CNC Plasma Dross: 304SS Test Plate Cutting Optimization

CNC plasma dross and slag is just a part of life when it comes to cutting metal, especially stainless steel, but as I keep playing around with my CNC plasma cutter, I’m learning through trial and error how to produce the best parts possible.

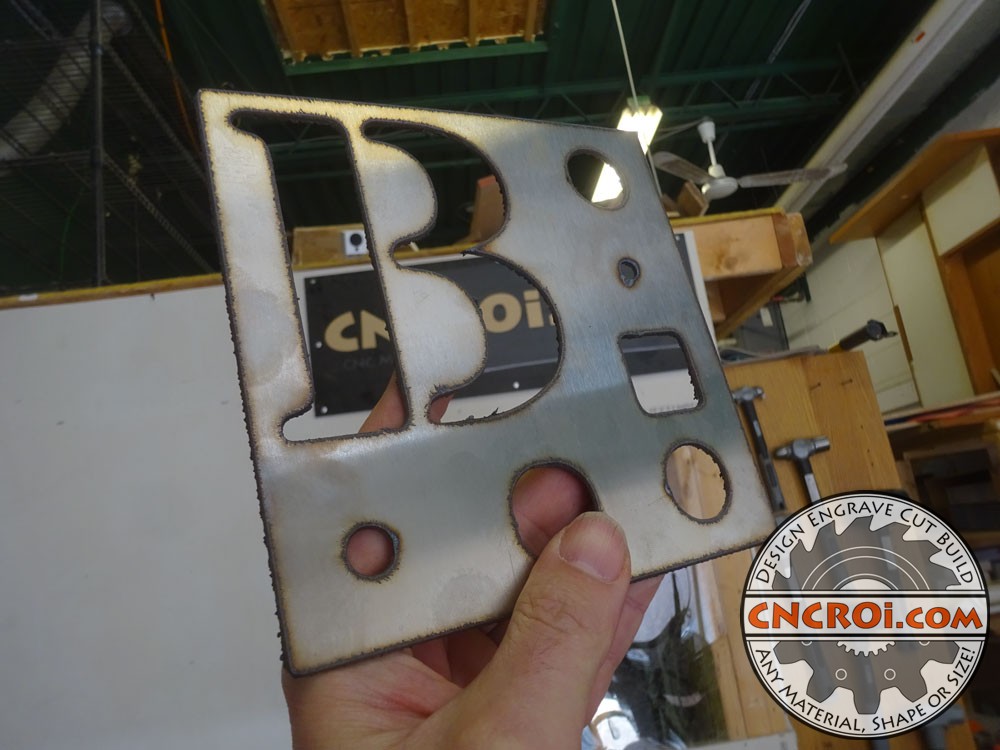

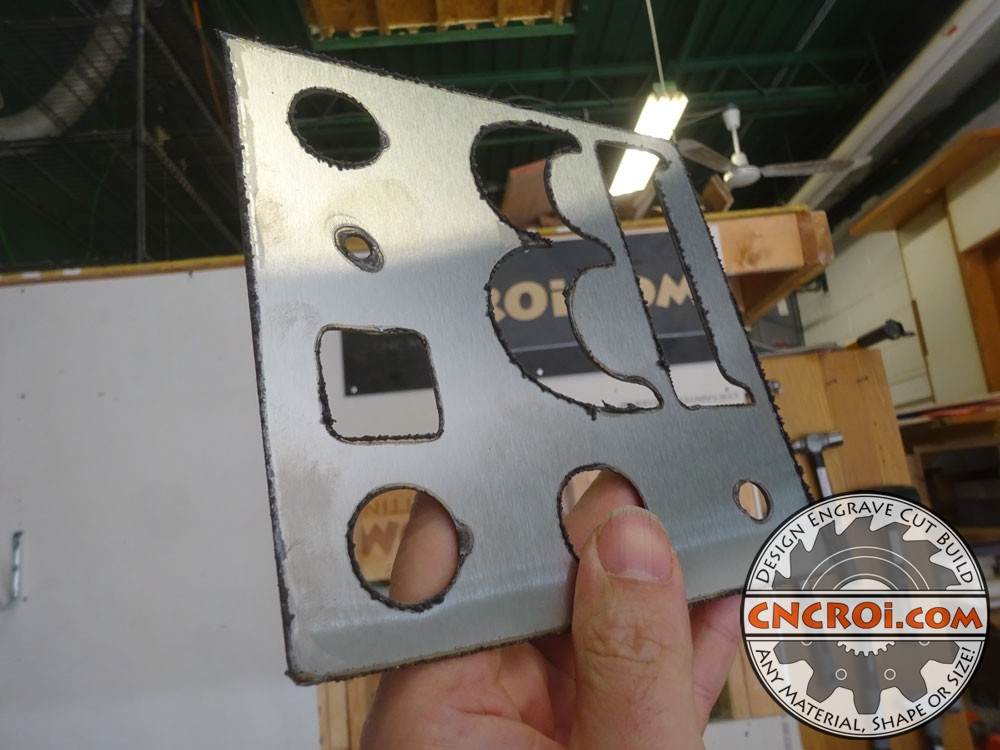

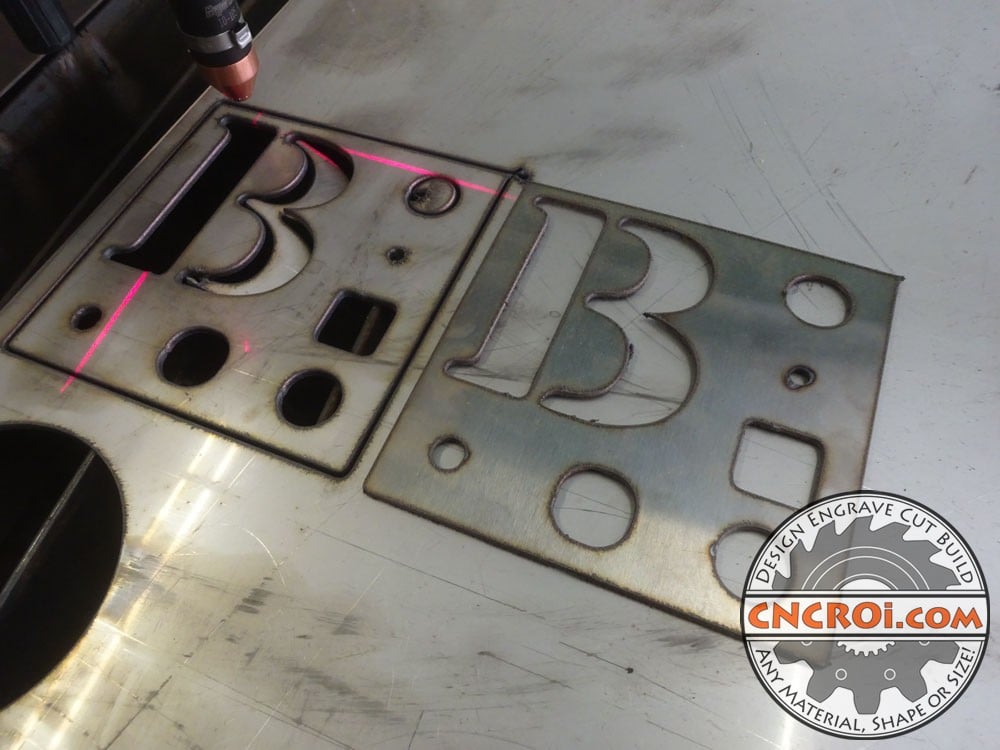

So just to show you an extreme example, you have a thicker part with almost zero dross on the bottom (a little on top) compared to one half as thick with wicked more dross and slag build-up on both the top and bottom using my test plates which I use to optimize my cutting settings.

Of course, this is a rough test, once I got my settings down with the 1/16″ 1.5 mm thick 304 stainless steel, it will produce a finish just as good as the thicker version but I figured it’s a great example showing an extreme of what some of the issues I have to fix-up and optimize when it comes to CNC plasma cutting.

So how does cutting metal using our plasma cutter compare to cutting, let’s say, plastic with our CNC laser?

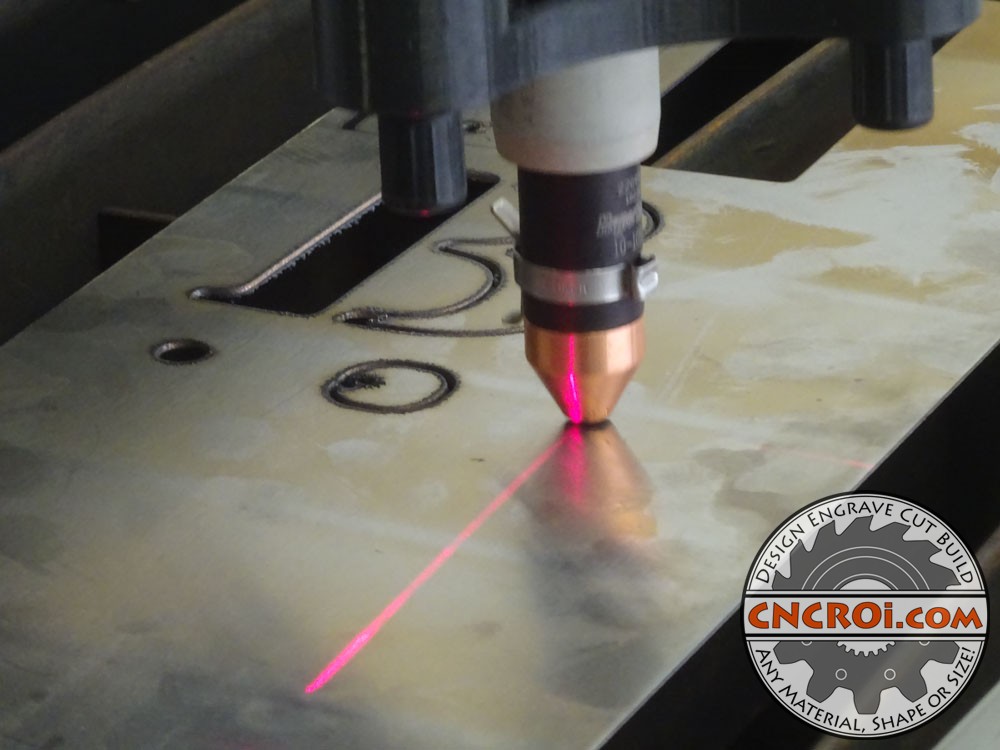

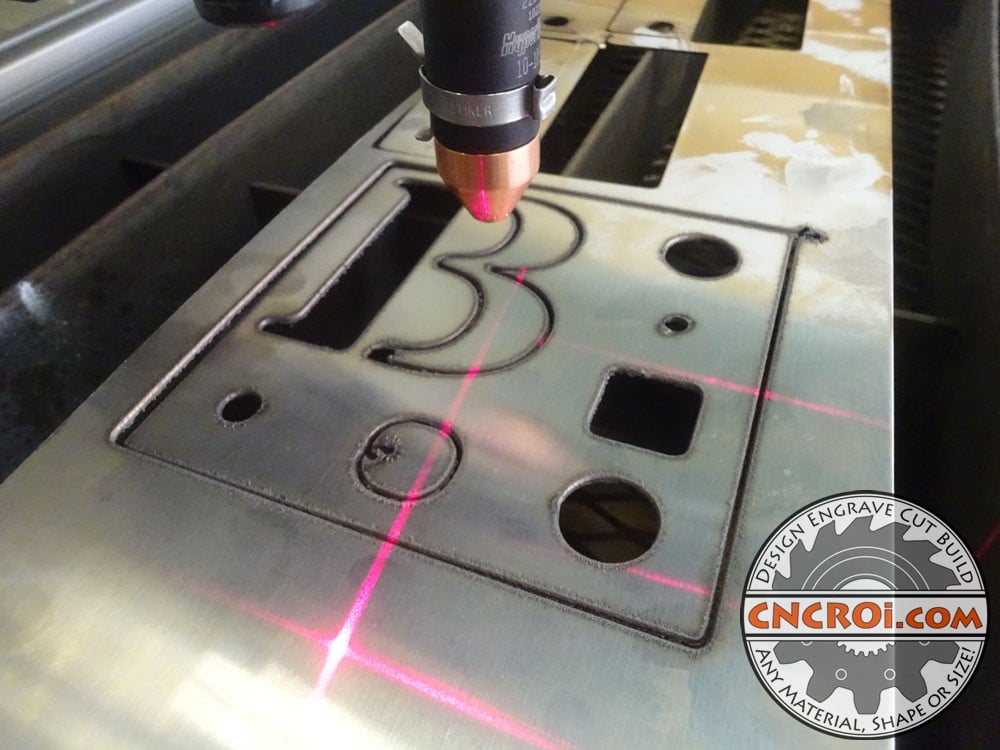

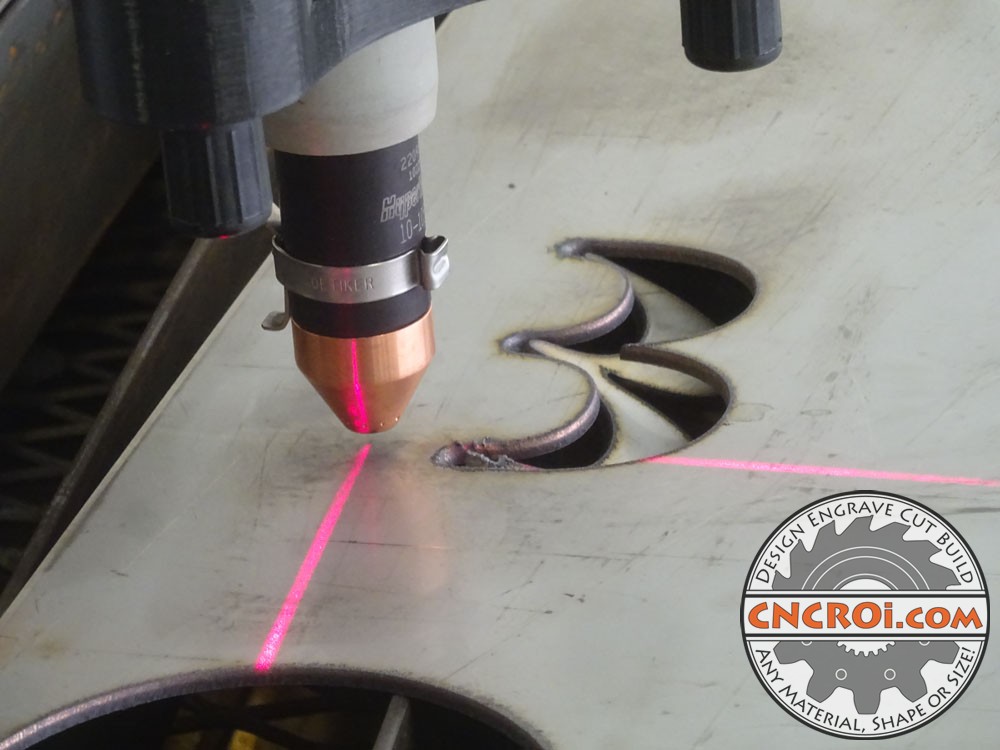

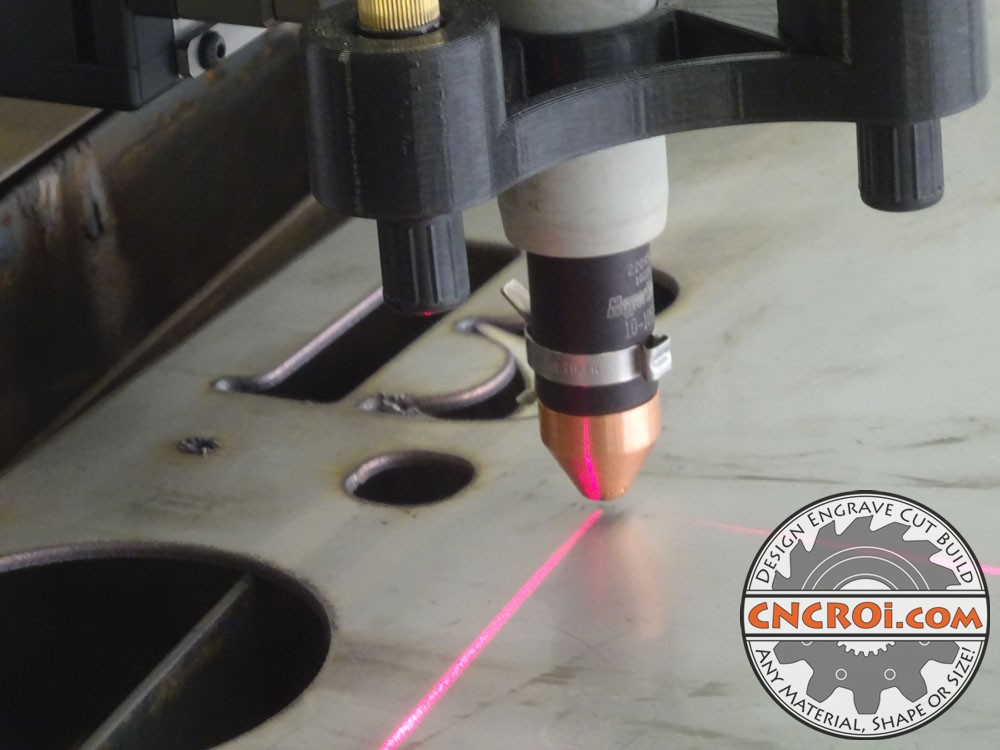

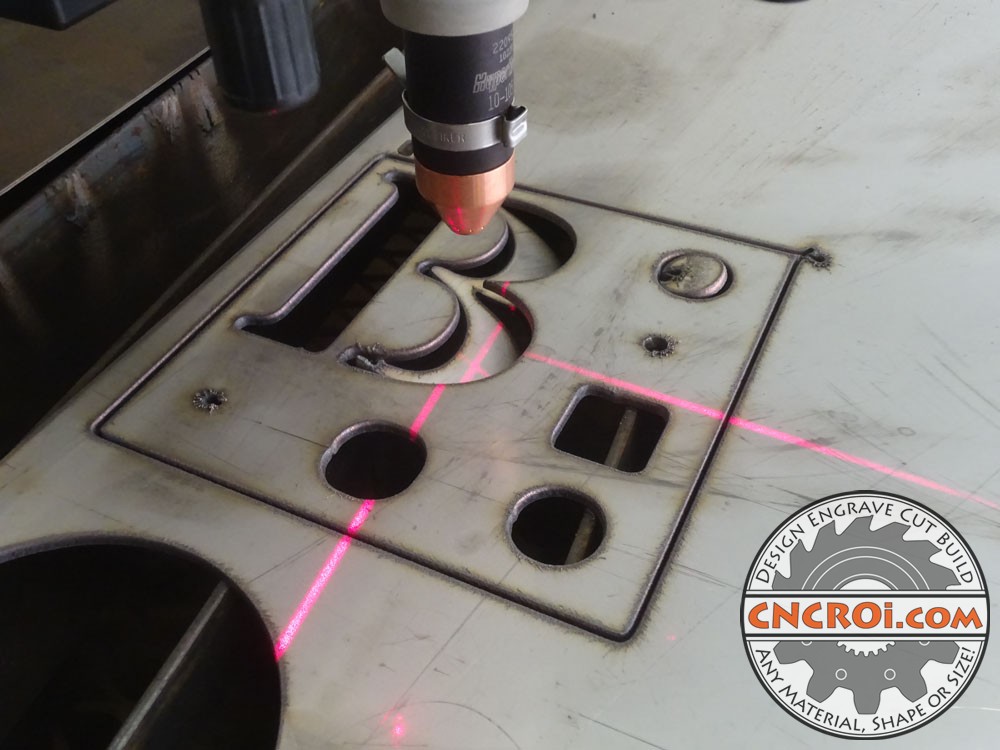

Just a few days ago, to help me with a big job I have coming-up, I added laser cross-hairs to my CNC plasma cutter, it does wonder but this solution does have many areas to be improved upon which I plan to do once I’m done my big contract but for now, it’s an OK solution.

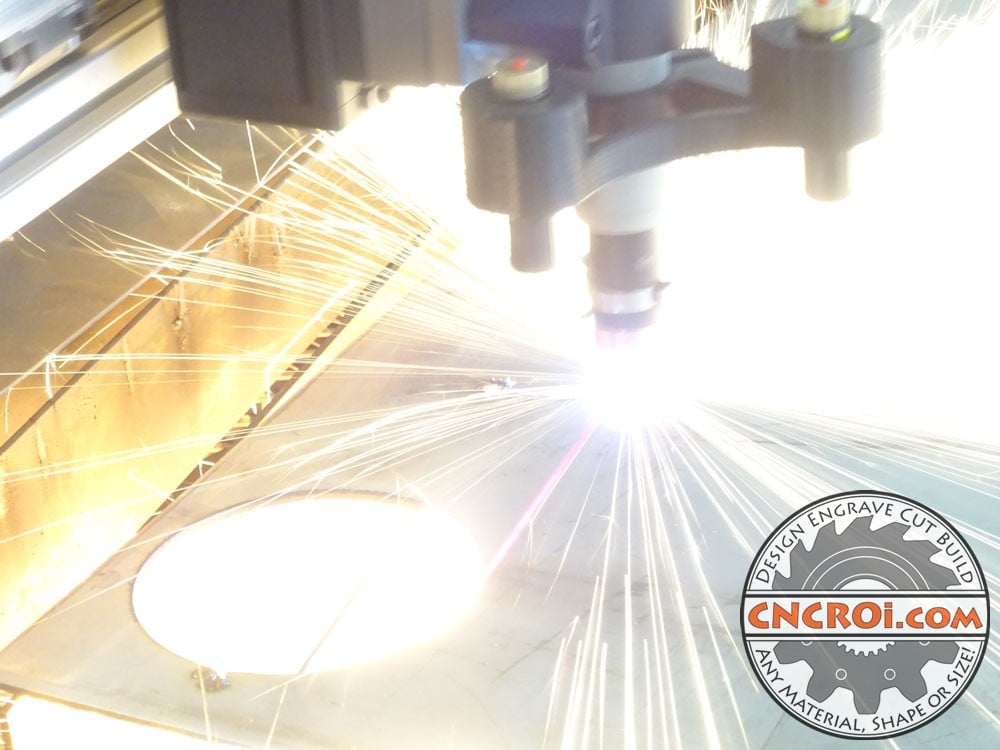

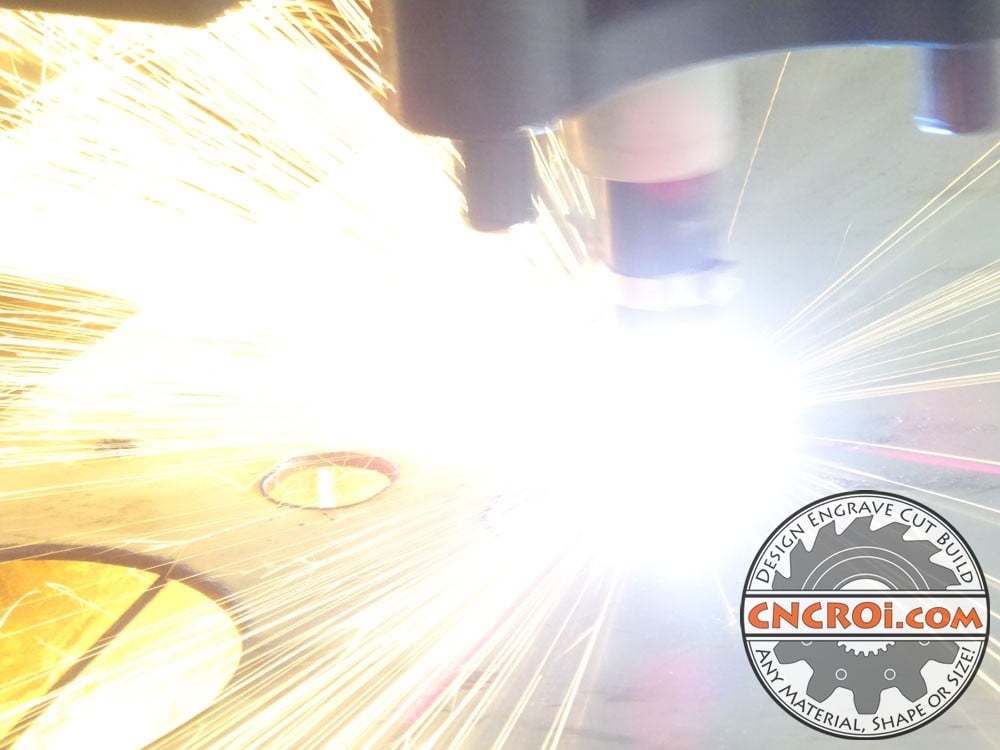

I have to admit, out of all the machines and processes I have in the shop, the photography for the CNC plasma cutter really does rule them all, I certainly never produce sparks this big with my laser cutter!

What I’ve come to truly love with my CNC plasma cutter is the incredible speed it has when it comes to cutting metal of all types compared to manual processes like drills and hole saws, yes, at CNCROi.com, I’ve used them all when the application didn’t warrant CNC waterjet cutting.

So how does CNC plasma cutting compare to the process of CNC waterjet cutting?

For this job specifically, CNC plasma dross and slag was the focus, I got my settings almost down on the 1/8″ stainless steel and before I optimize them for the 1/16″, I thought I’d cut out another test plate as/is and see how much of a difference using the wrong settings does.

You’ll notice this thinner piece of 1/16″ 1.5 mm 304 stainless steel has an extreme amount of CNC plasma dross and slag front and back, it’s pretty hard in there too, which is counter-intuitive because you’d think using settings way too high would produce a better cut as metal is vaporized whether it’s thin or thick but nope, just more melted metal.

So, let’s cut the same design, same settings, using 1/8″ 3 mm 304 stainless steel, which is the metal I’ve optimized these settings at originally and compare the two.

Although other materials can be cut using our CNC plasma cutter, it’s really best focused entirely on metals which can then be fiber laser etched with additional details and information!

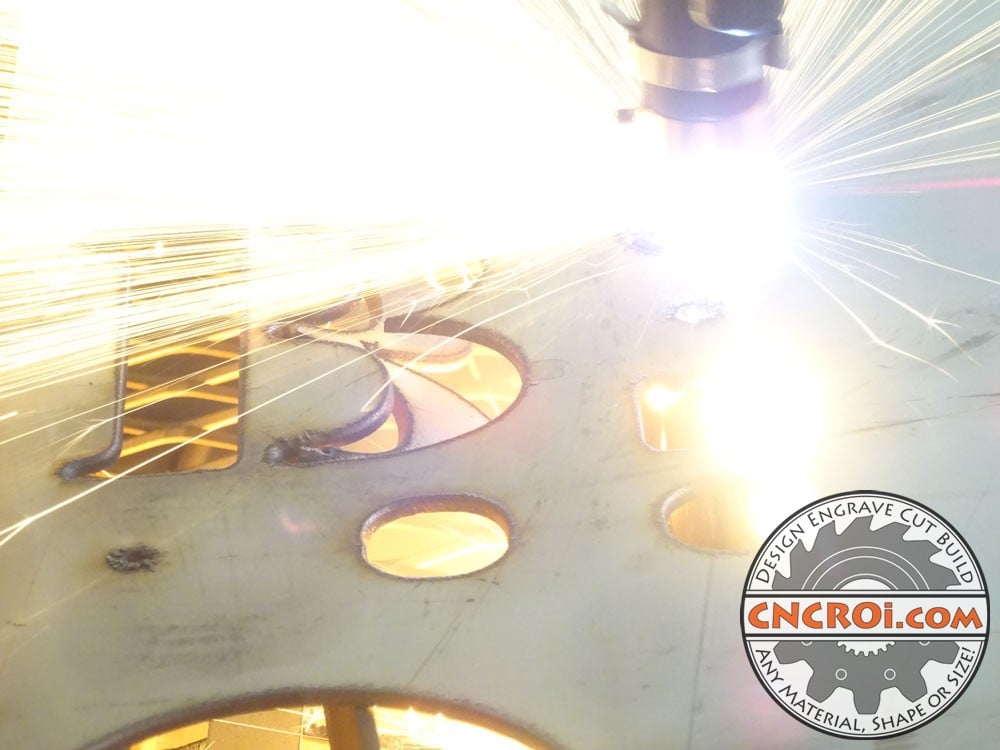

You an already see, no change in spark production really at CNCROi.com, but the surface finish is WAY better and what you don’t see is the underside has literally nothing.

I’m really digging the photos I’m making with the plasma, more than half come-out over-exposed or junk but those that do work, come out great, below you can see CNC plasma dross and slag being produced realtime, though, only a small amount of it.

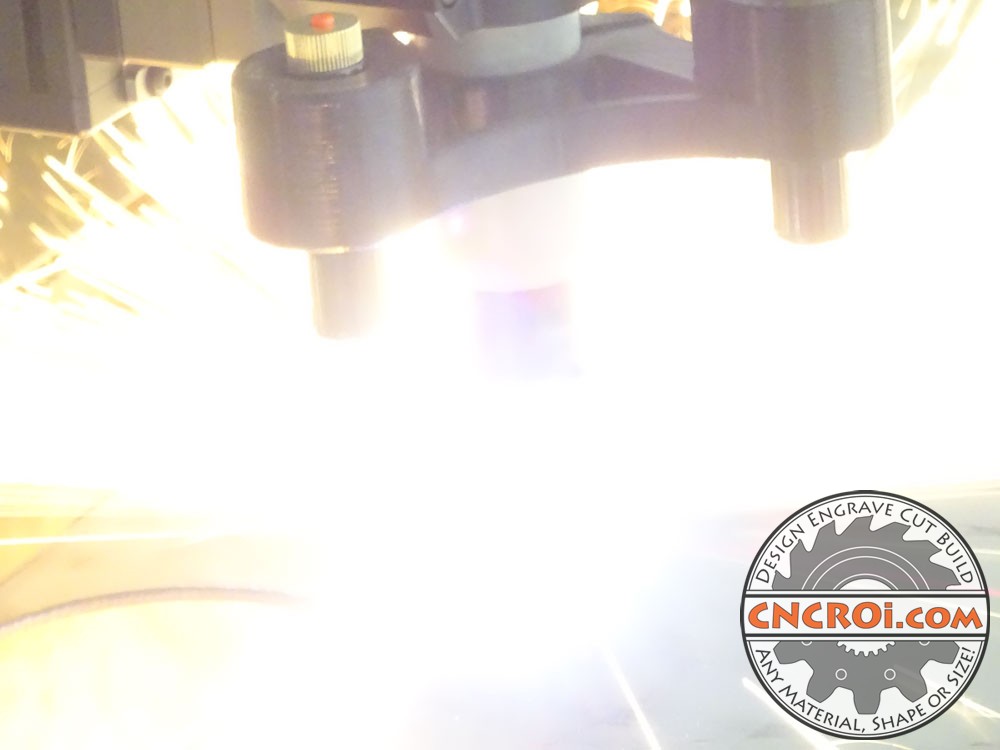

And below is how most of my photos come out as at CNCROi.com when it comes to cutting metal and trying to photograph it at the same time using my camera.

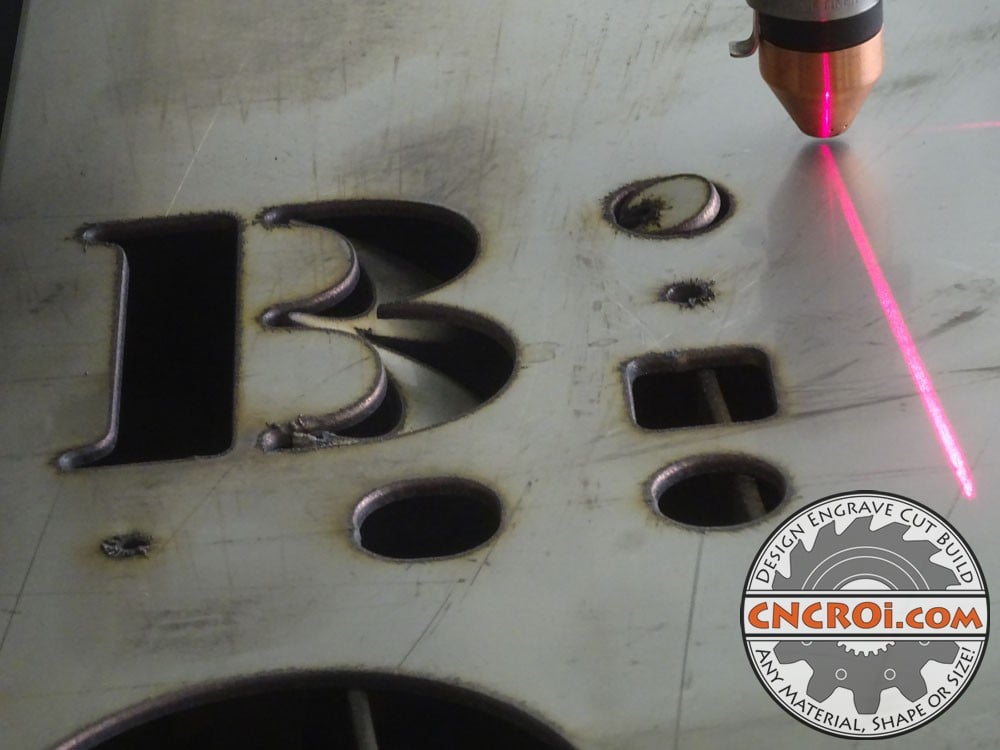

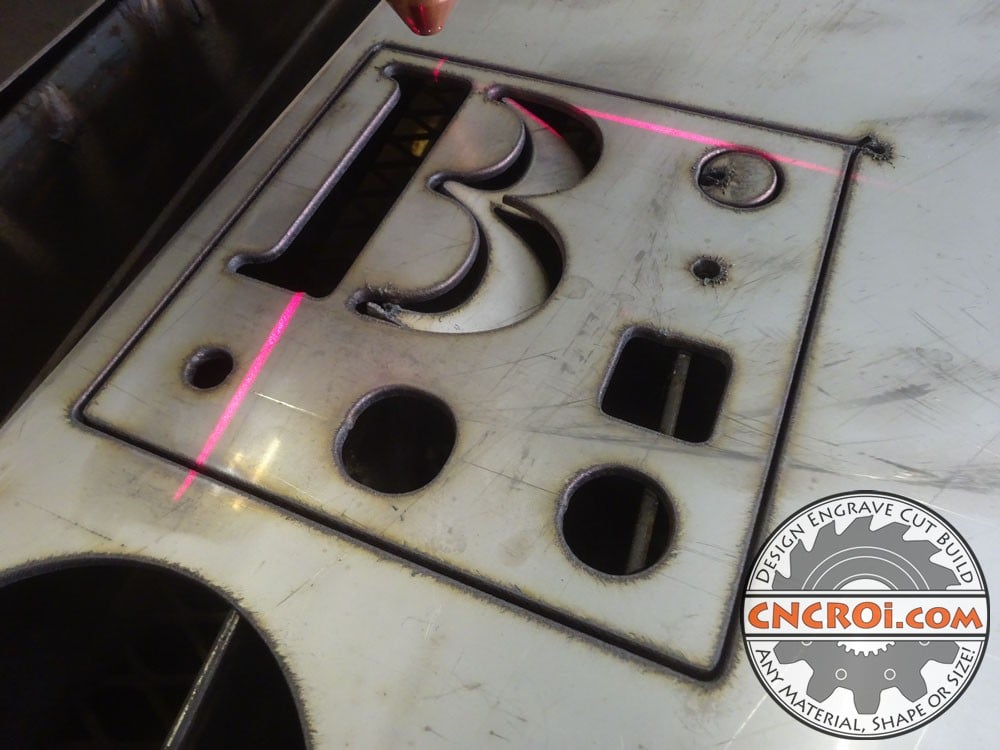

Just looking at the surface, CNC plasma dross and slag is almost non-existent, and better yet, what is there, just flakes right off with your finger, not like that 1/16″ 1.5 mm thick stuff produced earlier on the test plate that’s almost welded on.

There is an amazing synergy that comes from having multiple CNC machine types under one roof, CNCROi.com can pick and choose which processes will produce the best results.

The temperature of the plasma is hotter than the Sun, so it cuts through metal like a molten knife through butter, it’s ridiculous just how well CNCROi.com‘s plasma cutter cuts though even the hardest material at lightning speed.

You’ll notice that while I’m making some CNC plasma dross and slag, some parts move and others don’t, that’s because there is a grid underneath where sometimes the parts hang onto it or get welded on while other times, they just drop down onto the under table.

Where does all the CNC plasma dross and slag that doesn’t stick to the parts being cut go? Well, it’s mostly vaporized and whatever solidifies, just drops down, under the under table, there is the extraction system.

You’ll notice in the above photo while I was making some CNC plasma dross and slag, there was a misfire on the bottom left, it pieced the metal but didn’t cut the relevant hole, no big deal, I just passed over it again and it cut it out afterwards.

If you are wondering out laser differentiates itself from waterjet cutting, now that you are an expert in plasma, here’s a great video that goes more in-depth.

Some more awesome shots at CNCROi.com making some CNC plasma dross and slag, when I’m cutting this, I can’t actually SEE this clearly because of the UV rays shooting out along with the sparks, I got to wear a welding hood as otherwise this light is just like welding, it’s blinding and dangerous.

You’ll see the misfire on the bottom of the photo, left side, the B got slightly welded in place and the circle just hung-out there, everything was easily fixed and it had no bearing on the CNC plasma dross and slag production.

You can now see in the image below, the properly cut hole, I didn’t notice this until after it cut out the outline, which is why it’s important to have two paths and a break in between just in case the plate moves, no different a process than the other machines at CNCROi.com.

Here’s a comparison of the same settings using the two plates at CNCROi.com, side by side, now you know why I choose a B for the letter, then I know which side is up!

Applications, well, I’ll be making some metal signage, metal house number signs, metal coasters and a wack load more stuff using CNCROi.com‘s new CNC plasma cutter but this is a wonderful introduction and first blog post focused entirely on the biggest issue with CNC plasma cutting, dross and slag production.