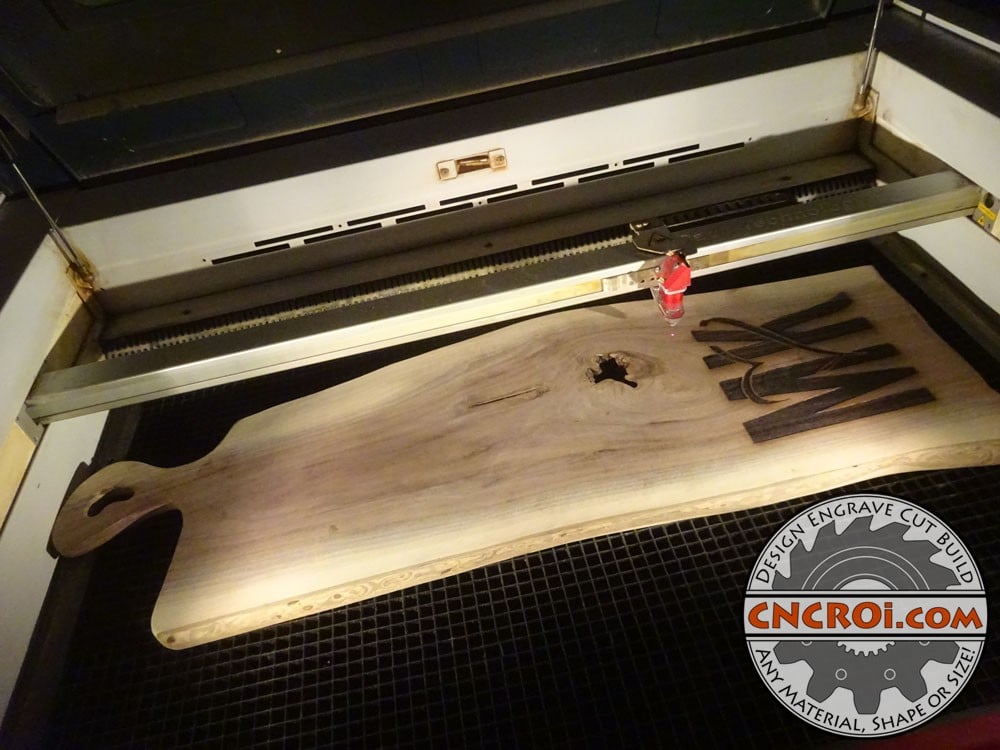

It wasn’t into a few years of running CNCROi.com that I actually got into using live edge lumber on a regular basis and I’ve come to really enjoy working with it for a variety of uses.

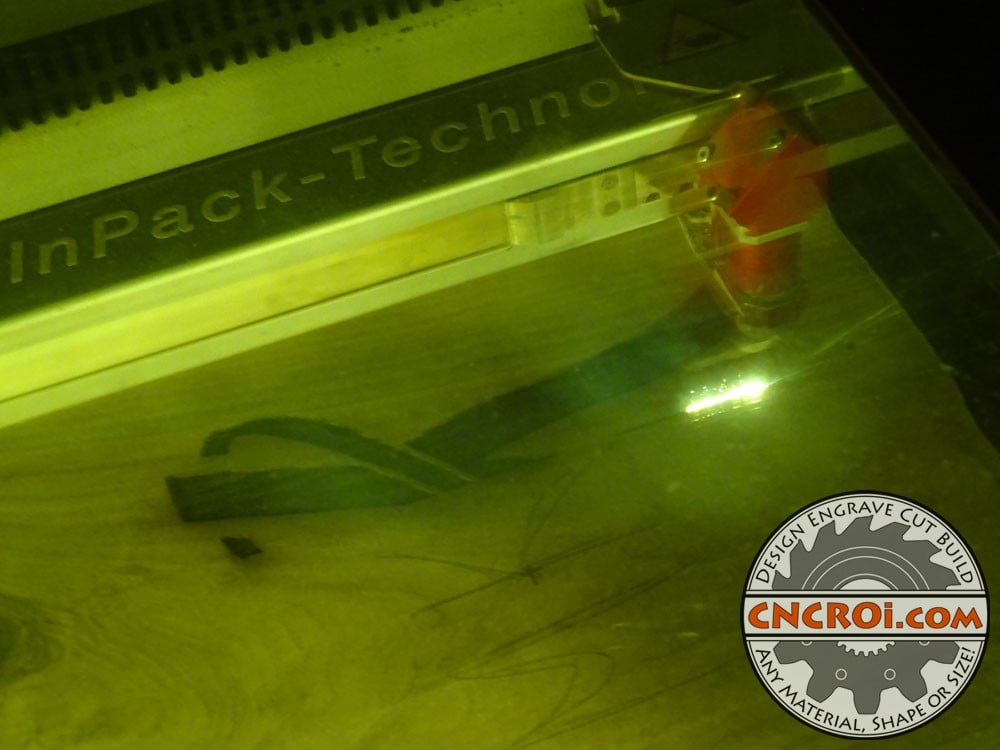

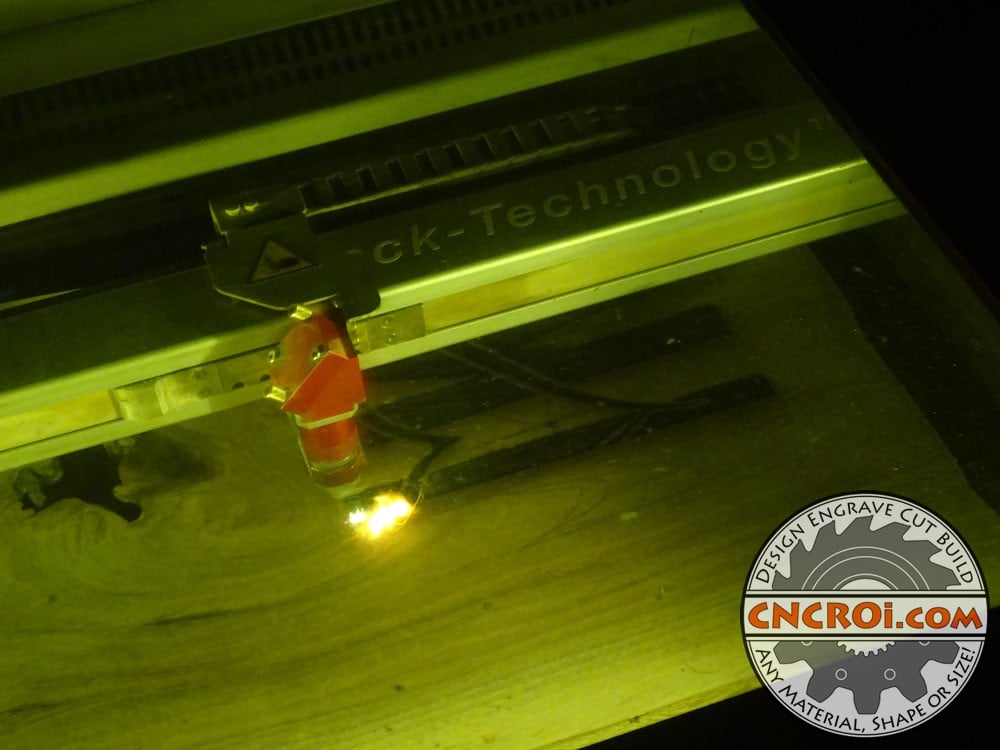

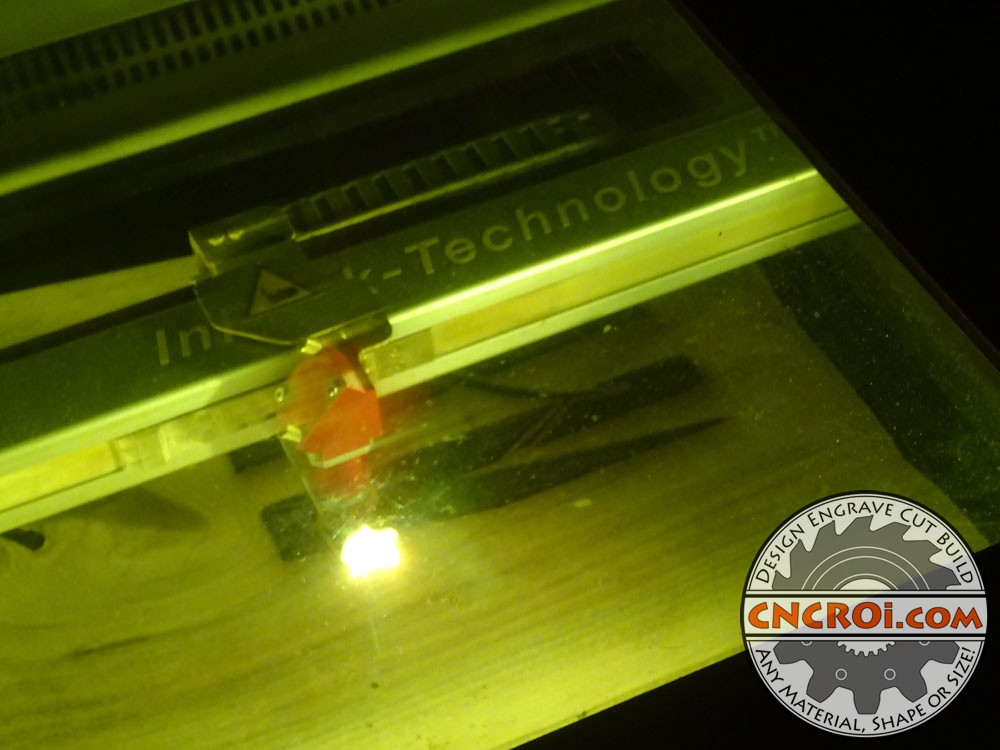

Using our CNC laser for Black Walnut engraving produces a sharp result, with a crisp edge, this happens to work wonderfully for epoxy fills by the way.

Additionally, the very rough surface quality of the Black Walnut engraving itself lends itself to amazing adhesion qualities, again, wonderful characteristics for epoxy filling live edge specifically.

The high detail options with Walnut are impressive to say the least, yes, CNCROi.com can also make clearly legible business cards out of Walnut!

https://www.youtube.com/watch?v=v12dcQZCWG0/

When it comes to your design options, Black Walnut engraving or any other species or type of wood really makes no difference, whatever you want, CNCROi.com can produce.

Any mix of fonts, imagery (vector based is best) or branding ideas work fantastic with Black Walnut engraving.

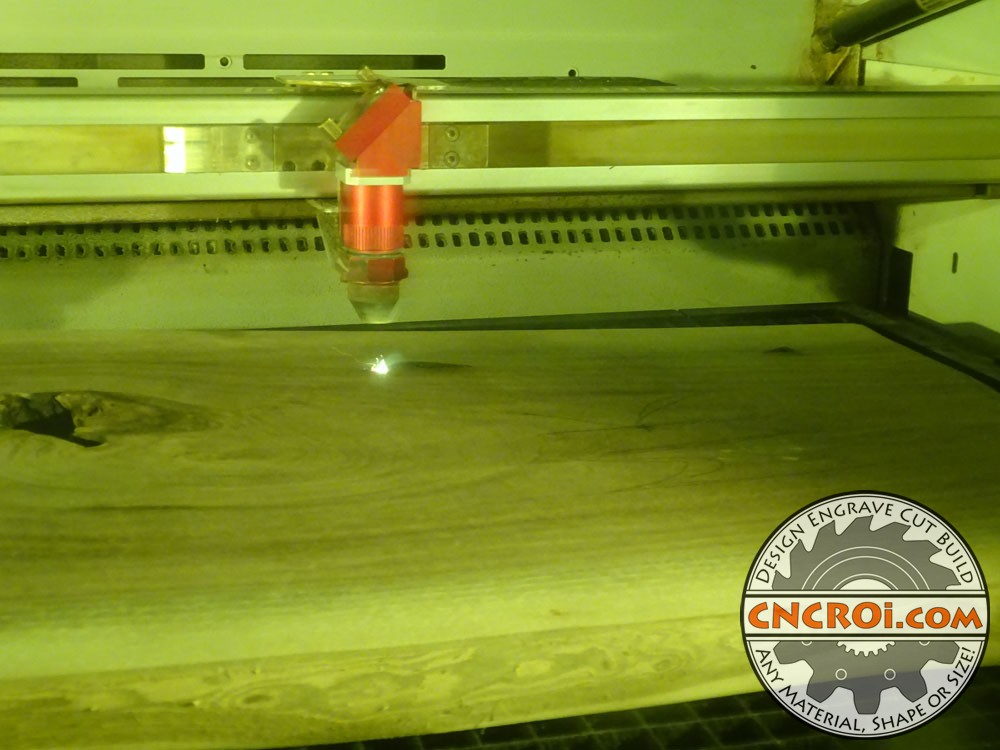

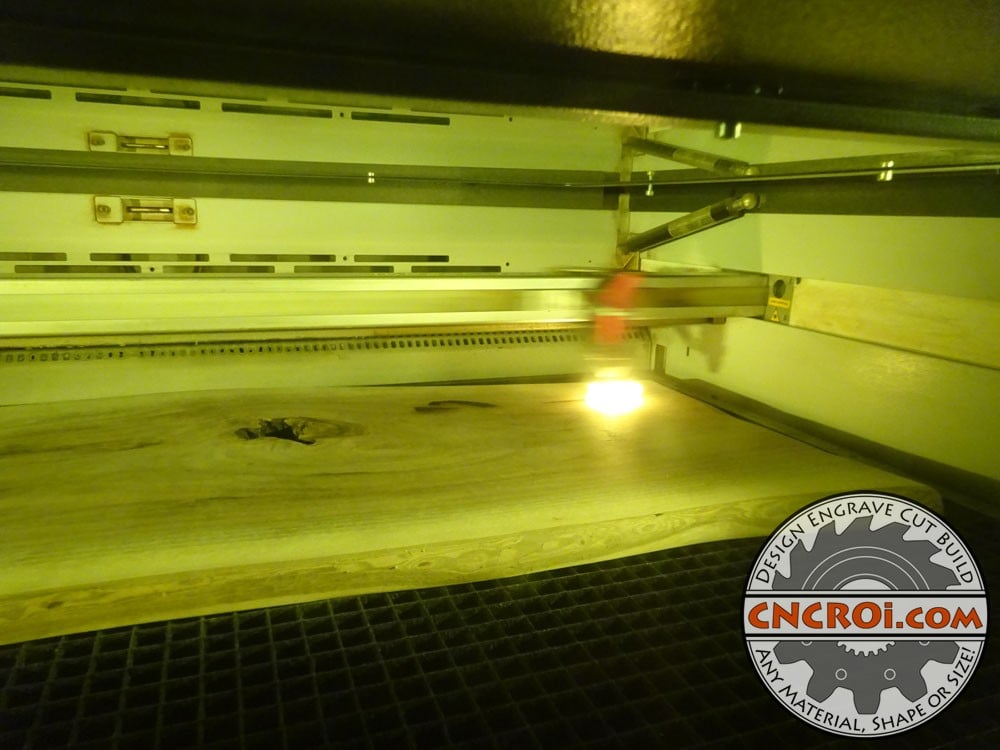

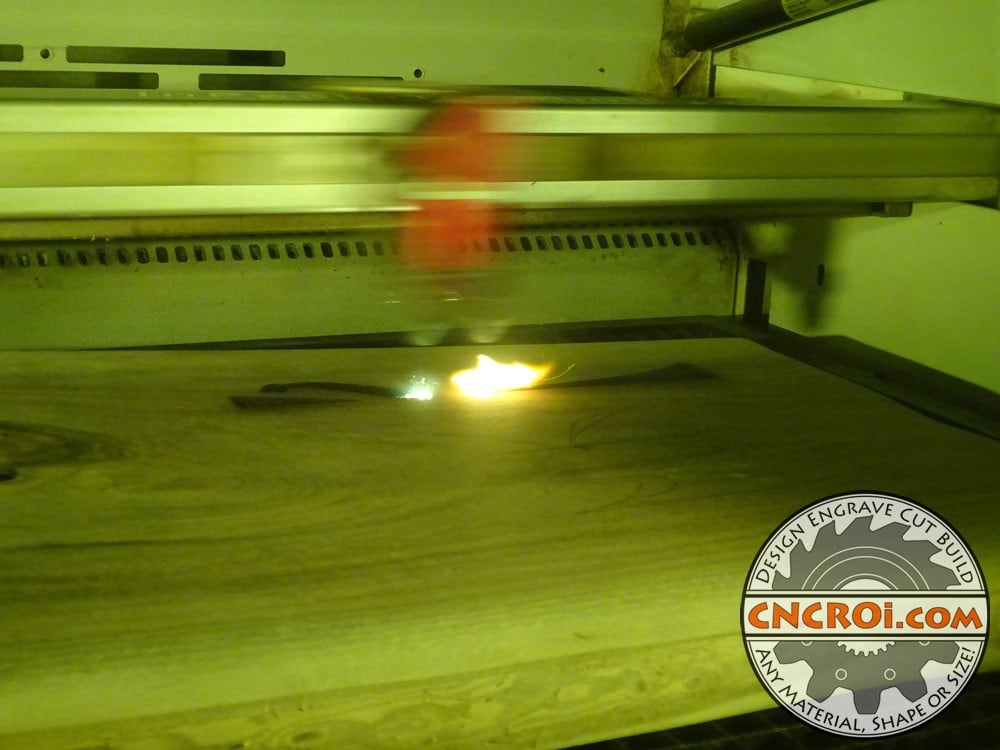

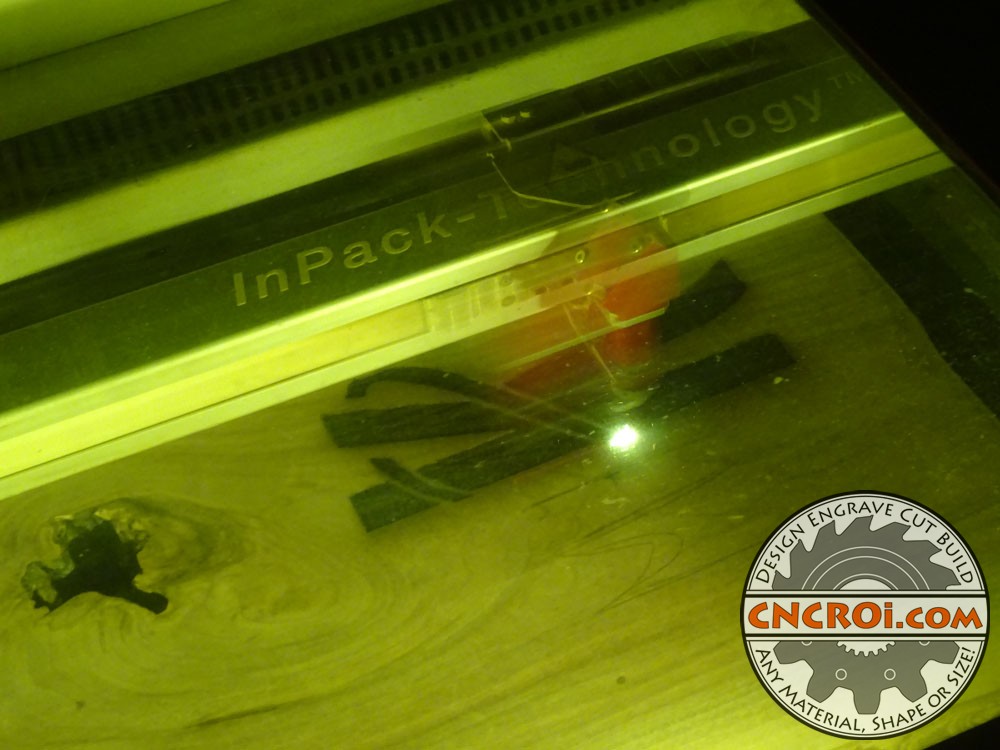

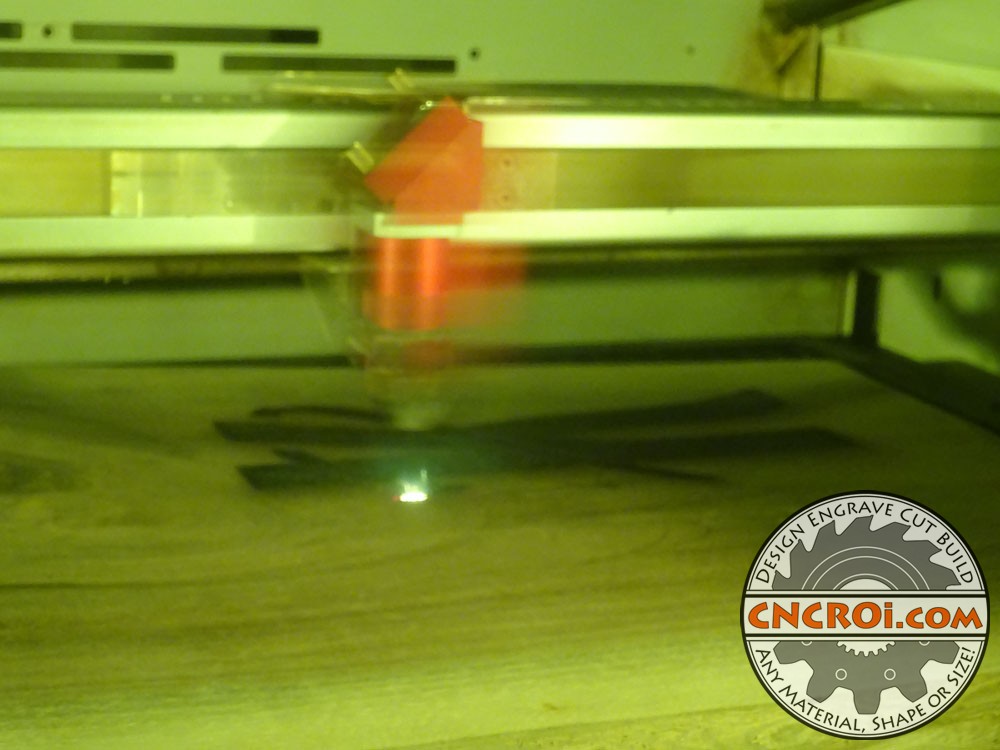

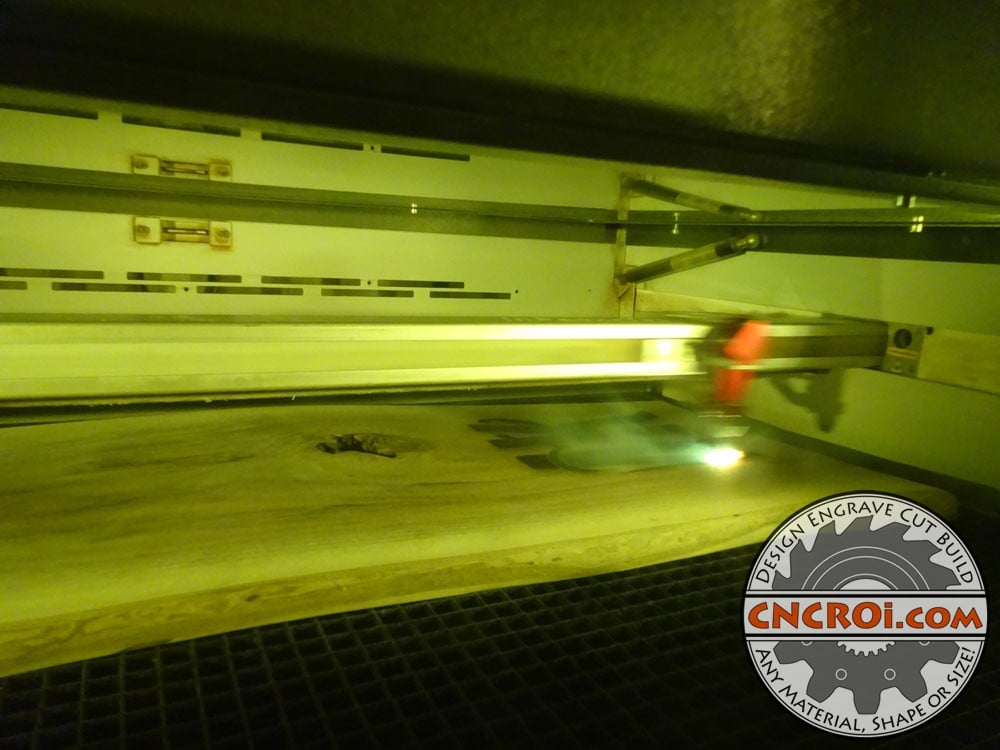

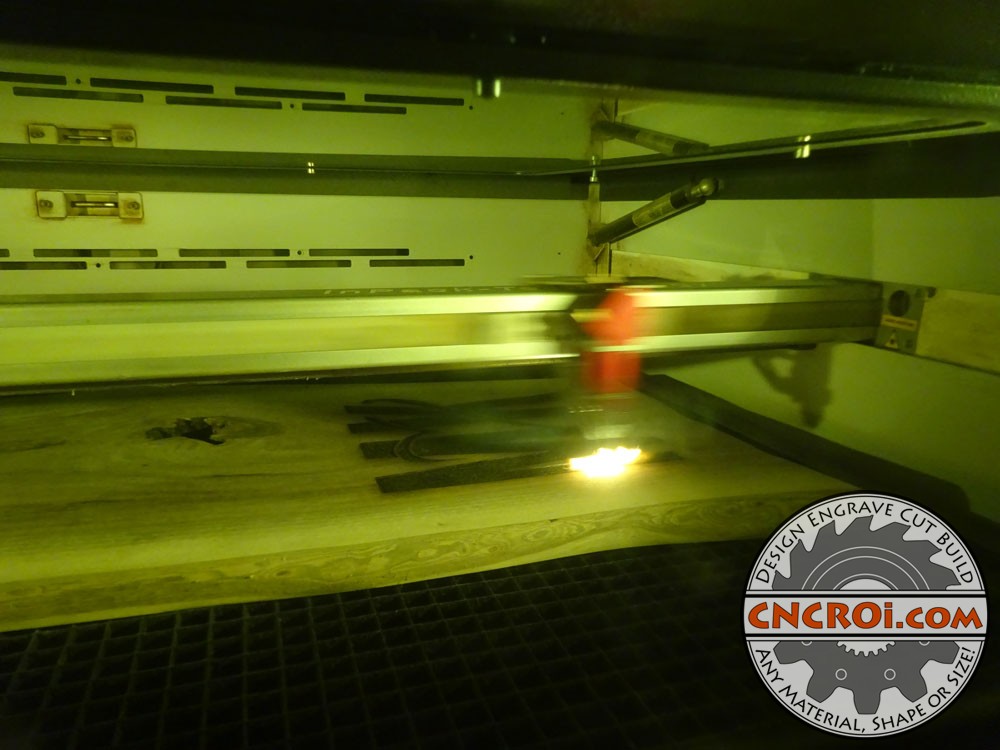

The fire and smoke you see generated under the laser head is instant vaporization of the Black Walnut, it creates both the depth and the contrast at the same time, with multiple passes creating additional depth.

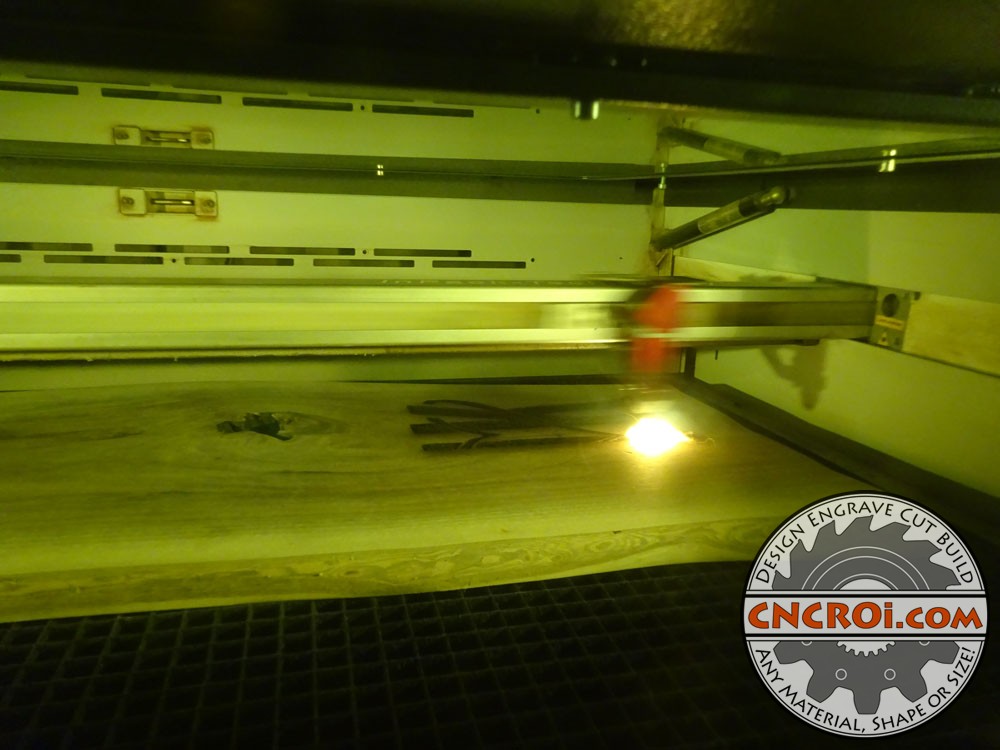

When it comes to larger work using Black Walnut, CNCROi.com has the tools to make it all possible.

https://www.youtube.com/watch?v=vpvcYljzB6U/

When it comes to Black Walnut engraving at CNCROi.com it makes the whole shop smell like a camp fire, which is something I really enjoy, it’s just a wonderful smell compared to some of the other stuff I do in the shop.

Black Walnut engraving is also a non-contact method, meaning there is no need to hold the material down, the major advantage to CNCROi.com and our customers as a result is that it gives us edge to edge branding opportunities, including the edges should you wish to use them.

Black Walnut engraving using CNCROi.com‘s CNC laser is also very precise, this is why we can pass over the same area multiple times and actually HIT THE SAME AREA rather than off a deviation or offset of the engraving itself.

At the front of my house, I made a Black Walnut sign, again, it just shows you how detailed CNCROi.com can go when it comes to engraving quality.

https://www.youtube.com/watch?v=xr_QpXOyCHc/

As for depth, it really depends on the density of the material as to how deep our laser goes, multiple passes create additional depth but we can’t control precisely how deep the laser is going.

This is because there is no two-way depth feedback system, unlike our CNC router, which if you tell it to go 1/8″ or 3 mm deep, it will go PRECISELY that deep.

As a result, it really comes down to operator experience and lots of trial and error through the years to get a depth that looks great and is functional, in this case, for an epoxy fill.

Coat racks are also a wonderful use of Black Walnut, it can be customized endlessly both hardware and engraving wise.

https://www.youtube.com/watch?v=Y-5ndlh72Zk/

Black Walnut engraving is a fun process for me, I don’t know how many thousands of boards I’ve engraved through the years at CNCROi.com but it’s always interesting and fun even to this day.

You will start to notice smoke along the edges of the laser engraving, this is easily sanded, sometimes I mask the wood, other times I don’t, it really makes no real difference to the end-product other than the time used to sand the surface clean.

Some CNCROi.com customers actually prefer the smoky look, we’ve done lots of those too, it gives it a branding iron look.

When it comes to branding iron look, the nice thing about Black Walnut engraving is that no paint is used, so just like branding, the engraving will not peel, crack or fade overtime, maybe fill with dust, but that’s easily blown off.

Wedding plaques using Black Walnut are also a popular option, engraving gives it that ultimate personalization.

https://www.youtube.com/watch?v=Vk5cwg-rJ_8/

The surface characteristics of the Black Walnut engraving is equivalent to maybe 40 grit sand paper, roughly the same as you get walking on the beach barefoot, which is why it’s so fantastic for epoxy fills.

Now that CNCROi.com is finished this Black Walnut engraving, you can get a feel at how sharp everything is.

CNCROi.com can do big pieces of Walnut or little ones, if we can fit it in the machine, we can do the work to make it happen!

https://www.youtube.com/watch?v=LI3_64z9MGc/

A close-up of the Black Walnut engraving shows you how deep it is, roughly 1/8″ or 3 mm, which is plenty for this job specifically but if you wanted deeper, we can do that too.

When it comes to Black Walnut engraving, contact CNCROi.com with your job, we can of course, also provide the wood so it’s a one-way shipment straight to your door.

Need engraving? Contact CNCROi.com right now!

https://www.youtube.com/watch?v=VxWqo03wnYY/