Custom Barrel Head Stencil: Polycarbonate

CNCROi.com offers custom barrel head stencil production using pretty much any vector based design and material you can imagine.

https://www.youtube.com/watch?v=0j7SOQVaI4o/

The major advantages to polycarbonate as a material for custom barrel head stencil production is that it won’t rust, is transparent and a very durable, cost-effective material to make them with.

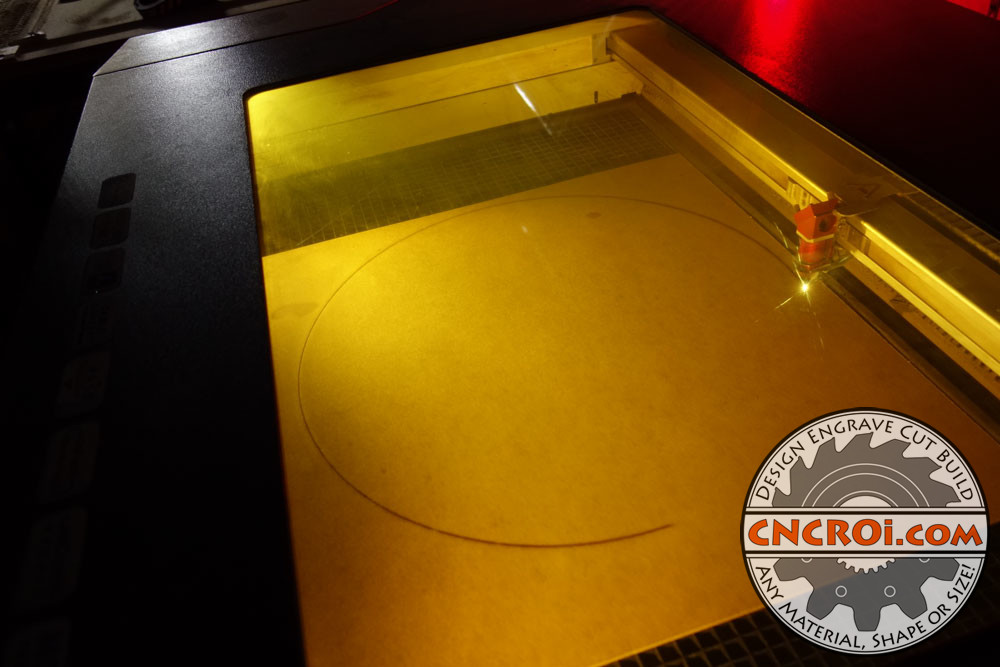

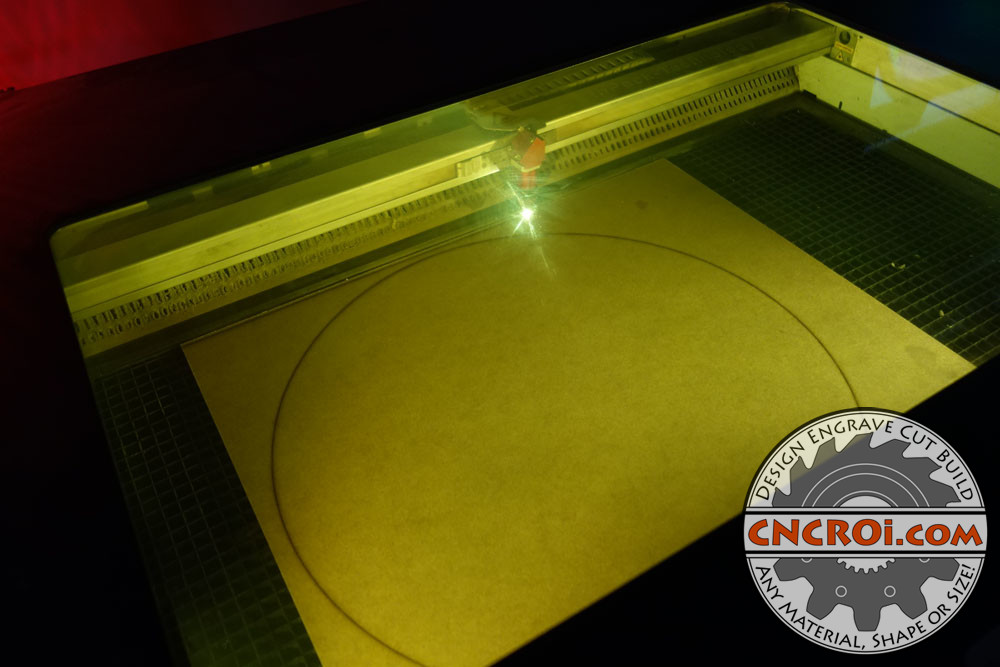

For this specific custom barrel head stencil, you’ll notice that it’s round, that’s because the top of a wine barrel is of the same shape.

CNCROi.com has been cutting custom stencils since we started as a business, and since then, we’ve cut them using materials from MDF and plywood to stainless steel and plastics of all kinds, including polycarbonate.

Just for comparison sake, here’s another custom barrel head stencil we made, different design, same process.

https://www.youtube.com/watch?v=xgaqYllL5nI/

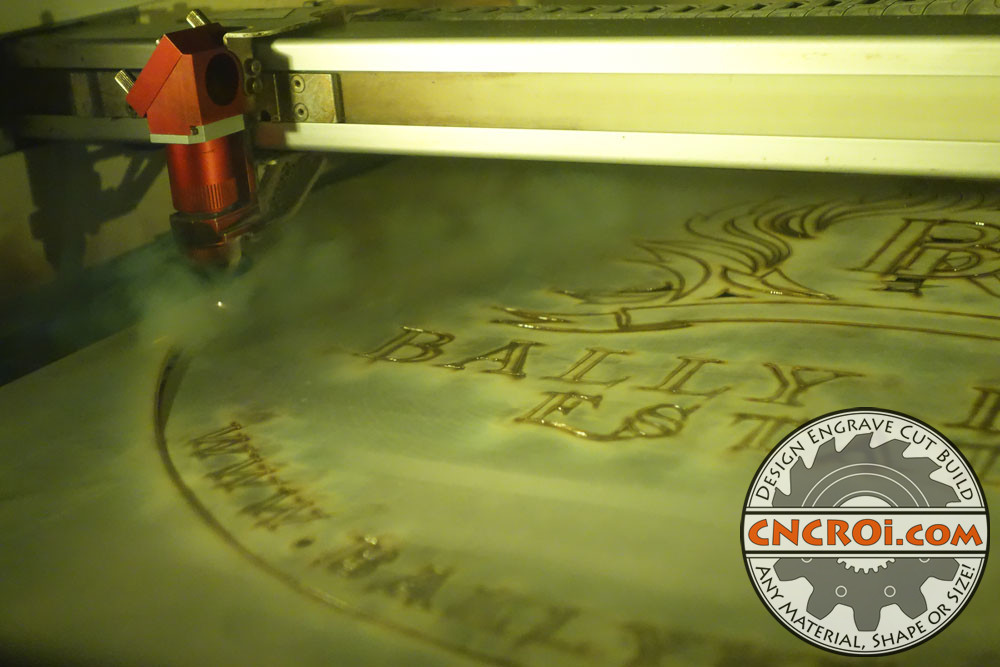

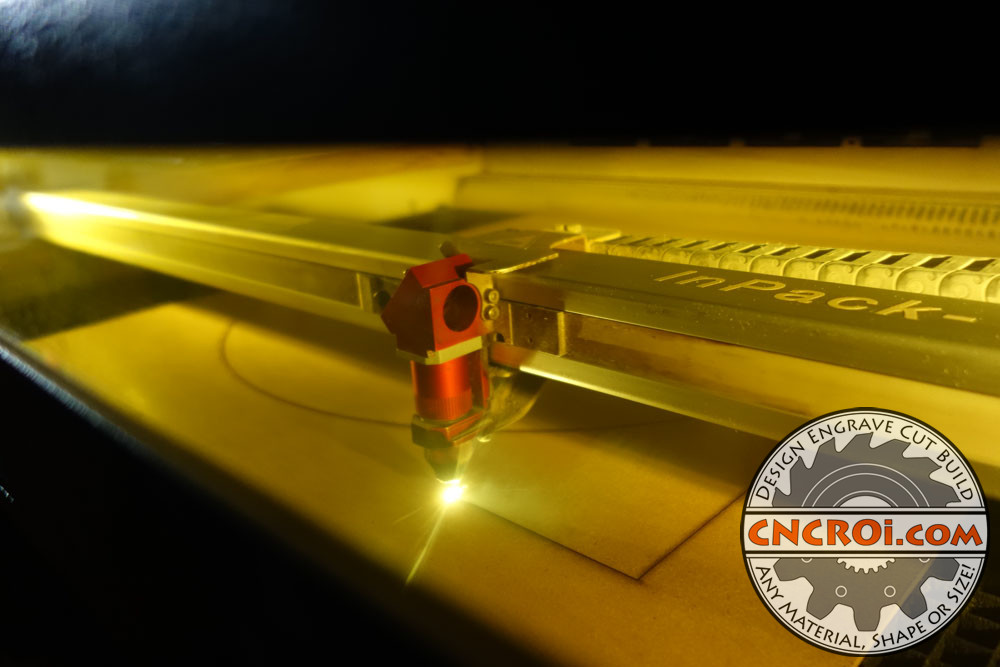

Using CNCROi.com‘s laser to produce this custom barrel head stencil is a very fast and efficient process, the results are sharp and as there is no material contact with the cutting head, there isn’t any need to hold things down like we’d have to with our CNC router.

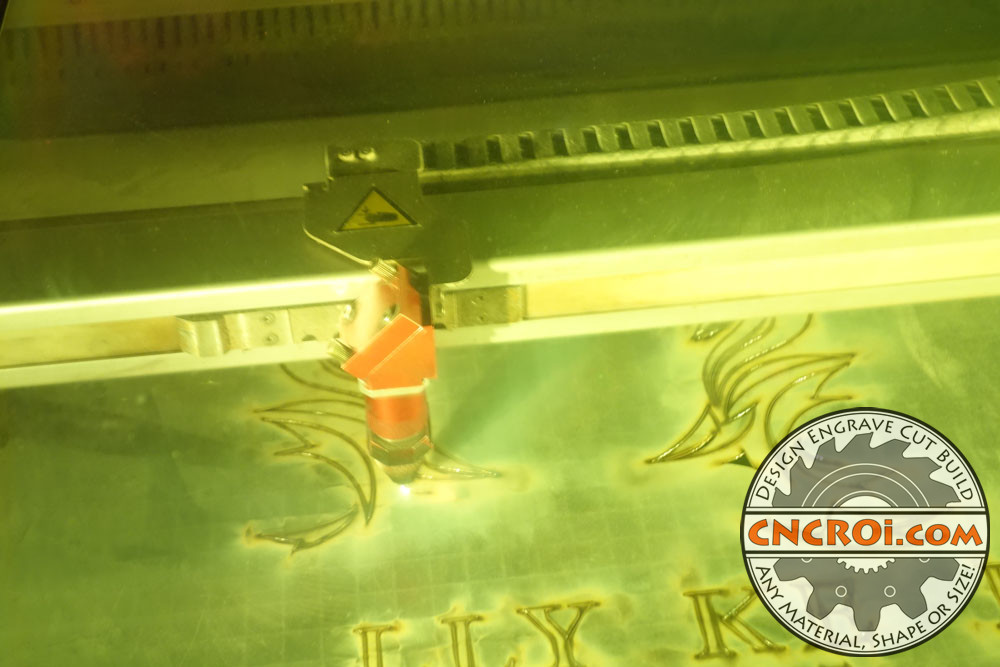

The other advantage to using CNCROi.com‘s laser to produce this custom barrel head stencil is that even small details come out sharp, there are no rounded inner corners or things out of position due to material movement.

Laser cut polycarbonate is incredibly durable, this is literally the same material used to produce bullet proof glass, though at this thickness, I wouldn’t recommend it as a way to keep yourself safe from a firefight as it’s a stencil full of holes!

Custom stencils don’t all have to be round at CNCROi.com, they can be any shape you want, in this case, square, and perfect for a t-shirt printing business.

https://www.youtube.com/watch?v=dwEyYkcdJy4/

Unlike acrylic, which is another popular material for custom stencil production, polycarbonate will not break if it’s folded and can be dramatically thinner for the same strength characteristics.

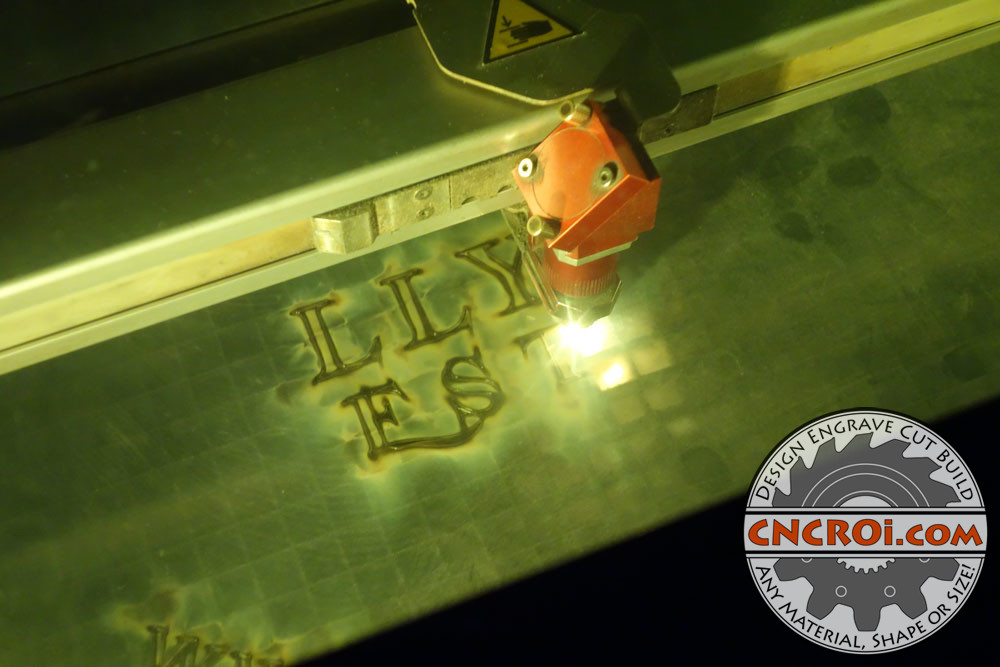

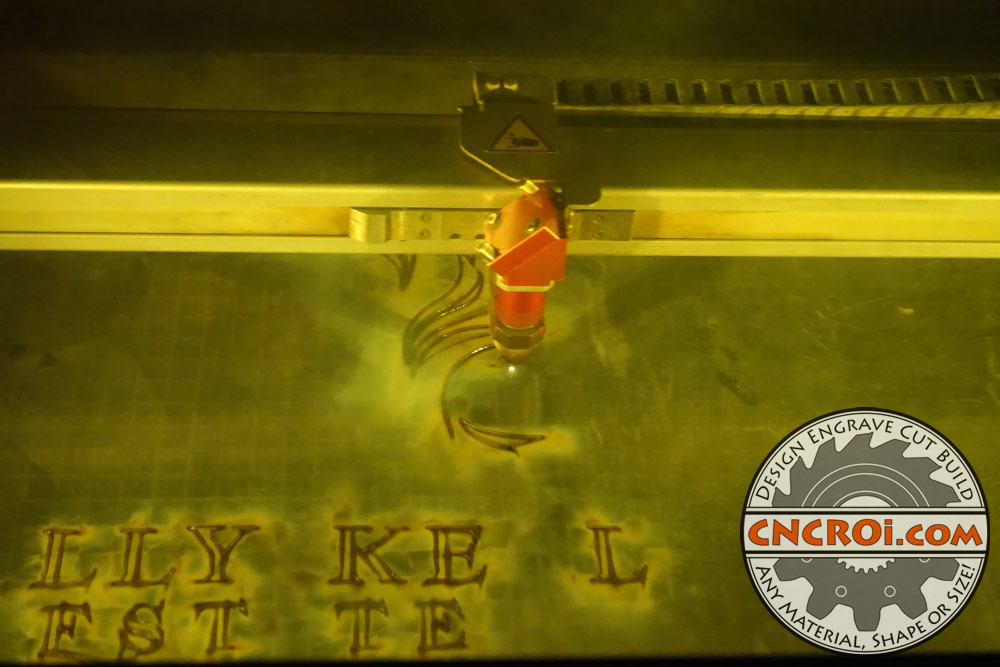

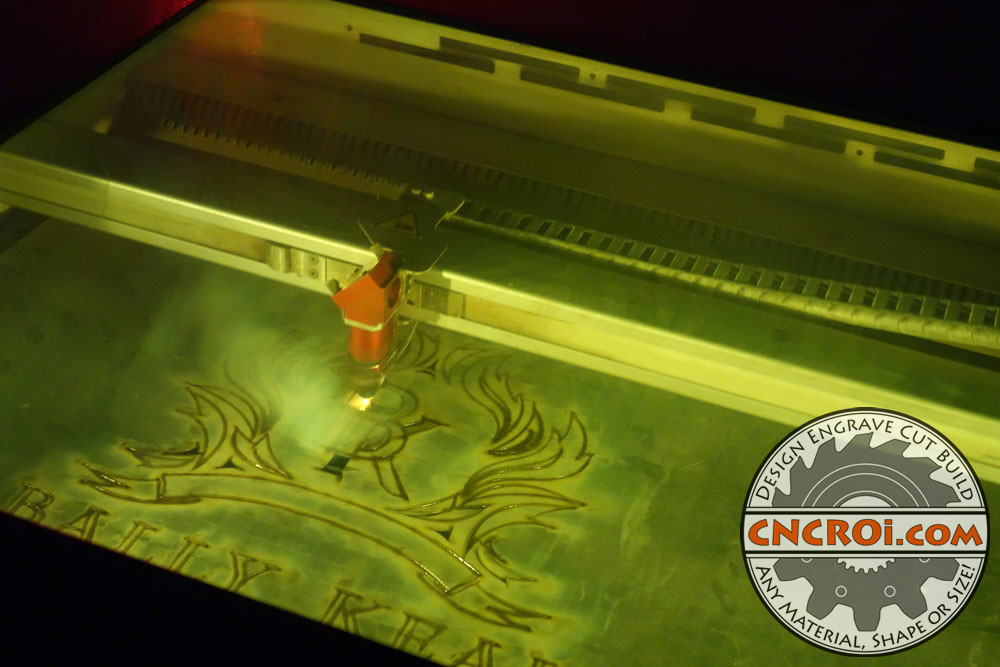

You’ll see smoke all over this custom barrel head stencil, that yellowing is all appearing on the finished stencil but keep in mind that CNCROi.com left the masking on both the front and the back of this polycarbonate stencil, meaning once this masking is removed, then the customer has an optically clear stencil to work from.

Alternatively, the customer can use this custom barrel head stencil for a while and as a way to clean it down the line once it gets cruddy, they can then remove the masking on both sides to have a brand new stencil to work with.

When it comes to metal, we have two ways at CNCROi.com to cut it out, the first is plasma cutting and the other waterjet cutting, each has it’s + and – so it really depends on the design parameters which tool we employ to do the job.

https://www.youtube.com/watch?v=fhwwm4DgLSA/

Your design options when it comes to having custom barrel head stencil production made are endless, you can easily mix and match vector graphics and fonts.

Additionally, when it comes to polycarbonate specifically, as long as the elements aren’t too compact, you can also have a stencil that covers every inch of the stencil as it’s a very strong material.

Laser cutting polycarbonate is very similar to plasma cutting steel when it comes to stencils, both processes are non-contact meaning the machine head never touches the material, while the router is a full contact production method that’s actively pushing and pulling the material to create a stencil.

When it comes to making custom stencils, CNCROi.com has made them for others as well as ourselves, whether it’s repeated branding requirements or full-on production of unique (generally wood related) projects, your options are limitless.

https://www.youtube.com/watch?v=b54_VdpHAq8/

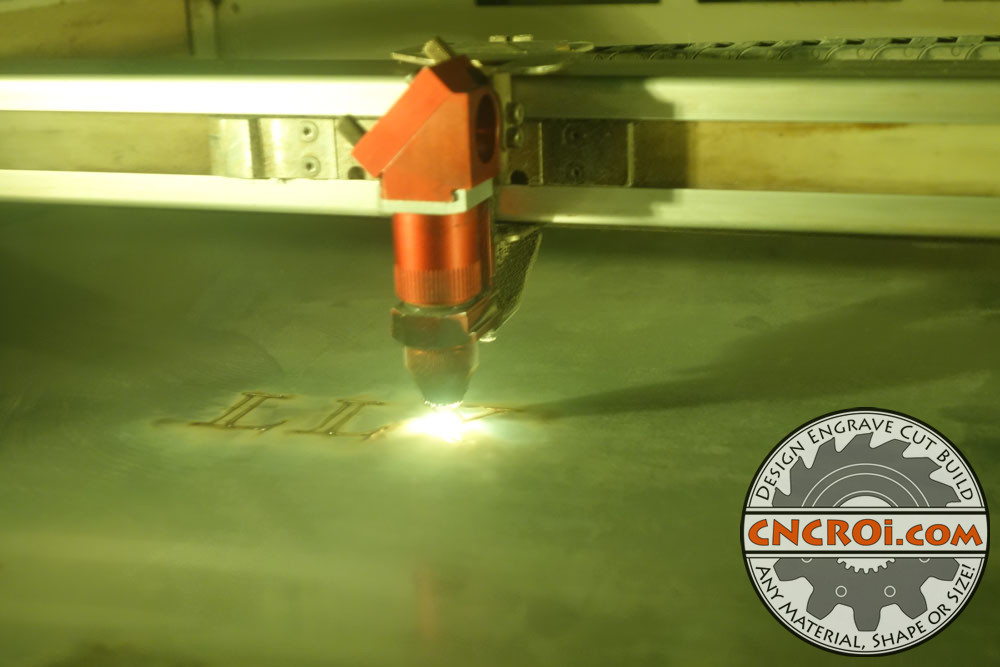

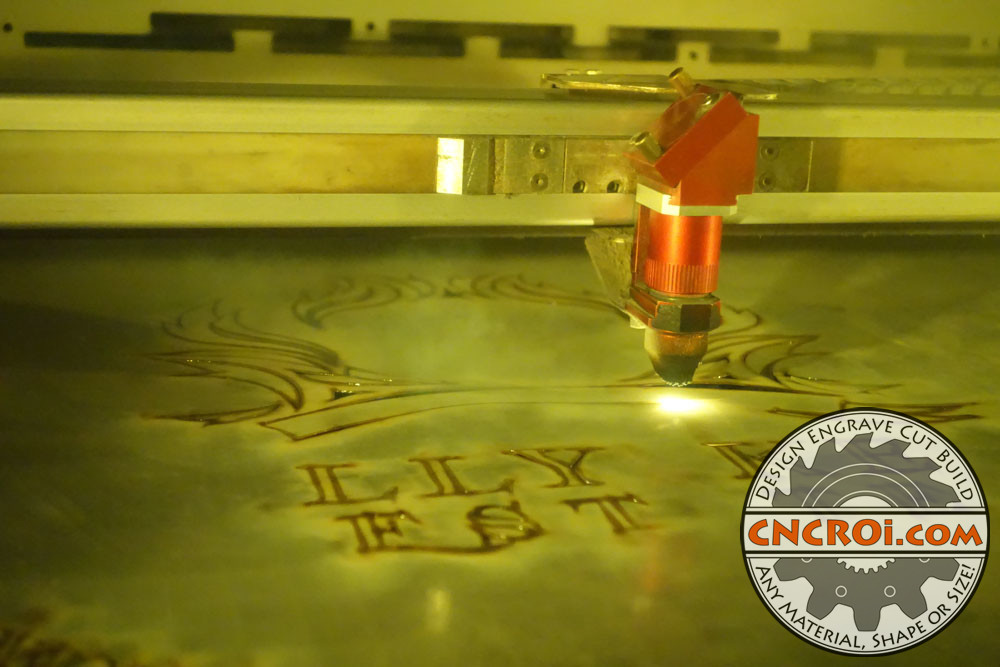

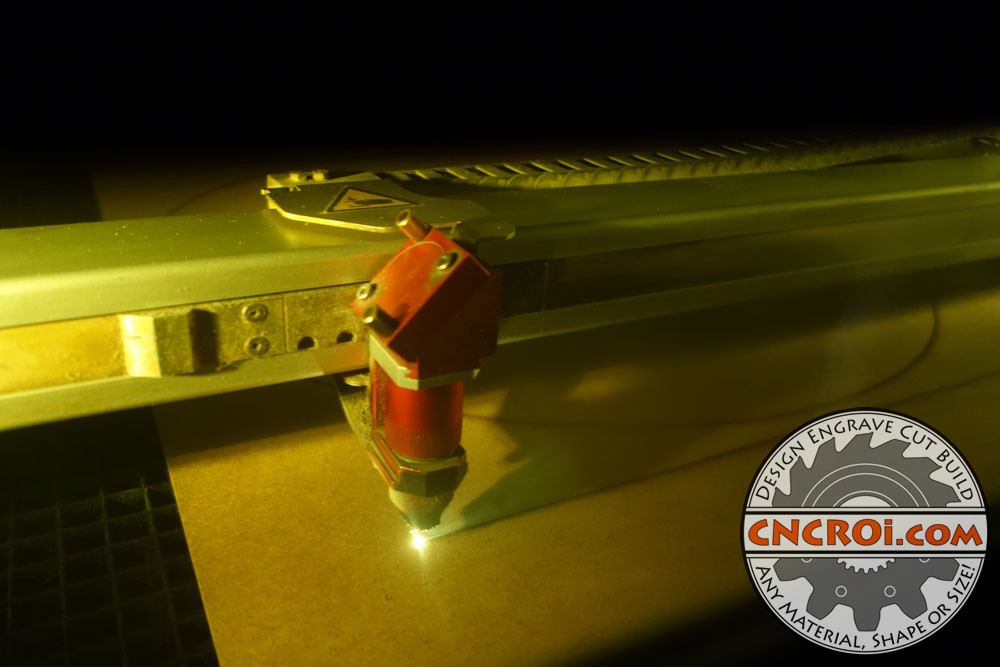

There is of course fire produced during the laser cutting process, all plastics become flammable when you put a high energy beam onto them to cut through this petroleum based product, this custom barrel head stencil is no different in that regard.

As all the pieces being cut are thoroughly cut, removing the scrap from the actual custom barrel head stencil isn’t an issue, there is no sticking or binding as you’d get with other materials, notably, acrylic.

The bright light you see is the instant vaporization of the polycarbonate under the intense heat of CNCROi.com‘s laser source, you can also see in the above picture that the polycarbonate sometimes lifts a little during the process, this happens because of differential heating, don’t worry, it has zero effect on the final results as it’s such a minimal lift.

Although CNCROi.com cuts plywood through paper stencils, it’s generally either polycarbonate or stainless steel, he’s why.

https://www.youtube.com/watch?v=xxFljG9iFJY/

Once the custom barrel head stencil is cut out, you can see how great the final results look like, it may be ugly, but again, that can be easily removed with the masking on both sides but it’s better to leave it on for reasons already outlined higher-up on this CNCROi.com blog post.

Removing the scrap, you can start to understand how sharp and precise this custom stencil is, notice the support materials used extensively in the BK area inside the flame and banner frame, otherwise, all those little parts in this custom barrel head stencil would fall out.

Plywood stencils have their place, it really depends on the application, he’s a unique one we did for sidewalks where the customer just used water to brand things.

https://www.youtube.com/watch?v=dz27x1cdrt8/

Next up is the packaging, I could easily roll up this custom barrel head stencil but I prefer to ship them flat, as such, to protect them during shipping, I like to make a hard MDF front and back shipping package for them.

It’s made-up of two parts, the first, the inside circle area where the custom barrel head stencil will be placed into, and this will also become the covering for the top of the stencil, thus, I’m only using 2 sheets to make the equivalent of a 3 sheet package at CNCROi.com for this customer.

I use stencils even at my house, it’s really a great way to do things quickly.

After laser cutting the hole, I cut out the outline of the overall package, things that are square or round cost the same to ship so I might as well make the stencil holder square, the weight increase is almost nothing for something of this size.

After the top of the stencil package is done, I cut out just a regular piece of square MDF, this will be the backing for the entire thing.

You can now see the final packaging with the stencil in it, minus the protective round circle that’s place onto the stencil before wrapping it up and shipping this job out.

Take a look at the close-up of the custom barrel head stencil, really couldn’t ask for a better stencil to do some amazing work with.

Need a custom stencil? Contact CNCROi.com right now!

https://www.youtube.com/watch?v=3hgRDaWNgSc/