Custom Acrylic UV Phone Case Jig

CNCROi.com can make any type of jig you may require, so here’s an example of a custom acrylic UV phone case jig.

https://www.youtube.com/watch?v=tc29NaiQeH8/

Keep in mind that we can and have made jigs using a variety of other materials, from steel to wood, for this specific application, acrylic was the best choice among those that are available to us.

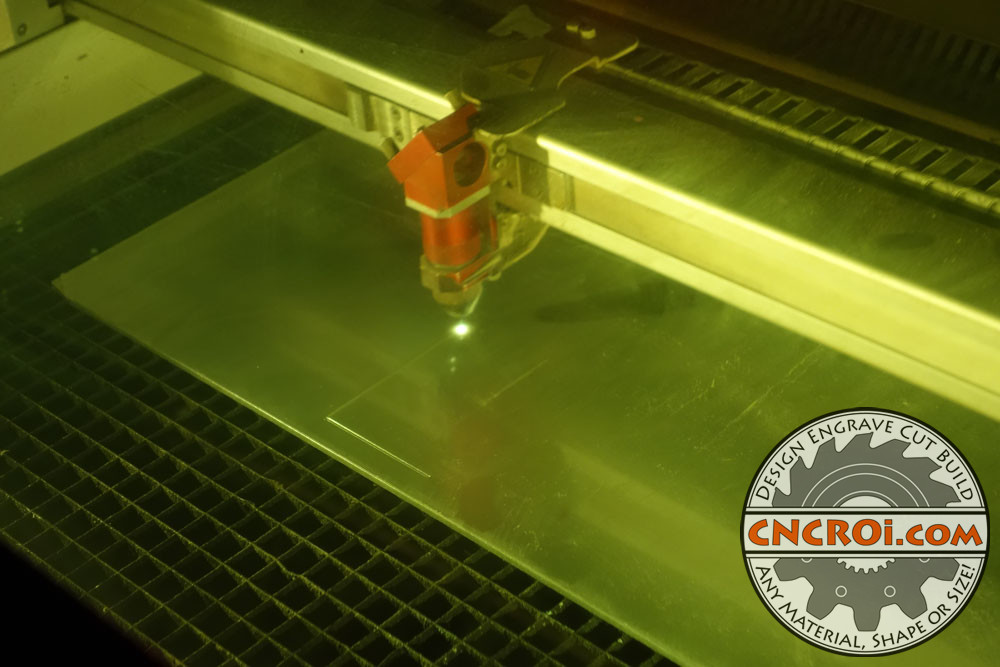

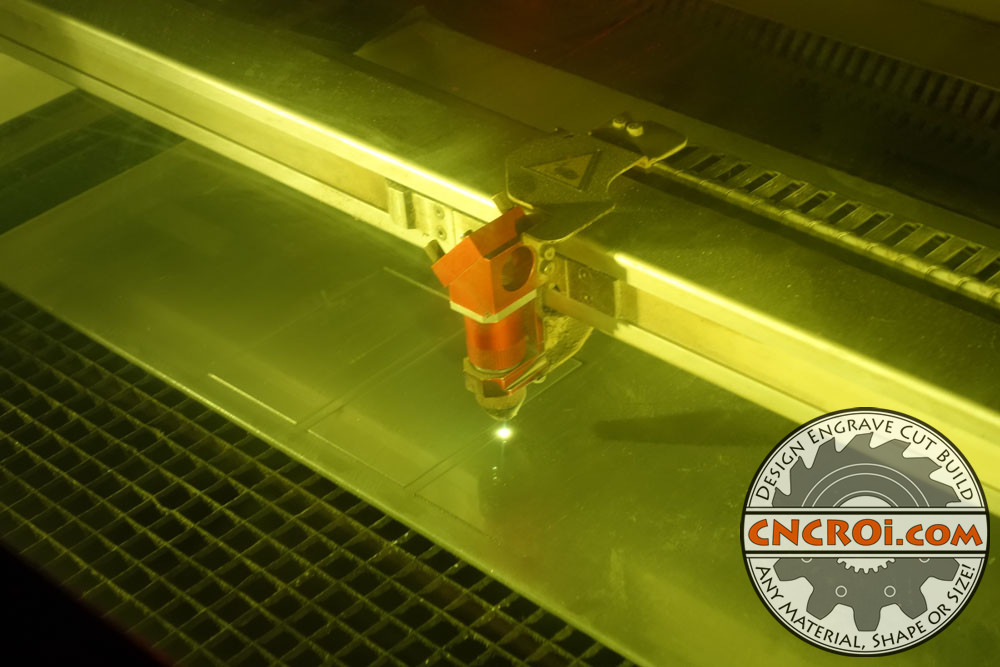

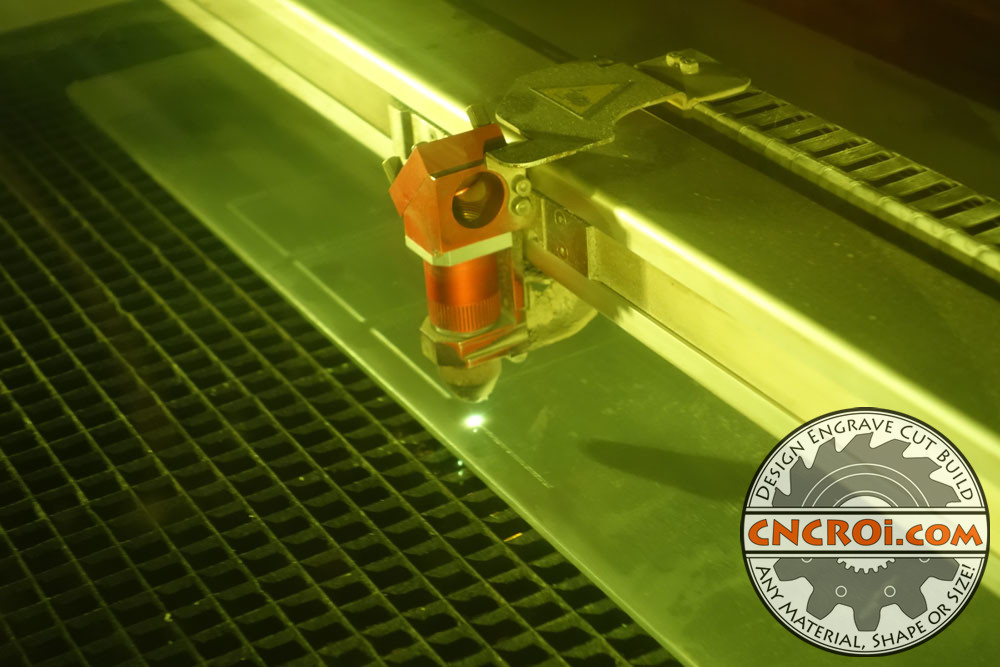

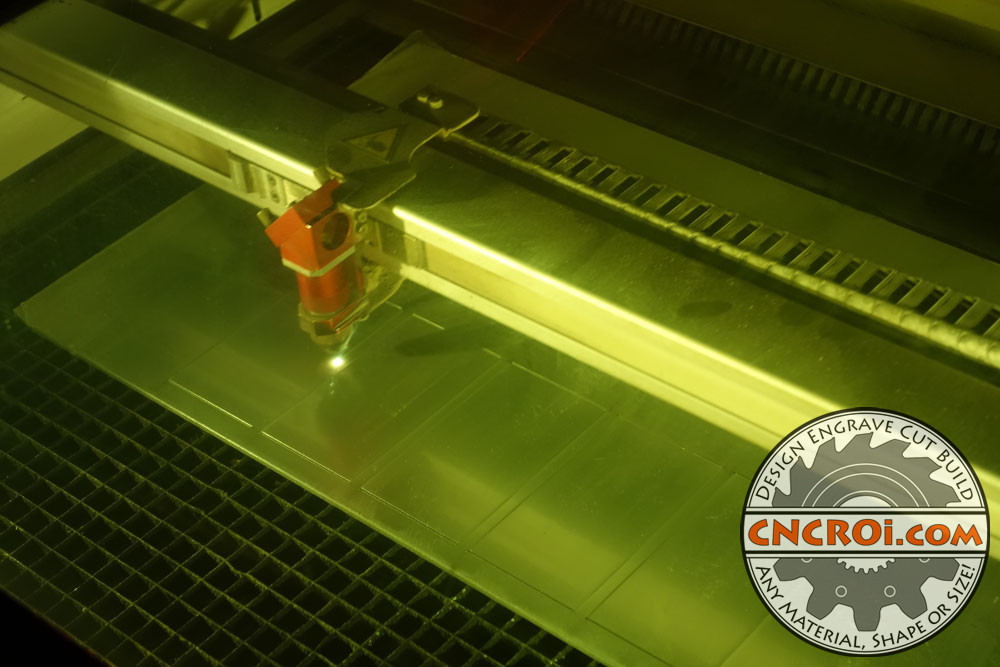

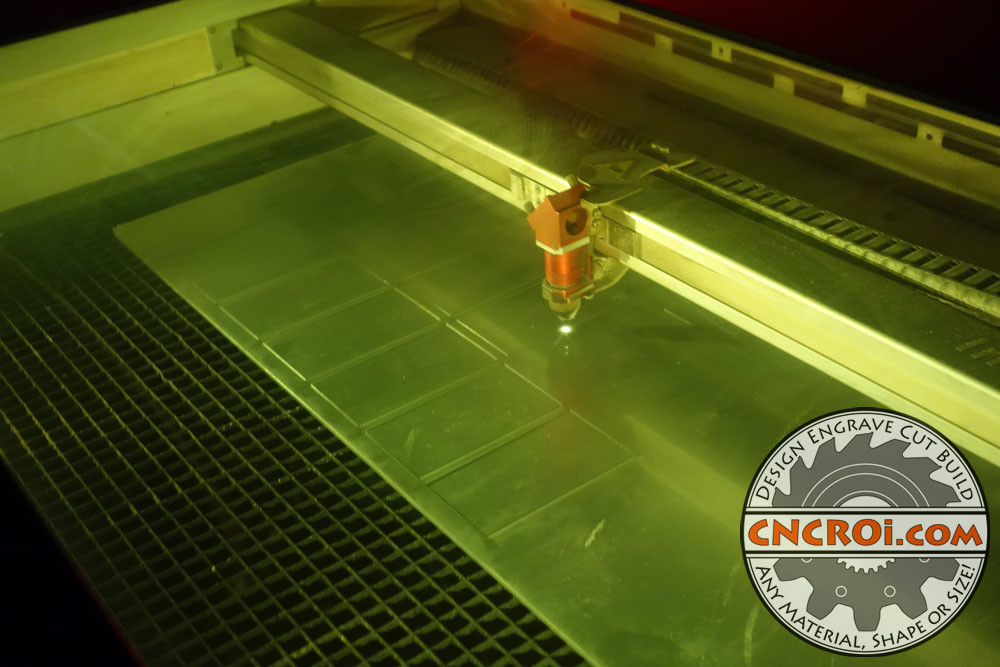

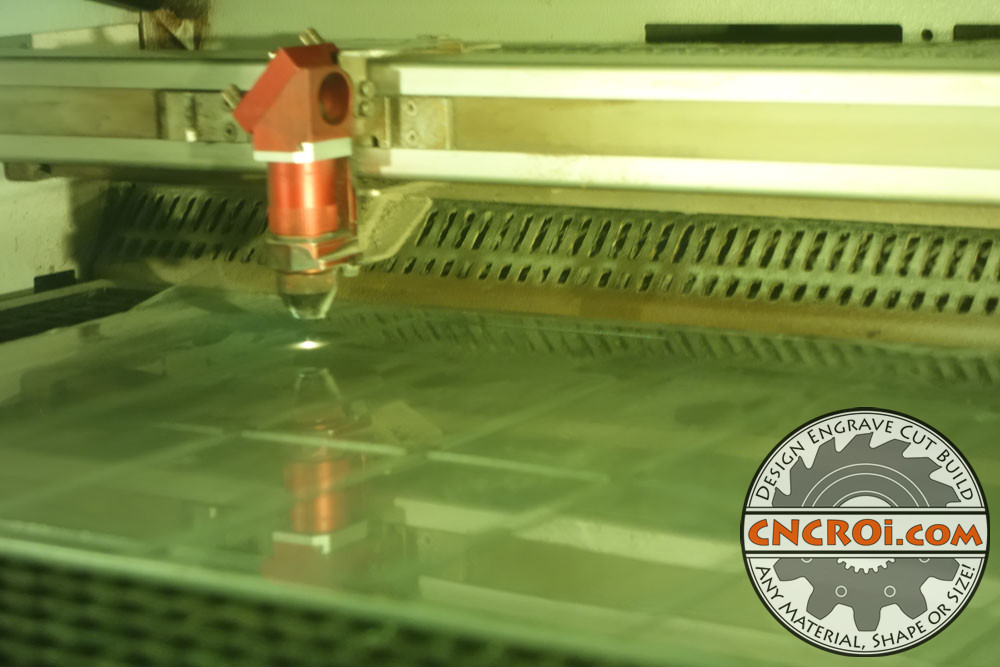

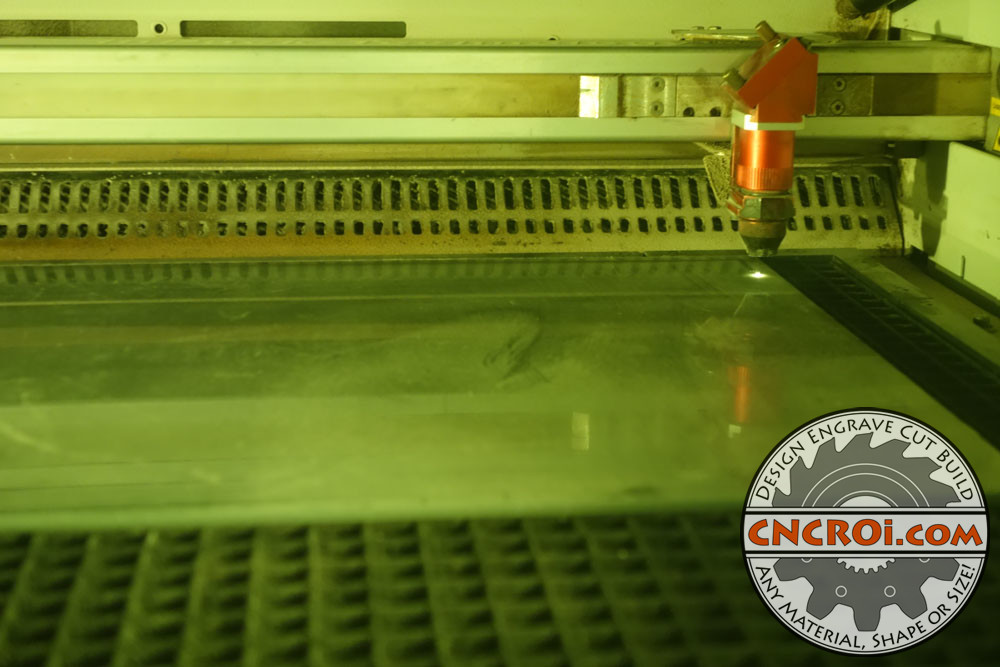

Laser cutting for this custom acrylic UV phone case jig produces a nice flame polished edge by default as we are melting our way through the material.

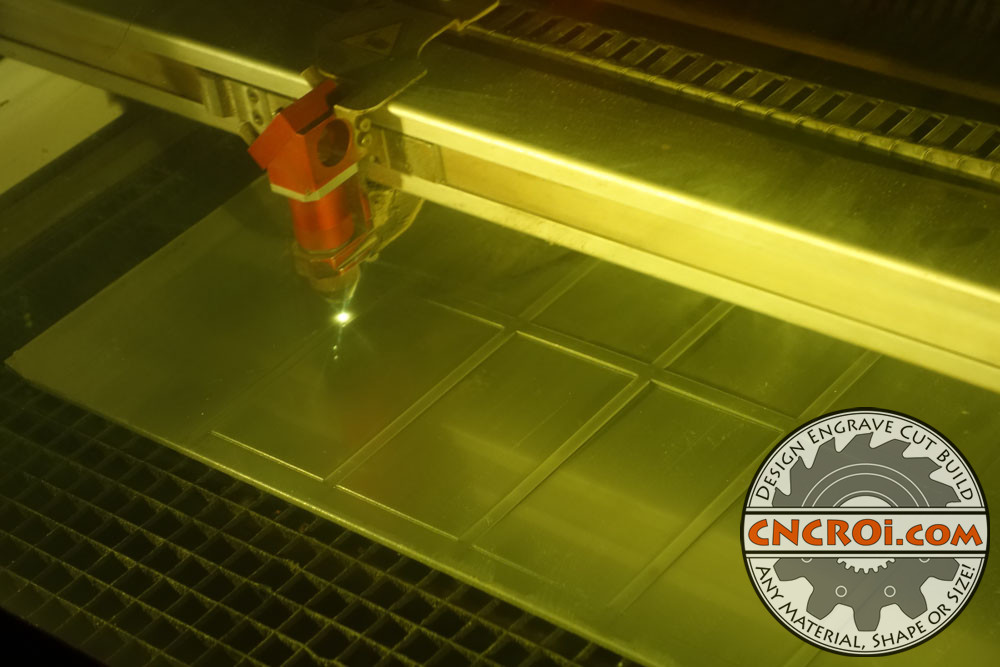

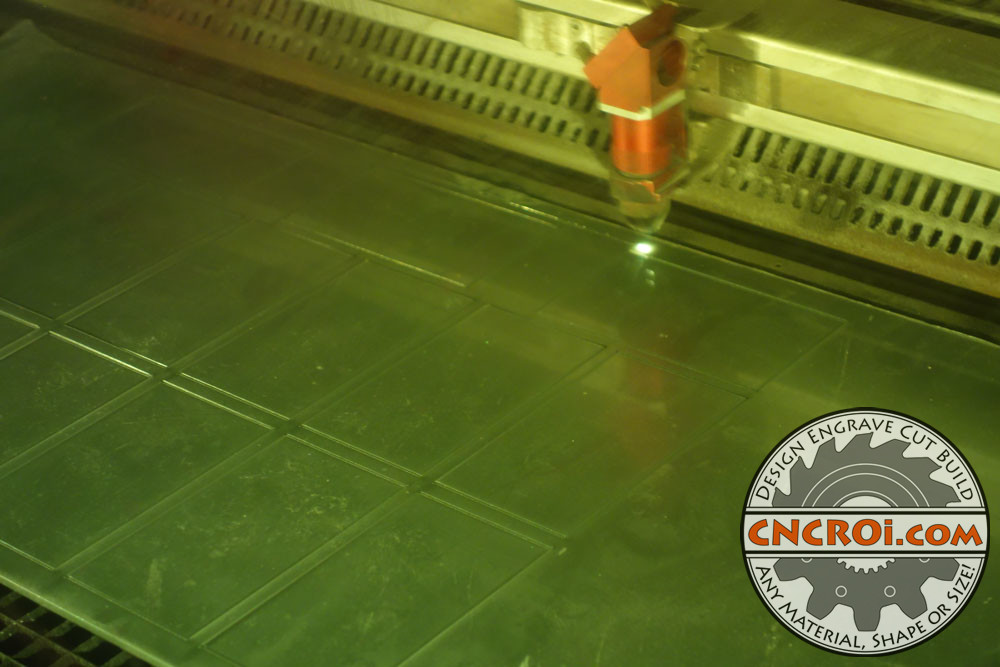

The precision of laser engraving is the same as our other CNC machines in the shop, they use all the same basic system that allows the gantry to move X, Y and Z so what this means is that regardless of what material or technology we use at CNCROi.com to make your UV printer jig, the results will be the same.

There are endless color and material combinations for a custom jig made by CNCROi.com, be sure to have an idea of what you are after to narrow the field a bit.

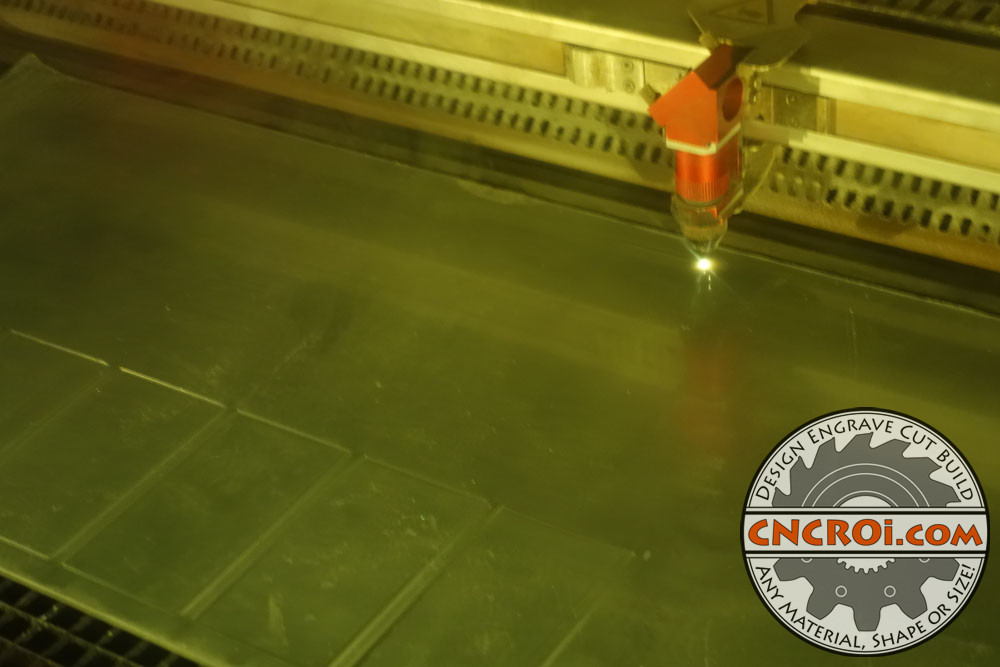

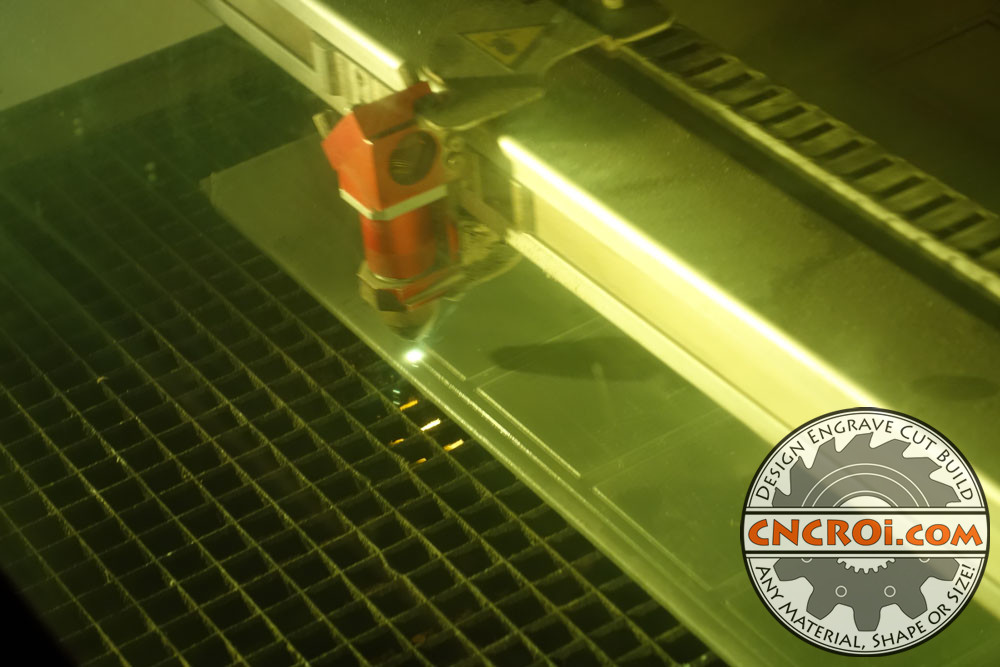

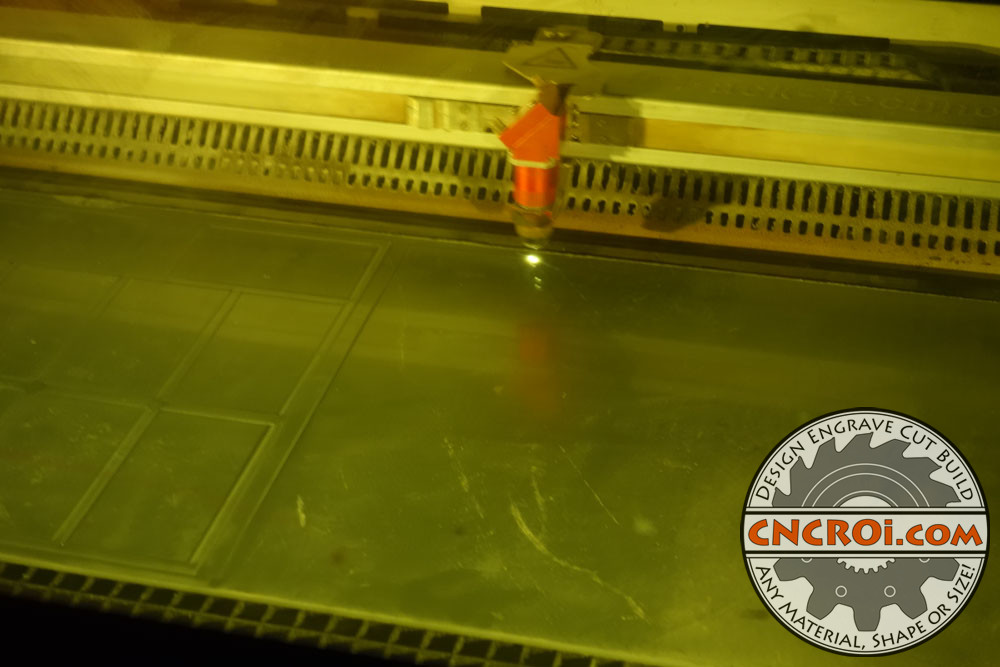

Keep in mind that we are cutting a petroleum product, as such, that’s why you see fire shooting downwards under the acrylic as CNCROi.com cuts the custom acrylic UV phone case jig.

The bright light you see is the result of the laser cutting process, it isn’t the laser itself, as that’s completely invisible, if you could see it, you would see a beam from the right of the photo into the mirror of the head of the laser.

Not all jigs are for holding items, sometimes, CNCROi.com makes jigs to produce products in a repeatable fashion.

There is a powerful extraction system going on in the laser, as a result, the combustive gases that build-up during the cutting process never have a chance to build-up to cause an explosion and the fire can’t go out of control cutting the acrylic as we have air shooting through the laser head to put it out immediately.

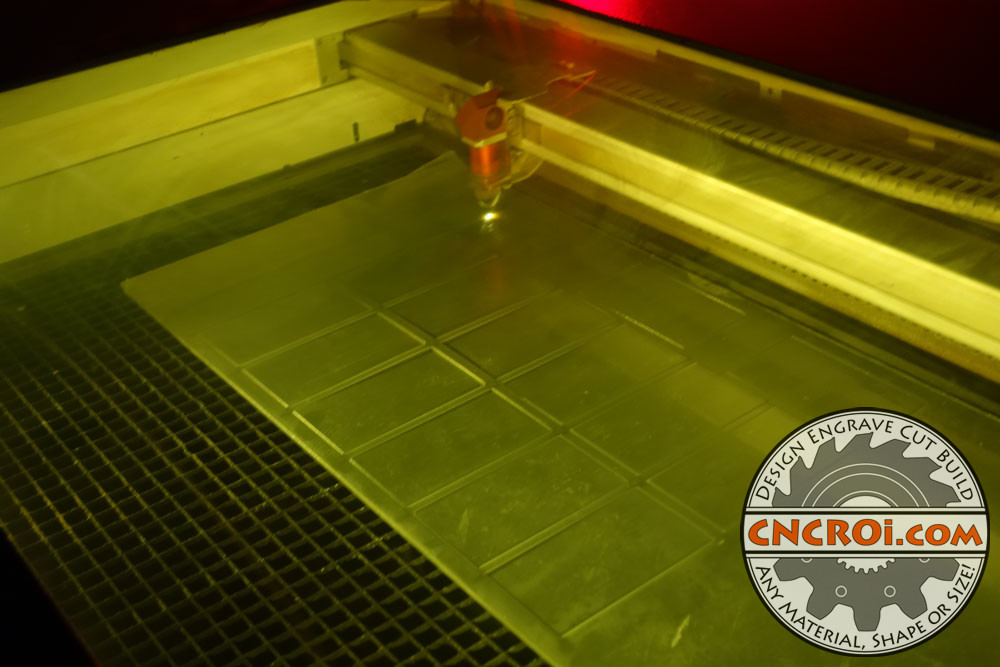

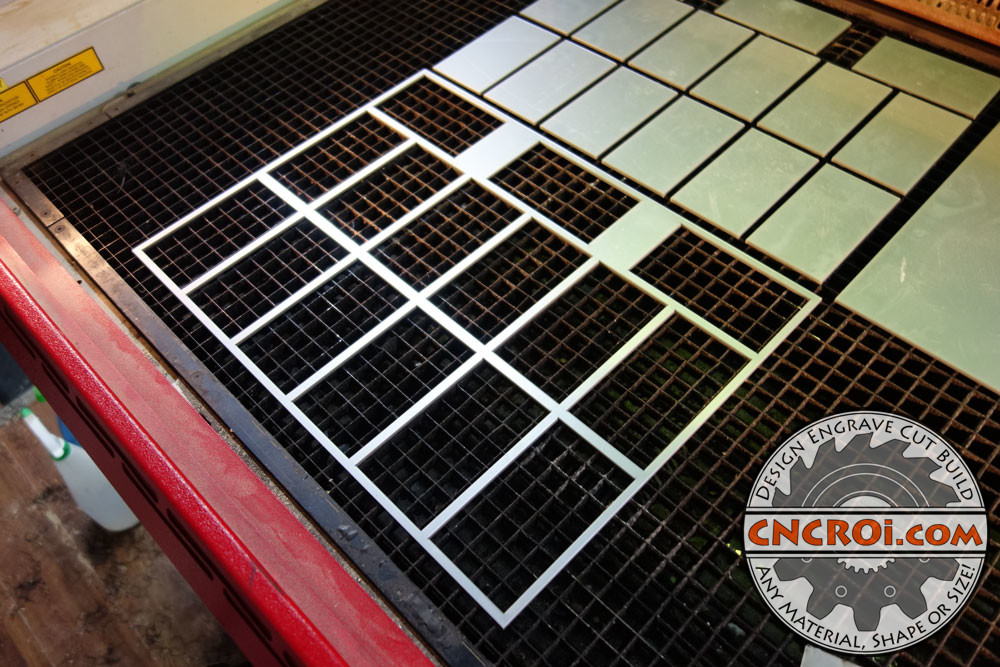

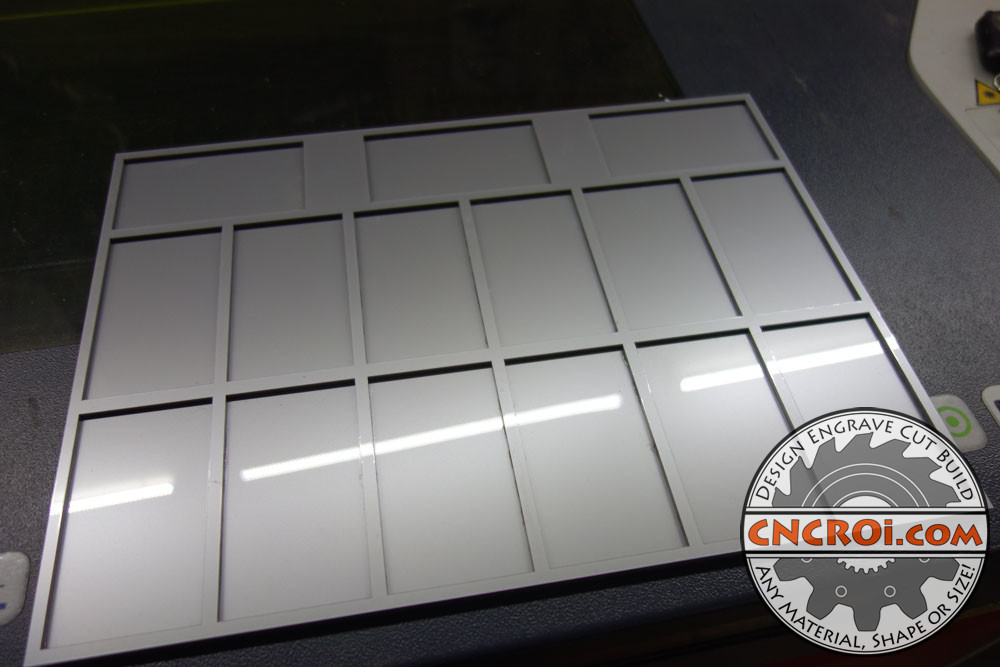

For this specific custom acrylic UV phone case jig, CNCROi.com used two layers of 1/8″ thick acrylic, but if you wanted it to be quarter inch or more/less, depending on your application, we can do that too.

Having jigs made is a relatively straight forward process, use DIGITAL CALIPERS to measure your items, tell us the dimensions, and we’ll make the jig to those specs.

Personally in the shop, I generally make my custom jigs using 1/8″ MDF but my second go-to is just as you see for this custom acrylic UV phone case jig, 1/8″ acrylic.

The reason is quite simple, it’s a very durable material, I have jigs I made YEARS AGO, that I still use to this day out of acrylic and it seems to have the perfect weight to strength ratio for the jobs I use these jigs for at CNCROi.com.

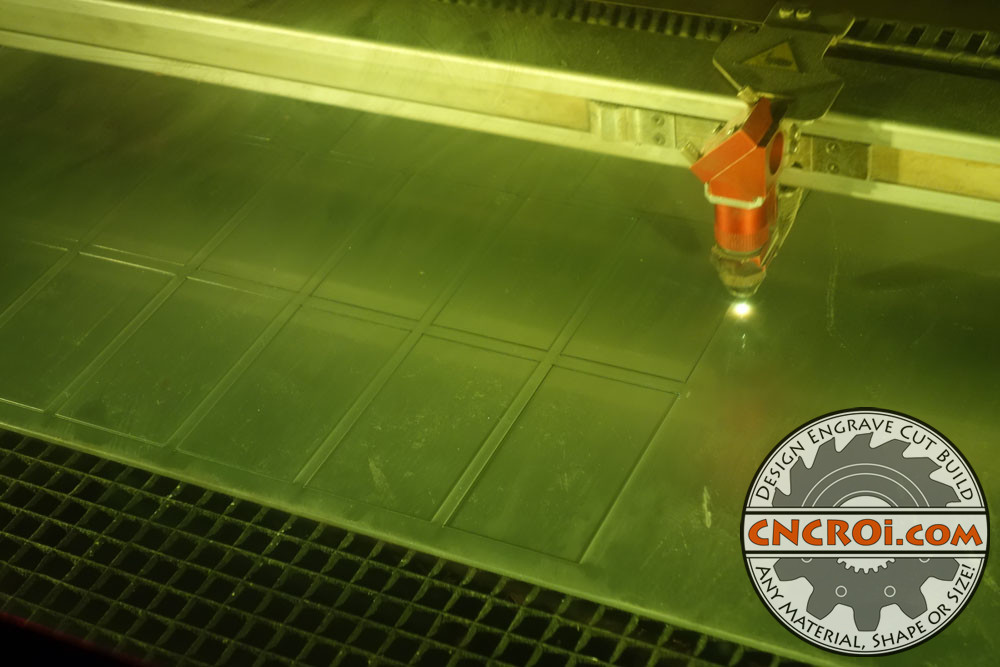

Laser cutting always happens ON THE LINE, so this is the built-in tolerance of vaporization that I use for my own jigs and it has never left me with issues, of course, I also use our plasma and router to make custom jigs too for use in the shop, but I’ve found the combination of acrylic and lasers to be tough to beat for the vast majority of the applications we do custom engraving for using jigs we make for our own internal use.

Acrylic makes for great jigs, but it isn’t the best for ALL applications, this is why generally, I ask the customer how much their stuff weighs and how often they plan on using it so I can suggest a good material for them.

You may think that having two layers of acrylic bonded together, you’d lose some precision, but the instant bonding paste I use for my own jigs using acrylic and those of customers gives me a few seconds of align something perfectly before setting permanently, and that hasn’t let me down.

The nice thing about acrylic is that it’s available in a ton of color and thickness variations, as a result, you can get feeling for what works and what doesn’t, for color matching a variety applications in your shop, for instance, you can have contrasting colors for some jobs, red for others and blue for yet others, so you can quickly make them out in a pile or hung on the wall.

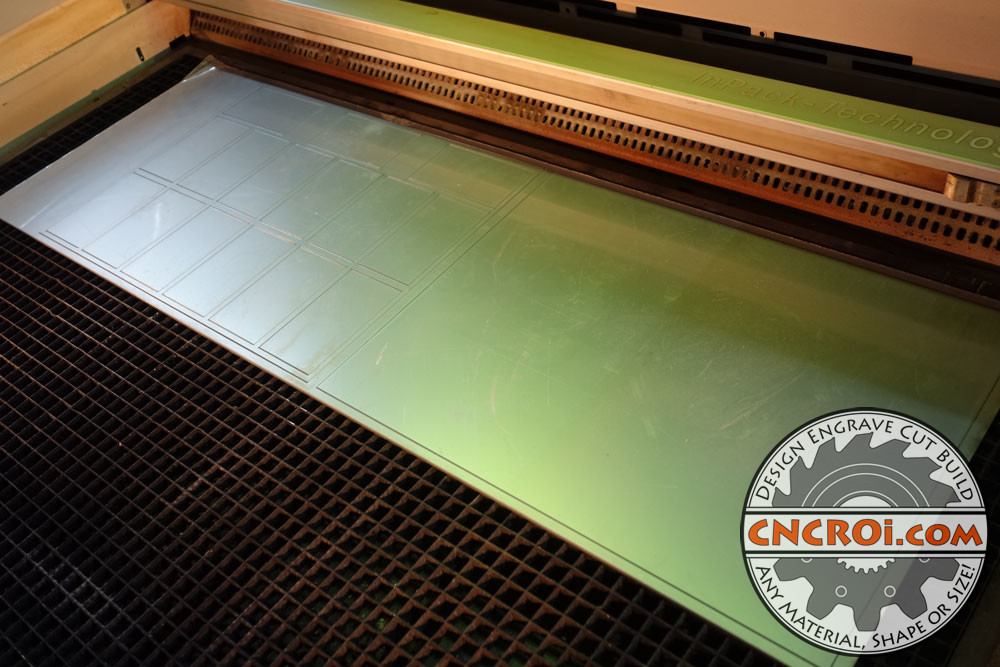

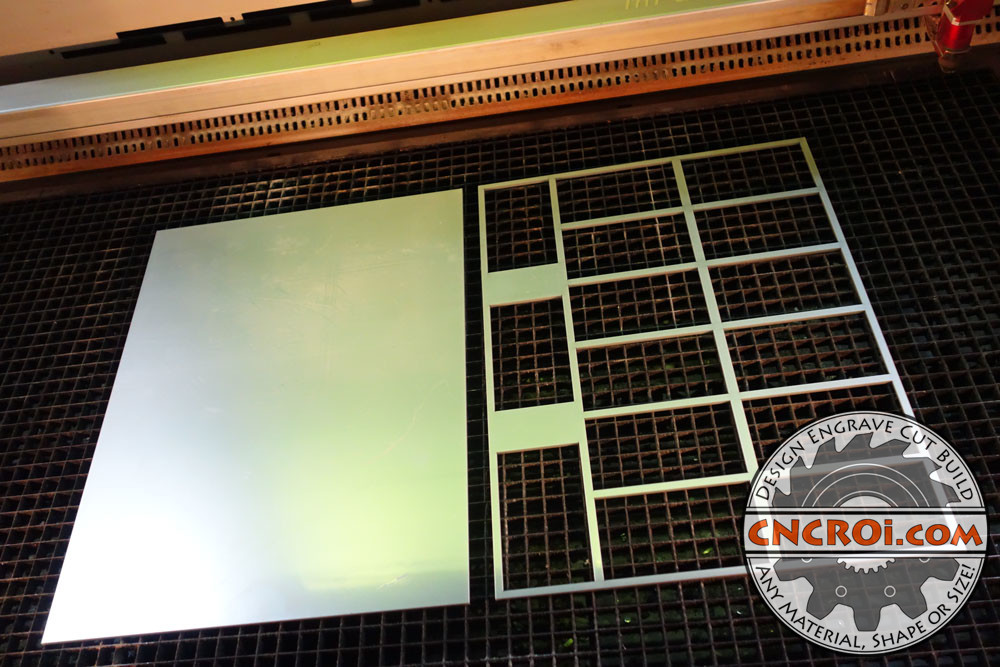

The order of the custom acrylic UV phone case jig cutting out process doesn’t matter, as long as internal parts are cut out before external ones, as a result, the jig on the left is done, that’s the top layer, and the jig on the right is the base, both cut from the same sheet of material.

Jigs are great for repeating a process over and over again, at CNCROi.com, we have many custom engraving jobs that require just that, and that’s why we are both a customer and supplier of custom jigs.

Cutting acrylic is a very cool process, it burns very little and the results look fantastic, compared to other types of plastic that tend to catch on fire or just produce awful black smoke during the cutting process.

Below is what the custom acrylic UV phone case jig looks like, top to the left, base to the right, all perfectly square and accurately cut.

The inside parts of the acrylic are recycled, as those are no longer required, and the outside scrap is recycled as well.

You’ll notice a lot of MDF and acrylic in the jigs we make at CNCROi.com, both materials are relatively durable, strong and easily recycled.

The goal of this jig was to get as much as possible on said jig, as a result, you can see the positioning is a little odd, with things going in two directions, but that’s still more efficient than leaving those three spaces empty.

After all the scrap is removed for this custom acrylic UV phone case jig, you can see the two parts that will be permanently bonded together more clearly, the jig is rather fragile until the bonding process, because the one full of holes is very easy to break compared to the one that’s solid.

But once both layers are bonded together, the jig is very strong and will be great for this customer for years to come.

Need custom acrylic UV phone case jigs? Contact CNCROi.com right now!