Custom Maple Leaf Carving for Resin Inlays

Custom Maple leaf carving for my customer’s resin inlays are a perfect way to cost-effectively add a lot of character to any piece of wood.

https://www.youtube.com/watch?v=rQvnGBs2WqU/

Of course, CNCROi.com could have used our CNC router to make custom carvings of any shape at any dimension, so we aren’t limited to ONLY doing Maple leaf carvings.

For this specific project, all three Maple leaf carvings shown were the same size but we’ve done far smaller ones and even bigger ones in the past.

The added challenge with Maple leaf carving or any carving in general, on live edge boards are that they are rarely flat, for bigger jobs, CNCROi.com will flatten the board using the same CNC router you see in these photos and video carving out what will be filled with resin by the customer.

The reason why live edge boards are rarely flat right out of the kiln is generally because of natural warping caused by humidity differences and stresses found right in the wood itself coming into being.

https://www.youtube.com/watch?v=auFEfgpm2tE/

Big boards also have warping, it’s just less apparent.

The best way, other than using a proper wood drying techniques to get rid of humidity as evenly as possible across the entire board, to deal with warping is to actually just CNC flatten it after it has been dried, and making sure there is a good thickness to the board as well, giving it more strength and resistance from warping.

The thinner the board, the more it will warp and the less that can be done to resolve the issue, that’s why you see hold-downs along the boards during the Maple leaf carving, this pulls the board flat as possible against the CNC router bed, during production for an even depth, but the board go back to warped thereafter.

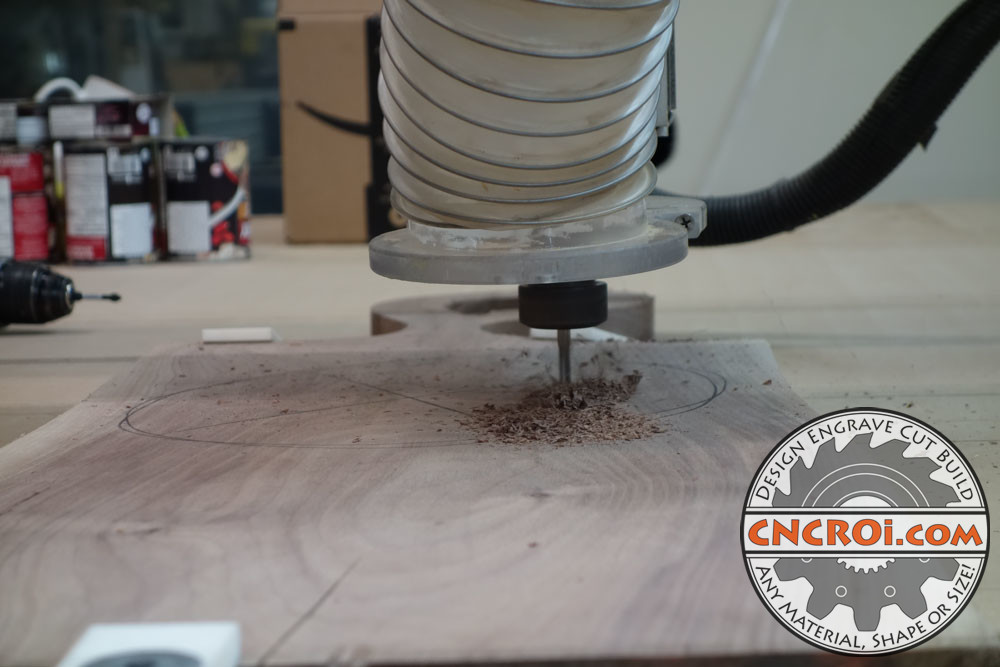

The chip size is perfect for these Maple leaf carving, you can see how they aren’t too dusty or too chunky, just the right mix!

https://www.youtube.com/watch?v=dG-InGGf4kY/

The use of live edge has no end, from kitchen countertops to custom wall signage.

CNCROi.com has a lot of experience with both woodworking and CNC machinery, which means there is very little that we can’t make on your behalf for either you to finish or us to ship as a complete project right to your door.

These Maple leaf carvings all look the same, they were all done at a quarter inch in depth, which is perfect or resin infills as you still have plenty of give when it comes to the final sanding and finishing of the wood products.

You’ll notice the board below was a little raised at the right end, there really was no good way to flatten it, so I just added supports to make sure it didn’t move, is it was a little bowed in the center, to allow for an even Maple leaf carving.

CNCROi.com can carve out not just flat designs but also dimensional ones out of solid wood, so if you wanted the Maple leaf carving to have some relief to it, that’s no problem, either on Maple or any other wood species.

https://www.youtube.com/watch?v=8Jvgg3ncdLw/

Literally anything goes when it comes to carving, we are only limited by your imagination.

CNCROi.com could have also done the Maple leaf carving at any depth, even through the board completely, so your options aren’t limited in depth at all.

For these Maple leaf carvings performed by our CNC router, they were meant to fill-up most of the board to fit with the customer’s design requirements and having something bit like this works great with resin and epoxy fills because you can add a lot of swirls and different color variations across the entire engraving which would be more challenging on a very small carved out item.

The Maple leaf carving came out fantastically across all the boards, the time was the same for all of them as the design and depth were all identical, it was only the set-up and location that had a bit of give during production but once everything is ready to go and warmed-up, production goes rather smoothly.

https://www.youtube.com/watch?v=DwZQ8Z8fOj0/

Live edge carving can be done on man made wood composites as well.

You’ll notice some of the chips are very fine and other very large, that’s dependent on the wood density in a given area, wood isn’t a man made substance, as such, it has differences in character that produce different results when worked upon in different areas, the machine always ran at the same power and speed.

The size of the boards that CNCROi.com is doing the Maple leaf carvings into are relatively consistent for this production run but we can of course work off far larger boards, and heavier ones too boot, with both our CNC router and our CNC laser.

Here’s the finished Maple leaf carving, it looks sharp and is highly detailed, it was done using a 1/8″ diameter bit at a quarter inch depth.

https://www.youtube.com/watch?v=SZbDwgCE8iw/

Custom live edge house numbers look great, this isn’t something you see too often, but we can make it using any wood species or sizing.

You’ll notice that the grain pattern follows from the surface of the live edge Maple board all the way through.

Here’s what the finished Maple leaf carvings look like from many angles, so you can clearly see how clean the results are.

The wood used for these Maple leaf carvings is black Walnut by the way, a Maple leaf looks better than a Walnut carving.

Need some live edge work done and shipped to your house? Contact CNCROi.com right now!

https://www.youtube.com/watch?v=iyDXD6pTj3s/