CNC Laser Engraving & Cutting A Custom Paint Filled Mirror

It has probably been close to a year since CNCROi.com did a video showcasing what we can do with engraving and cutting a custom paint filled mirror so it’s time for a long overdue update!

The first step with laser engraving and cutting a custom mirror is placing the acrylic mirror, mirror face down. This is why the protective coating is left on so that no scratches are done throughout the production process, engraving through cutting and paint filling.

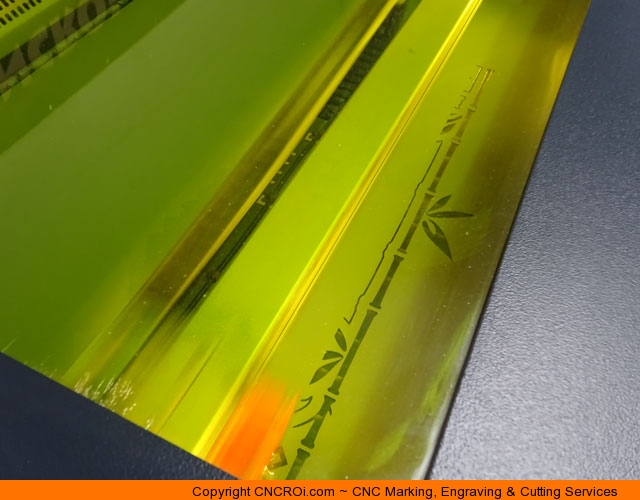

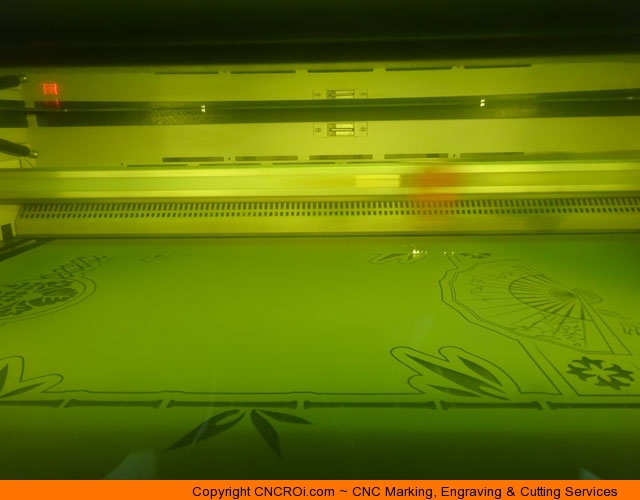

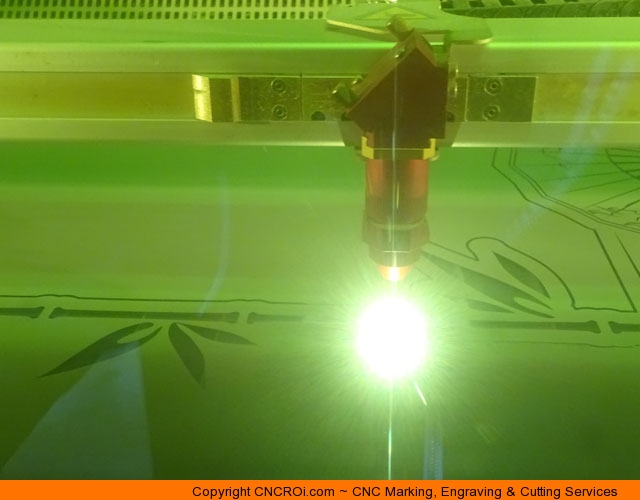

Our industrial wide-format Austrian Trotec Speedy 400 flexx laser is vaporizing off the “mirror” material that’s on the back of the acrylic mirror. The acrylic itself is completely see-through, it’s only this material that prevents you from seeing straight through it.

By vaporizing this mirrored material on the back, we are also creating some engraving depth which will be used for the secondary process in custom mirror production, paint filling. The machine is doing two things at once here, removing material and giving us the opportunity to fill it with paint after!

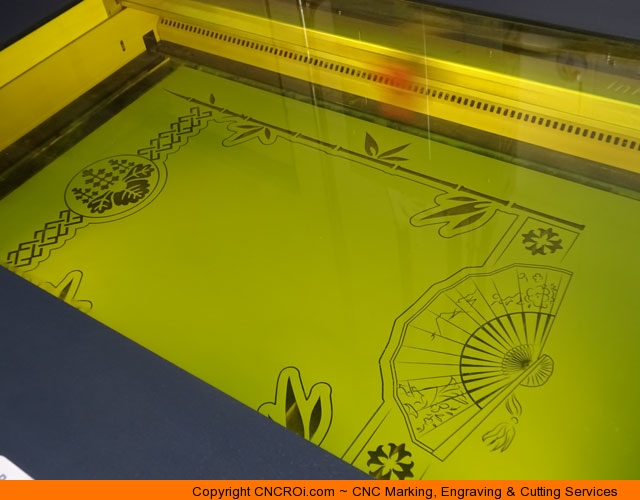

The resolution we can achieve is over a thousand DPI on this material but with paint filling, you won’t notice is so the additional production time required to achieve that high a DPI isn’t a good investment in time or resources. This was done at 500 dpi which is still overkill but hey, if you are going to do something, might as well make it the best it can be!

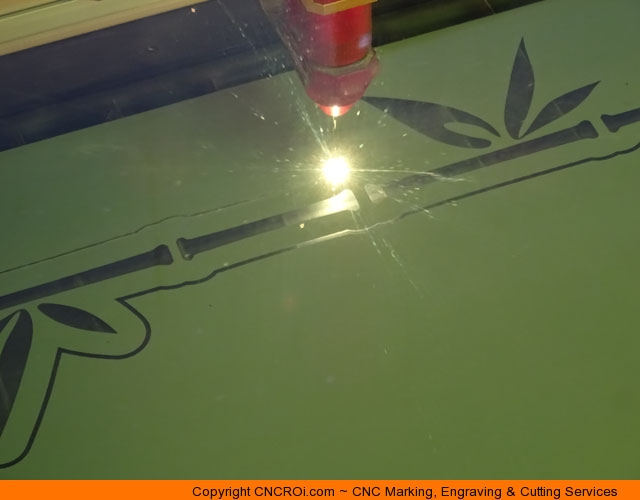

The absolute precision of our CNC laser shows here, the lines are straight, there are no gaps, skipping or other issues that happen with lesser laser systems out there. The depth is consistent because this acrylic mirror material is consistent.

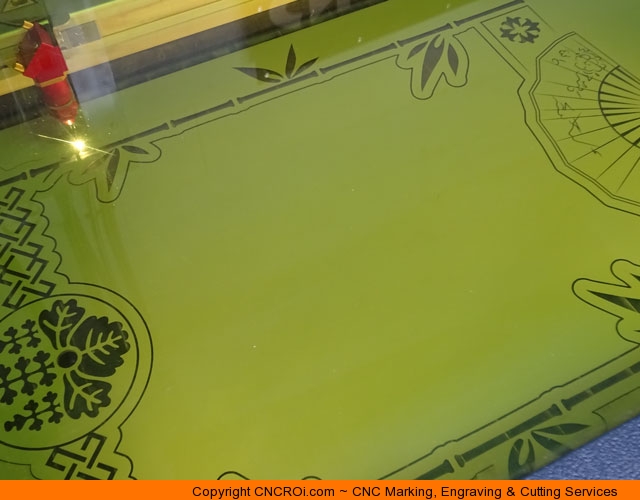

We have a huge CNC laser, if you wanted this mirror to be 3 meters long and a meter wide, we can actually do that! Going back to the project at hand, paint filling can be done in one color or many, in this case, as this is a showcase piece, it will be done using several colors.

The production of these custom acrylic mirrors application wise runs the gamut. For some clients, we make these for their wedding or birthday as gifts while for others, industrial mirrors in bathrooms that are branded with logos (and the shape of logos) is what is done. There is truly an endless variety of options for these, we can of course cut out text using this mirrored acrylic as well!

This mirror measures about 700 mm x 60 mm and what’s really neat is that we can cut out hundreds of these BIGGER or smaller and not lose any resolution, you can have one huge mirror for instance as a showcase and then distribute a bunch of little ones as gifts to clients with your logo and custom branding.

This material is acrylic, so for maintenance, you don’t want to use harsh detergents to clean off finger prints, using a soft cloth like people use to clean glasses and warm water or diluted windex is totally fine. As this is acrylic, we can technically buff out scratches as well.

The intricate details we can achieve are only limited by your imagination, if you are a graphic designer, whatever you make in your software can be applied to making custom mirrors such as these, stamps, stencils and a host of other promotional and functional items. Let your imagination run wild!

We have a powerful CNC laser, that means we are able to cut through this material in one pass, that’s important as this is plastic essentially, you don’t want to put heat on it repeatedly as it melts and deforms. We’ve done A LOT of acrylic work here at CNCROi.com, cutting acrylic from half an inch (12.7 mm) through to one eighth (3 mm).

We aren’t limited by the way to paint filling, depending on application and budget, we can also make inlays within or using this material with any other material, wood through steel for that ultimate totally custom look that gets attention and showcases you and your company in the brightest of lights!

Now the pictures are showcasing our industrial laser finely cutting through the acrylic, we spent all this time engraving off the mirrored material, time to liberate the rest of the mirror from the sheet!

Having something completely custom made for you is easy for CNCROi.com, that’s our business! We do stuff that nobody else wants to touch or can do! We can go as nuts as your budget affords!

Things that affect pricing are material selection, size of the finished project, processes required (sanding through paint filling) and the designing aspect as well. The more your design has in it, the higher the cost of production generally. For instance, for this custom acrylic mirror, if we skipped the paint filling process, the price would be less and just putting a colored board behind it would be visible.

Alternatively, making the mirror smaller would reduce the unit price as will volume. Taking time to set-up one mirror cost more than setting-up a couple of hundred. CNCROi.com is set-up for mass personalization and production.

What that means is that if you wanted to give, for instance, this mirror to select clients and employees, we can customize it with their name or any other information you want using a database – during the laser engraving and cutting process itself! We can go as custom as you want!

You can watch the paint filling process in the video above but here’s what it looks like on the business side, as the mirror backing is opaque, you don’t see all that paint going where no paint filling is required.

The results are nice and sharp, even with the protective mask on the custom paint filled mirror. I left this on because it’s hard to photograph a mirror, this dulling at least makes it easier for the camera to focus on the right parts!

As you can see, this custom laser engraved and cut mirror with paint filling looks AWESOME! Whether you need one or a thousand, we are set-up to handle it professionally, promptly and within budget.

Taking a closer look, the paint comes out clear and consistent, this is because the engraving itself is even and consistent. Using different colors also adds a bit more to the mirror instead of just using one color. Because the paint is on the backside of the mirror, it will never come off during cleaning as you are just cleaning acrylic on the front, not paint.

We can use this process for everything from custom corporate awards through parting gifts and literally, anything in-between. Contact CNCROi.com today to get something awesome done for you or your company today!