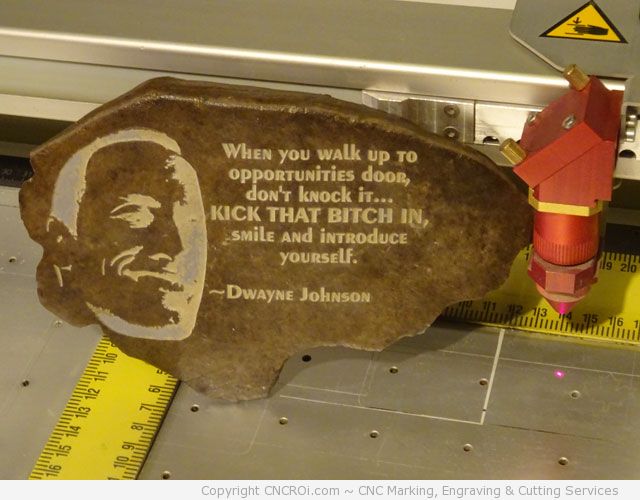

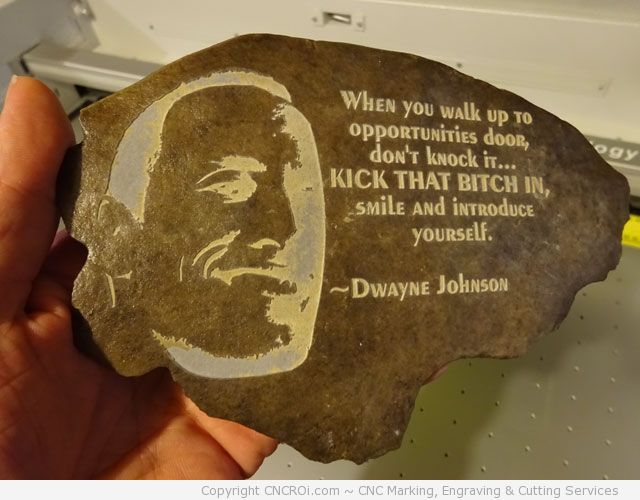

CNC Laser Engraving Dwayne “The Rock” Johnson on a Rock

I had a rock that needed something neat on it so I decided to CNC laser engrave Dwayne “The Rock” Johnson onto it with one of his motivational sayings “When you walk up to opportunities door, don’t knock it… KICK THAT BITCH IN, smile and introduce yourself.”

CNCROi.com has done a lot of aggregate of all types from granite to slate, brick to field stones… we’ve even done some man-made “rocks” that were made out of an industrial plastic (without melting it) for one of our customers!

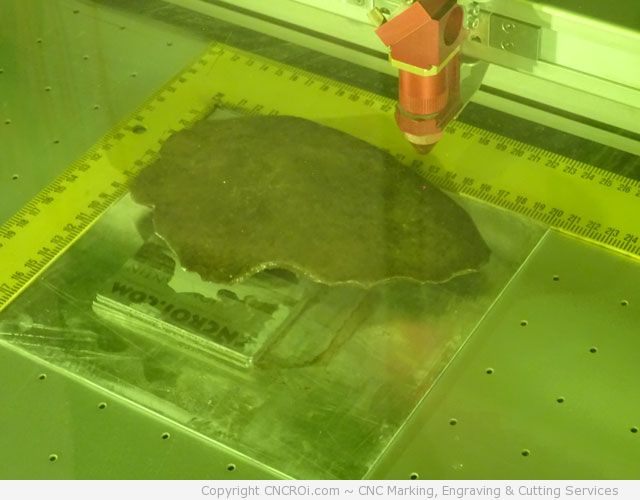

Although not necessary, the stone was sealed before engraving to increase the contrast – it looks “wet and shiny” with the sealant rather than dull. This was done in several “passes” as the rock absorbed the sealant in multiple coats.

This isn’t any special stone, just something picked-up during a hiking trip. The challenge with stone is that it’s rarely FLAT which means the laser goes in and out of focus but due to the high power requirements to actually engrave INTO stone, this is somewhat offset.

Regardless of the type of rock or stone put under the laser, the settings are pretty much the same, it’s a very slow process even with our 110W CO2 tube found on our industrial wide format CNC laser. Take a look at the stainless steel business card (scrap) under the stone propping it up, you’ll see more and more soot build-up onto it. That would be dramatically more if it wasn’t for our powerful extraction and gas kit.

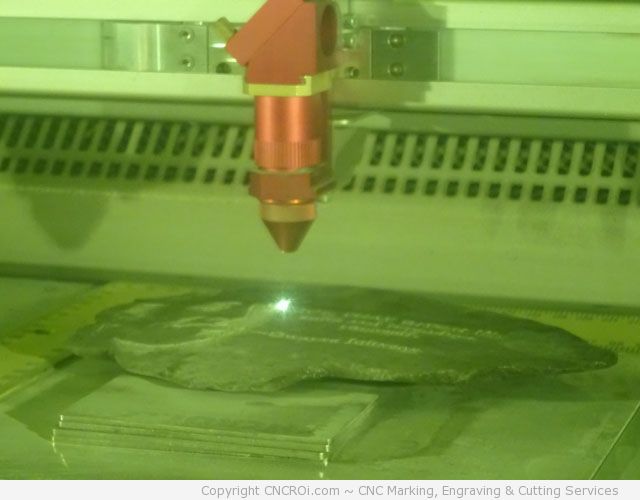

Looking at it from a different angle, you can see we have plenty of clearance on this rock. The brightness from the laser vaporizing the aggregate is almost blinding by the way, there is A LOT of power going into this, even more than what we use to anneal our stainless steel tags! As for depth, you are looking at almost a mm… if deeper is needed, we can do multiple passes.

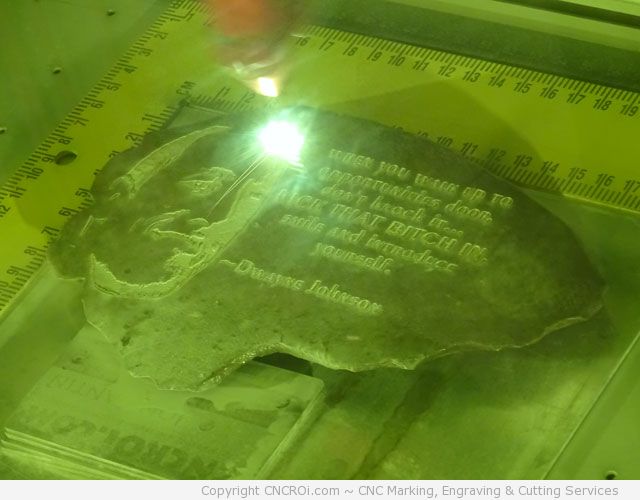

The rock engraving could have been slightly better centered, working on awkward pieces like this with many variables to track means sometimes something is forgotten and of course, it will be when doing a blog post to show potential customers and suppliers!

As this is rock and all that dust is bits of vaporized rock, it’s easily cleaned under running water, unlike wood which has resins or glues (plywood). This rock will now have Dwayne’s saying for the rest of human civilization but for now, it will find a new home in my sample case.

As you can see, after a quick clean, the results look fantastic. The yellowing you see in the face mostly is due to the laser getting through one layer of rock but not another, if I were to do this project again, I’d go over it again with a secondary pass to vaporize straight through to the “bed rock” of the stone.

CNC laser engraving rock, stone, marble, pebbles… even bricks, is just about the only way to leave a permanent mark on them. A CNC router produces lots of chattering around the edges due to it being a round bit, a problem we don’t have with laser technology. If I wanted to seal this once more, that wouldn’t be a problem but I like the feel of the gritty rock compared to the now smooth sealed stone.

If you are looking for an awesome CNC laser company, you’ve found us. Contact CNCROi.com today!