Custom Lighthouse Softwood Plaque V2

Sometimes CNCROi.com does jobs twice for various reasons, this custom softwood plaque is just such a project and the outcome the second time around was far better.

https://www.youtube.com/watch?v=fOS0dGDU8Tw/

Here’s the video of the same custom lighthouse plaque we made earlier.

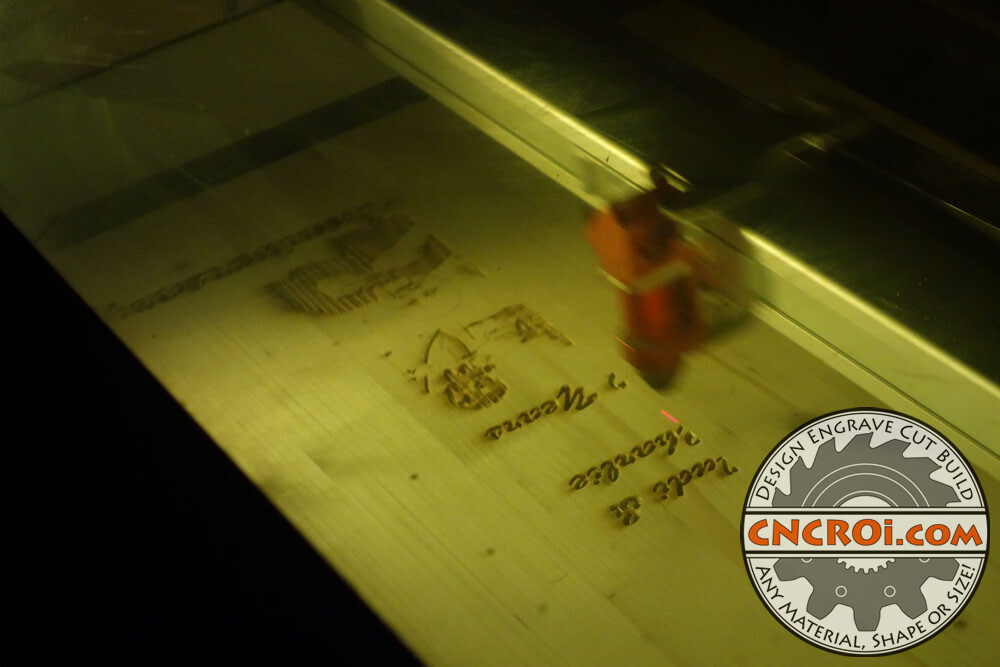

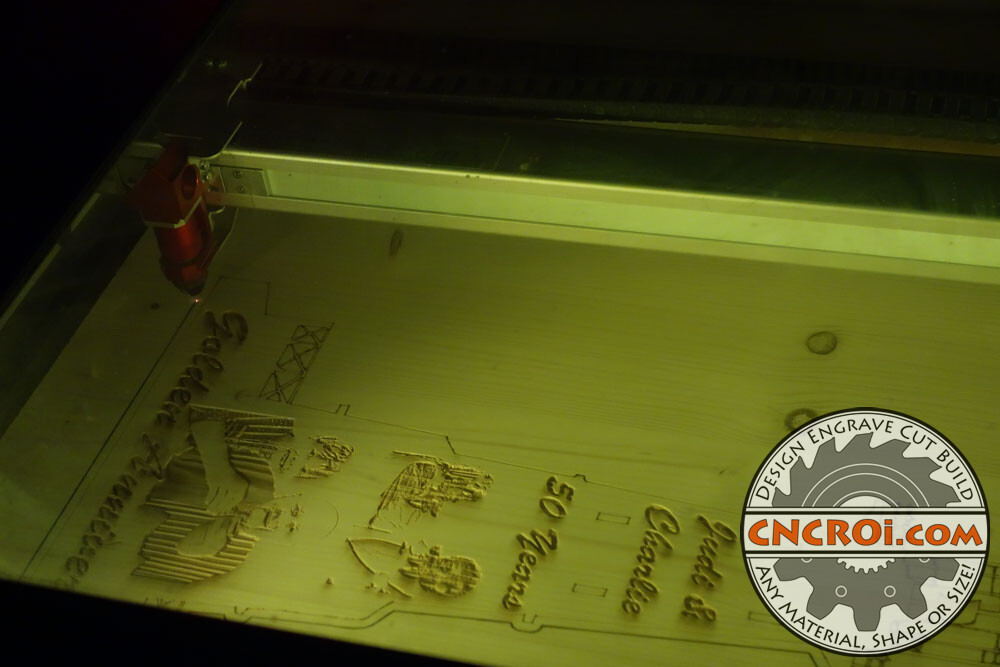

If you compare the two videos above, you’ll notice some fundamental changes in approach that were taken based on lessons learned in the first round of this custom lighthouse plaque.

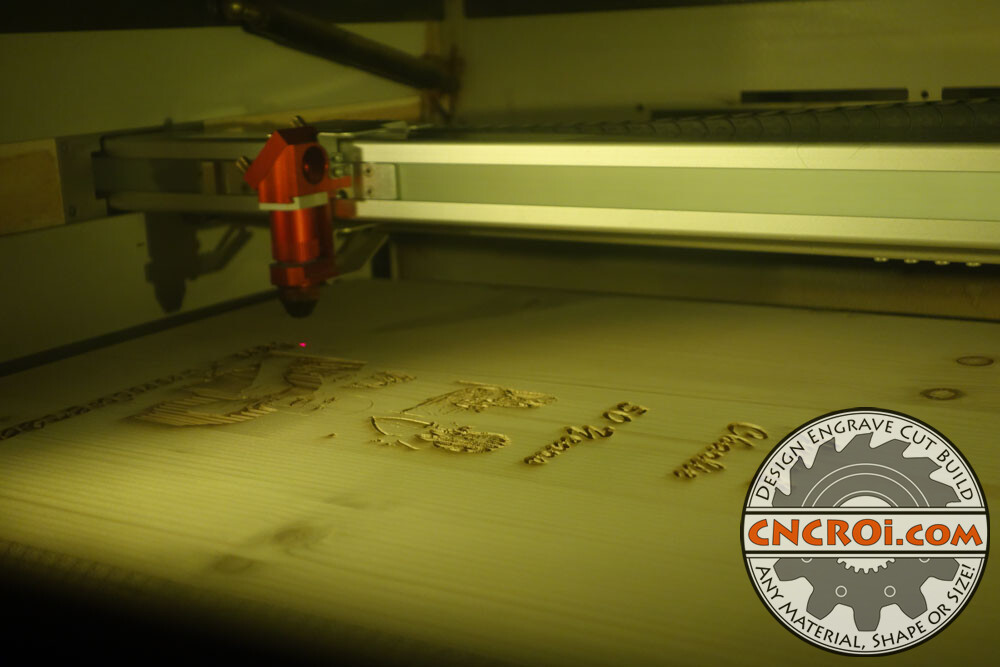

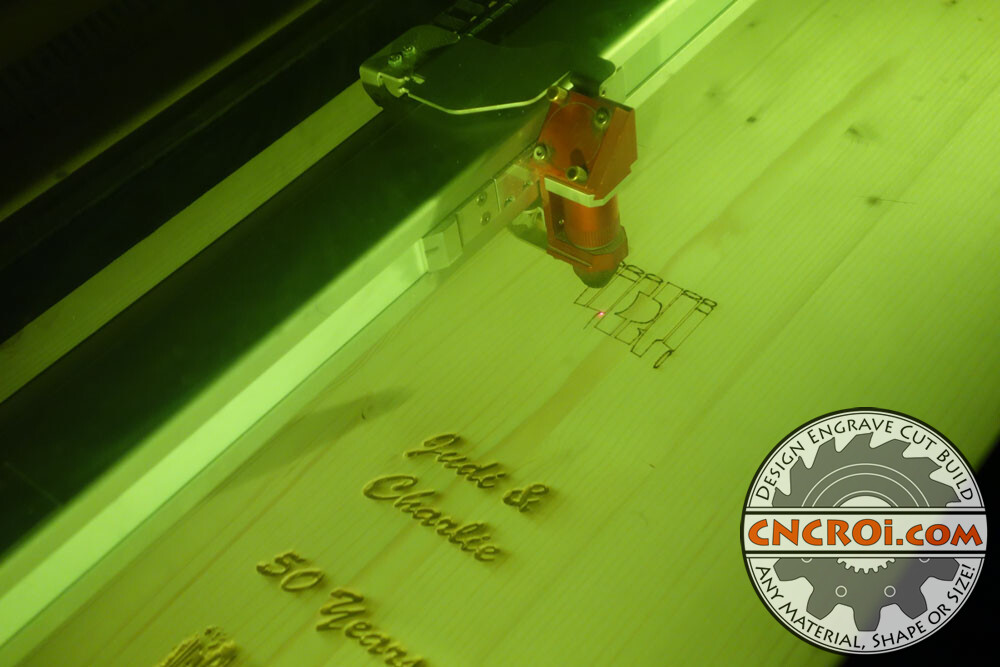

For this custom softwood plaque, we used 3/4″ laminated Pine because it’s readily available, cost-effective and machines (or lasers in this case) very well with built-in contrast when engraved.

The aesthetic of Pine is tough to beat, the wood is relatively knot free, except for where you don’t want them to be, and yet, has a good grain pattern that makes thing pop.

The nice thing about laser engraving is that the charcoal built-up in the base and sides of the engraving will not peel, crack or fade over time and best of all, it smells great!

Of course, CNCROi.com has other machines and equipment in the shop so we aren’t stuck using a laser for making this plaque but the process is so much more efficient using this tool that it wins more often than not when “signage” is involved using wood.

The reason for redoing this plaque at CNCROi.com, the first was that there just happened to be a knot in exactly the wrong place, I didn’t notice it but the customer did and as a result, they wanted it redone… but more importantly, better photos were found which came out far better so all around, it was an obvious choice to redo the work.

Pine just has so many uses, from plaques to key holders and literally anything in-between.

When it comes to custom plaques, keep in mind that with CNCROi.com you are not limited to just wood or Pine, we could have made this using laminated Oak which we make in our shop or any other wood species, or even jump into other materials such as plastics and metals.

Pine just ticks so many boxes when it comes to this specific project that it was by far the best go-to to complete this custom softwood plaque for the customer.

Whether you want deep contrast or just a lighter sway, CNCROi.com can produce a whole host of “looks” depending on what you are after.

The other advantage of Pine is that it machines very well, it sands great and accepts stain or other finishes like a champ.

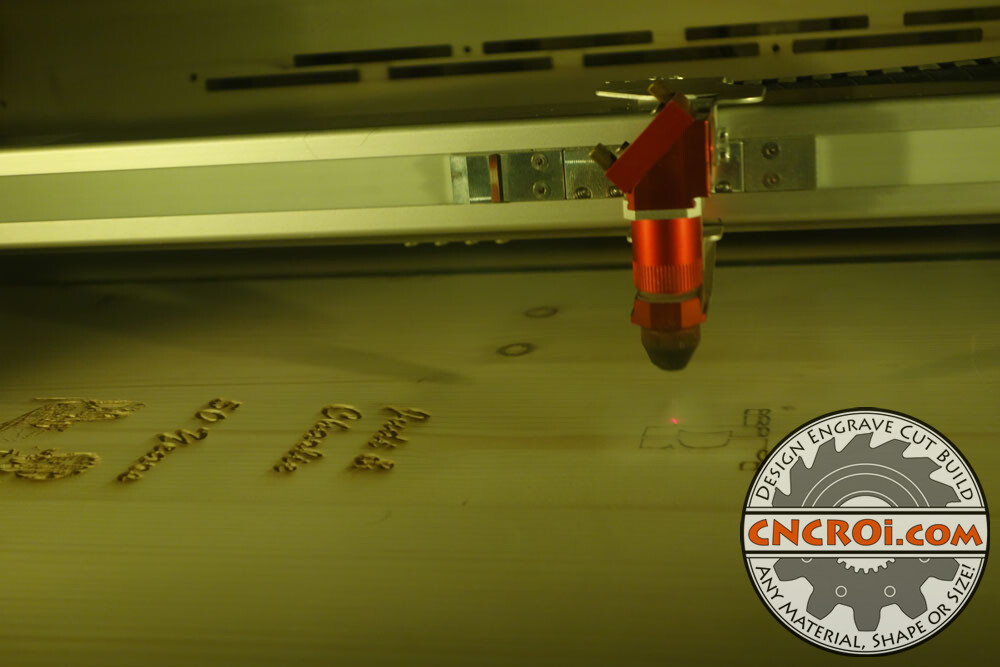

With CNCROi.com, literally any mixture of fonts and high-contrast photographs work well, the challenge is when the photographs are old and hence, very low and muddy resolution and contrast wise, as it was an issue with this plaque, most obviously the first round of making it.

Unlike the first round, I decided to “cut” the details of the lighthouse on the custom softwood plaque we produced at CNCROi.com, it’s not faster (in this case) but does produce finer lines in a more efficient manner.

The process of cutting engraving details is a process I developed at CNCROi.com to handle large fiber etching jobs on stainless steel where the machine would spend more time traveling than etching, so I got the bright idea to “cut” the “engraving” as engraving is side to side while cutting is only where it’s required, saving a lot of machine time.

https://www.youtube.com/watch?v=S4Qx6w0og9o/

Although the image above is a steel button panel we made at CNCROi.com, you’ll notice the engraving process is the same, as a result, we could have made the above panel out of Pine and this plaque out of stainless steel, the processes are really that interchangeable!

After all the custom softwood plaque details are engraved, it’s time to actually cut it out, I do this in two passes, although most likely, one pass is more than enough, because sometimes Pine has very tough and hard strands of grain that make taking out the plaque a more destructive process than it should be so the few extra minutes I spend having the machine redo something in this case, saves me a lot vs not doing it should that potentiality exist, which is unpredictable.

After laser engraving and cutting the custom softwood plaque, it does look a little rough, the smoke has settled all across it and it needs a light sanding to remove it, no masking was used because I felt like sanding this and the plaque is so small relatively speaking, it’s more efficient to sand than to mask then remove that and then sand at CNCROi.com.

Once the sanding is complete, it’s time to apply a few layers of clear coat over the custom softwood plaque.

https://www.youtube.com/watch?v=S2IlY9DtyVg/

The steps involved with custom wooden plaques are essentially the same regardless of what we are engraving or cutting them into.

The photographs this time around were far better!

You can easily tell which photos are “old” vs new, the detail and contrast is far harder to workout in the resultant laser engraving.

Once the finish has been allowed to settle, you can see how this unique custom softwood plaque will fit wonderfully on any wall in any home, the laser cut contrast along the edges also provides instant contrast against any wall it’s put onto by default.

Remember, send your best photos if you can for this type of work, regardless of what CNCROi.com is etching or engraving it onto.

Need a custom softwood plaque? Contact CNCROi.com right now!

https://www.youtube.com/watch?v=Ns_pjx8E8_g/