Custom Hardwood Coins: Laser Engraved & Cut Oak

Custom hardwood coins are made by the thousands at CNCROi.com using real wood, from various kiln dried sources and suppliers.

https://www.youtube.com/watch?v=SEirZRgnfiI/

Custom hardwood coins can be made out of Oak, Maple, Tulip, Walnut, Cherry and the list goes on, it all depends on the look you are after and the characteristics you want your own special set of coins to have.

In this case, the solid oak isn’t from live edge but the remainder of oak planks from a renovation my parents had to their house, so the work to bring them into small pieces is a lot easier than starting from live edge lumber though the process is almost identical.

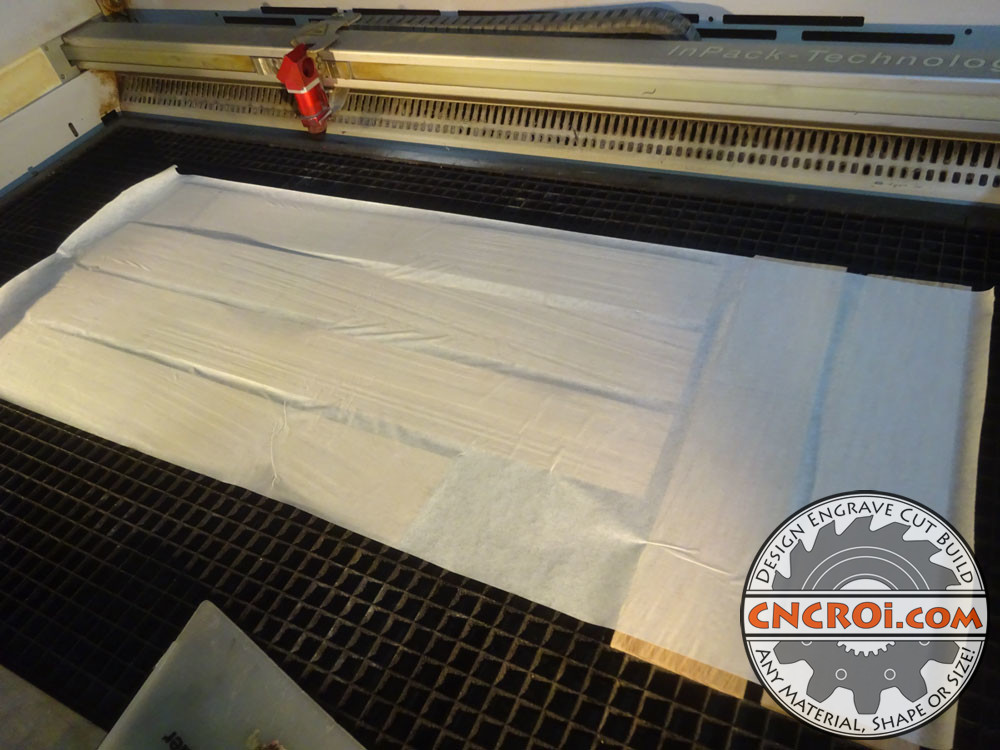

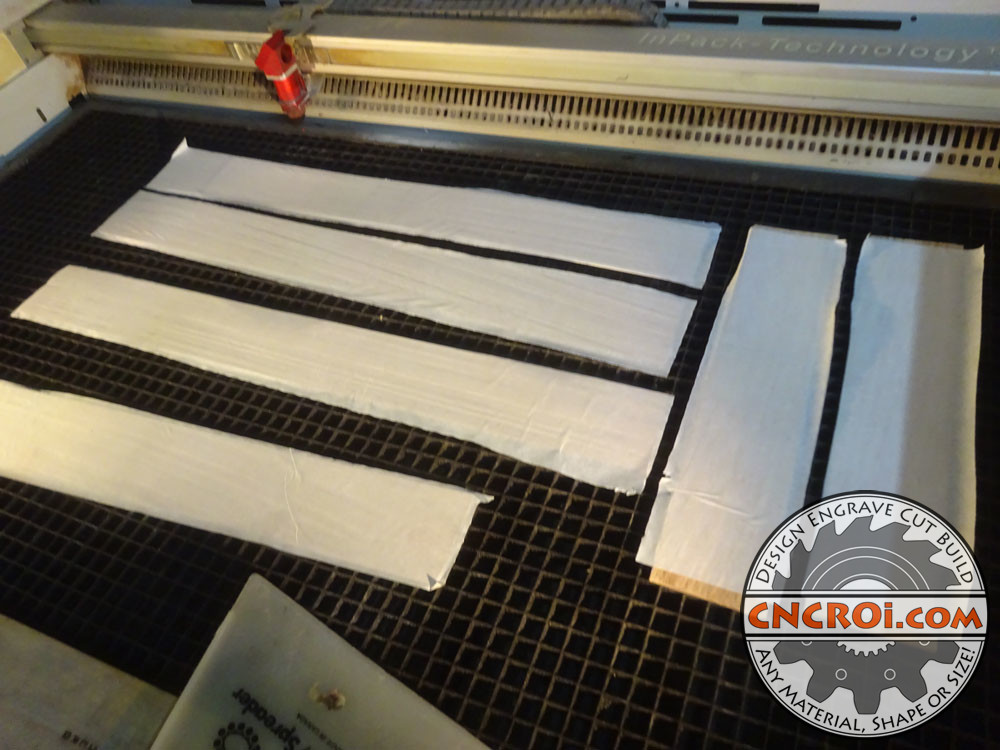

The first step involved adding masking to the backside, as that’s where the flame and smoke come back up during the cutting process at CNCROi.com during the custom hardwood coin production.

We are of course able to make related signage and other items to hold your coins or have something that augments their presents at special events.

https://www.youtube.com/watch?v=Ezi8hSTxHp8/

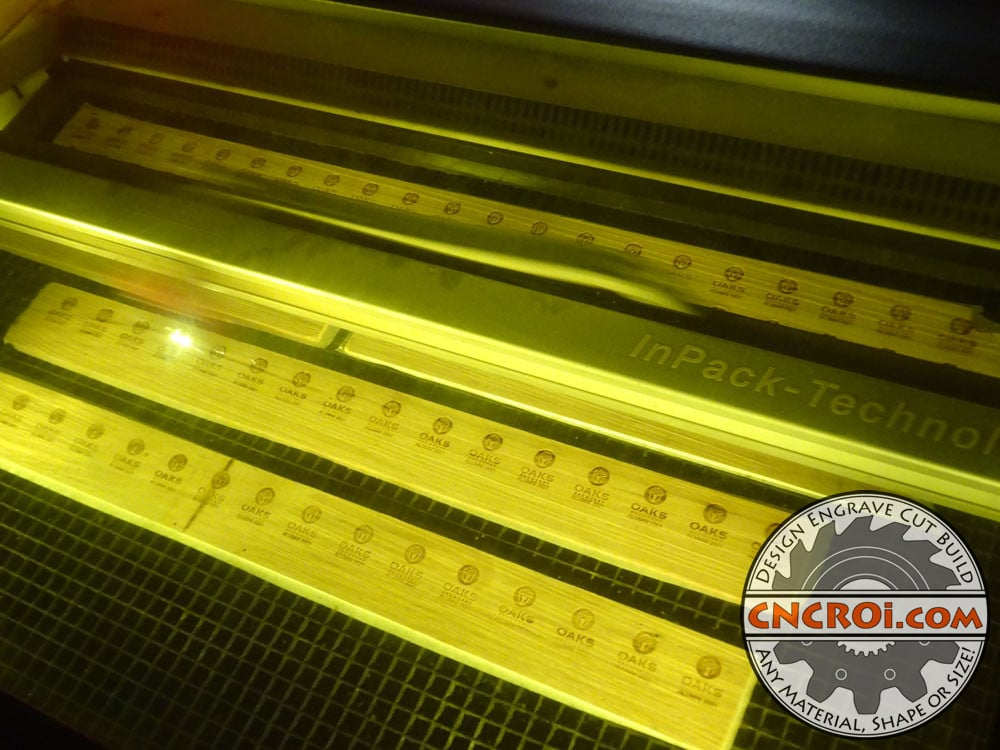

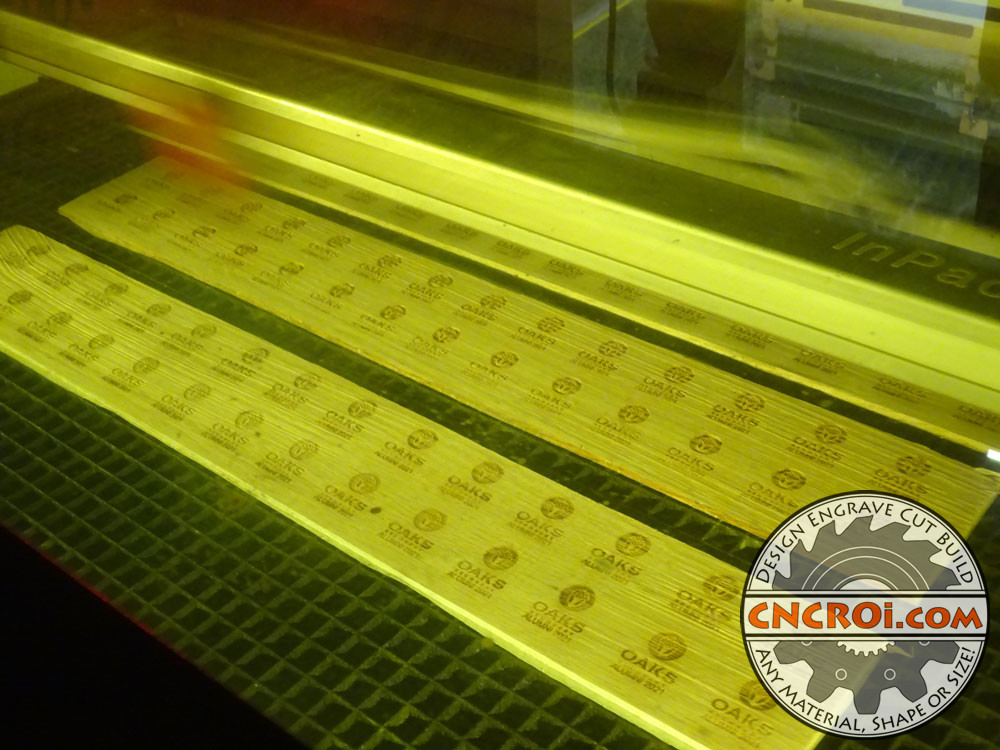

The next step is cutting the excess masking and then flipping the oak boards over so that we can begin the process of laser engraving and cutting out the custom hardwood coins from the boards you see below.

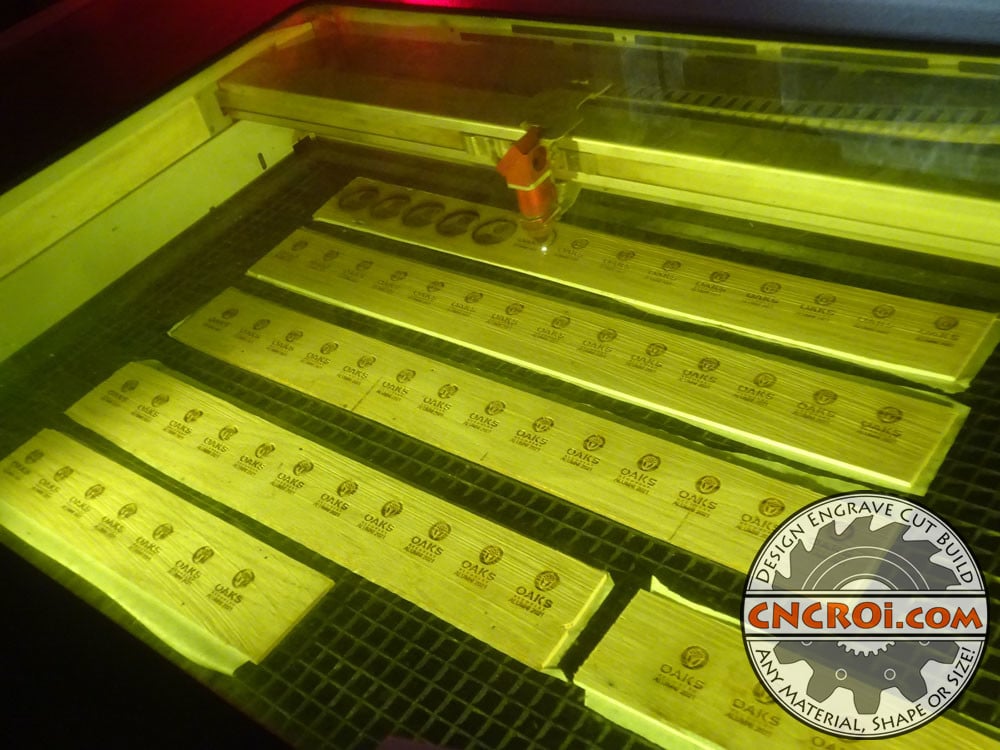

Laser engraving doesn’t produce as much smoke as the cutting does, so if that’s all we were doing at CNCROi.com on these coins, then the masking wouldn’t be necessary but in this case, we are engraving THEN cutting them out, so the masking is a necessity, otherwise my life would be wasted sanding coins all day at the shop.

Laser engraving and cutting the Oak happens across the entire board, regardless of nail holes, rot or problems with the wood surface, it’s just a more efficient process to optimize what we cut out of the boards NOW and triage it later rather than drying to dodge the problem areas when we are doing hundreds of these in a shot at CNCROi.com.

Making custom novelty coins can be made in any quantity you wish.

https://www.youtube.com/watch?v=NhblovD14MM/

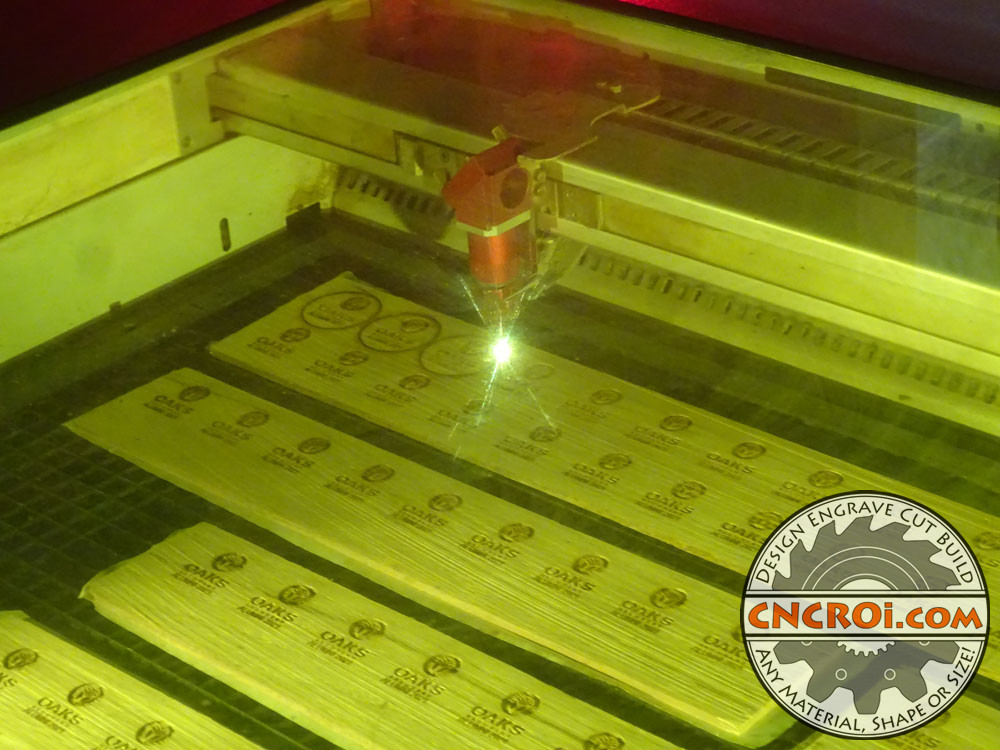

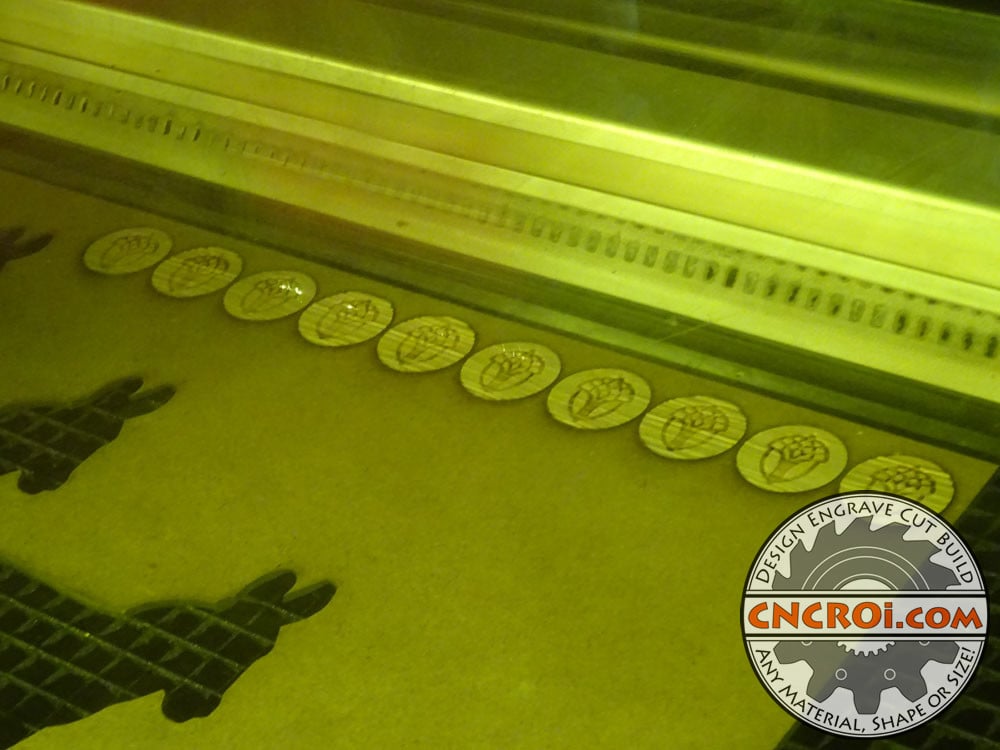

After all the boards have been laser engraved, the next step is cutting out the individual coins, this makes sure that everything is precise and the solid custom hardwood coins are all to spec for our customer to enjoy handing out to their clients.

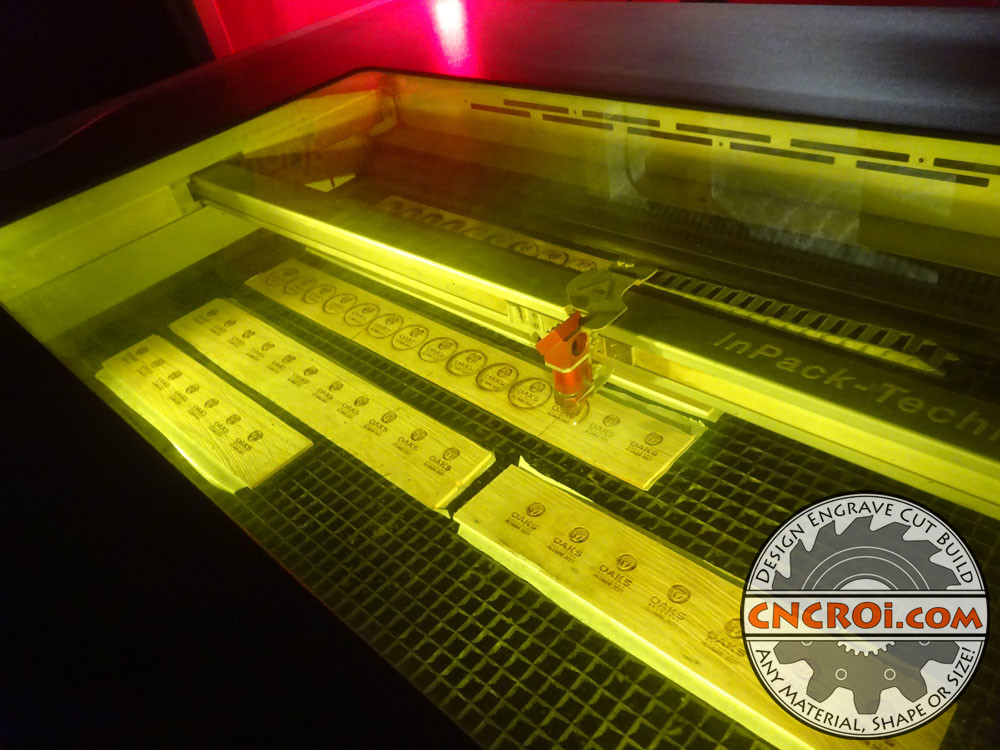

It’s fun seeing the custom hardwood coins take shape right in front of my eyes, the cutting process is a slow one but it’s the first time you start to see the coin actually taking form from the boards that were used to make them.

Each board has it’s own unique grain pattern and areas that are challenging, but batching them out allows for efficient production of custom hardwood coins at CNCROi.com.

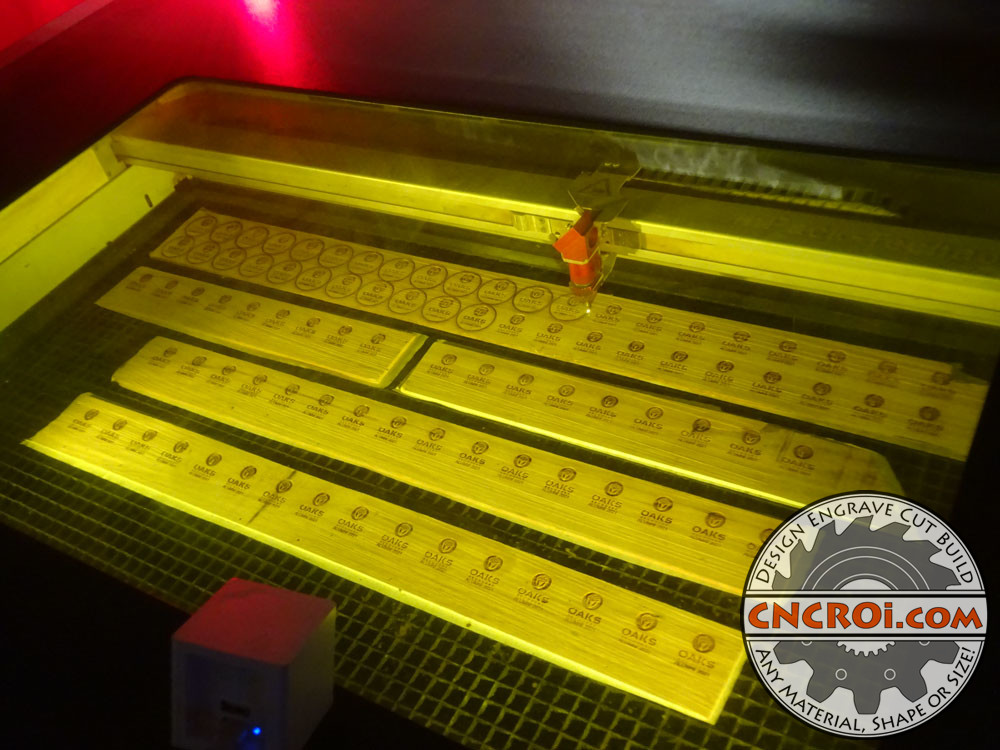

Same steps as the last batch, mask the back, cut the mask and then flip over and start the laser engraving and cutting process all over again until the required amount is produced.

CNCROi.com can also make plastic coins as well, one potter’s mold is another customers coins.

https://www.youtube.com/watch?v=AndwUMu-Jbw/

When it comes to design options, they are endless, the custom coins don’t have to be all the same size or design, you can mix and match styles however you wish as you can see from this production run, each is individually made, it just happens that both sides of these custom hardwood coins are the same.

After the laser engraving process, the next step is to cut them all out – the wood does raise a little from all the heat which is why you see the coins “falling down” under the wood in some areas.

The results from laser engraving Maple, Walnut or other hardwoods are generally the same, the only difference is that the contrast isn’t as spectacular as the laser always darkens the wood, for Walnut, the wood is already dark so dark on darker doesn’t provide as much contrast as Maple that’s far whiter with a dark brown engraving.

If you wished to make your own coins and just have CNCROi.com make the blanks for you, that’s also an option, as we can make custom rubber stamps too.

https://www.youtube.com/watch?v=eif1VIiGbvY/

Of course, CNCROi.com sands both sides of these custom hardwood coins so most of the smoke stains you may see on the coins are actually removed before going to finishing.

CNCROi.com has an industrial CNC laser that’s capable of working 24/7 all year without issues, we do not have hobby machines at our shop.

CNC laser engraving is done in two passes as is the cutting, just because it provides additional contrast and makes sure that we totally cut out the coins as sometimes wood has stronger grain that wouldn’t allow the laser to pass all the way through on the first pass.

CNCROi.com tries to optimize as much as possible when it comes to material usage but sometimes the wood has flaws above or below were the custom hardwood coins are being engraved and cut from so it’s best to just go straight across in one row.

Although a lot bigger in scale, we can also make coins using stainless steel and other metals too, the process is the same as this Sasquatch sign.

https://www.youtube.com/watch?v=mOsxRyCauCU/

This is what it looks like in the laser department when we are filming and photographing for these blog posts, I don’t do many videos from here now introductory wise because I have the machine working on important jobs and it gets too loud in that little room at CNCROi.com.

After one set of Oak planks are finished, another is set on our laser table to begin production all over again – our laser chews through this stuff at a hefty rate and I’m very happy to keep feeding the beast until it’s full.

There were quite of few more planks fed through the machine in this production run but I only took photos of a few of them, and filmed equally as few as it’s basically the same steps repeated over and over again.

If you want products made out of plastic instead of wood, CNCROi.com can turn that dream into reality just as well.

https://www.youtube.com/watch?v=eXuXENklLh8/

Again, the coins are finished on one side after each run, they look great and everything is centered correctly but we have one small issue, this is a double sided coin!

So CNCROi.com needs to make a jig that allows us to precisely position the coins upside down to laser engrave the back side of each and every custom hardwood coin.

The lighting in the machine greatly exaggerates the grain pattern on these coins, of course, as we laser engraved some depth into the coins, they are then sanded and much of this relief is taken off as a result.

And here’s what the finished production run of endless custom hardwood coins looks like, these are finished with a semi-gloss clear coat to provide additional protection and contrast to each and every coin.

Need custom coins? Contact CNCROi.com and we’ll make them and ship them right to your door!

https://www.youtube.com/watch?v=6r4_9HFiOUA/