Custom Cabinetry Front Covers

CNCROi.com can refresh any kitchen quickly by just making you custom cabinetry front covers, no need for an expensive total renovation!

https://www.youtube.com/watch?v=zjuQCPhiEio/

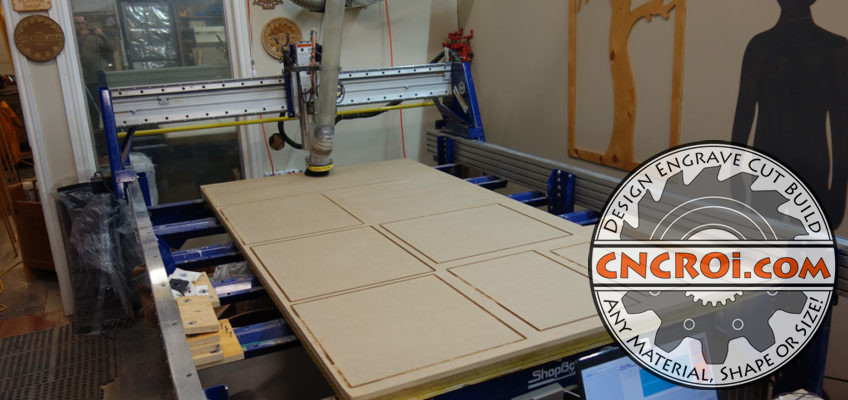

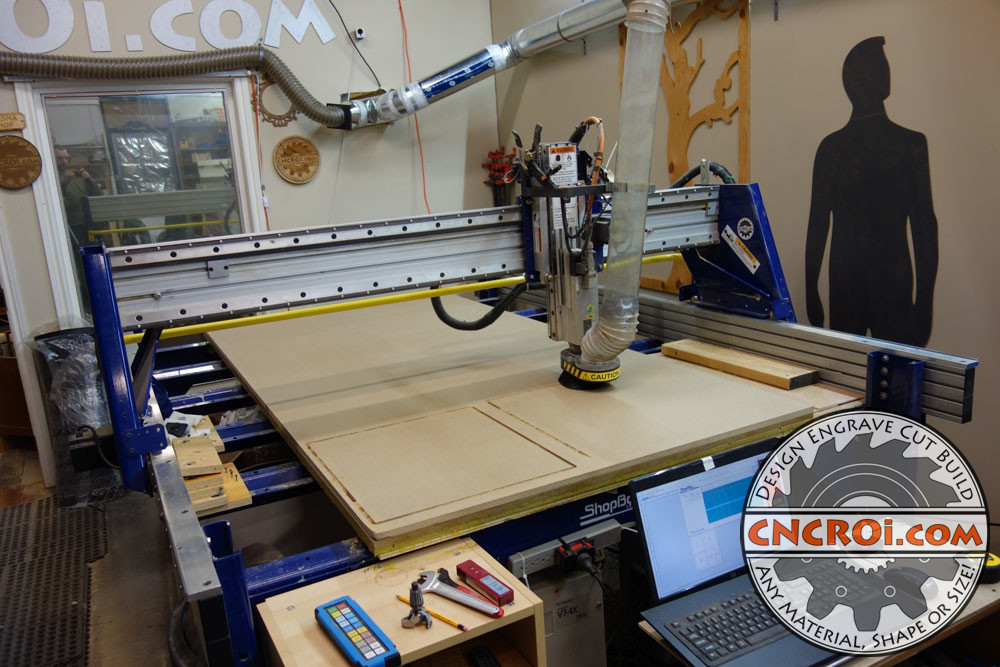

As this was the next job on queue after putting on a new sacrificial board, the first order of business with making this custom cabinetry font covers was to make the table dead flat.

You can easily tell what part of the table is cleaned-off and flat vs what the hard coating on the MDF was beforehand, this is a vital step as it ensures proper adhesion when the vacuum table is turned ON.

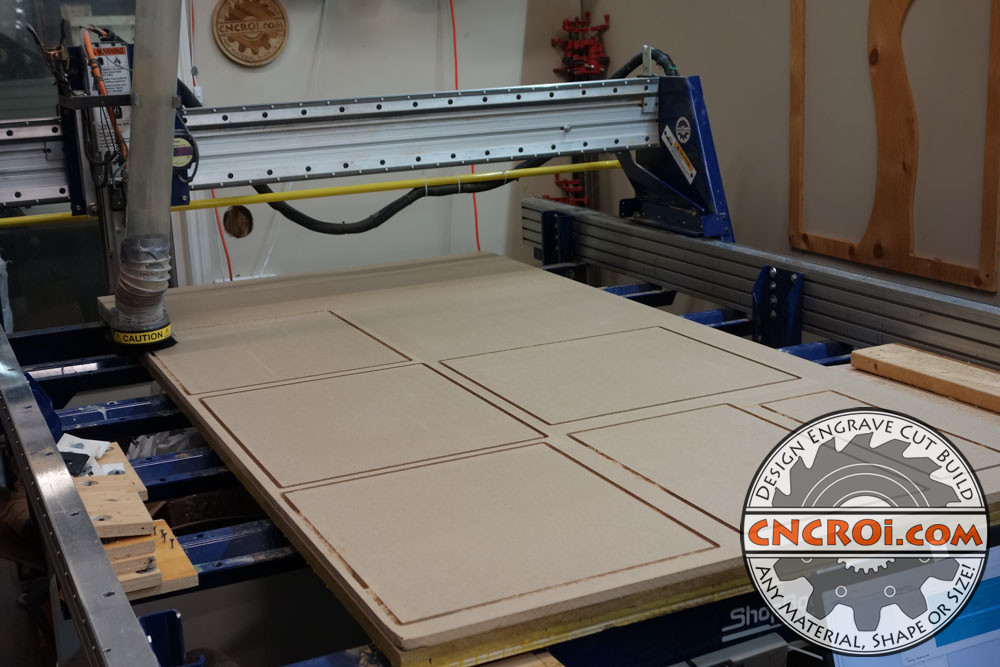

Once this process is complete, the next step is to get right on making the custom cabinetry front covers at CNCROi.com using a parallel and totally flat sacrificial board using our vacuum system to hold everything down.

Of course, you aren’t limited to only MDF with CNCROi.com – any material goes!

https://www.youtube.com/watch?v=z1Frz_5yQd4/

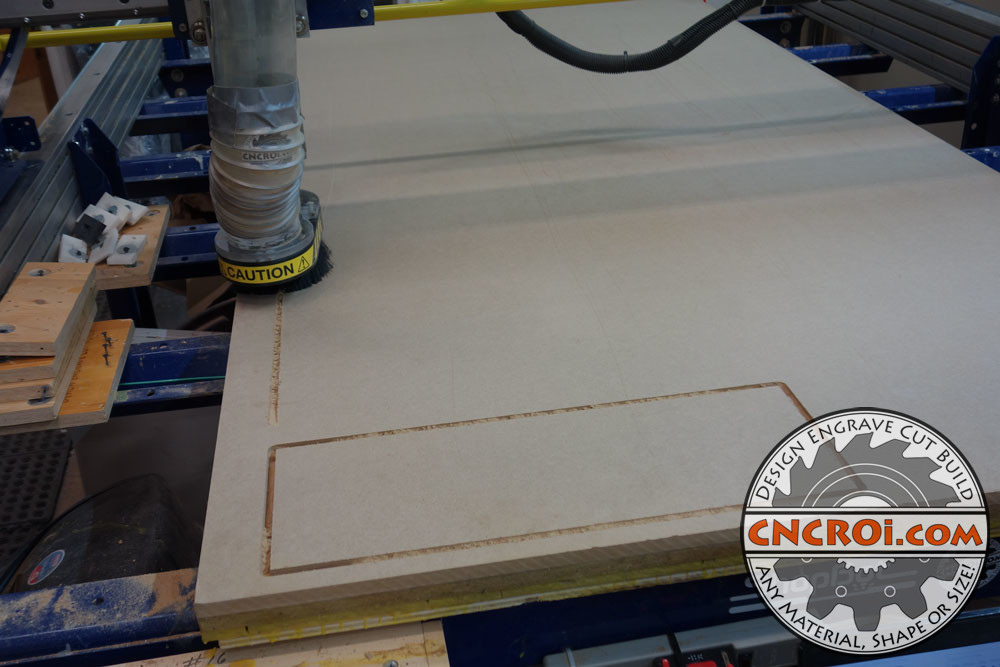

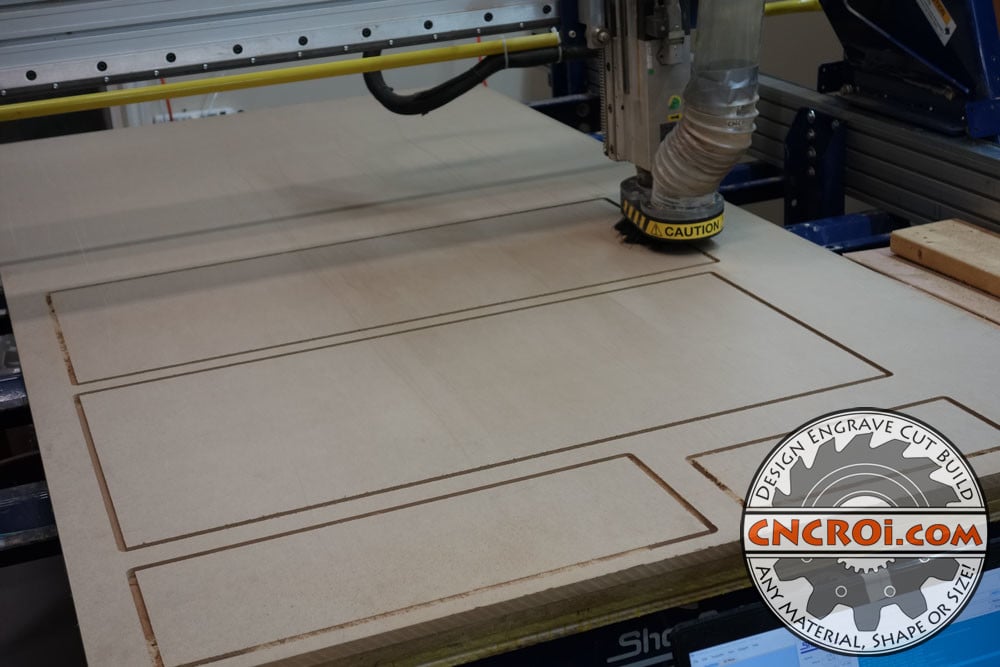

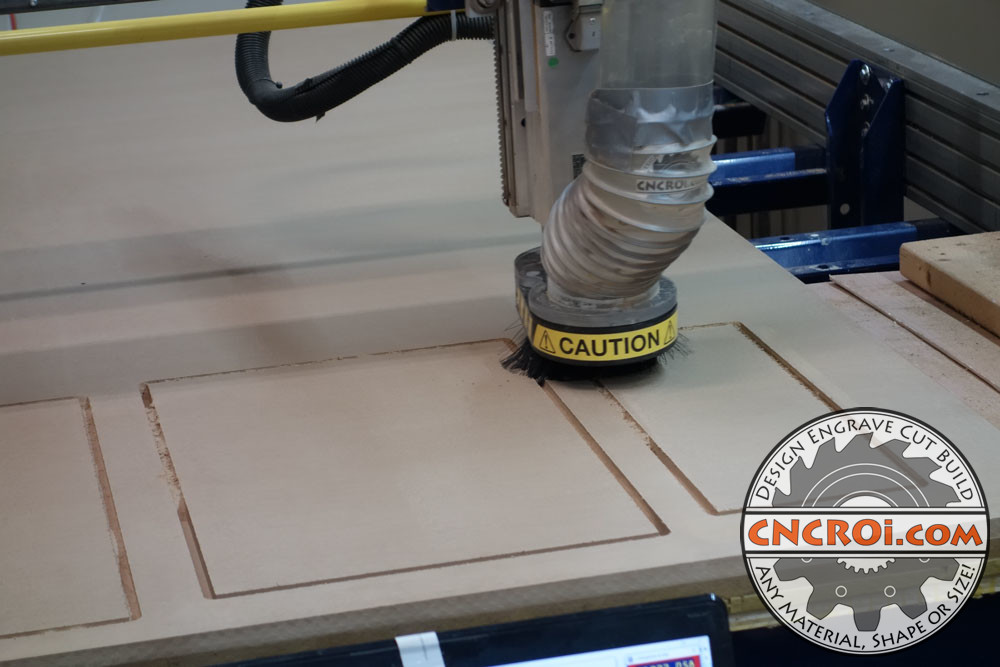

For this specific job, CNCROi.com is making the custom cabinetry front covers using 5/8″ thick MDF, it has the perfect strength to thickness ratio for this application and being MDF, we know it will love to be sanded and painted.

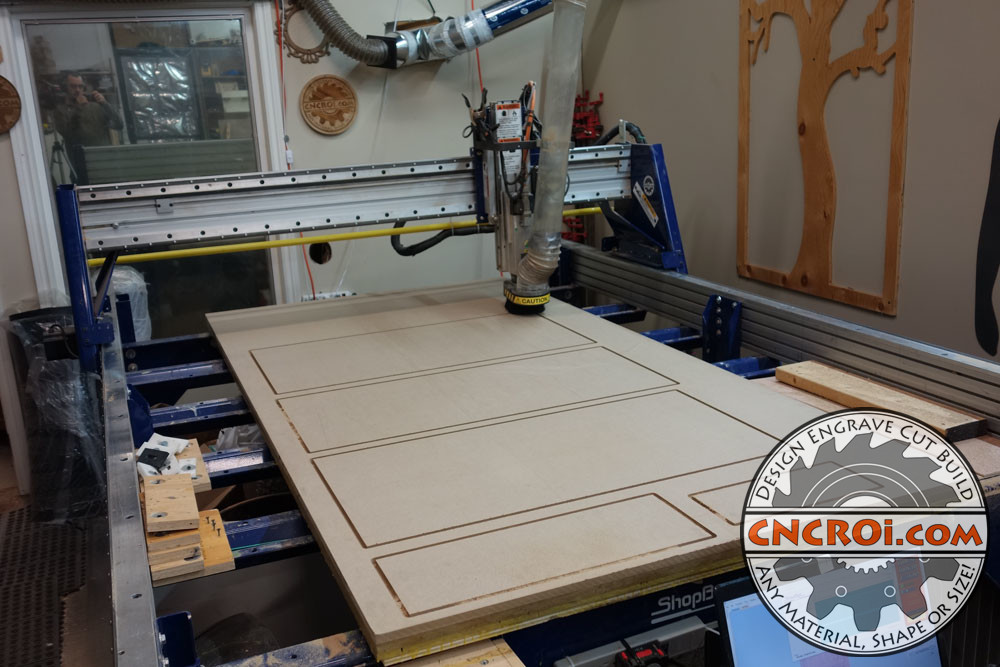

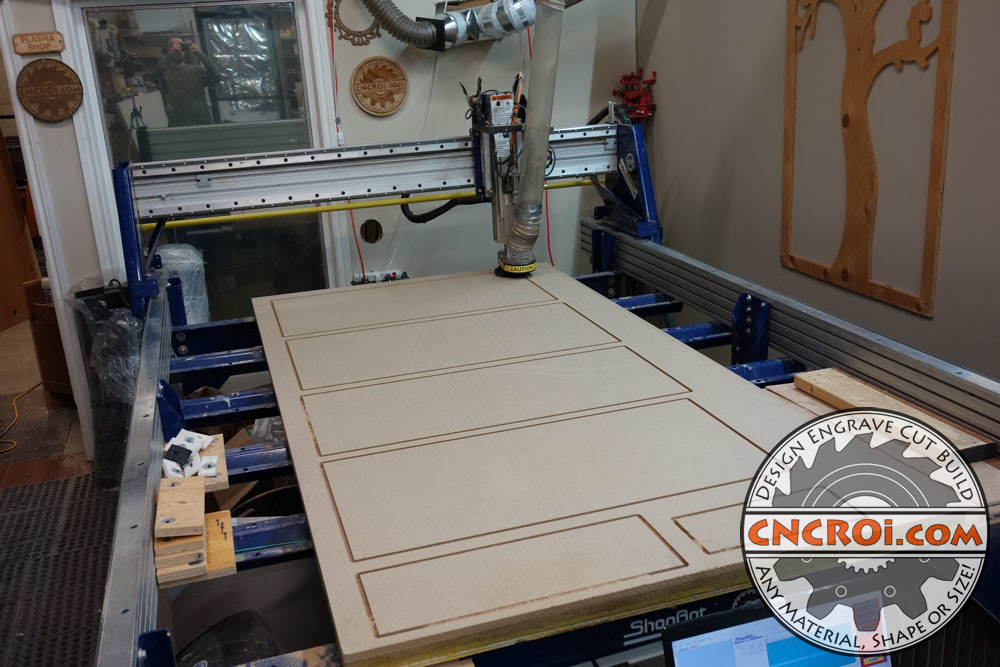

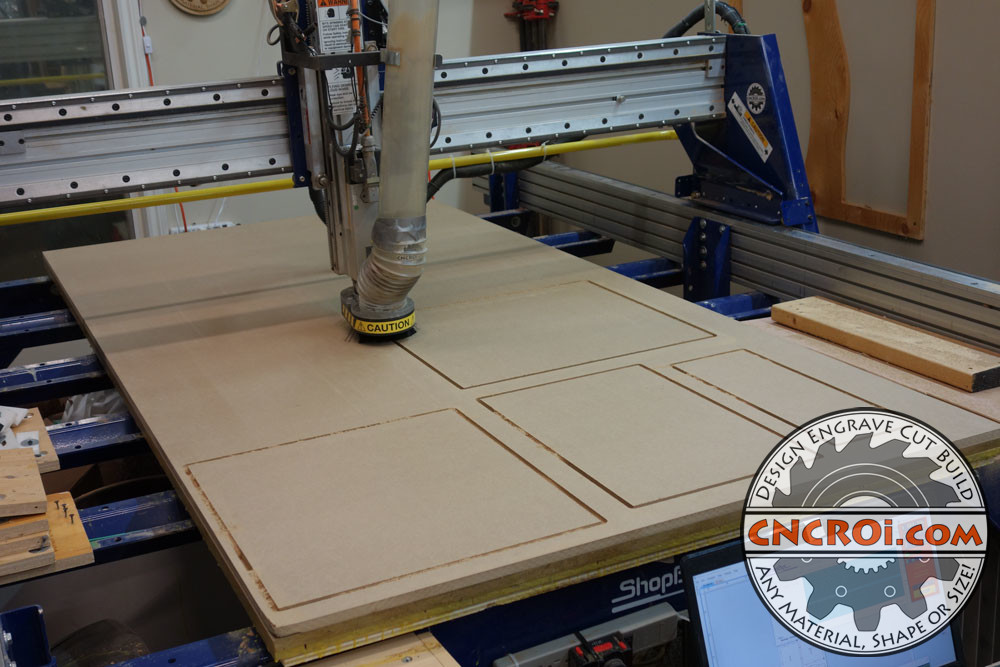

Regardless of the shape, size or dimensions that the customer comes up with, CNCROi.com will cut these custom cabinetry front covers right to spec out of the 4x8ft sheet of MDF.

There is relatively little dust because we have a dust system right next to the spinning bit, what this does is pick-up the dust as it’s being made by the CNC router, meaning very little clean-up is required afterwards.

CNCROi.com also uses MDF for a lot of other purposes at the shop, from templates to artwork for customers across North America.

https://www.youtube.com/watch?v=UKUB_LRe9AA/

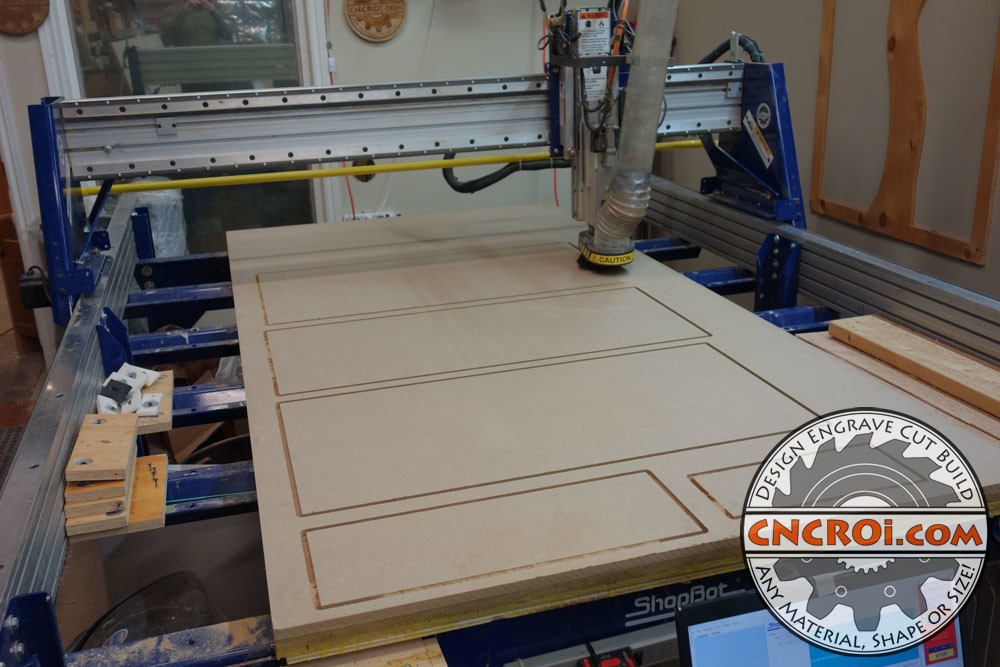

Having a vacuum table also means that there is no need to bolt or screw this MDF that’s going to later become a whole bunch of custom cabinetry front covers down to prevent it from moving, that’s the wonders of suction for you!

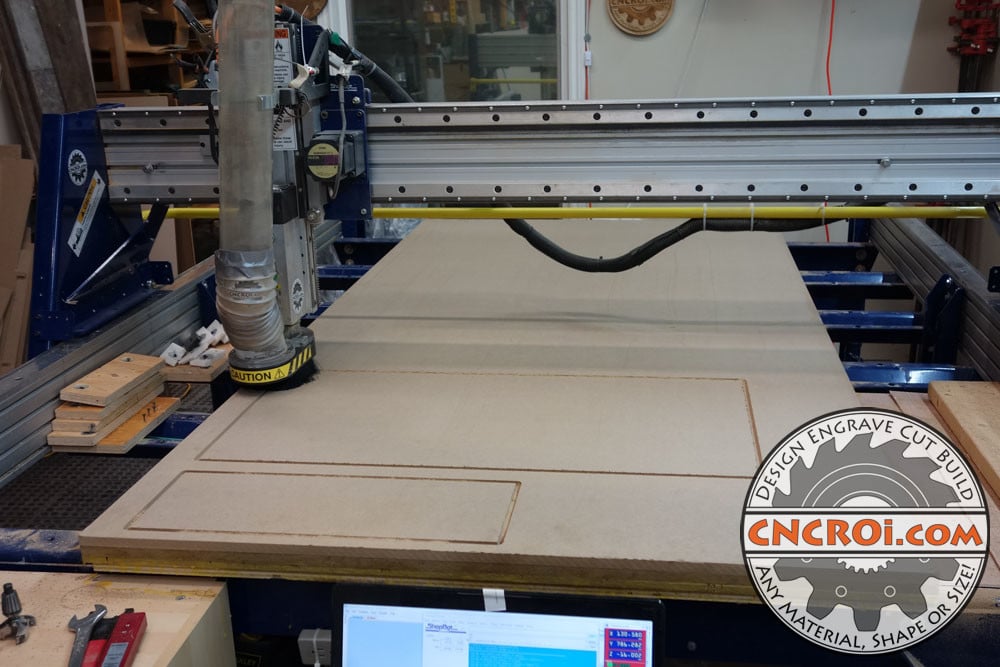

For this job, there were quite a few different sizes involved when it comes to custom cabinetry front covers, doors are bigger than drawers and so forth, each is done at the right size by CNCROi.com.

Cutting out the MDF, you can see how efficient the process is compared to having to do this using a normal table saw or old hand saw, there really is no replacing the power that CNCROi.com can offer any cabinetry shop to quickly produce what would have taken hours or days otherwise.

Just to show you the power of paint on MDF, here’s what can be done using just a spray can.

https://www.youtube.com/watch?v=TThHgeoadTg/

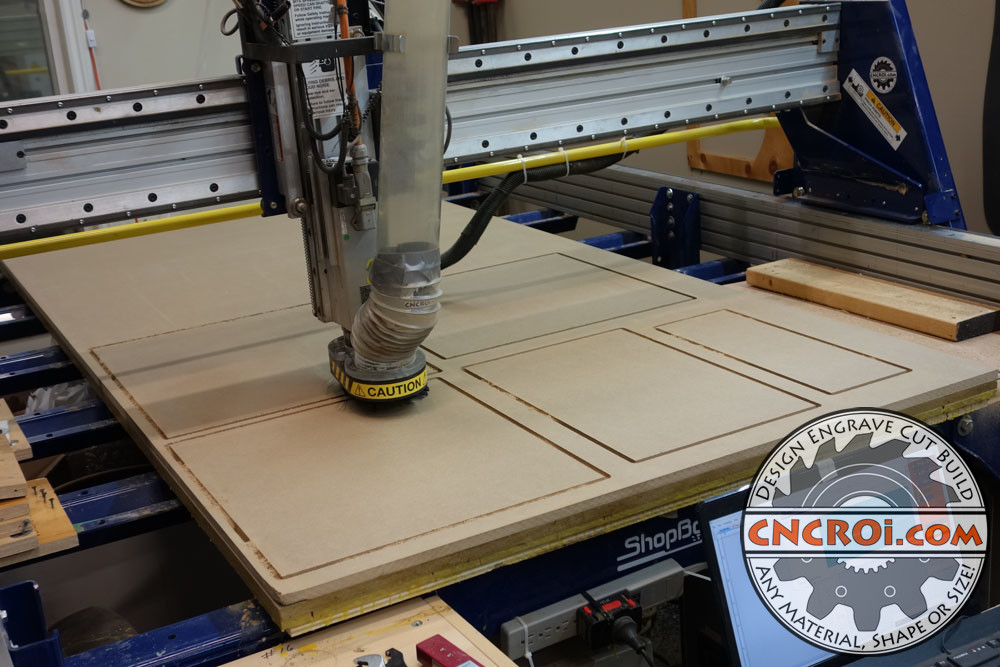

When it comes to cutting the MDF, any design spec you an come-up with is possible, including intricate inner carvings and relief areas or reference holes for screws on the job site.

MDF on its own isn’t very special, but for applications such as kitchens and cabinetry, it’s a great material as it’s so easy to work with different machinery and platforms in order to achieve your finishing goal.

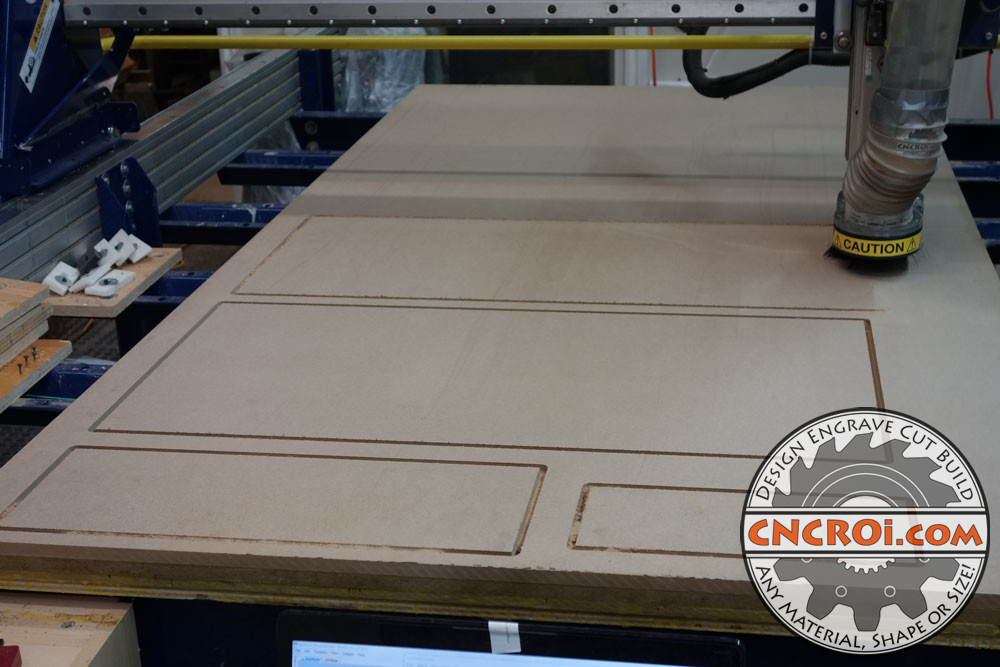

For this specific project, you can see there is very little material wastage, other than the borders left along the edges (was going to be lost anyways), most of what’s left is truly scrap and will be dealt with at the fire pit.

CNCROi.com has also performed MASSIVE MDF cutting jobs, so big or small, we do them all!

https://www.youtube.com/watch?v=uvHMBQN0-sI/

I’ve done a lot of custom cabinetry front covers at CNCROi.com through the years, they are fun jobs to do, pretty straight forward, easy for the customer to finish and the results always come out great.

Generally the order of production for custom cabinetry front covers are the biggest covers first with any “holes” being filled in the MDF sheet by the next biggest that fit and so on, otherwise, it’s possible to waste a lot of material because at the end, the nesting wasn’t efficient and you end-up cutting a bunch of big pieces with no more little empty spaces to fill with smaller covers.

I don’t know how any shop can do a job like this without a CNC router, it’s just such an enjoyable and relatively easy, after the feeds, speeds and programming are completed, way of making stuff.

If you want perfect circles and ovals, there really is no other tool that does it as seamlessly as CNCROi.com‘s CNC router.

When it comes to making custom cabinetry front covers, the easiest way for you to send us your drawings, if you can’t produce them digitally, is just to sketch-up the sizes you need on a piece of paper and send us a photo of that.

From there, CNCROi.com can digitize the sizing to be accurate and go right into production literally cutting these custom cabinetry front covers out of any material you want, from stainless steel to Corian and yes, MDF.

This was a fun little custom cabinetry front covers job, one of many more to come, I really enjoy getting pictures from my customers once they are done the finishing process.

Need custom cabinetry front covers? Contact CNCROi.com right now!

https://www.youtube.com/watch?v=KwkHYjqDU-M/