Custom Foam Tooling Inserts

Need some custom foam tooling inserts? CNCROi.com can make them custom to your spec.

Generally speaking, our customers go with two thicknesses of foam for their tooling inserts, half-inch or 12 mm and quarter-inch or 6 mm.

If you are wondering how much room to leave around for the different items to put in your tooling insert, it should be less than half an inch as space is needed to both grab the tools out comfortably and so they don’t hit one another causing damage during transport.

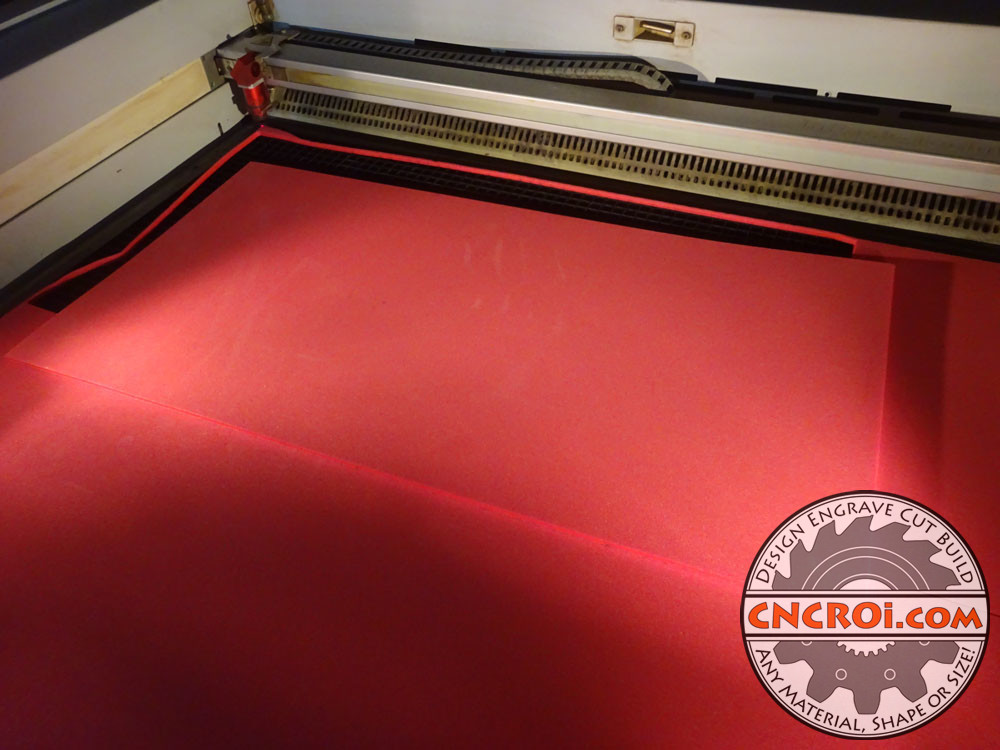

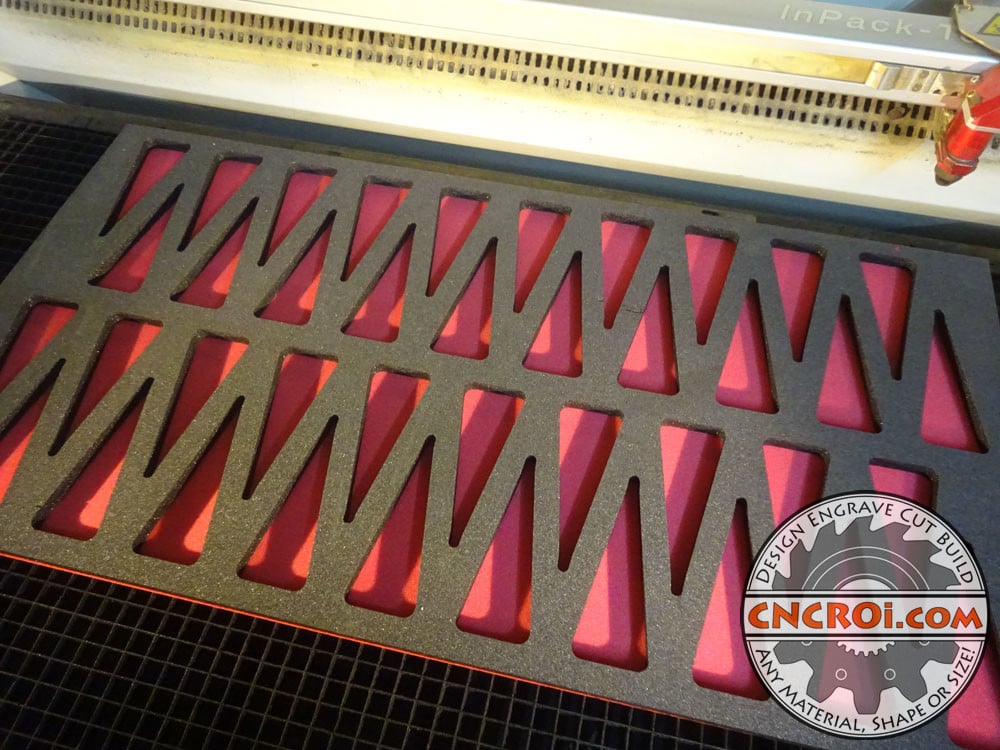

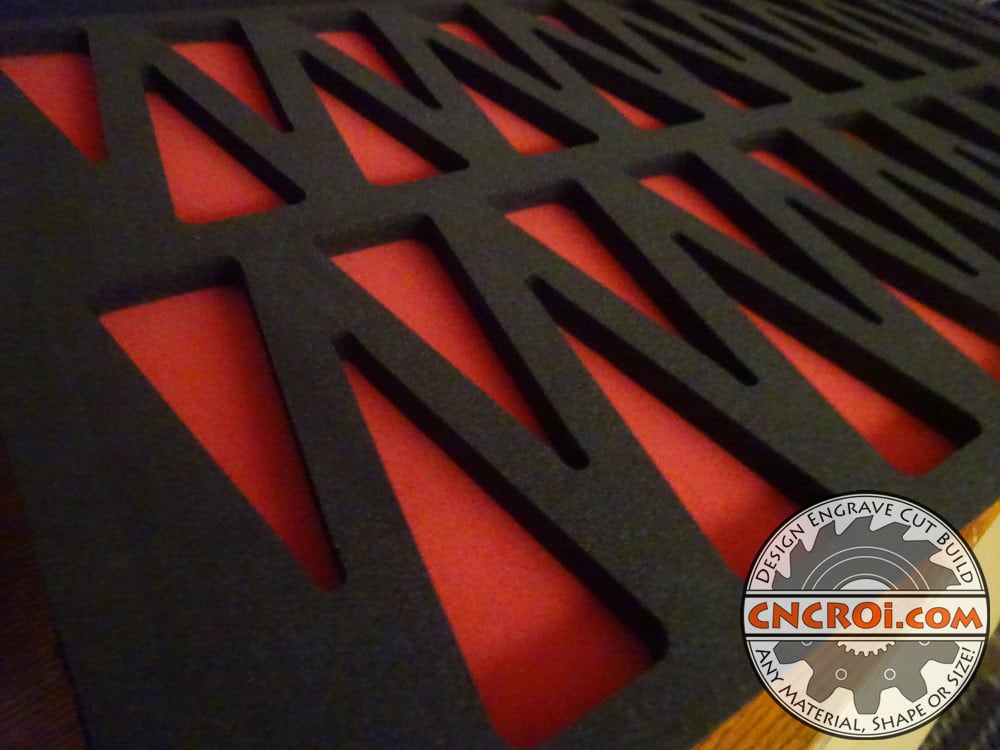

The red foam you see for the base of the tooling insert is solid because it’s what the tools will rest on, if they are heavy, then CNCROi.com can make them using half-inch thick but for the vast majority of projects, quarter-inch is plenty with a MDF or plywood base.

CNCROi.com has made custom inserts for a variety of applications, from musical to industrial, huge mega inserts and extremely small ones.

You can see the finished base for this custom foam tooling insert, the reason for the contrast is to allow for an instant recognition that a tool is missing as the red POPS and can’t be miss when a tooling isn’t at the right place or gone all together.

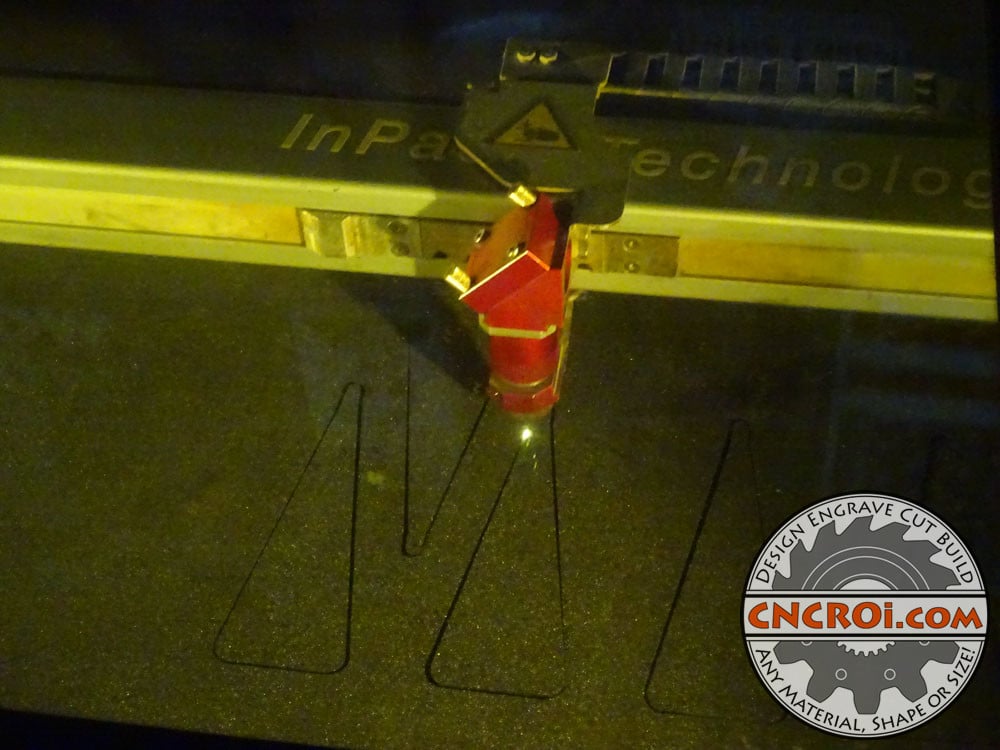

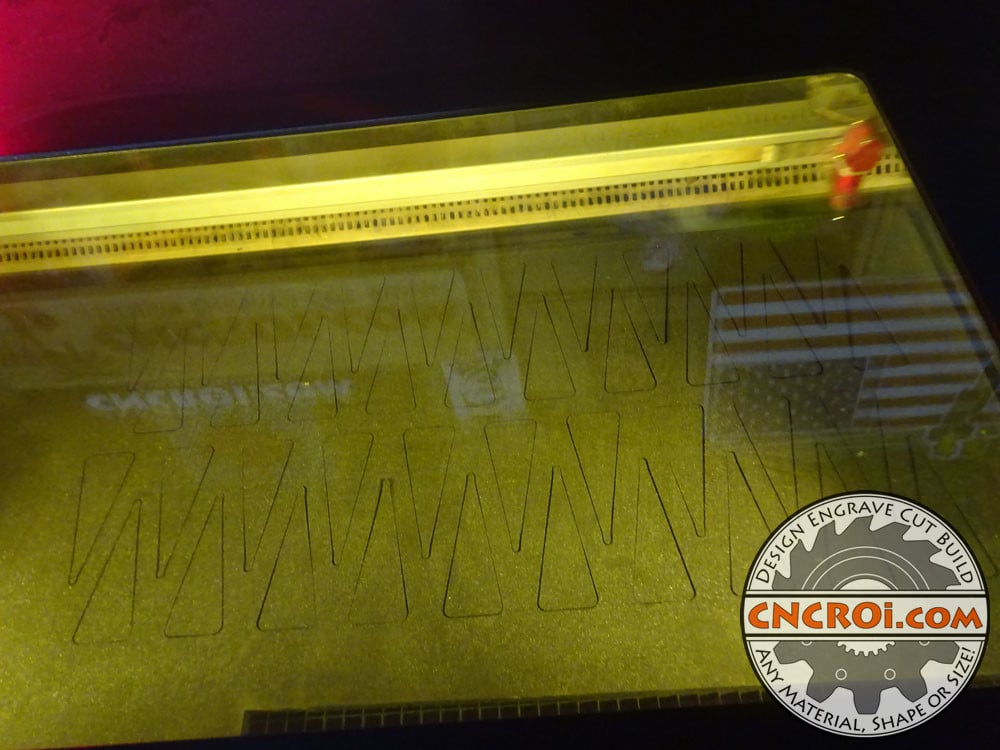

Now for the half-inch foam for the custom tooling insert, just like the red quarter-inch base above, CNCROi.com can make them with any shapes cut out of both the overall insert for a drawer and the pieces cut out of them for the tooling.

Due to CNCROi.com‘s on-demand approach towards custom fabrication, each custom foam tooling insert can be the same or different made-up of one or multiple layers by our shop.

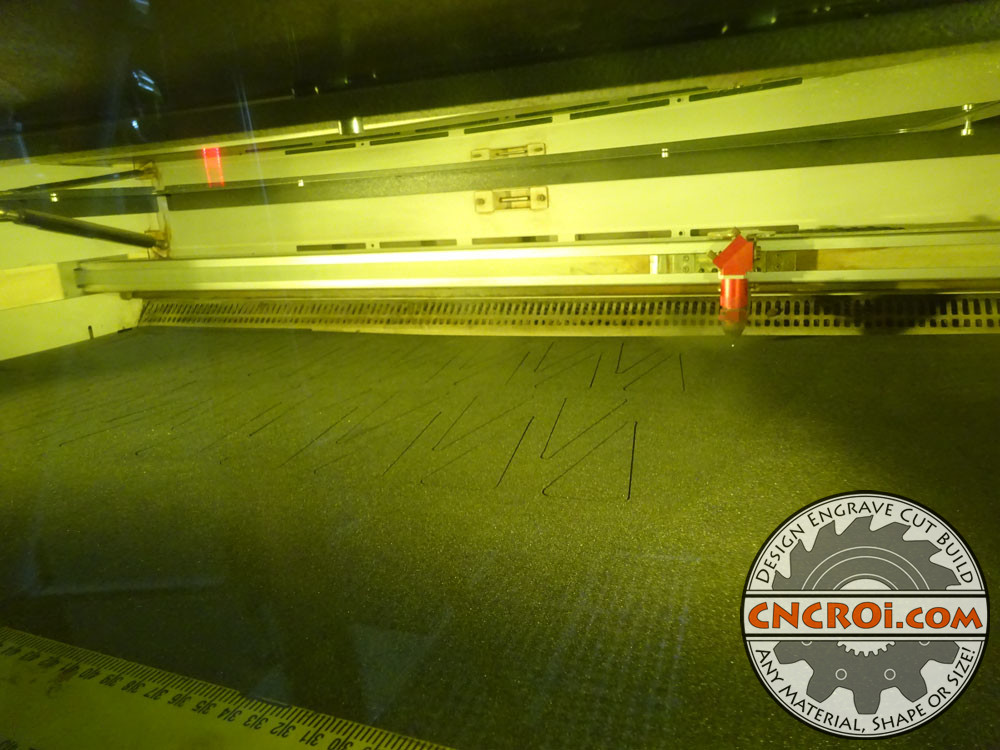

As for sizing, we can work with a variety of combinations along the X, Y and Z axis for the best fit and customization in both low and high volume production environments.

When it comes to sending us the cut files, the easiest way we’ve found is for you to just trace the tooling on a piece of paper using a pen, scanning that in (or taking a photos) then making those into a DXF.

For instance, if you have a tool that’s awkward because it’s taller than it is wide, CNCROi.com can make a tooling insert that’s higher for that “section of the drawer” while lower for another for the smaller shorter items that will go into your tooling insert.

Additionally, CNCROi.com can make each layer a different color if you wanted, so you aren’t stuck with only red and black but a variety of different colors to outline different items or processes within your manufacturing plant.

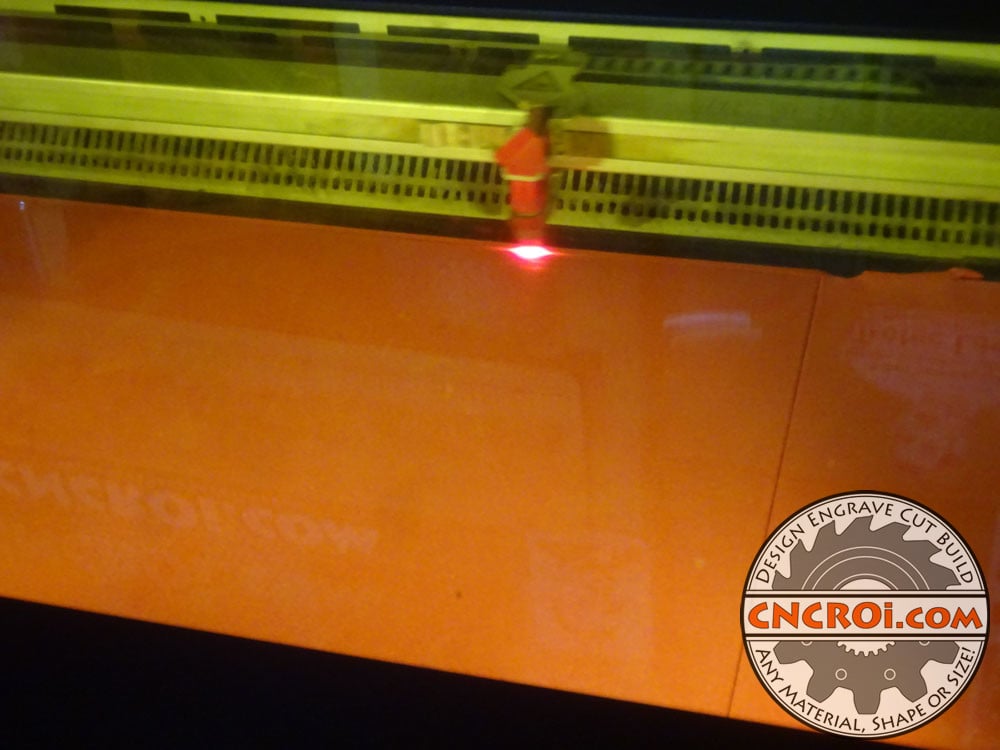

The flexibility doesn’t end there, CNCROi.com can also permanently brand each insert so if we make a tooling insert for drawer A, the custom tooling insert will have a permanently branded A (or whatever you want) on the surface so you know exactly where it goes, alphanumerics are fine too.

CNCROi.com is very passionate about customer service and making the absolute best custom tooling inserts for your business, whether it’s a big multinational corporation or a small mechanic’s shop.

The shapes we can cut in the foam, regardless of the thickness or color, can be anything, circles, squares, outlines of tooling and each layer can be slightly different to accommodate unique shapes or requirements when it comes to holding your items perfectly.

CNCROi.com doesn’t just make custom foam inserts, we also make them out of hard plastic, plywood, MDF and acrylic depending on what our customers require in density and protection.

If you hear rattling while transporting your tools, that’s being caused by tooling hitting and rubbing against one another, with CNCROi.com‘s foam inserts, this sound is gone because everything is well protected which makes the overall shop a lot quieter if you need to carry specific items from one end of the shop to another.

In this case, these custom foam tooling inserts are holding the same shape for transport from one department to another but it could have been a mix and match, including orientation and sizing if the customer wanted it to be so.

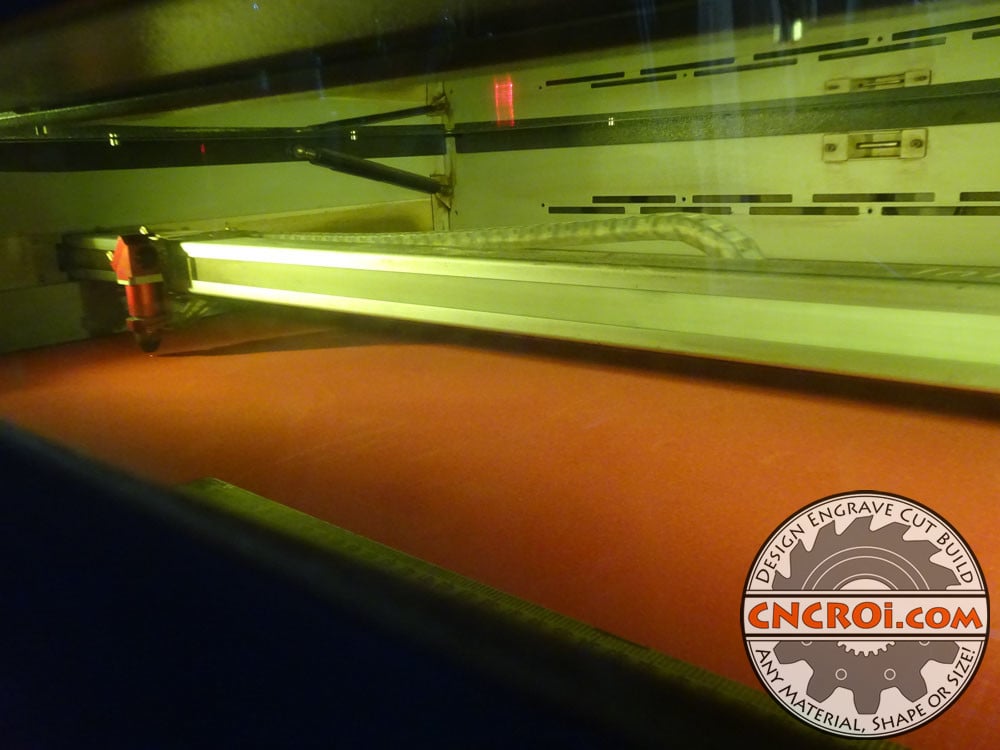

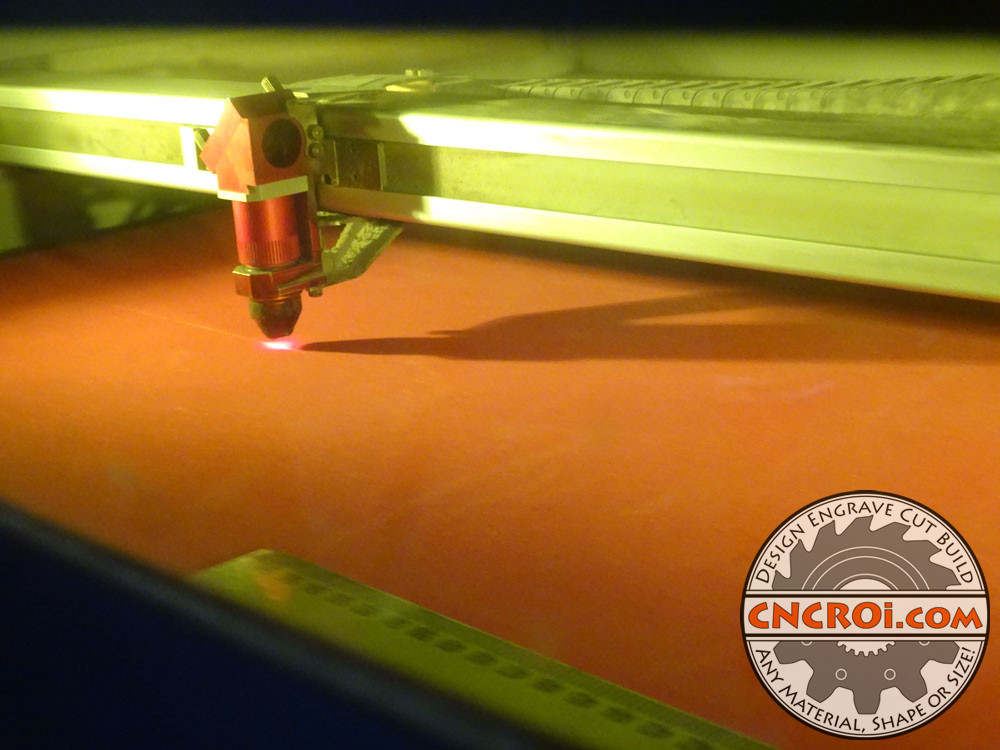

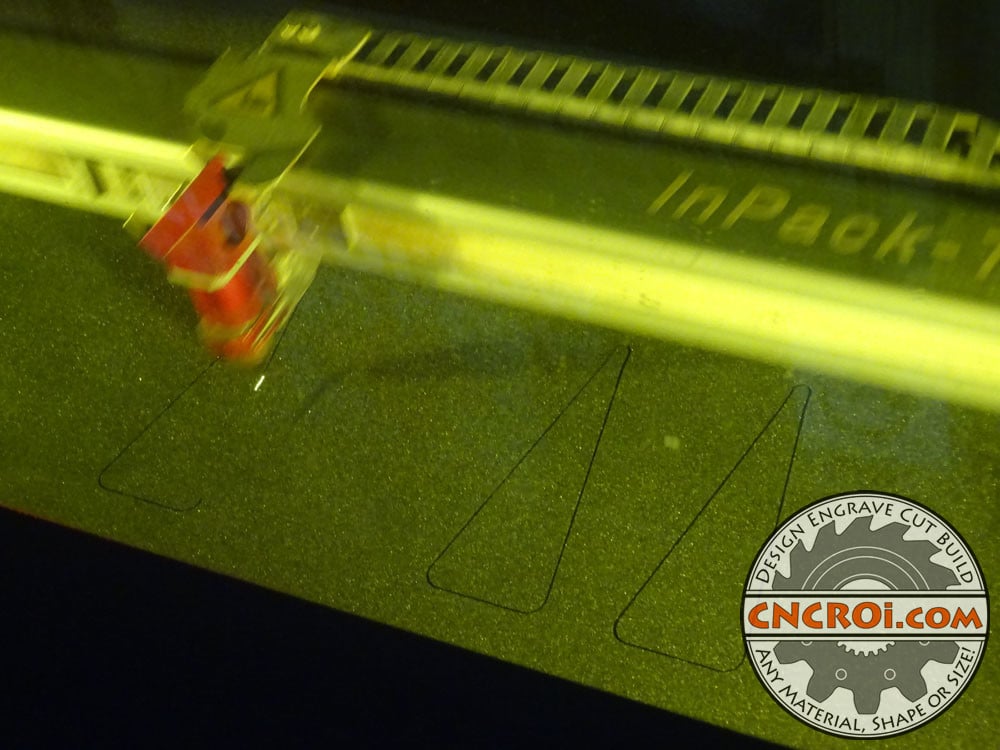

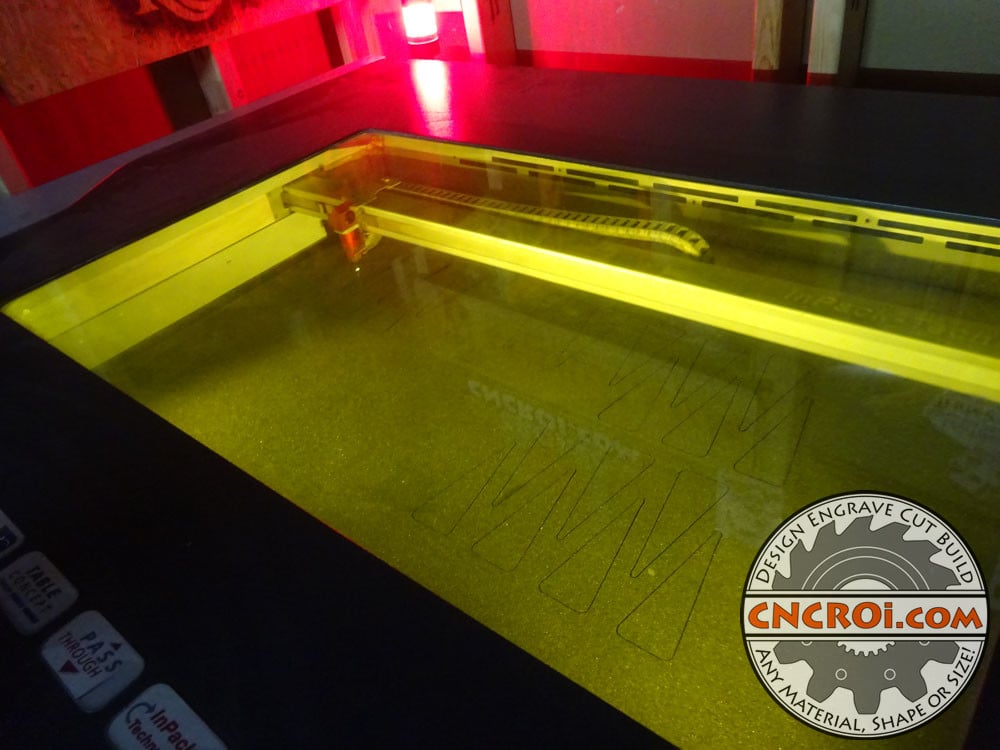

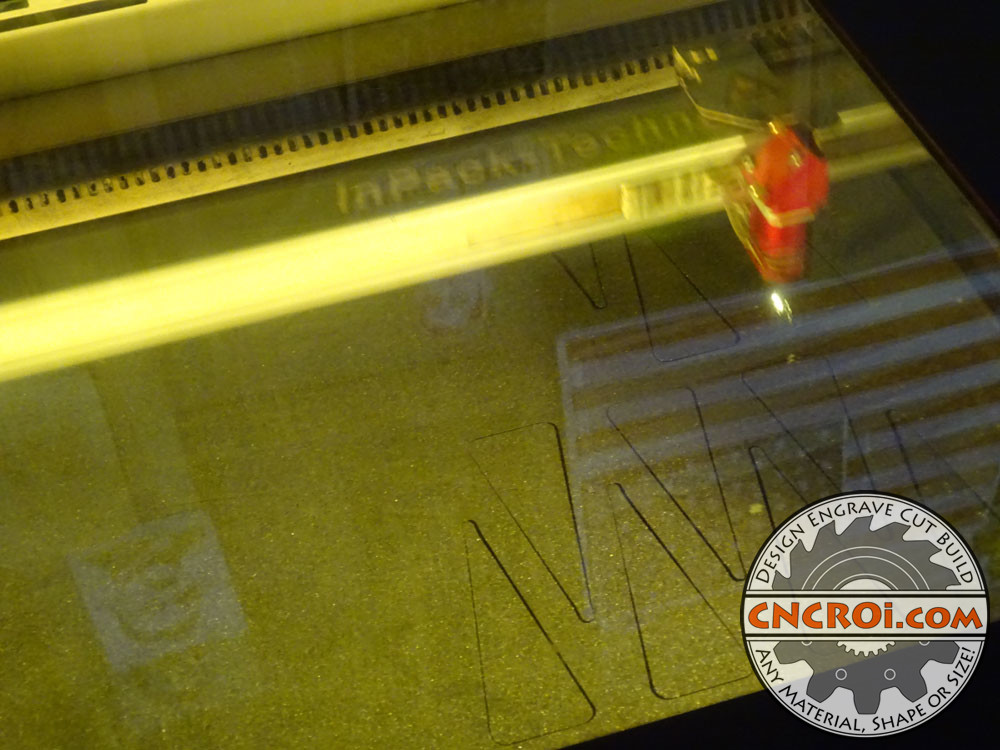

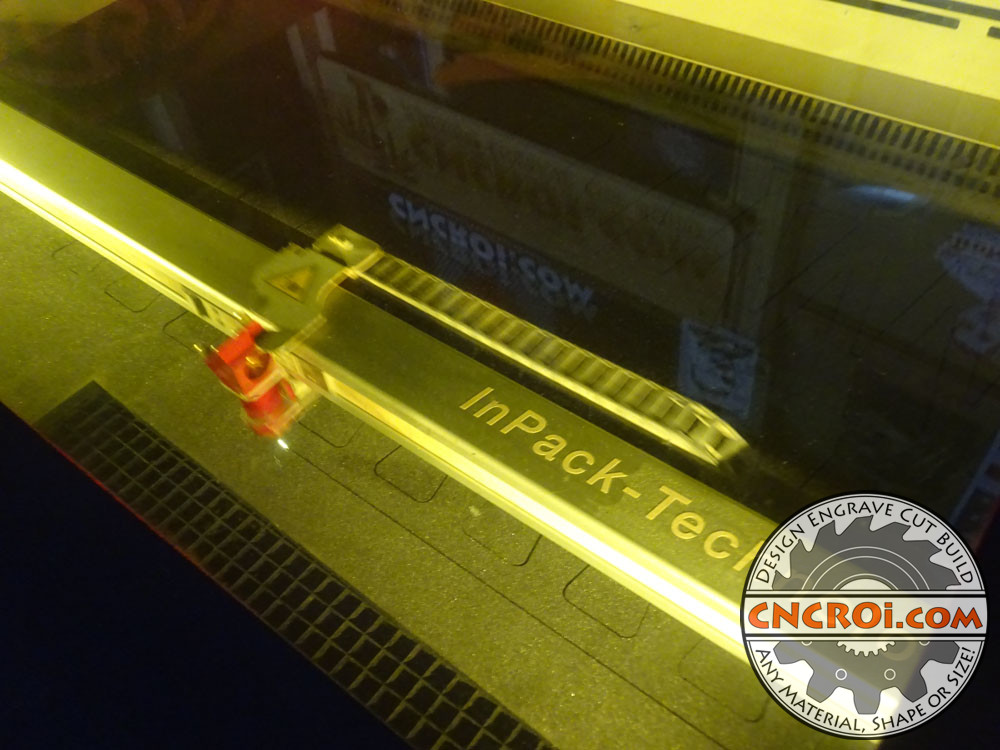

CNCROi.com uses a laser to produce its custom tooling inserts because they are the best regarding precision over our CNC router or waterjet when it comes to making these for customers.

You may think that a waterjet could do a decent job of this as well but something a lot of people don’t recognize is that waterjets cut using abrasive and is a wet process, meaning the entire tooling insert would need to be cleaned-up of muck and water while with our laser, this isn’t required.

As CNCROi.com can feed rolls of foam into our CNC laser, we can really make a lot of tooling inserts in short order and the nice thing about shipping is that they weight almost nothing, the charges are mostly based on volume when it comes to the mailman bringing these to your door.

CNCROi.com can also make 3D inserts, although this video shows a cabinet front door cover, the same technology can be applied for custom tooling inserts of any size or shape.

As for placing multiple layers of foam to create the custom tooling insert for your needs, a friction fit is more than fine for the vast majority of our customers, meaning they just place the foam inserts one on top of the other in the drawers or cradles as they are met on all for sides.

If you wish to use adhesion to hold them together, CNCROi.com can apply double-sided tape on one side before cutting but we’ve found just spray glue works wonders and is a more cost-effective method of holding multiple layers together.

Need custom foam tooling inserts? Contact CNCROi.com right now!