Custom 316SS Machine Plate: Fiber Etching

Fiber laser etching a custom 316 stainless steel machine plate is something CNCROi.com has been doing for years, generally in much larger volumes than one-offs BUT with that, we’ve made stock thus even if a customer only wants one, we can make it cost-effectively and with very fast turnaround.

https://www.youtube.com/watch?v=ttptMJH8h2Q/settings

The massive advantage that CNCROi.com has is that we are material and process agnostic, meaning, you aren’t pigeon holed into modifying your specs to be towards something we want rather than what you want.

As such, any gauge (thickness), or metal spec you require, CNCROi.com can cut and make what you need in any volume you want for your custom 316 stainless steel machine plate or preferably, many many plates!

So if you want 5 different tags at 5 different sizes using 316 stainless steel at 3 gauge (quarter inch) and a bunch more at 11 gauge (1/8″) then that’s no problem for CNCROi.com and quite frankly, a lot of our jobs are like this.

To get an idea of what can be made by CNCROi.com, here’s a quick little job we did using anodized aluminium and fiber laser cutting.

https://www.youtube.com/watch?v=DMCVOf9IXqQ/settings

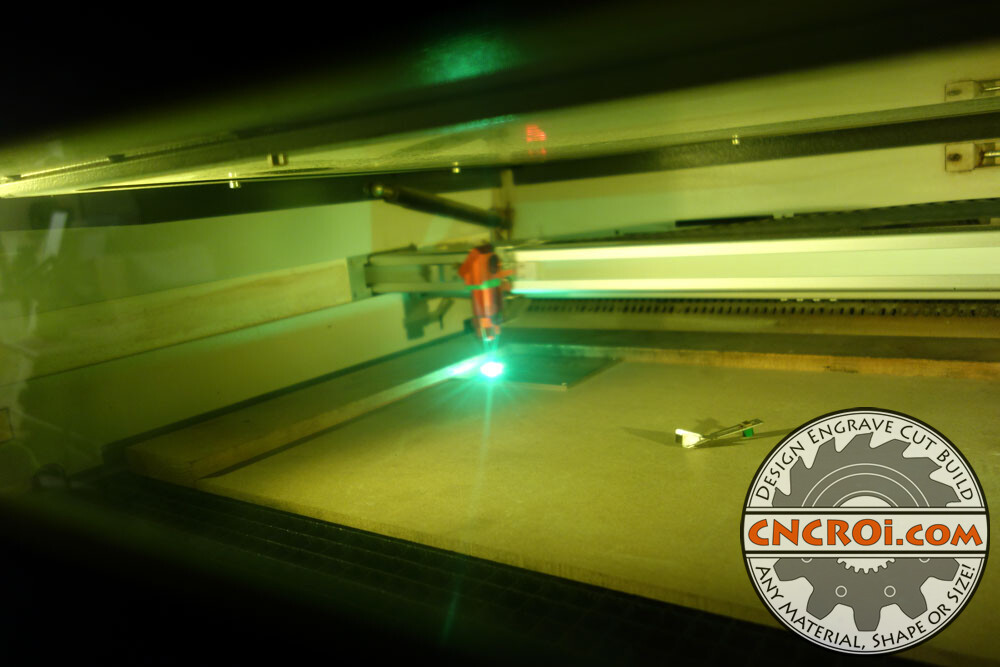

For this specific custom 316 stainless steel machine plate, the customer only needed one and needed it within a day, although CNCROi.com could have cut this using a variety of materials at our shop but for speed and the spec they had in mind, it pretty much matched our stock 4″ x 5″ plates which we use for a variety of on-demand requirements from a few regular customers.

Whether you want to have a custom 316 stainless steel machine plate that’s with holes or without, square, round, or any shape you want, CNCROi.com can produce these for you however you wish in any quantity you require AND etch them too before shipping them right to your door.

Fiber laser etching involves no dyes, inks or paint, as such, the etching that CNCROi.com produces on this custom 316 stainless steel machine plate is completely permanent and will not fade, crack or peel overtime.

When it comes to making these custom 316 stainless steel machine plates, there are a variety of methods that CNCROi.com employs from plasma to laser and even waterjet – each has their plus and minus.

Of course, CNCROi.com can also do deep fiber laser etching as well, in the case of the plate found on this blog post, that wasn’t required, but it was to the size and spec where if it was needed, we could have done it using our galvo based fiber laser.

https://www.youtube.com/watch?v=CxuDTZxXNrM/settings

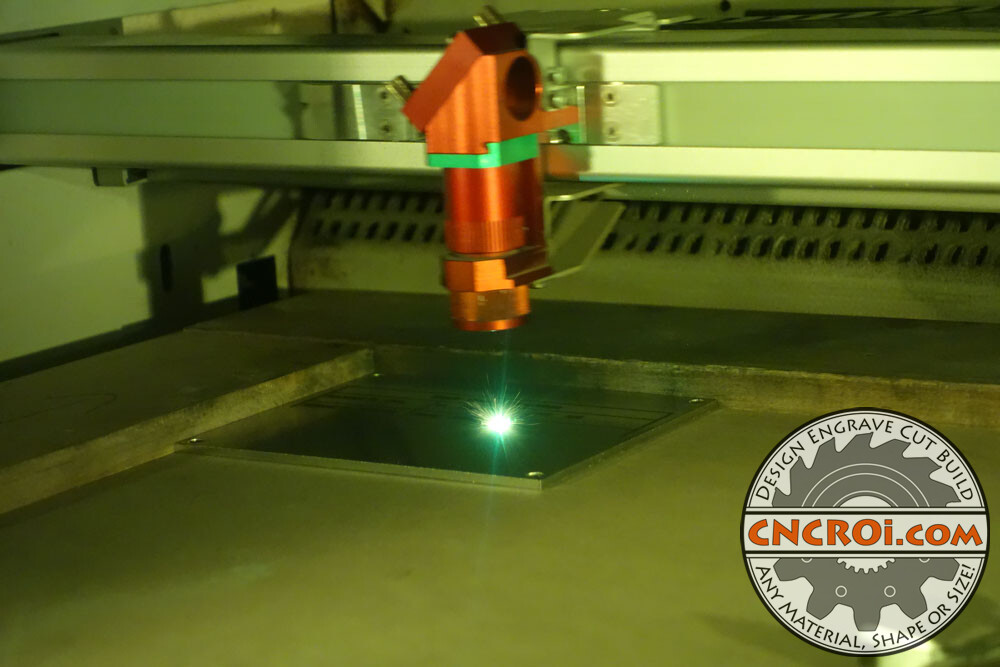

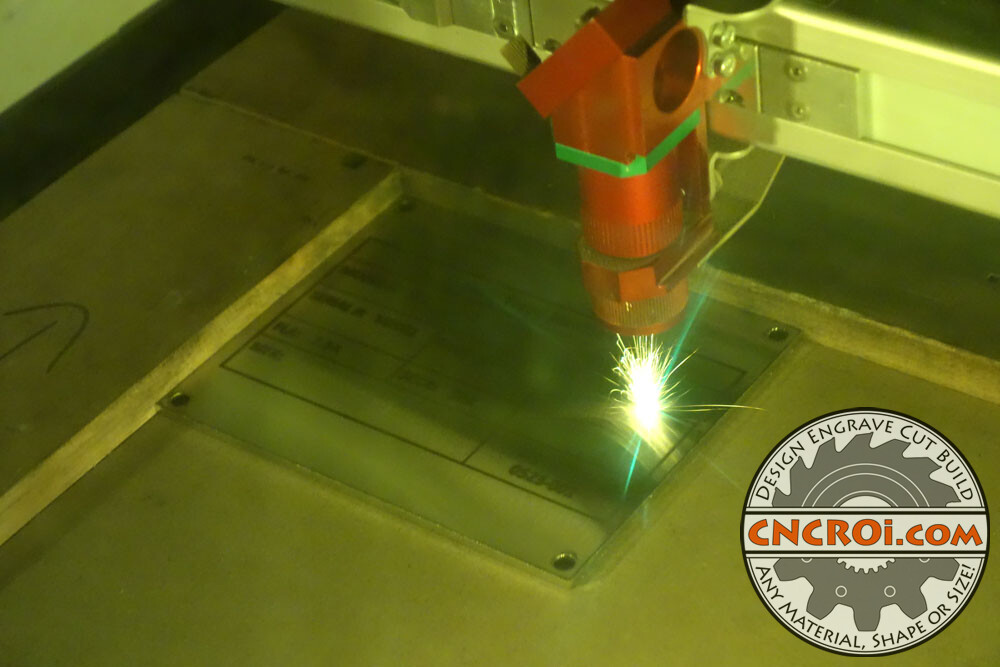

In this case, the plate we are fiber laser etching is 316SS, which is more corrosive resistant than 304SS but something to keep in mind is that 316SS costs more and is harder to come by in specific gauges and finishes, in this case, it’s #4 finish.

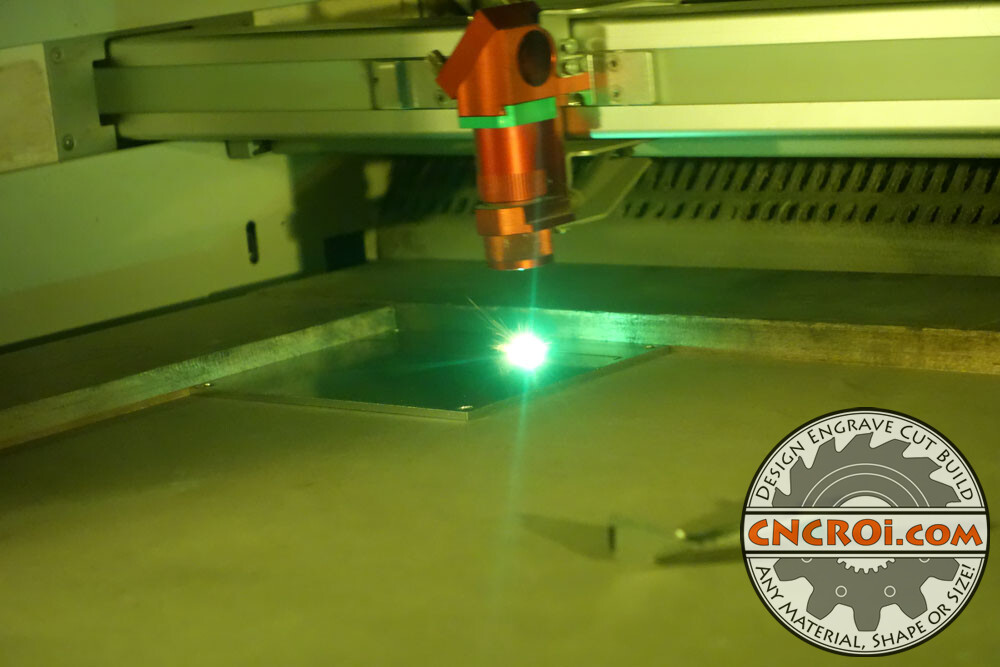

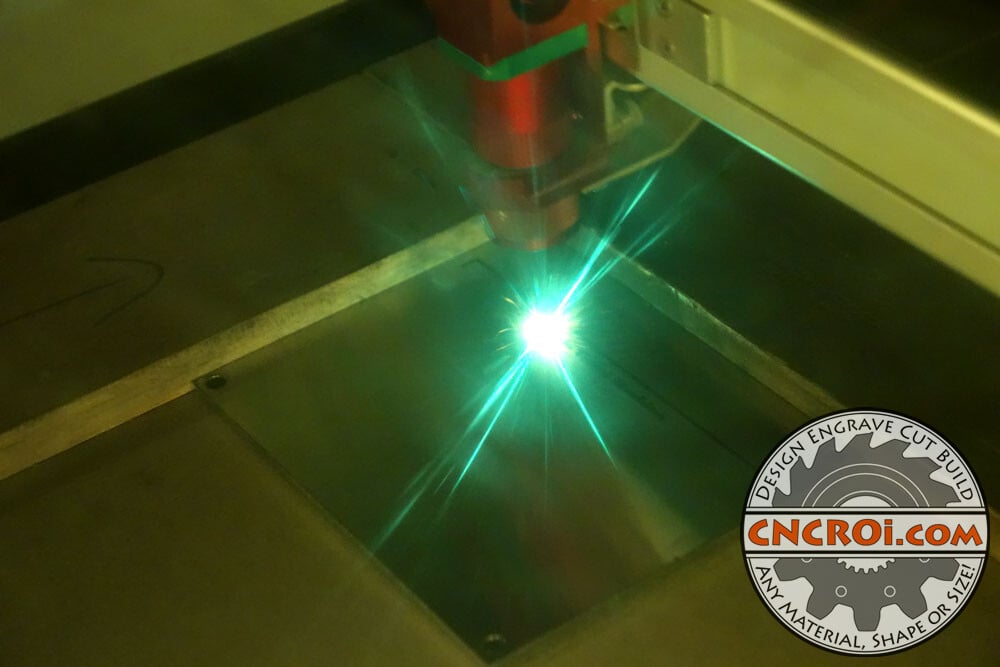

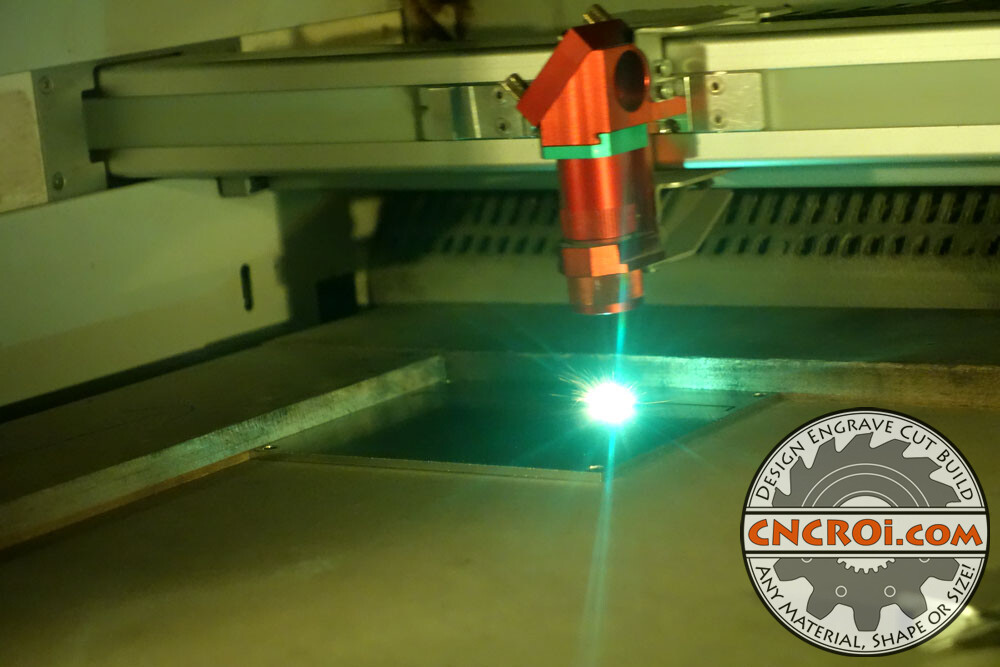

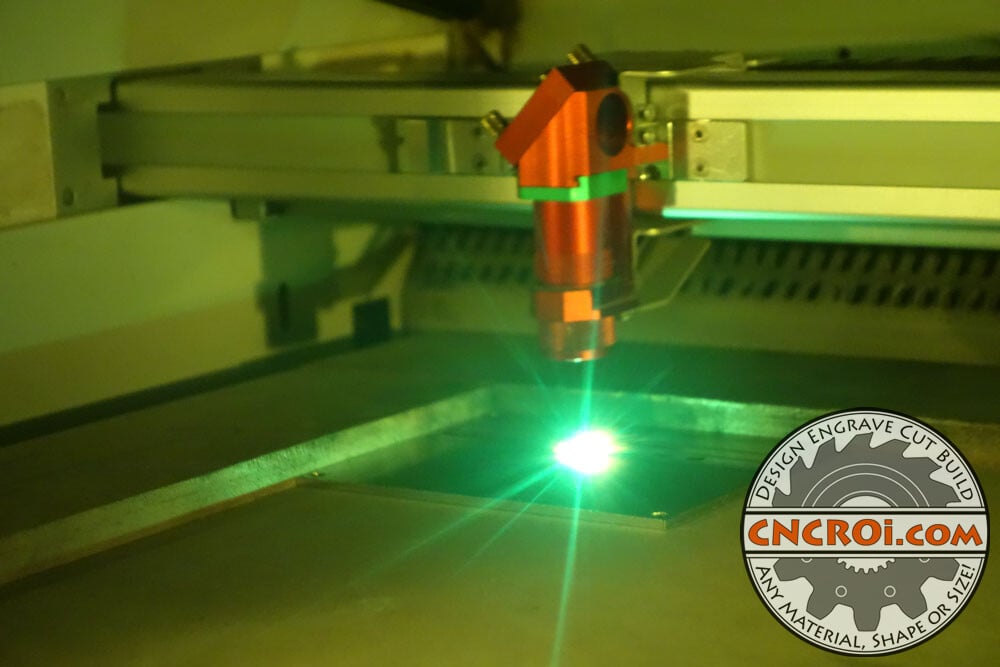

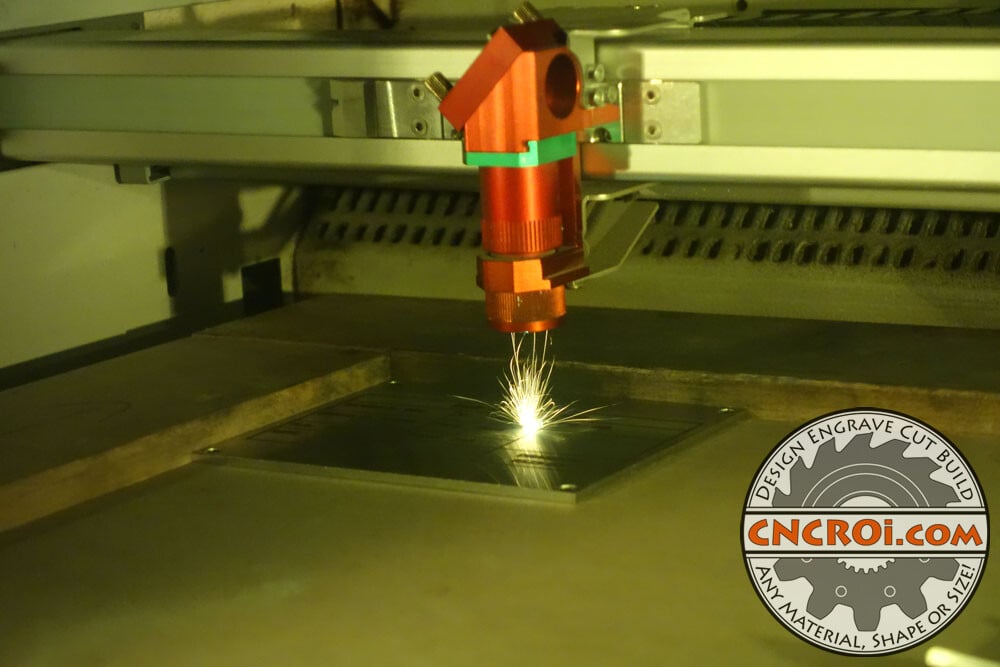

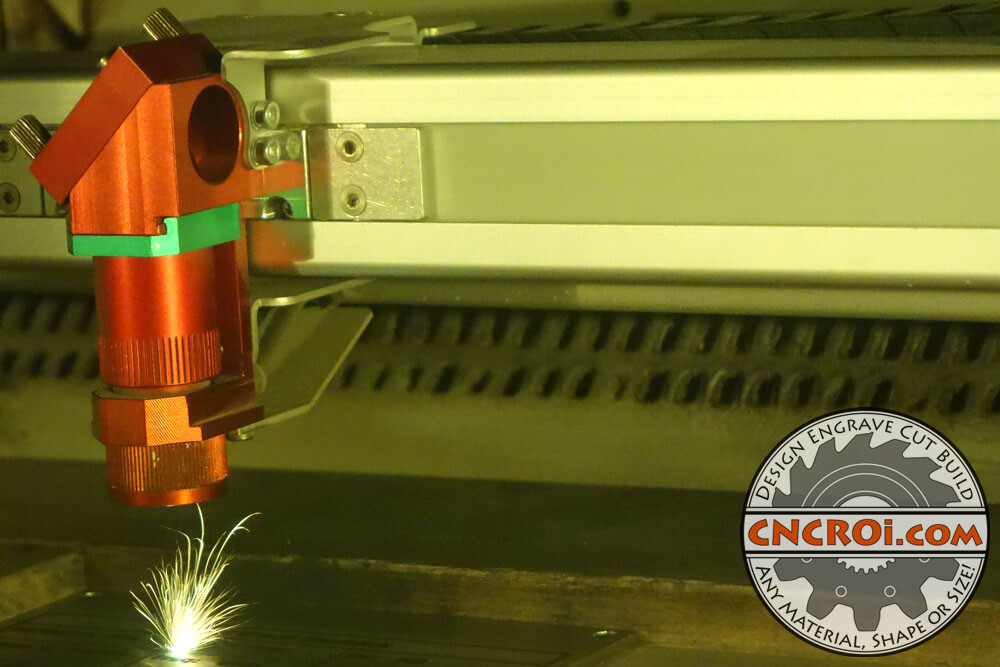

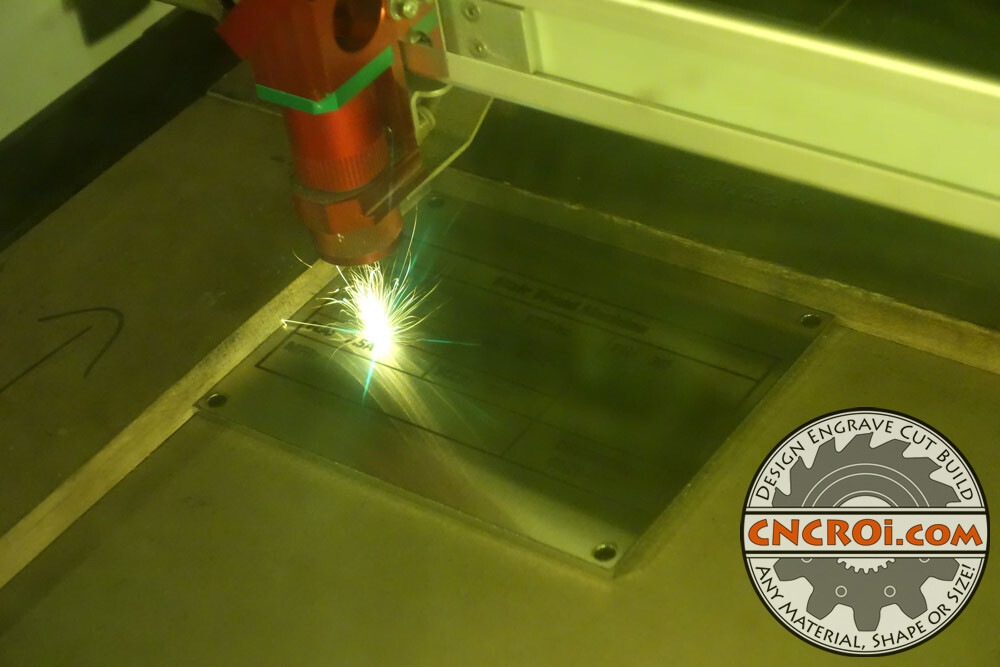

As mentioned in the video, fiber laser is fiber laser, but CNCROi.com employs two production methods to etch metal plates, the first is the one that you see the most of on our website and that’s using our gantry system to go back and forth over the plate, etching where it’s required.

This method is what you see in the picture above and below of this custom 316 stainless steel machine plate etching, it’s slow but allows for thickness to be created in the lines, which isn’t really possible using our second method which I call our “cut” method of etching, though this laser isn’t made or powerful enough to actually cut this plate.

And yet another method we use to make custom plates and tags is our plasma cutter, there is quite a diversity in equipment and processes that CNCROi.com employs, and that’s our strength for quick turnarounds.

https://www.youtube.com/watch?v=jISTiXIxx0c/settings

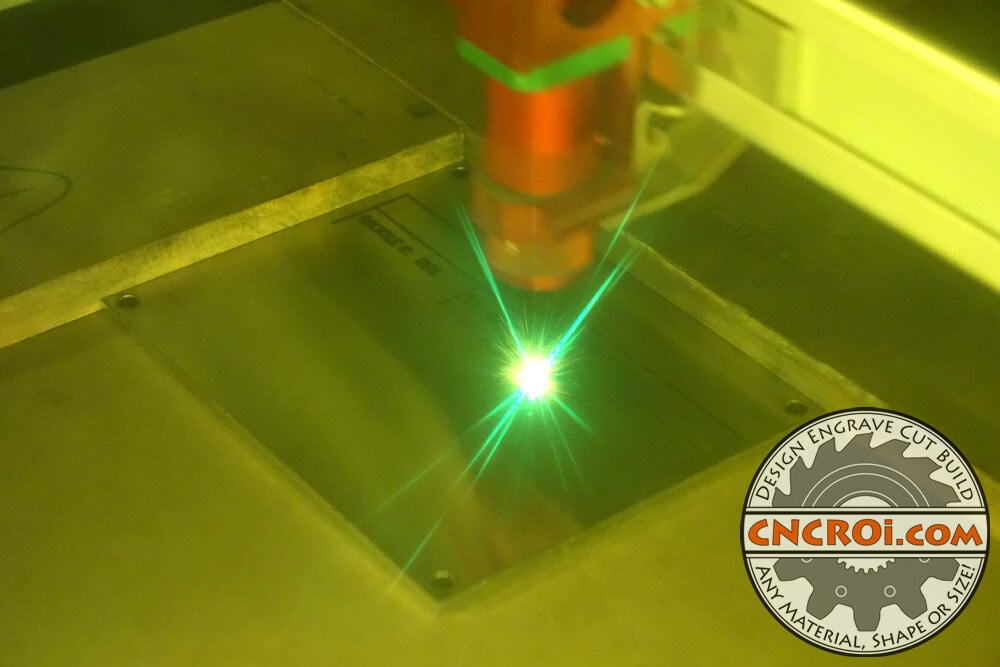

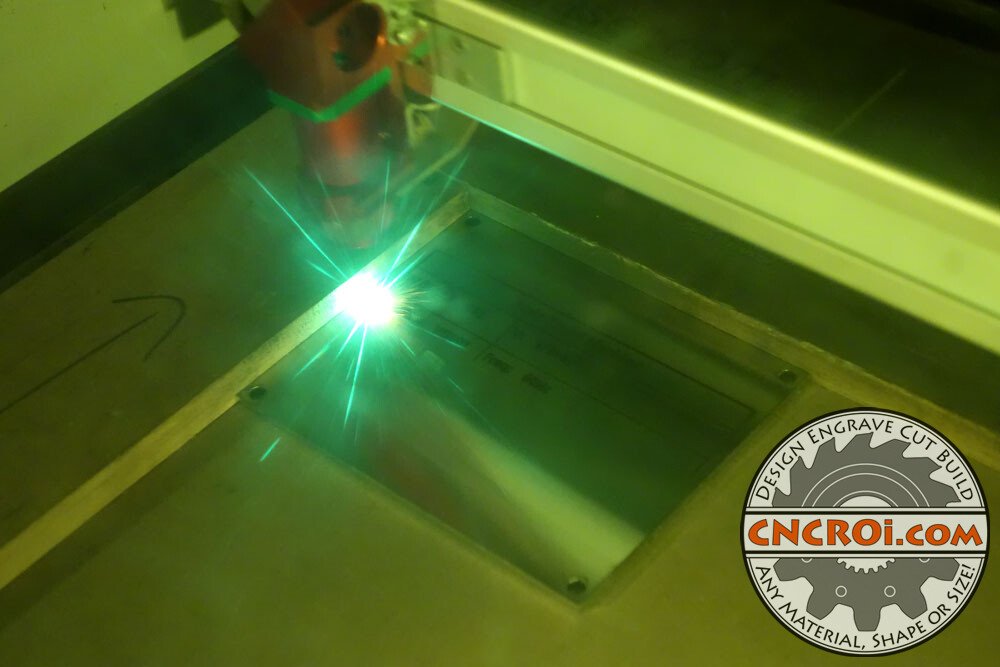

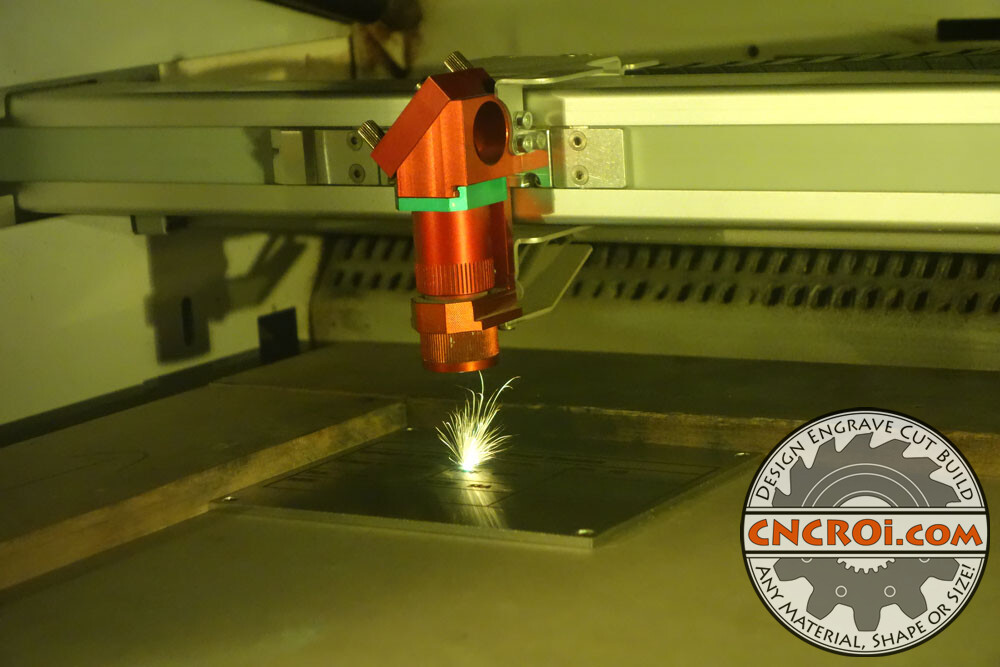

The cut method is faster than the gantry method because we only etch where it’s required, similar to how CNCROi.com‘s galvo system works, so you skip all the dead time where nothing is happening and only spend machine time on actually etching rather than traveling.

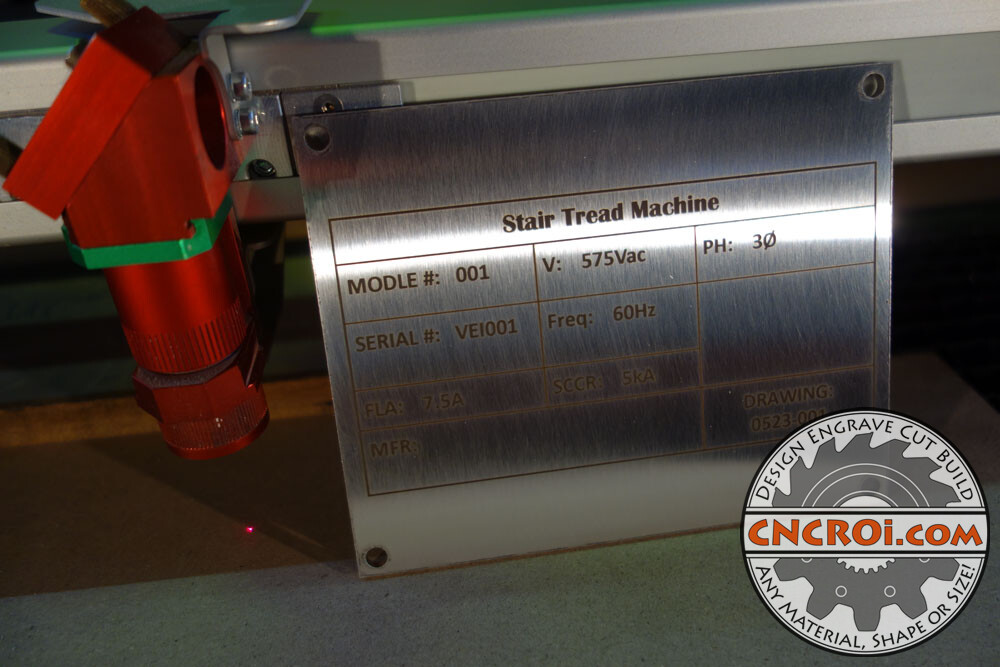

As such, yes, I could have used our gantry engraving method to do this entire plate but for fine lines, even if, in this particular case, it took longer, I prefer this for very fine details and it looks nicer in my opinion.

Again, the fiber laser from either method is the same power but the process underlying is different.

If you are wondering what fiber laser cutting stainless steel looks like, here’s the video showcasing that process.

https://www.youtube.com/watch?v=0SzcxkXvtY8/settings

You must remember that the fiber laser diameter is extremely fine, far more than our CO2 laser which also resides in the same machine, as such, the very fine lines you see on the custom 316 stainless steel machine plate are best made using this method over the gantry method.

As this plate is just about done, you can start to see and appreciate the finished work CNCROi.com performed on this stock blank we keep in inventory for a variety of projects.

The reason why you see far more noticeable sparks using the cut method over the gantry method of fiber laser etching is because the laser can move slower yet etch faster doing line work over fill work.

Yet another method of cutting stainless steel is waterjet, again, each machine has a cost and benefit and the specs dictate the best way forward.

https://www.youtube.com/watch?v=qg7wasENHd4/settings

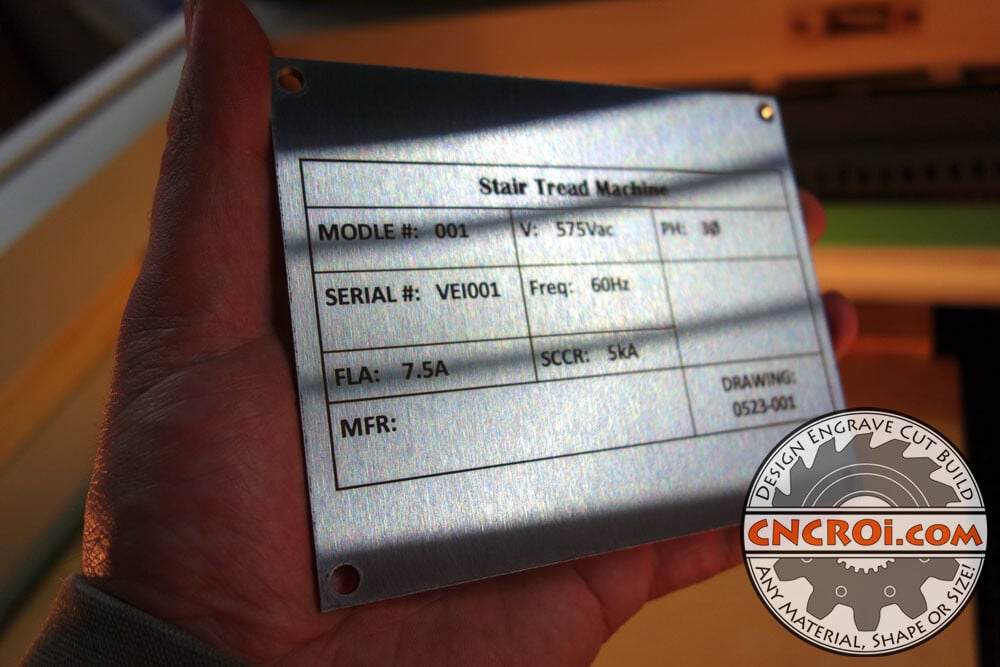

And here’s the finished custom 316 stainless steel machine plate, looks awesome and the customer already has it in their hands!

Being stainless steel, of course, this is very hard to videotape and photograph properly, but everything looks fantastic in my book!

Need one or a thousand stainless steel plates? Contact CNCROi.com right now!

https://www.youtube.com/watch?v=51nCm-Co3dc/settings