Custom Live Edge Levelling

When it comes to custom live edge levelling and finishing, CNCROi.com can do it all or only part of it so that you can say you finish it yourself.

Before we jump into our ShopBot PRSAlpha performing some custom live edge levelling, I just wanted to point out that levelling is just a “start” and not a finish.

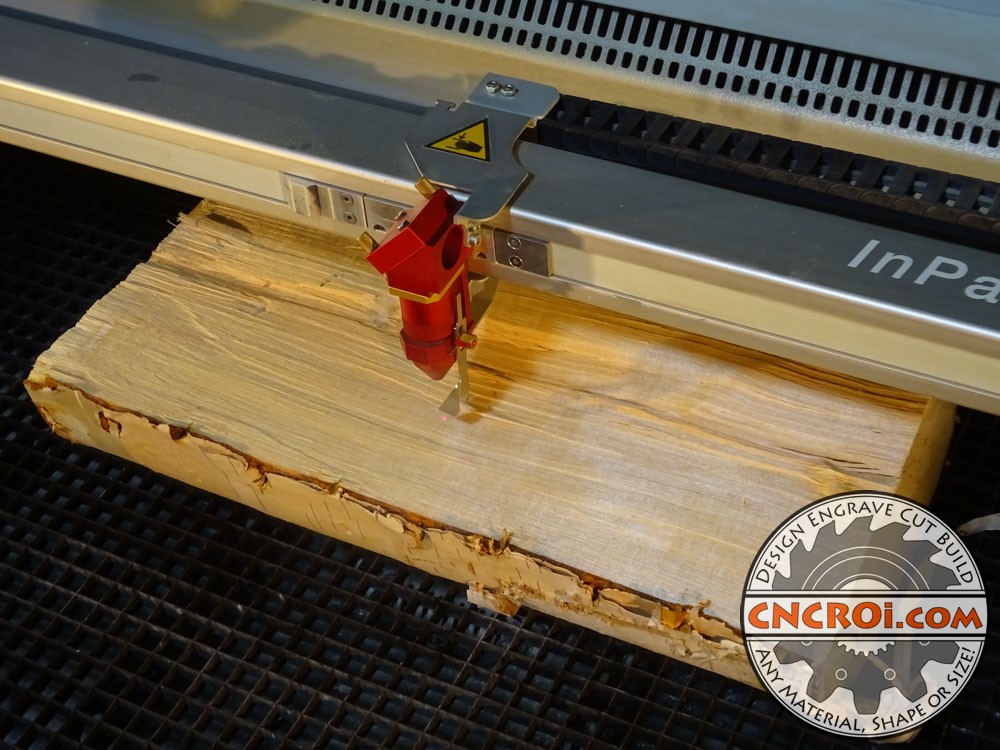

After a plank of live edge has been leveled, we can laser engrave into it and/or carve into it using a variety of machines and processes at CNCROi.com.

Without further delay, let’s start levelling this huge slab of live edge wood, its incredibly heavy and overall, CNCROi.com shaved about an inch off it’s thickness.

When it comes to custom laser engraving live edge wood, CNCROi.com‘s Austrian wide-format Trotec laser does an amazing job across a host of species.

Even with this custom live edge levelling, this slab of wood still weighs a few hundred pounds which is why no hold down was needed throughout the process, nothing was moving this piece of wood without some extensive effort.

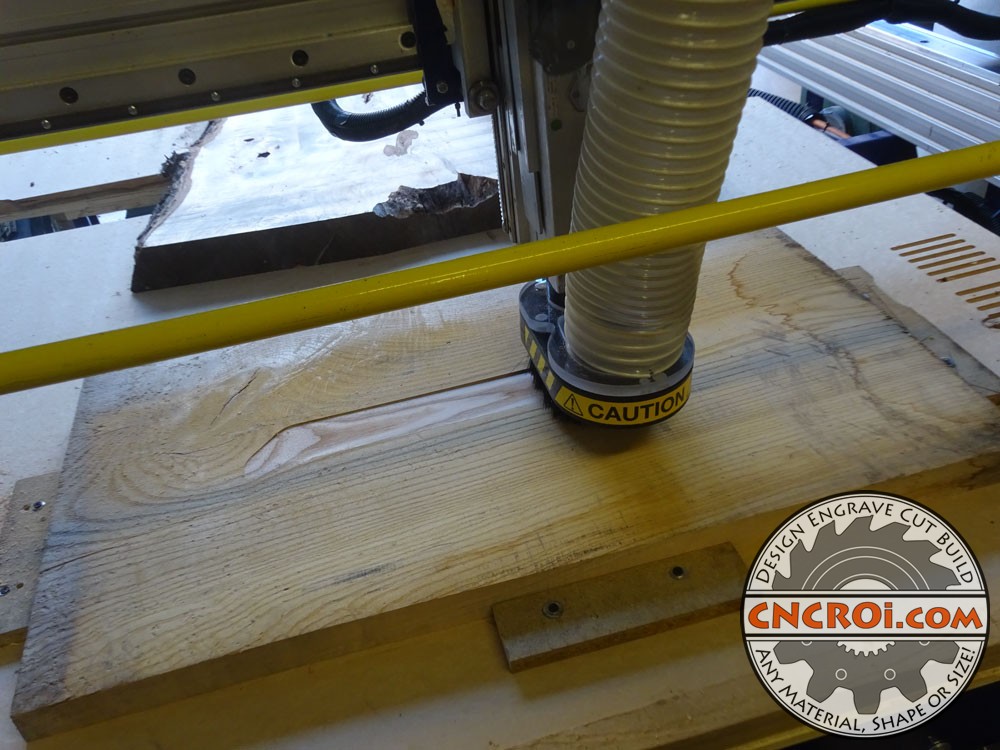

The tricky part with custom live edge levelling is that you can’t start doing this right away at the thickness you want, taking off too much material causes as much problems as not enough, so it’s a very interactive process slowly taking off layer after layer until you end-up with a flat surface.

When it comes to softer woods that have less density, such as Pine or Basswood, CNCROi.com excels in getting very precise imagery and graphics for a wide variety of applications.

CNCROi.com‘s ShopBot PRSAlpha does a wonderful job custom live edge levelling this wooden slab but we also have a HUGE BIT that makes the effort faster too, but again, it’s listening to the machine if I was overly ambitious as to the amount of wood the chipper could remove.

The above picture shows you just how much material is removed from each pass, any warps in the wood don’t need to be worked down, they are just sliced as-is at CNCROi.com.

After one side of the custom live edge levelling is performed, it’s time to flip the entire slab around to do the same on the other side. Why?

Whether you have a need for a small or a huge live edge custom plaque, CNCROi.com is here to help you make it happen!

Because the customer wants a FLAT table, leveling just one side mean that the other side is still uneven and unparalleled, by custom live edge levelling both sides, you end-up with a totally flat and parallel live edge table.

This side is especially rough-looking, but the finish we achieve with our industrial CNC router is almost polish quality, just a bit of sanding is required to complete this custom live edge table.

We can also make custom Christmas ornaments using live edge just as easily as corporate plaques or signage of any size, shape or wood species.

The levelling process at CNCROi.com can take a few hours per side, it all depends on how big the slab of wood is, the density of the material and what else needs to be done, such as carving or laser engraving.

Bark and all are custom live edge leveled to perfection though some weaker parts do fly off so eye and hearing protection are a must when doing this type of work at CNCROi.com.

After the other side of the slab is totally level, it’s time to clean it up and take a look at the surface finish.

When it comes to laser engraving Basswood, the results are nice and consistent as it generally has very few if any knots.

Much like cutting grass, there is a difference in how the bit cuts the wood, as such, you can see the polishing pattern on the surface of the custom live edge surface, this is quickly sanded into consistency.

Next-up was a smaller slab, this was done far faster than the bigger one, it’s still pretty heavy but it’s the same process regardless when it comes to custom live edge levelling.

Again, removing big chunks of wood at each pass, for this board, CNCROi.com ended-up removing half an inch of material before the entire surface was FLAT.

CNCROi.com can manufacture custom furniture using live edge or any other material, the nice thing about live edge is that each piece has its own story and character.

The work is really coming into its own, the wood grain looks amazing and no matter how dirty or worn the wood slab was before, it’s almost polished ready by the time CNCROi.com is finished with it!

Layer by laser, custom live edge levelling takes time to do properly, it’s like peeling an onion, until you end-up with a flat surface.

If you want some accessories as well for your custom wooden item, we can help you on that front as well.

Some bits of the wooden slab have a lot of material removed, others literally nothing, but by the time CNCROi.com is finished, the entire surface is nice and level.

The results of custom live edge levelling are quite amazing, and it’s one of the videos I most enjoy seeing afterwards because this process takes so much time, it’s nice to see time compressed and see it all happen within minutes instead.

There is A LOT OF SAW DUST made by our ShopBot PRSAlpha during this process, imagine for the bigger slab something the size of 1″ thick that’s 6ft x 3ft and it gives you an idea of how much wood was pushed through our CNC router.

Have some live edge work?

Contact CNCROi.com right now!