Custom Christmas Tree Stencil

CNCROi.com plasma cut a stainless steel Christmas Tree a few weeks back and now the customer wanted a stencil of the same design, minus the trunk.

https://www.youtube.com/watch?v=ZsfqMnXtoIY/

If you want to see the video of CNCROi.com plasma cutting this Christmas tree stencil using stainless steel, watch below.

https://www.youtube.com/watch?v=3Tkn8fuTcCM/

Whether it’s metal or wood, plastic or some mystery substance, we can cut it to make the best stencil possible.

This Christmas tree stencil wasn’t going to be used for a very long time nor for a lot of impressions, so making it out of a more durable substance wasn’t necessary – remember, the number of times you can use a stencil is directly related to the material you plan on having CNCROi.com produce it from.

One of the major advantages of polycarbonate stencils is that they are incredibly durable and can be rolled-up when not in use.

https://www.youtube.com/watch?v=-fCItLVr2pk/

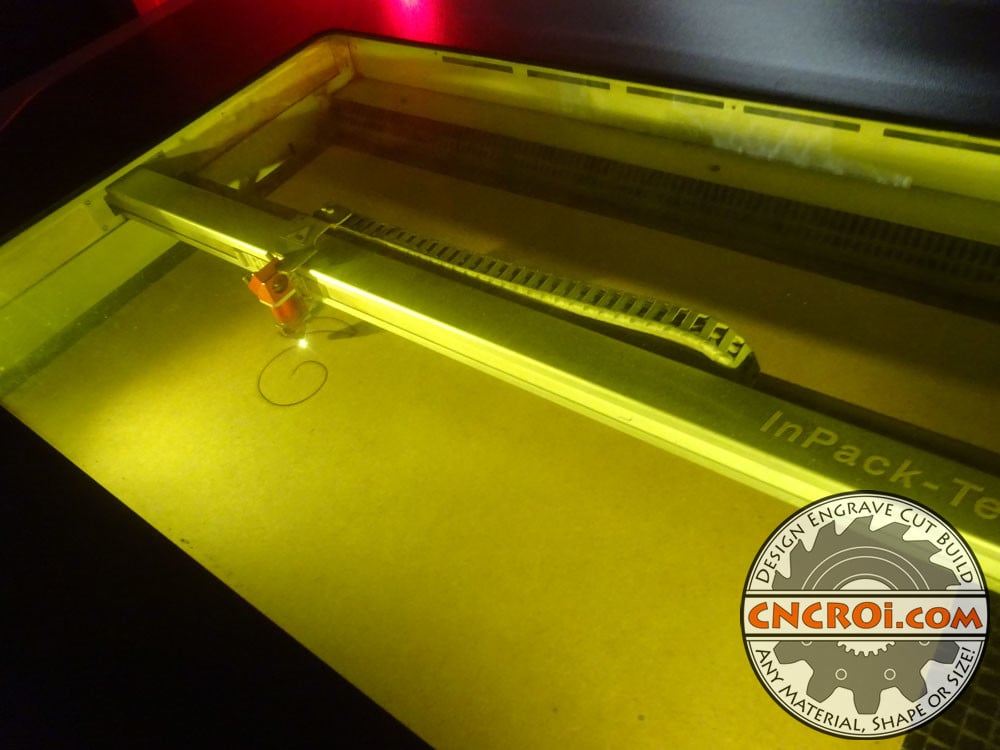

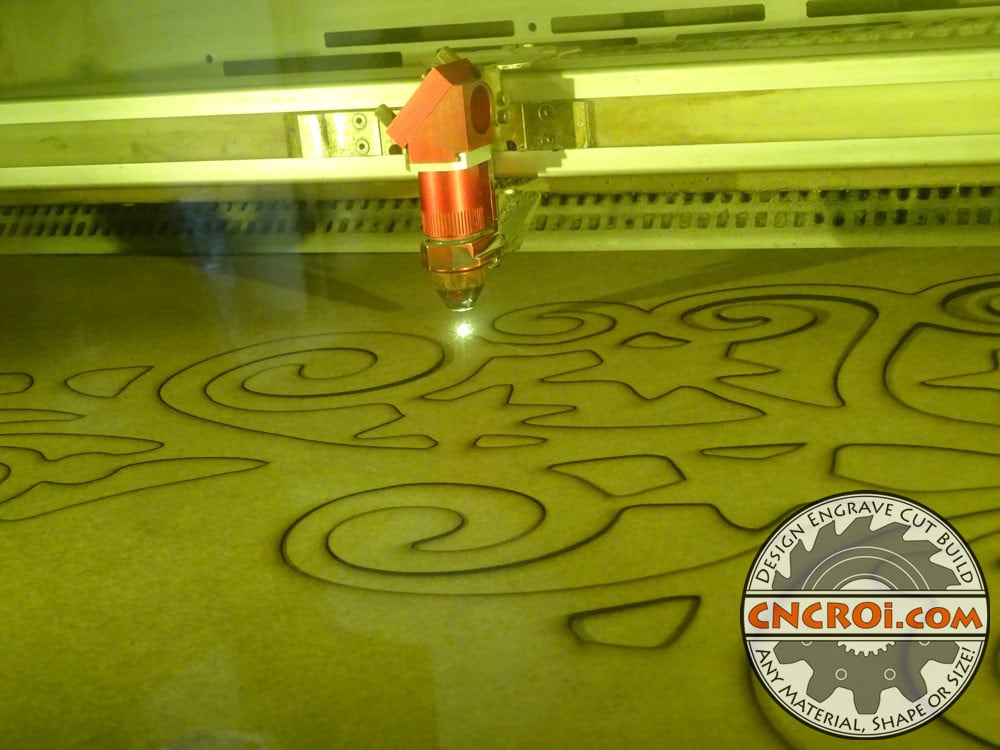

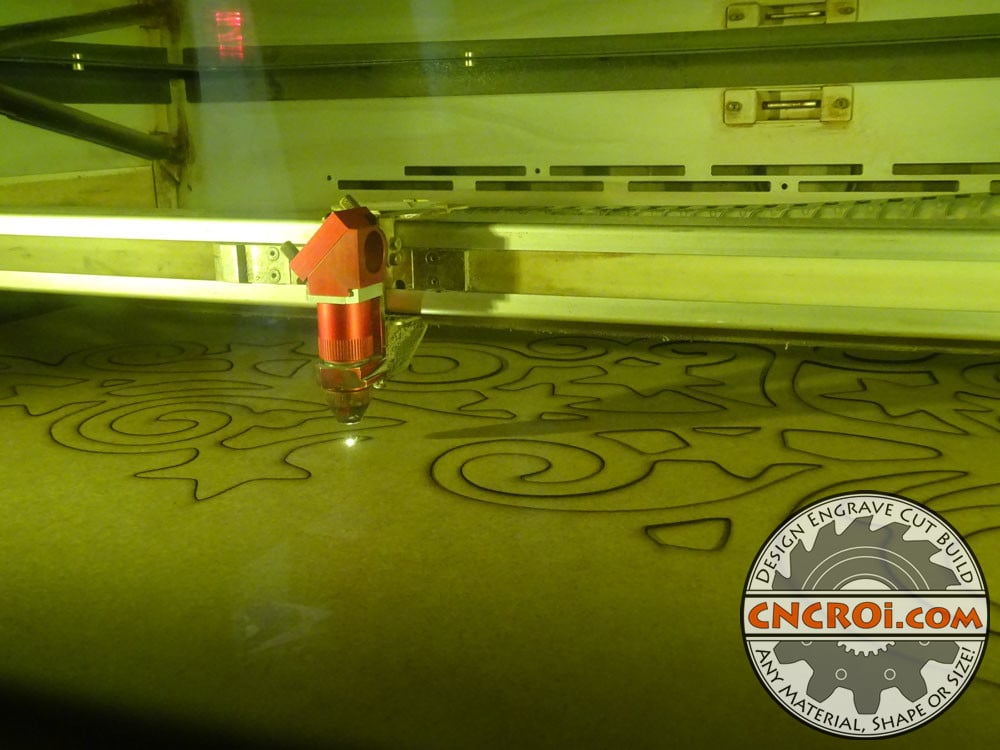

As with all the other stencils CNCROi.com produces, we always cut out the inner parts before the outer parts to make sure nothing moves during production, whether it’s the stainless steel you saw in the plasma cutting video above or laser on MDF in this blog post, makes no difference.

The precision and accuracy is the same between the plasma and the laser, the only difference is the diameter of the beam, laser is dramatically smaller but it’s also a lot slower than the plasma.

There are lots of material options when it comes to custom stencils.

https://www.youtube.com/watch?v=xxFljG9iFJY/

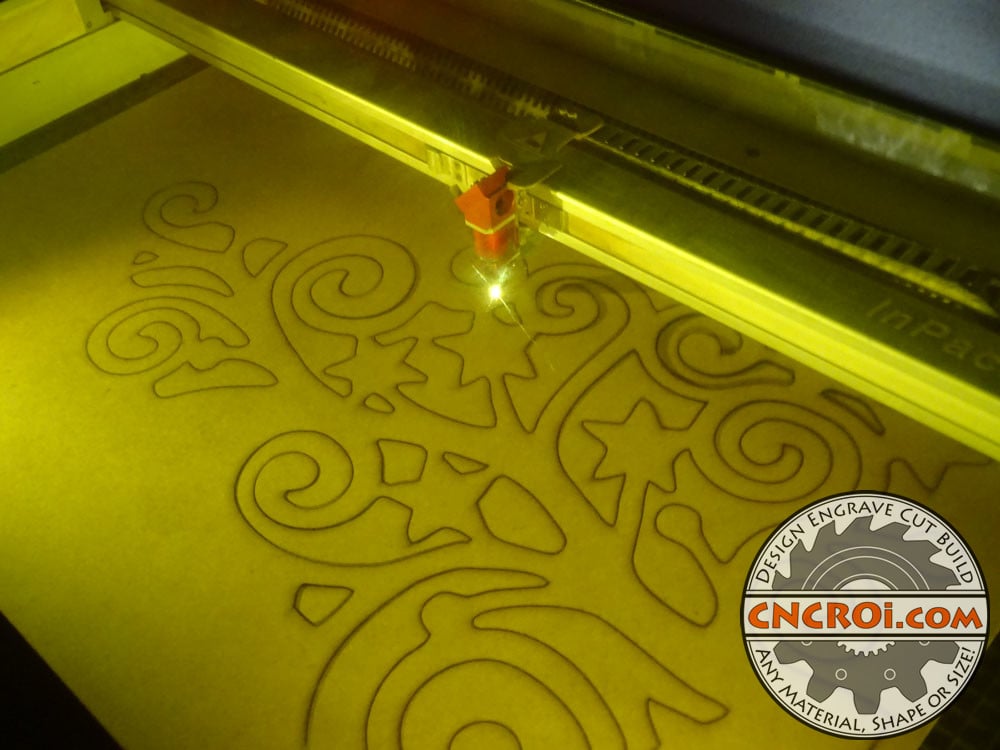

All the heavily ornamental aspects of this Christmas tree stencil are no problem for our machines, we buy top of the line equipment and optimize the design files to produce the absolute best stencil possible in any given material.

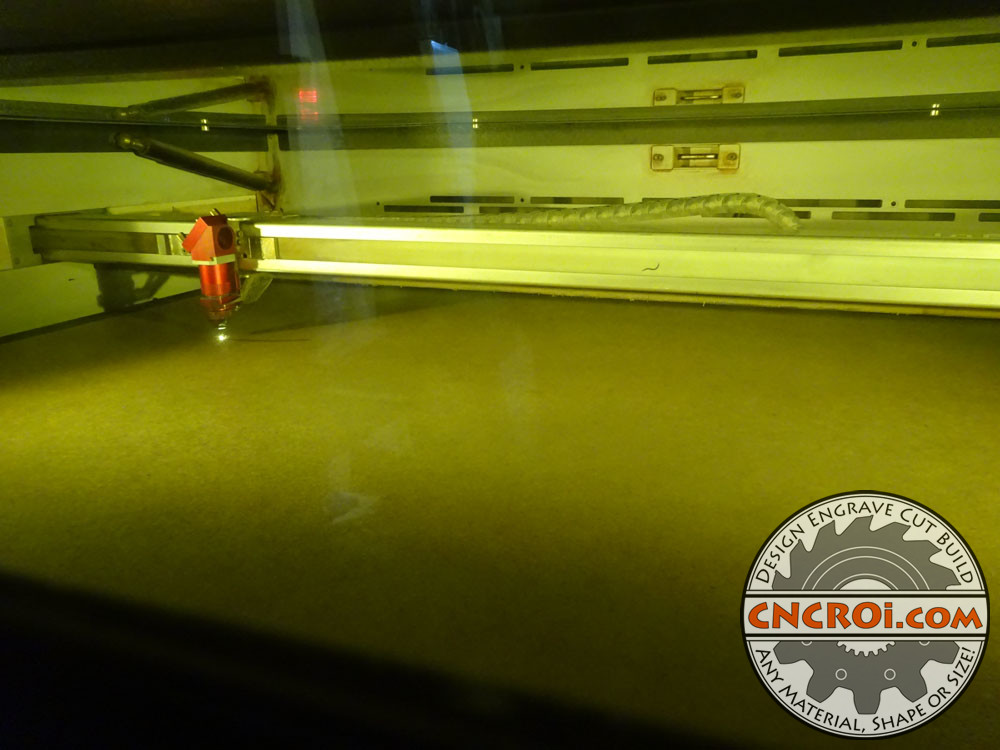

Like the plasma cutter, the laser isn’t touching the material it’s cutting, unlike our router, the advantage of this is no hold down is required, the only reason we get parts that flip on the CNCROi.com plasma is because the grid table isn’t as tight between the slots.

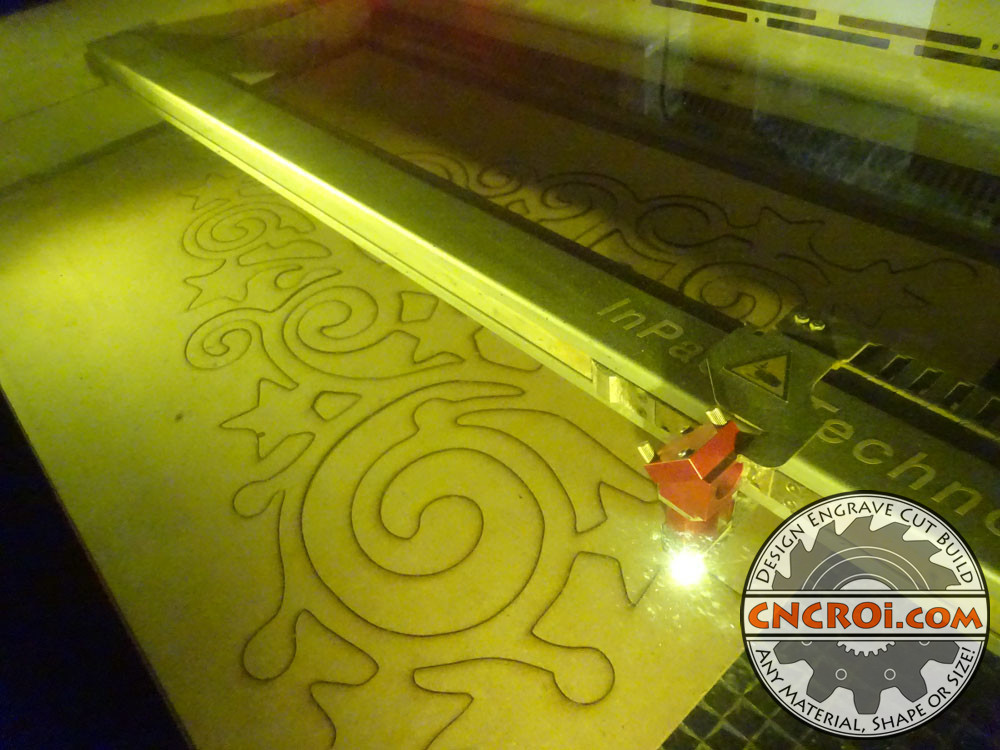

Although CNCROi.com‘s laser is very fast, powerful and efficient, it only lightly touches the grid table under the MDF, unlike the plasma where we have a shot of extremely hot plasma shooting down through the material, cutting the slats at the same time, this laser grid table would vaporize under those stresses.

Plastic makes for great stencils too, it all depends on the application and use of the finished product.

https://www.youtube.com/watch?v=b54_VdpHAq8/

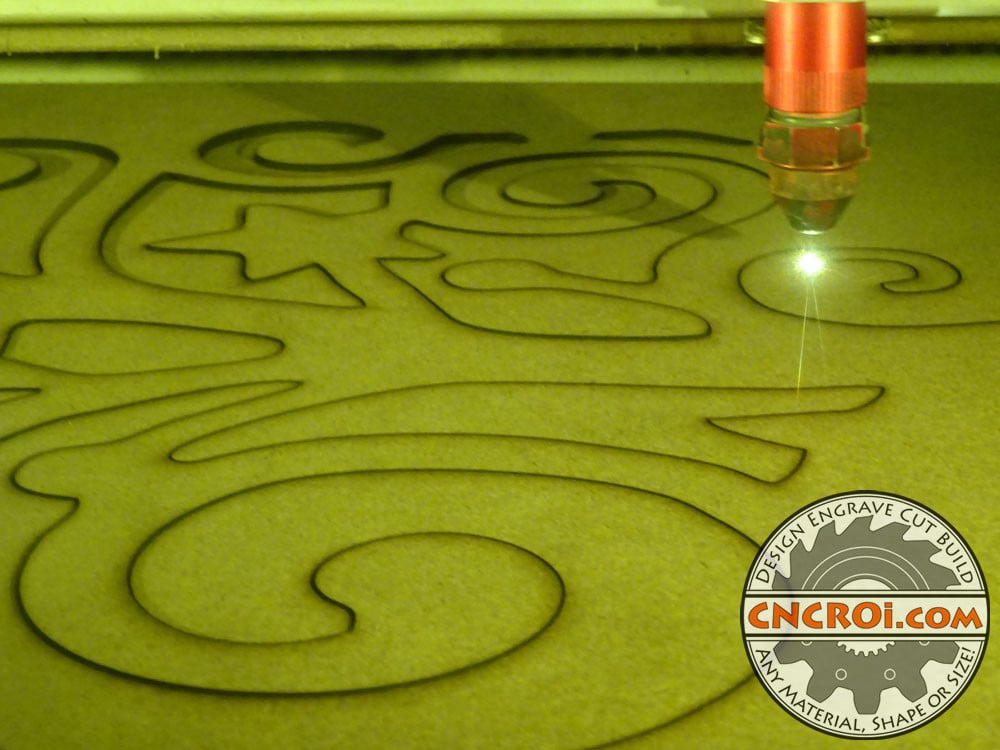

You’ll notice that all the curves are curved, they aren’t jagged, or with fuzziness, everything is nice and smooth, as all stencils should be.

This Christmas tree stencil looks great regardless of what material CNCROi.com cuts it out of, it’s always great fun designing for various CNC machines we have in our shop to proceed with amazing jobs for all our customers.

Plywood also makes for wonderful custom stencils.

https://www.youtube.com/watch?v=dz27x1cdrt8/

When it comes to laser cutting, there are hundreds of blog posts and videos on CNCROi.com showcasing it’s capabilities across a host of materials, Formica to Acrylics and woods of many different species.

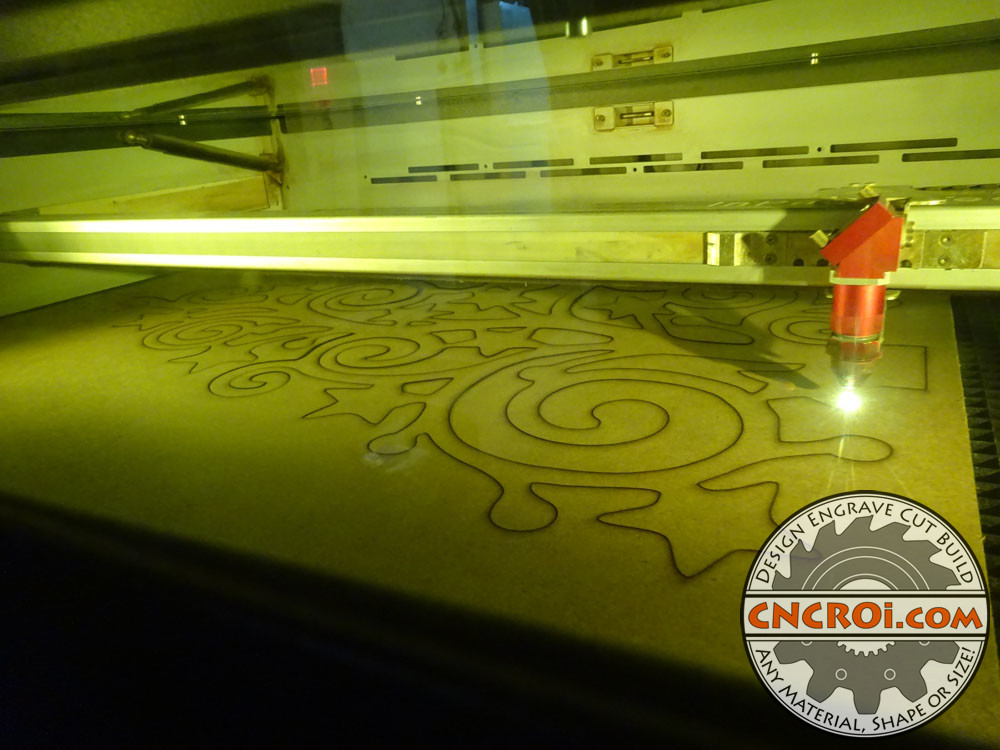

The laser is now finished cutting out the ornamental inner parts of this Christmas tree stencil so it’s proceeding with the outline now, as this customer will use it both as a stencil and a negative stencil, we are shipping the entire thing to them, with all the inner parts – hence the duct tape.

It’s quite a contrast cutting a design using our CNC laser over our plasma, there are no sparks or super heated gases shooting all over the place, it’s a lot quieter too.

Stencils can be incredibly sharp and highly detailed or meanderingly curved like today’s Christmas tree stencil.

https://www.youtube.com/watch?v=jA1SC61tp3s/

The thickness of material cut during the laser cutting process on this Christmas tree stencil is less than the width of a hair, it’s incredibly thin, unlike our plasma that would be about 1-2 mm depending on the type of metal we fed through it at CNCROi.com.

We can’t plasma cut wood because it’s an awful ground, the way plasmas work, you create a ground between the plasma head and the table with the material between being cut, with the laser, no grounding of that type is required thus not an issue.

No matter how ornamental or highly detailed the Christmas tree stencil in this case is, CNCROi.com can reproduce them perfectly, first to millionths.

The bright light you see is the instant vaporization of the MDF material under the laser head, the laser is shooting straight into the material, but it quickly loses power as it goes out of focus, thus like the plasma in a way, it won’t keep cutting through into the floor.

Stencils have endless uses, I even make some for my own home to label recycling boxes.

There is no perfect machine, just best optimized for the process involved, as a result, having multiple CNC machines allows CNCROi.com ultimate flexibility when it comes to produce the best result possible for our clients.

As this Christmas tree stencil finishes up, you can get a fuller picture of what we are able to produce, we can also scale this drawing up or down, so if you wanted a miniature version of this tree, no problem.

There are two things you need to keep in mind with custom stencils, the first, we need to add support bridges to fonts that aren’t stenciled fonts so the insides don’t fall off and secondly, shapes need to be bridged as well to keep everything together.

Looking for a custom stencil? Contact CNCROi.com.

https://www.youtube.com/watch?v=-idkUWEOXeI/