Custom Portrait Carving: CNC Routering Pine

Making a custom portrait carving of myself was a great first project to learn how to properly apply this technology for clients well into the future, if you want to get good at something, do a lot of it, and this is the first of many custom carvings to come.

If you are curious as to the origins of the portrait, I explained it a bit in the above video and below is the actual project of my big wheels.

And the resultant full page of me showing off my awesome custom big wheels.

I didn’t just deliver the news, I was also in it!

Of course, once I founded CNCROi.com, I had to cut a scaled down version of my model using the laser.

Now that you know the background of how this all came about, let’s proceed on the making of the custom portrait carving I had the joy of doing in the past few days at CNCROi.com.

It’s only apt that the CNC router that made my picture in Make possible is also the one making this custom portrait carving of me on it, it’s a pretty neat full circle that I was able to perform after a decade building custom projects for others with CNC machines over at CNCKing.com.

Probably the closest I got to true carving in the past was this little bird saying I did with my CNC router and then laser burned away the fuzzies with.

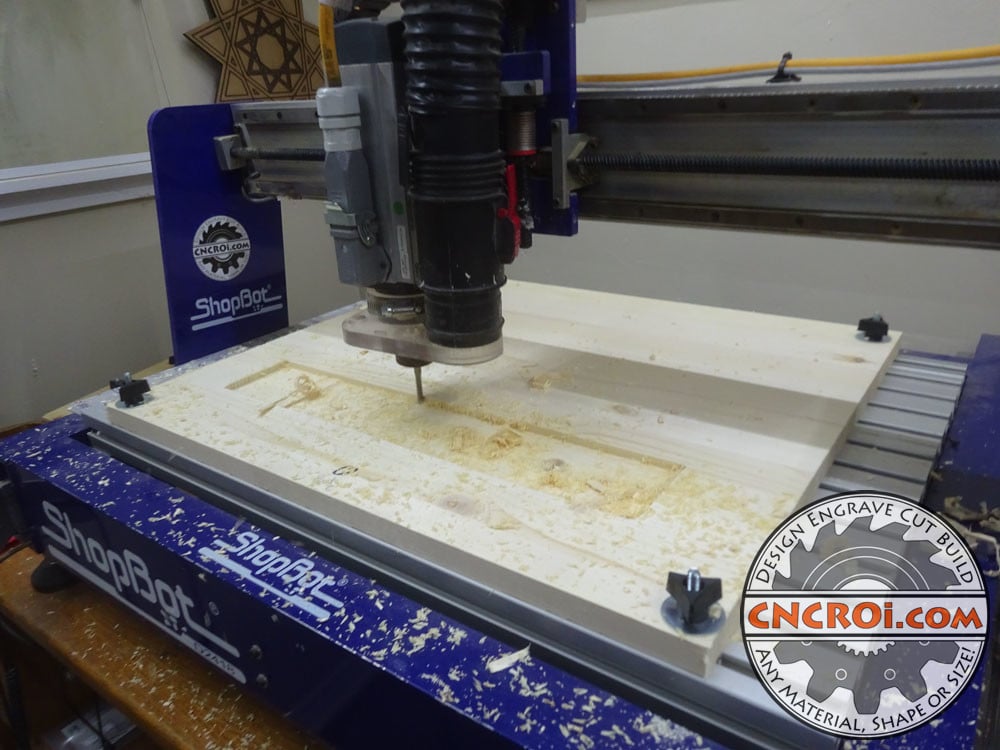

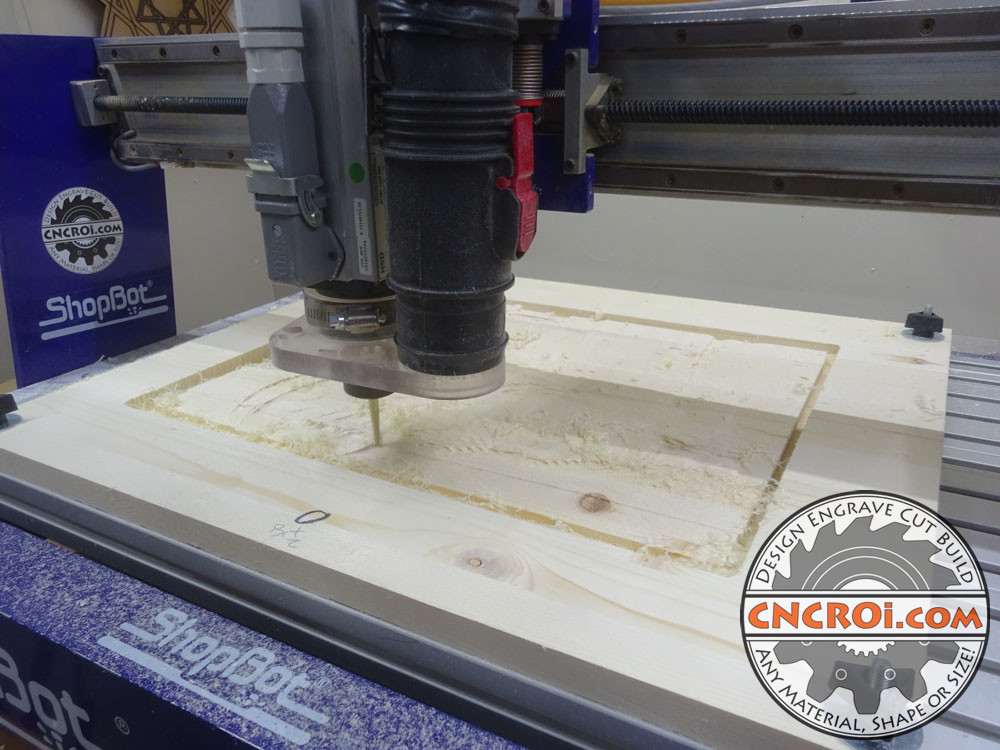

As my very first carving job, I decided to go very easy on myself to optimize processes, the first is using a fool-proof easy material to work with, in that case, 3/4″ softwood Pine.

Custom pyrography is a different process of creating a custom wall display of whatever you want, the results are finer than what can be achieved using router bits but they don’t have the relief that makes it feel great.

The reason why I decided to do a self-portrait using custom portrait carving techniques with my CNC machine is because it was a photograph I knew very well, so I knew exactly what to emphasize and what not to, something very important when learning how to do this stuff properly.

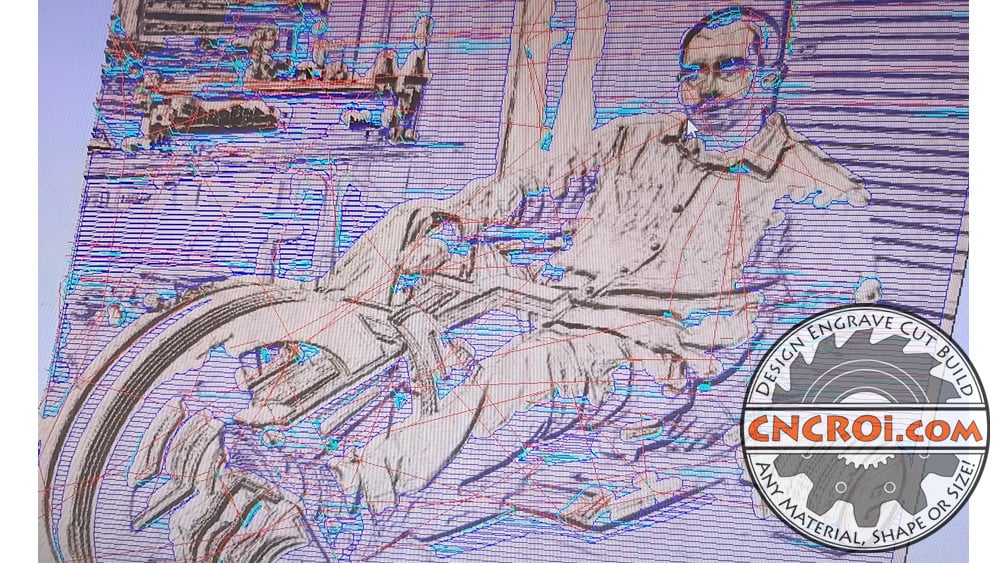

The custom portrait carving process is relatively simple after all the custom programming is done, just to give you an idea of the complexity involved, below is a screenshot of the tool pathing.

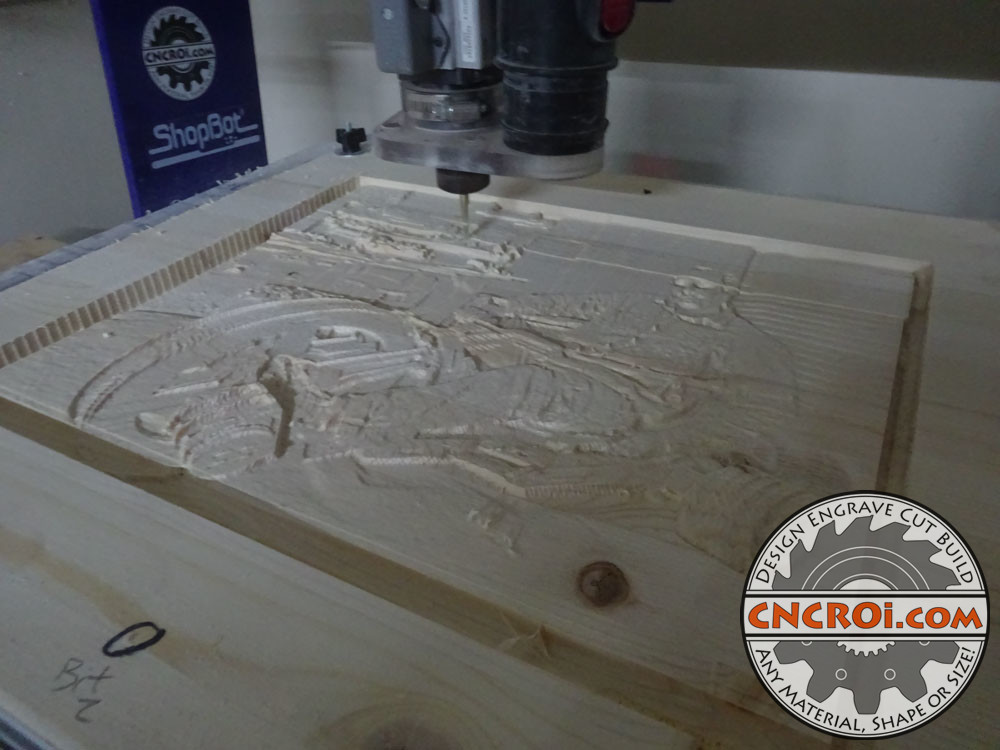

As you can see, there is a lot of work for the CNC machine to methodically carve out this custom portrait carving job and the whole thing took a few days to do at this scale at CNCROi.com.

The first few passes on this custom portrait carving job were performed using a quarter inch 6 mm diameter end mill, the reason is, I want to remove as much material as possible from the Pine before I go back using a very small 1/8″ 3 mm ball nose to remove all the details and do the actual carving.

Just to give you an idea of what can be done with our laser when it comes to custom carving, here’s our logo on an Acadia serving tray.

You can see how the end mill produces a jagged result, this is fine, again, it’s just removing material that isn’t needed before proceeding with a far finer bit to really begin the carving process on the Pine.

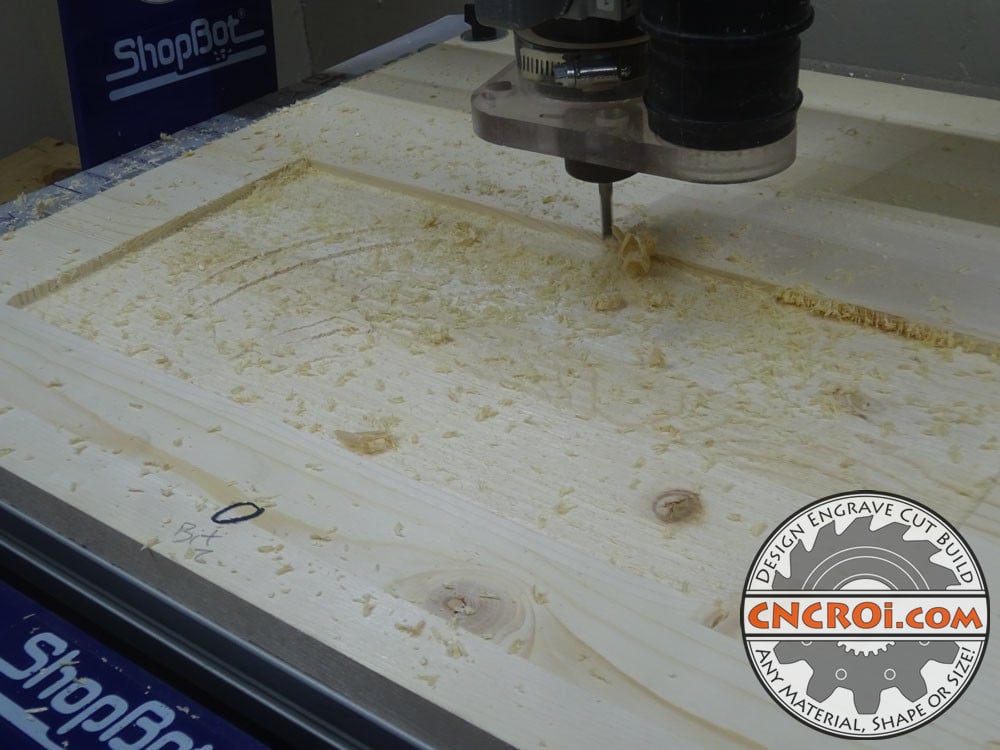

Now, this is where the days of work get done, I don’t leave machines running at CNCROi.com when I’m not there so I basically had this job running and paused repeatedly while I did other work in the shop for customers.

The reason why this takes so long is because I have a 10% step-over, meaning the bit is moving “upwards” across the custom portrait carving at 10% of 1/8″ 3 mm at a time, so it’s like watching grass grow but this is what must be done to produce a smooth result and yes, at the shop, I also have 1/16″ 1.5 mm ball noses to do this as well but at this scale, it would probably take a week.

Generally, CNCROi.com carves custom house number signs and other items using a mix of laser and router work, we’ve done big jobs and little ones, all with great success.

Like big screen TVs, if you are far away enough, you really can’t tell the difference between 4K and 8K resolution, you have to be up close to notice the difference, this custom portrait carving is no different, far enough away, the extra time needed to go even finer in resolution is redundant unless you plan on having this custom carving right in-front of your eyes.

You’ll notice a the bottom left of the above picture a little circle, with “Bit Z”, this is where I redid my bit height calibration, especially for an application such as this, you really need to make sure your bits are accurate height wise when ever you do a tool change.

You’ll see lots of fuzzies in this process, remember a ball nose bit is not FLAT but looks like ball, hence making strings of little dust as it slowly and methodically carves away the pine on this custom portrait carving at CNCROi.com.

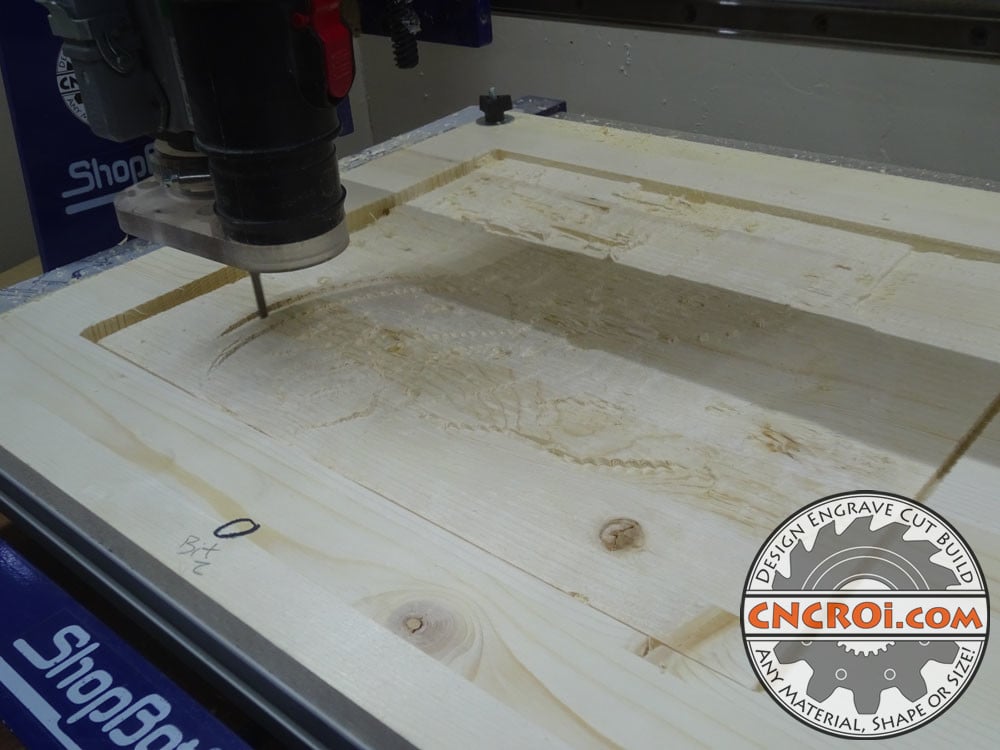

The results though look spectacular, it did requite a little sanding but not that much overall, what’s really great is running your fingers over a photograph and feeling the relief of the custom portrait carving.

This is quite a different process to the one CNCROi.com typically employs for it’s customers, generally flat carving.

When it comes to carving, for this specific job, I had a relief of half an inch or 19 mm, meaning from peak to valley, you have that much difference between the two in height.

I put the lights out for picture taking because the direct light made it very hard to properly see the relief, in the future, I know now to film it with just one light to show the proper relief being produced.

As this job was proceeding at CNCROi.com, I kept touching the relief, it was just so smooth, I couldn’t wait for this custom portrait carving to be finished.

I’ve also used our CNC laser to do custom carving as well, there are a lot of options when it comes to mixing and matching technologies and processes.

As with anything you do the first time, there were a few mistakes as I mentioned in the video, the biggest is editing the file while it was being made and then realizing I needed to get the machine to update it so I could run the job faster but forgetting I reversed the relief pattern.

That’s why I have a huge margin on the bottom, that was cut out of the finished custom portrait carving, and the top, well, nothing was happening up there so I just cut the job short, hence why you see a line way up there at a lower resolution.

After the custom portrait carving is complete, it’s time to cut it out using my table saw.

The results look great, so next step is a little sanding to remove fuzzies and dust build-up in some key valleys.

We aren’t limited to wood when it comes to custom carving, we can do the same amount of work on other materials, plastic through solid surface.

Once I have a very clean surface to work from, the next step is making the contrast really pop using a stain, Pine is a relatively consistent wood so it needs some color to make the carving I did at CNCROi.com come out.

The results of stain really are enormous, and of course, Pine can be easily stained into any wood species you can think of, CNCROi.com can of course carve just as easily in Black Walnut as Pine, if you wanted the real thing rather than a stain to make it resemble it.

As this is a 2.5D relief carving, the angle of the light hits it differently as you move around it, it’s a very neat effect that just doesn’t photograph or videotape very well.

Even on flat light, you can easily see the details in the finished custom portrait carving and the detail is so fine that you can actually see “ShopBot” and “Ryobi” in the carving, using a finer 1/16″ 1.5 mm bit would have made those badges a lot more clear.

A close-up of the carving and you can see just how smooth the finished result is for this custom portrait carving made at CNCROi.com, a great first step and I’m very proud of what I got done here, and can’t wait to do it for others.

Need something custom made or carved? Contact CNCROi.com right now!