CNC Laser Engraving & Cutting a Mirrored Acrylic Cake Topper

CNCROi.com makes custom acrylic cake toppers using a wide variety of materials, from wood to metal and today, mirrored acrylic.

Each material has a plus and minus to it across a host of applications and mirrored acrylic is no different when it comes to custom cake toppers.

The nice thing about wood custom cake toppers is that you have a built-in contrast from the burning of the lettering and outline, this makes it really pop compared to other materials like acrylic cake toppers where it’s best to paint fill or color change.

When it comes to custom acrylic cake toppers out of mirrored acrylic though, you have a built-in contrast just from the non-mirror that’s burned in the back and if you wanted even more contrast, this could be paint filled as well.

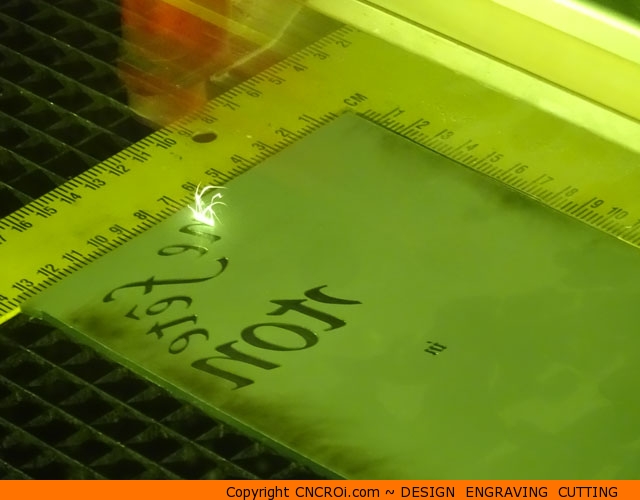

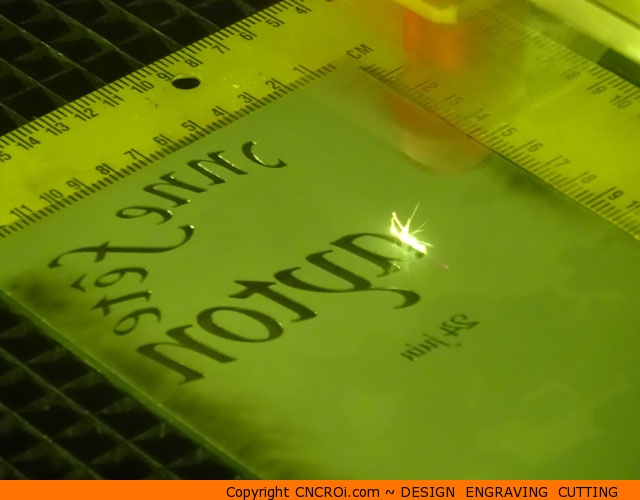

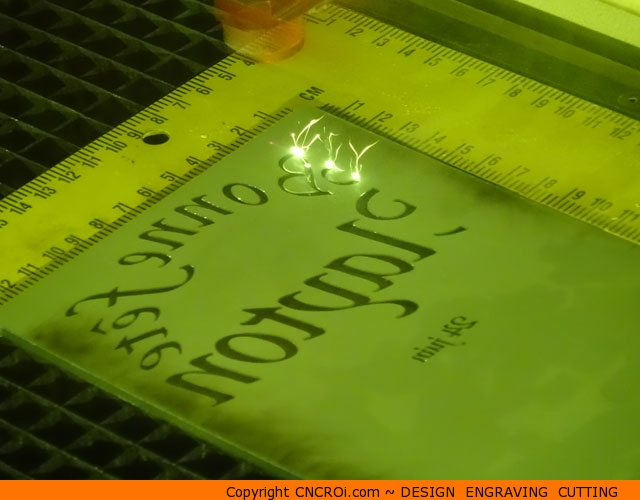

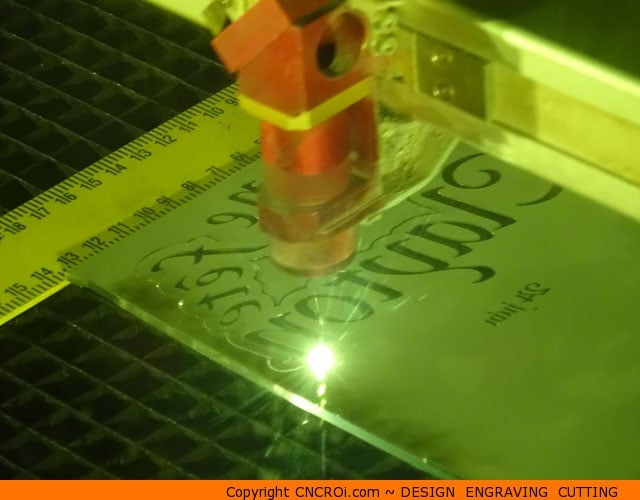

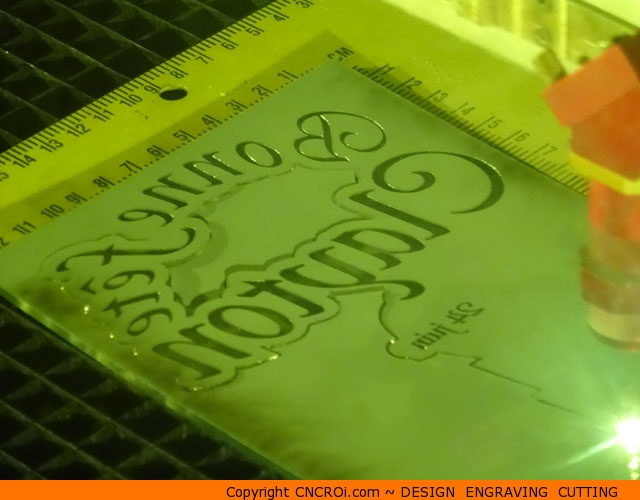

In these photos, you are seeing the underside of the mirror being vaporized, which causes sparks and flames to occur, these don’t damage the mirror in any way, it just removed the coating in the back of the mirror and engraves a bit of depth into the clear acrylic under it.

For this custom acrylic cake topper, mirrored acrylic was made to enhance the “wow” factor, regardless of material, all our custom cake toppers look great but mirror only works in some environments. If this is for outdoor use, it isn’t a good idea but indoors where you can control the lighting level, it’s a fantastic way to top a cake.

Where wood tends to absorb the icing and liquids from the cake it’s put on, custom cake toppers made out of mirrored acrylic don’t have that issue though they are fragile, so you must still take care, especially for very thin or highly detailed custom acrylic cake toppers.

These custom acrylic cake toppers made out of mirrored acrylic are great for a wide variety of purposes and applications, from replacing mirrors in environments where you don’t want shards of glass all over the floor if it breaks to lightweight applications such as in a boat. As it’s acrylic, it is more fragile in some environments than others.

After the custom acrylic cake topper is engraved, it’s time to cut it out, the edge quality is perfectly flame polished as a result, yet another contrasting feature of many other materials, it gives it a bit more of an edge-on shine as light refracts through the edge.

The bright intense light you see coming from our industrial dual-sourced Austrian laser is from the CO2 laser tube vaporizing, almost on the spot, the acrylic. The smoke generated goes through our extraction system as otherwise, the fumes would quickly take over the shop.

This is a relatively simple custom acrylic cake topper, the sizing, shape, names, details on these are infinite, and we can also do inlays of several different types of materials as well, so if you wanted a custom cake topper out of wood with mirrored names and paint filled dates, that’s totally possible too!

The inside is cut out of the custom acrylic cake topper before the outside to make sure nothing moves, the longer everything is part of a larger sheet, the higher the final accuracy.

Now that the custom acrylic cake topper is finished, you can already see the flame polished edge, what was engraved on the back (reverse) and the overall outline of the topper.

Here is what the front looks like, still with masking on the custom cake topper to protect it during shipping.

Once the custom cake topper mask is removed, you can see how brilliant and clear the surface of the mirror is, it’s a perfect mirror!

Looking at the edge now, you can see how the light refracts through the various flame polished edges.

No matter what angle you look at this custom acrylic cake topper, it looks great and we make them on-demand realtime for our customers!

Taking a look at it closer, you can see that adding a paint fill to the back isn’t a bad idea, increasing the contrast only affects the area engraved so your color options are endless.

Needing a custom personalized high-quality custom cake topper for your birthday, wedding or corporate event? Contact CNCROi.com right now!