Custom Carbide Clock: Fiber Etched

Making a custom carbide clock requires a few steps but at the end of the day, it’s no different than the typical stainless steel work we do at CNCROi.com day in and out.

https://www.youtube.com/watch?v=n56CCFPCMbE/

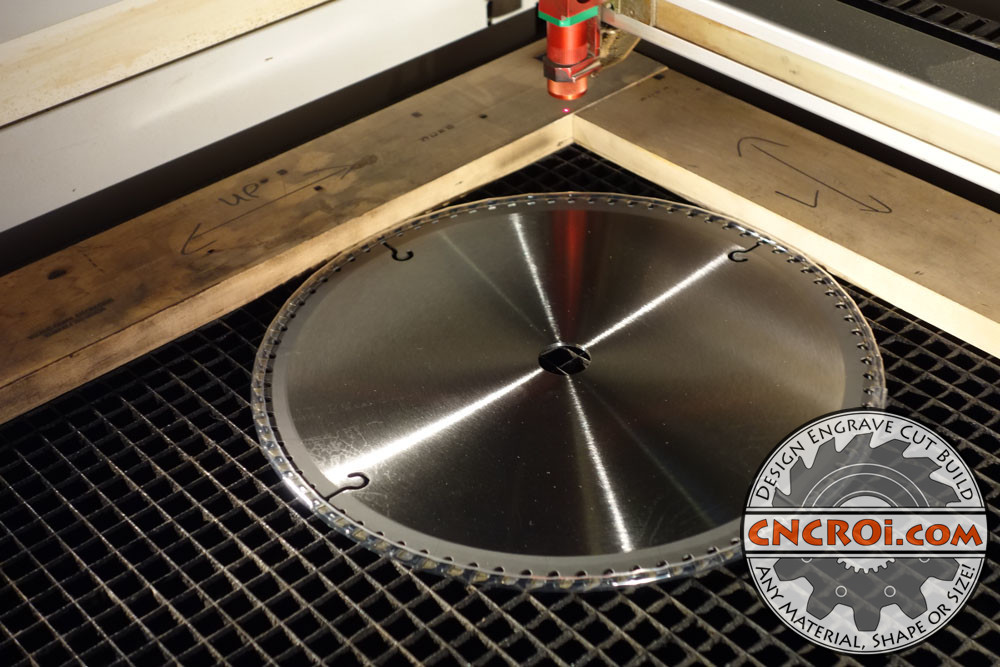

To make a custom carbide clock, you need a table saw 12″ carbide blade – the non-carbide parts are stainless steel so it etched wonderfully, again, no different than typical plates we etch all the time at the shop for customers around the world.

Fiber etching is a way to permanently mark or carve out (depending on the settings) metals of all types, aluminum though titanium and other ferrous and non-ferrous metals.

Fiber etching this custom carbide blade means that the marking you see on the blade will not crack, fade or peel off, unlike other methods that involve ink or dyes that are put on only the surface, additionally, the marking is actually harder than the surface virgin material, as such, if anything is going to wear out somehow, it will be what’s around the etching before the etching itself.

Of course, if you want a custom stainless steel sign cut, that’s just as easy for CNCROi.com to do.

https://www.youtube.com/watch?v=Ln9EXslzc04/

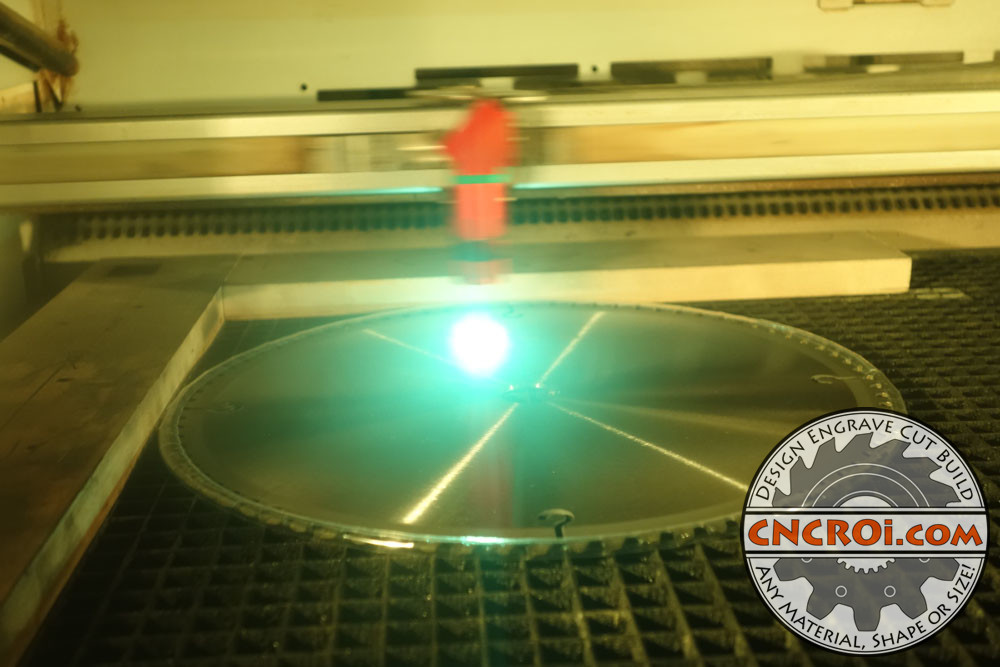

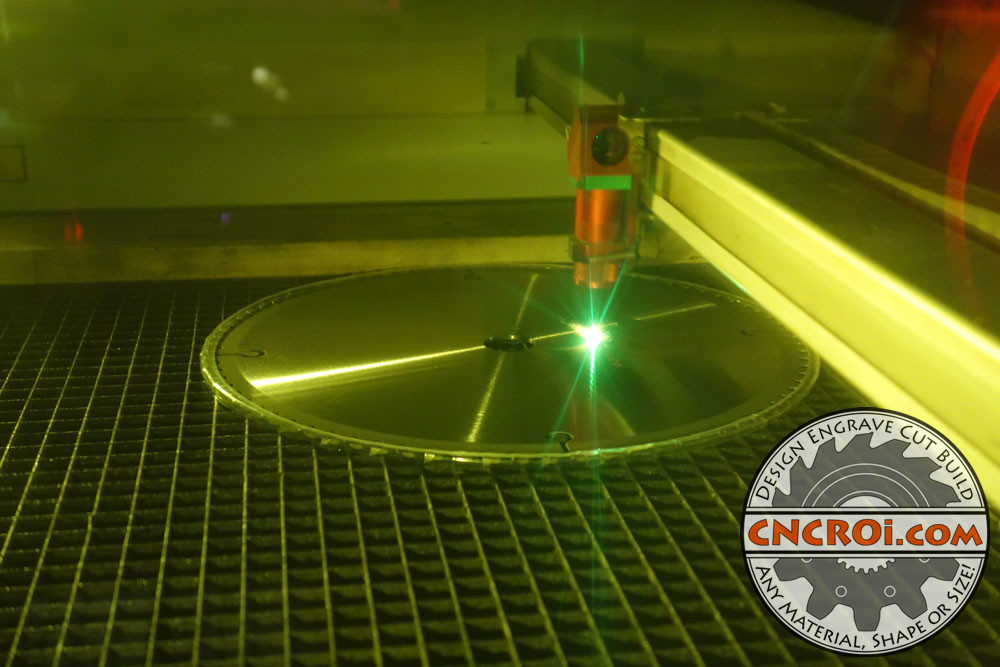

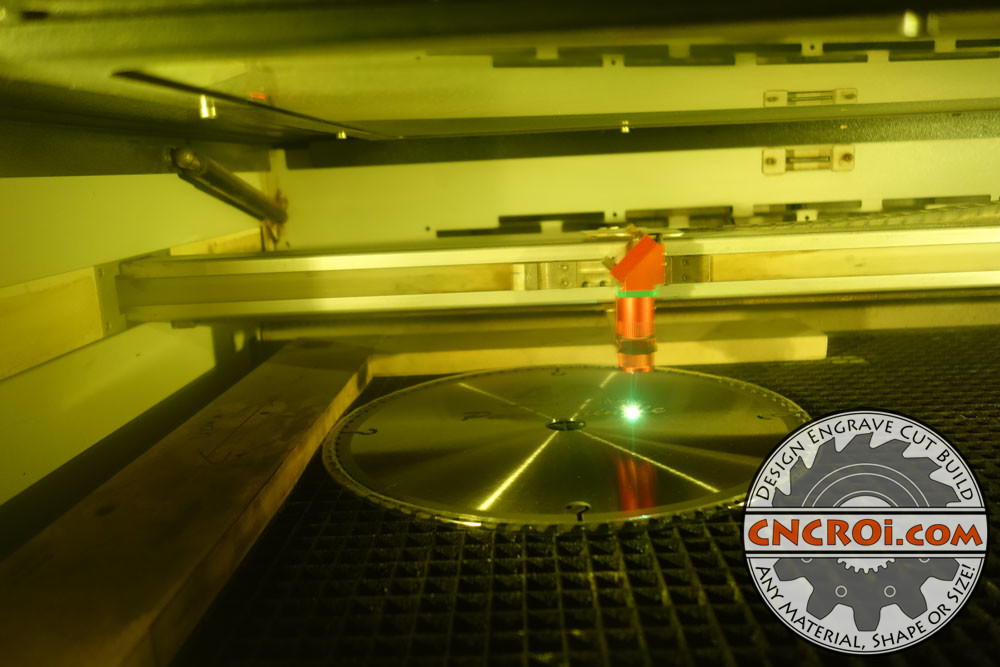

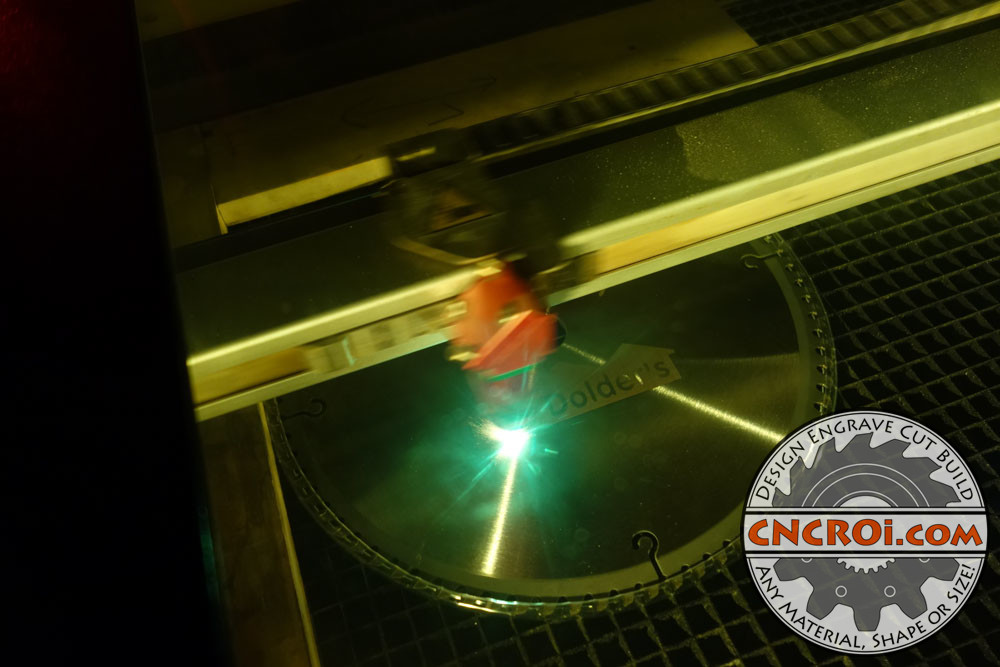

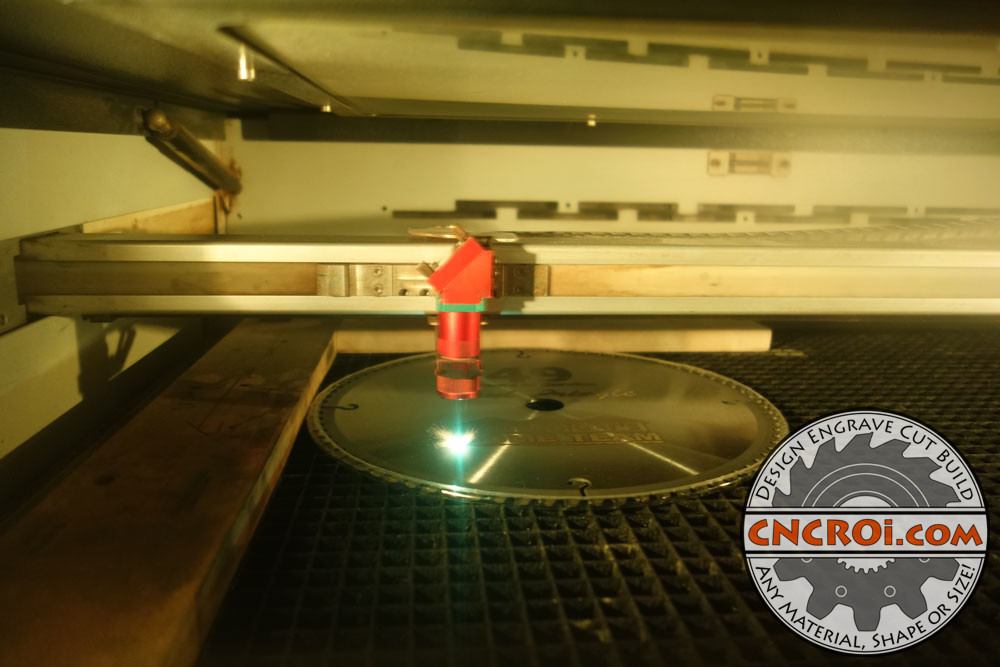

The heat generated by the fiber laser at CNCROi.com is plenty strong and hot, but it’s highly focused, as such, the plastic all around the blade protecting the carbide inserts doesn’t melt while we etch the custom carbide clock.

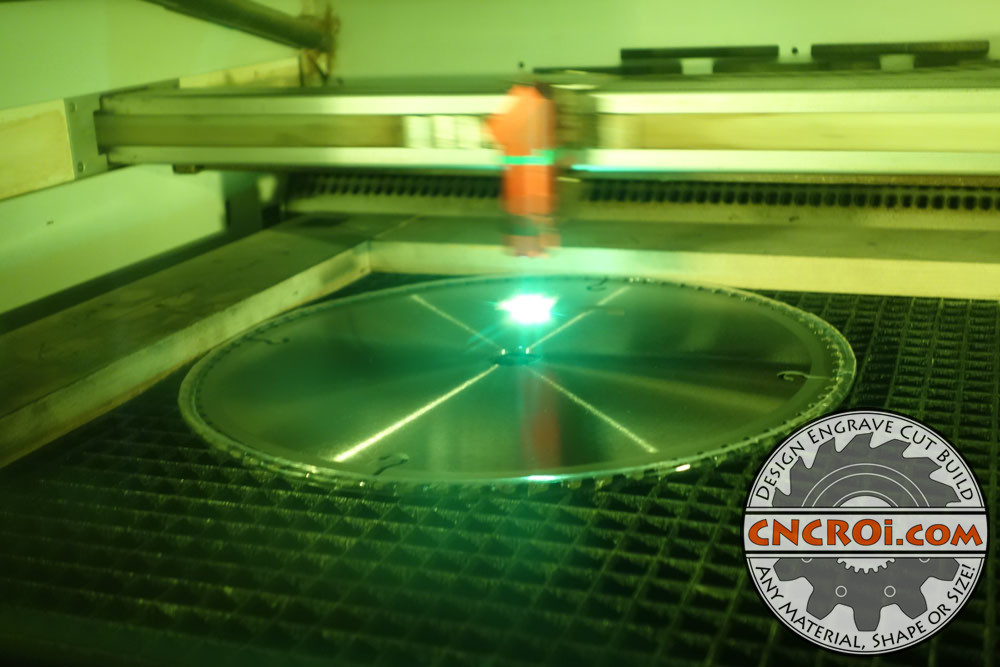

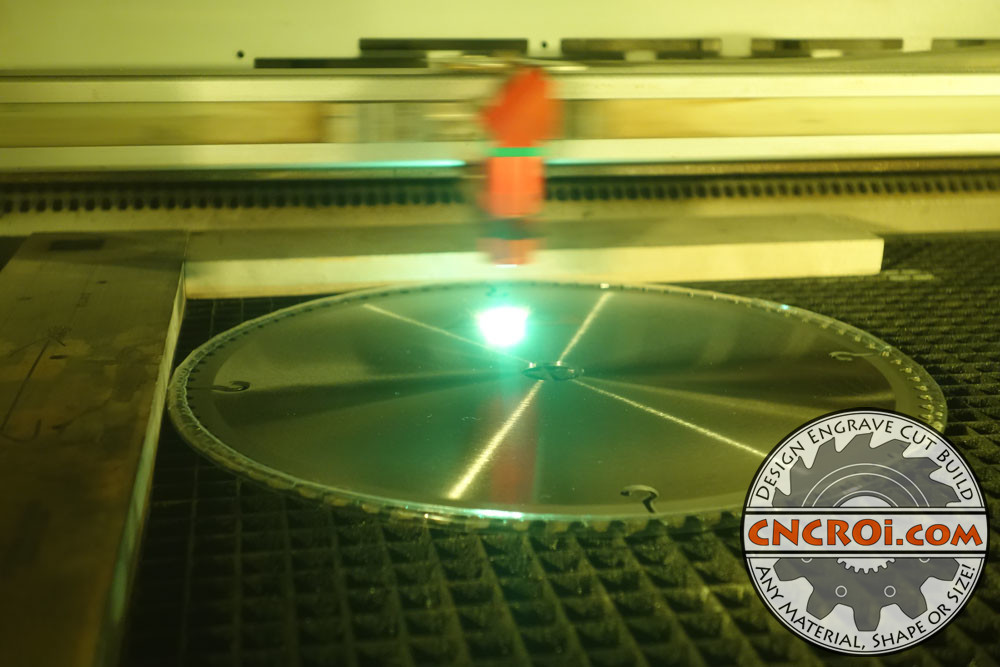

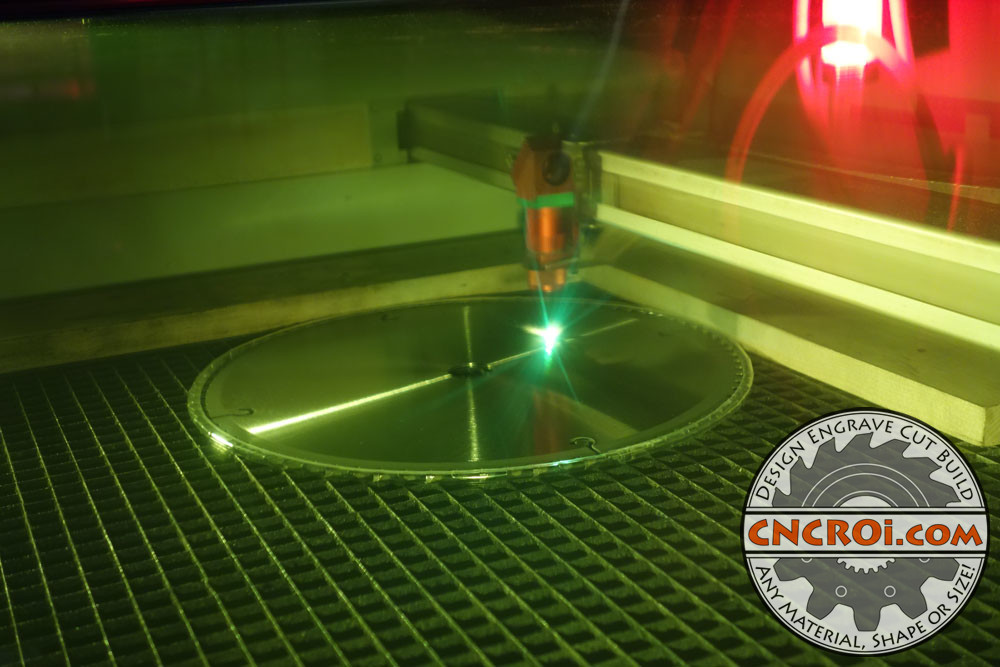

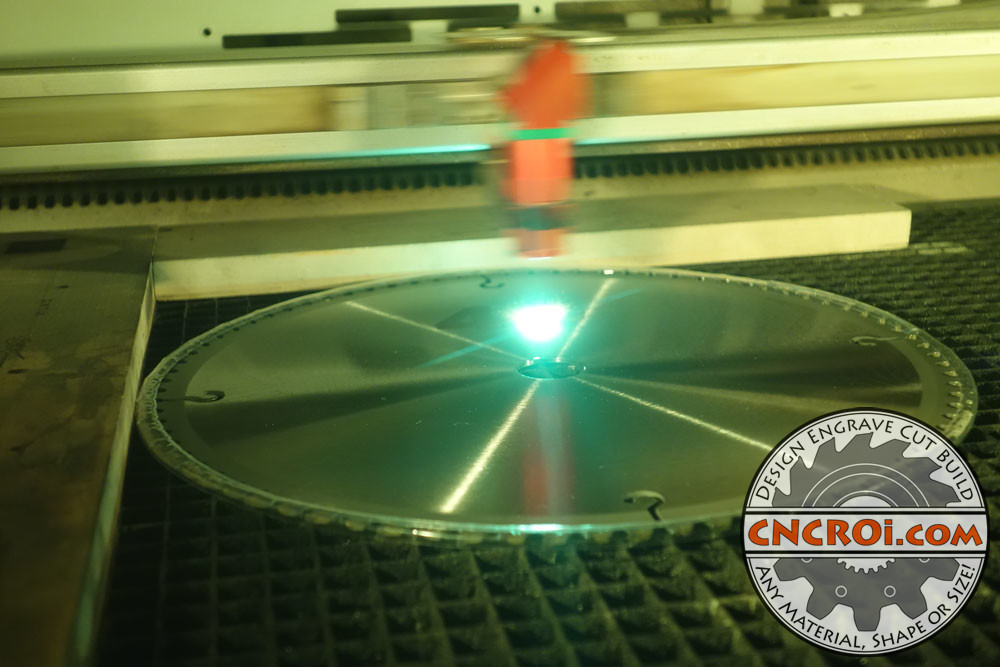

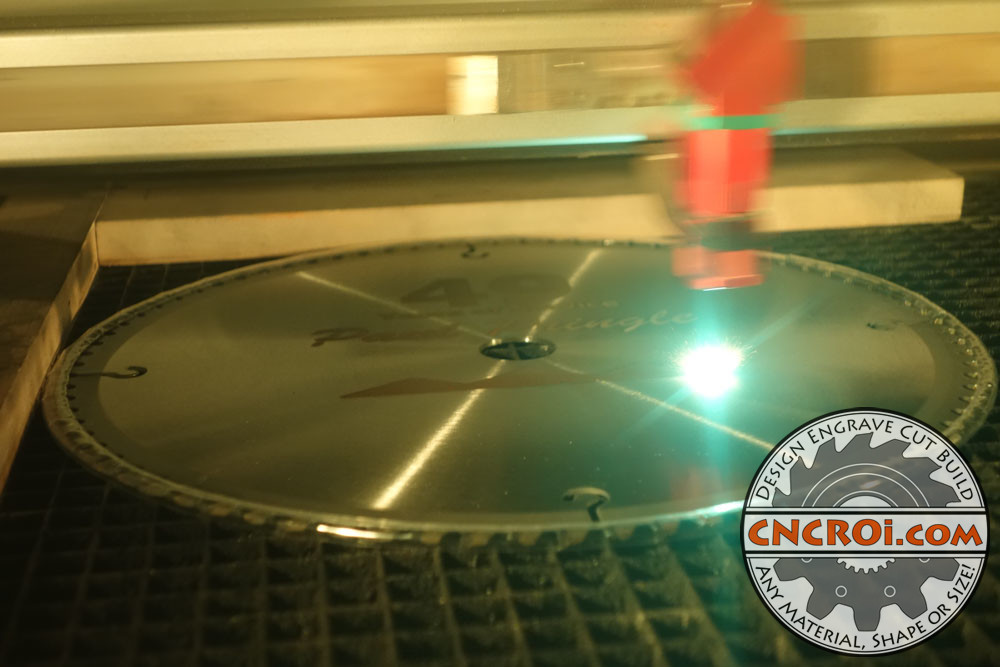

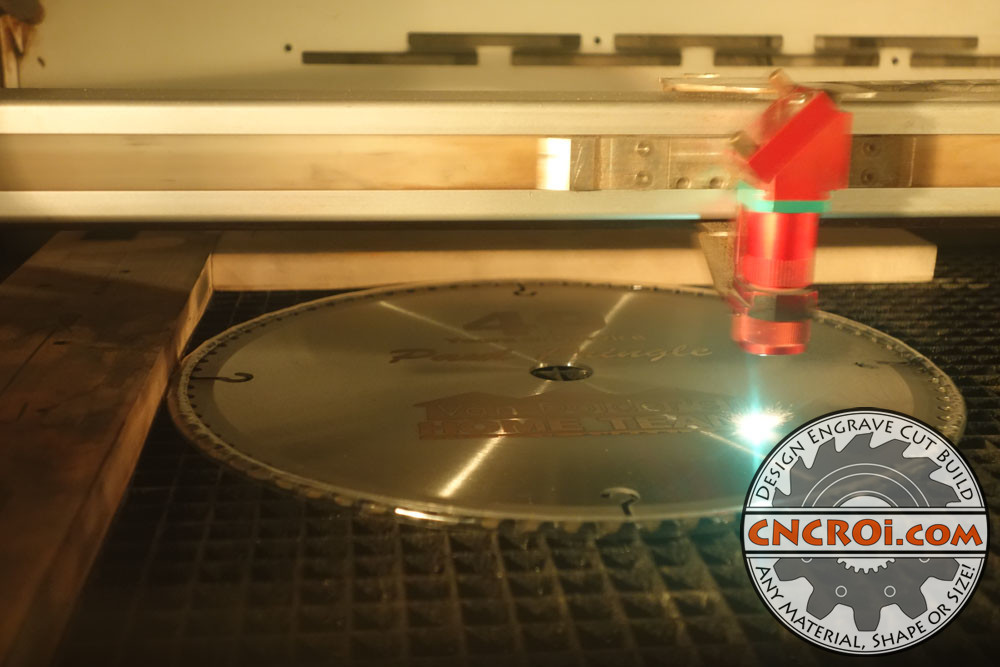

It’s very hard to get proper photographs and video of the fiber etching process, the light is blinding and the camera has a tough time adjusting and adapting to the light being produced during the custom carbide clock production.

When it comes to your image and font choices for your custom carbide clock, they are endless and limitless, anything goes, as long as it’s black and white and vector based.

Fiber etching this custom carbide clock is a pretty straight-forward process, start-off with a clean carbide blade, put it in the laser, get the design files designed and approved by the customer then let the machine do the work, after processing, the clean-up and integration of the clock mechanism as well as battery testing is all that’s needed before shipping this out to the customer.

When it comes to other types of jobs CNCROi.com can do for customers, the options are endless to mix and match materials and processes.

https://www.youtube.com/watch?v=VAasMmiPvy8/

What I like about carbide blades is how clean they are right from the purchase at the store but what’s cooler is that if we put this into our table saw, we could actually use it to cut projects out and the etching you see produced by CNCROi.com on the face of the custom carbide clock wouldn’t come off.

Fiber etching is great for memorial plaques, industrial tagging or anything that requires permanence, I can’t think of any other process that can offer the resolution and power that this technology offers our customers.

CNCROi.com can offer a wide variety of fiber etching possibilities, from just being on the surface to deep etching into the metal, generally we do these processes on stainless steel.

For this custom carbide clock, only one pass was required at our typical settings, but if the customer wanted something deeper or just annealed on the surface, CNCROi.com can perform those processes just as easily.

Here’s an option that is available to you as well, deep fiber laser etching.

https://www.youtube.com/watch?v=rWeM9-VUOII/

The bright light you see in these photos and in the video of the custom carbide clock production is the instant vaporization and heating of the metal under the gantry head of our fiber laser system.

Fiber laser etching can be done at a variety of resolutions, so there is a lot of flexibility that CNCROi.com can offer our customers when it comes to achieving processes at specific specs they need for their projects.

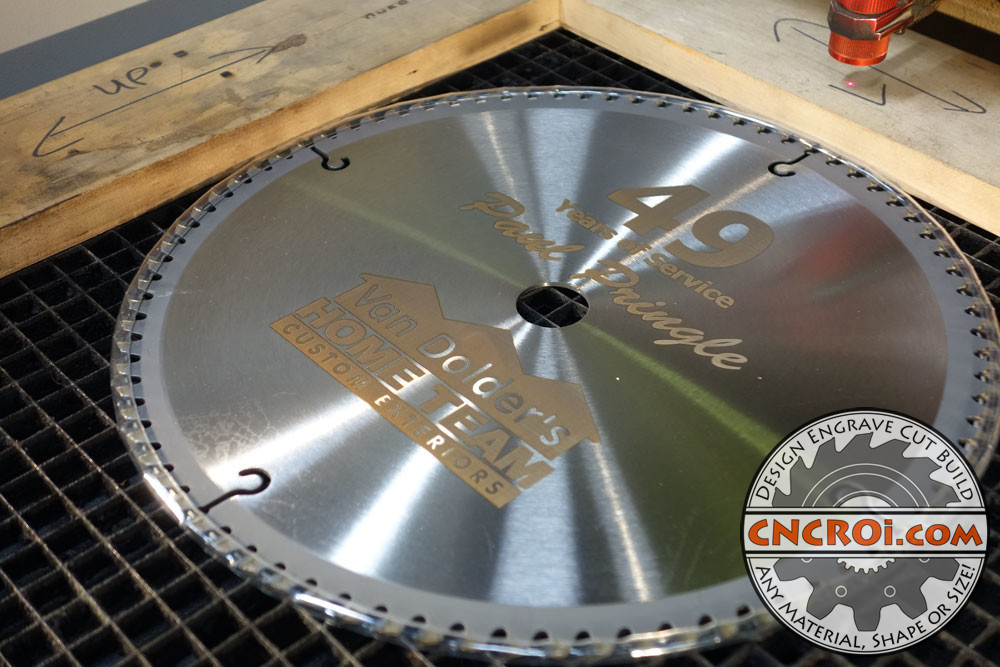

This custom carbide clock is just about done fiber laser etching, it’s one of the few photos that came out perfectly and yes, this is what I see during the entire process, it’s just the camera that has trouble taking the proper photo.

Fiber etching has a great visibility as unlike annealing, the reflectivity is taken off the surface of the material, this only increases after cleaning it up and sealing the surface.

If you want to see the difference between fiber laser annealing and fiber laser etching, take a look at what’s possible on this 316 stainless steel plate.

https://www.youtube.com/watch?v=EdEIRd9_c4w/

You’ll see that the reflection is gone where the fiber etching has been done on this custom carbide clock.

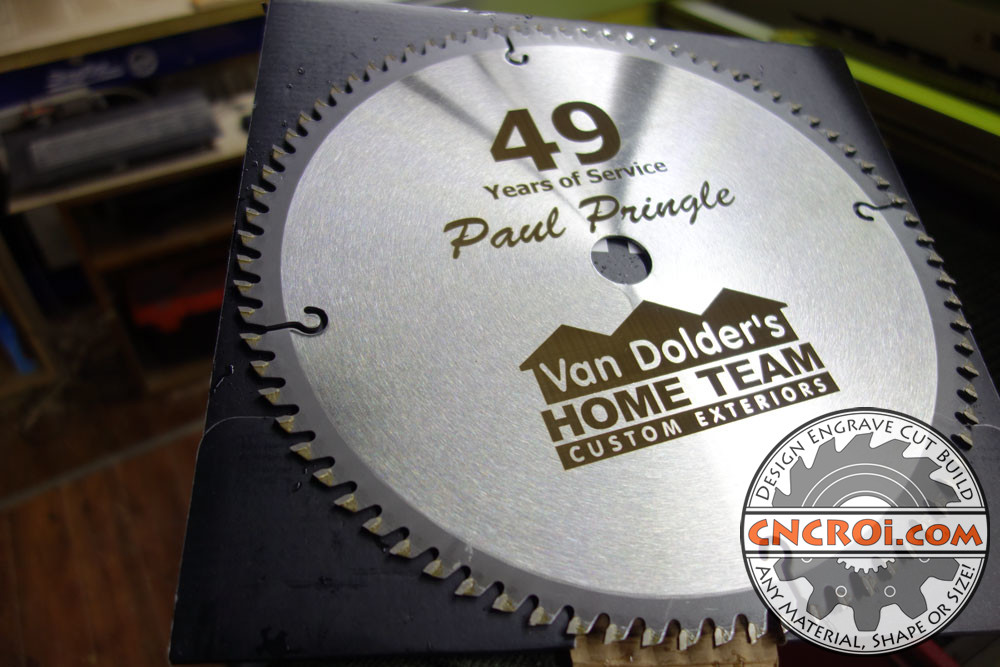

It’s quite impressive how much of a change already after cleaning up the fiber etched surface from the photo above to the photo below.

And again, after sealing, you go from the more visible top photo to the sealed highly visible fiber etching below on the custom carbide clock.

Making custom metal projects is relatively straight forward for CNCROi.com, we aren’t just a provider but also a customer.

https://www.youtube.com/watch?v=ObgxYj3yoLM/

Of course, the sealant does has some reflectivity built-into it, but it’s nowhere near as shiny as what would be achieved annealing the blade instead of fiber etching and sealing it.

Like the fiber etching process, it’s hard to properly photograph stainless steel as it takes-on the reflection of the environment it’s within.

Need a custom carbide clock? Contact CNCROi.com right now!

https://www.youtube.com/watch?v=QpmehwehCt4/