Custom MDF Cake Topper

CNCROi.com has made cake toppers in a variety of materials, acrylic to wood but only recently have we gotten into MDF cake toppers and we’ll show you why.

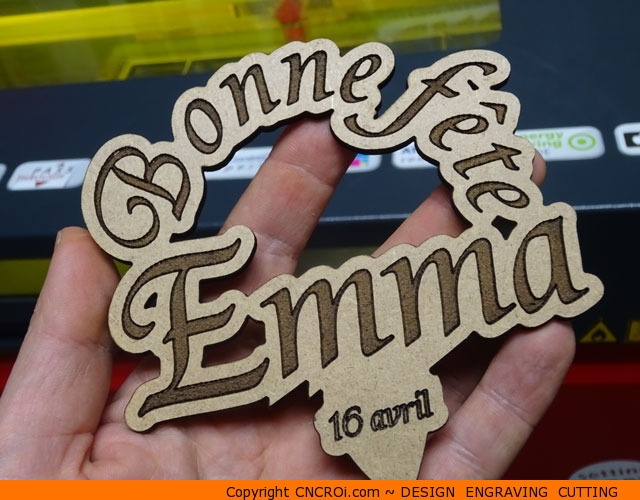

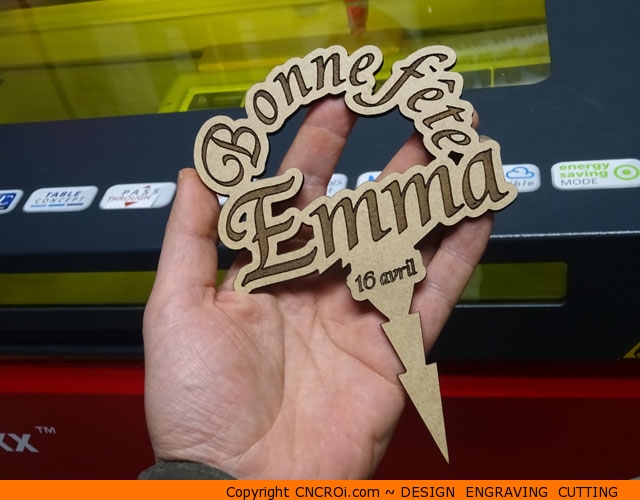

The advantage of MDF for a cake topper is the immediate contrast that is achieved and the consistency of said contrast. It really looks like it was paint filled even though it wasn’t.

The problem with MDF is that you really can’t sand it as it breaks apart, unlike plywood, so if the mask comes off or there is some vapors that sneak through, there isn’t really a way to take it off. This is 3 mm or 1/8th inch MDF after all.

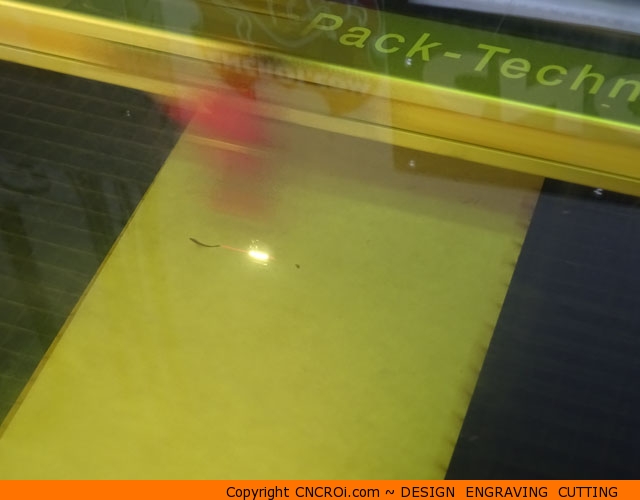

As for production speed, we have an incredibly powerful Austrian wide-format industrial CNC laser so whether the “wood” is 1/8th or 1/4 inch (3 or 6 mm), for this application, it makes very little difference but you don’t want to stick a quarter-inch MDF cake topper on your cake anyhow.

Luckily with MDF, the mask does stay on the wood very cleanly because of the consistency of this material’s surface. We could easily engrave straight through this material with our laser by the way, so during production, it isn’t the speed that’s decreased but the power setting.

These cake toppers are entirely customizable from font selection through to style including endless material options and even inlays. Budget helps to narrow down the options.

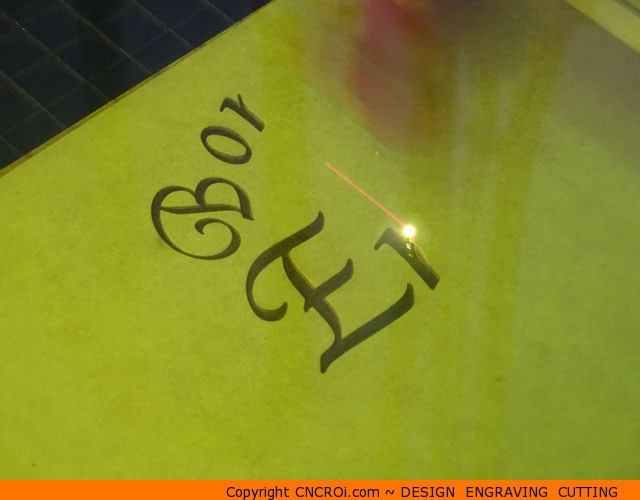

Although not needed with MDF, another pass using an outline is done just to darken the edges a bit more for that extra contrast – again, budget will dictate of this extra step is required or not. On plywood, it makes a massive difference but on MDF, not so much. We don’t do this extra pass on acrylics as you don’t see a difference due to the material’s properties.

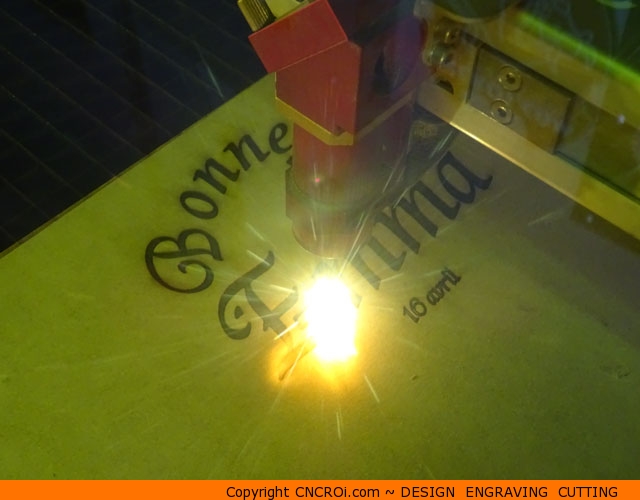

After engraving, a CNC laser cutting pass starts, first on the inside and then the outside to keep things consistent and non-moving as long as possible. The reason there is little smoke throughout the video and these photos is because we have a powerful extraction system working in our laser and gas kit throwing lots of PSI onto the work piece. This keeps dust and smoke at bay.

After everything is cut out, you can still see the resin build-up all over the mask, that’s why we use it, so that once the mask is removed, so is all this build-up, leading to clean and clear edges.

The top part is engraved and outlined, the bottom “16 avril” is simply outlined, engraving into it at this scale just isn’t needed, it’s faster to just outline.

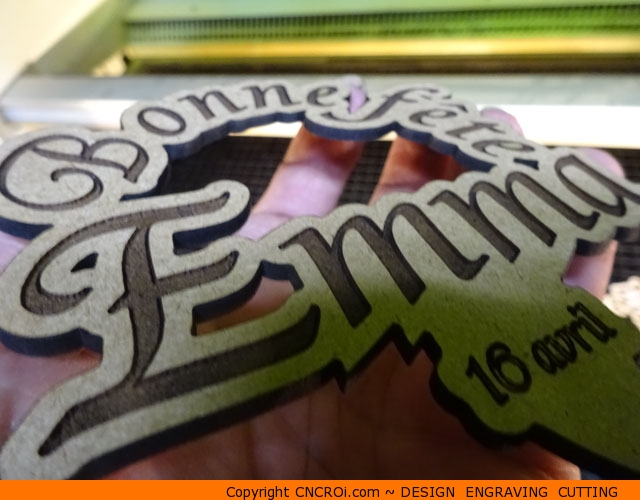

After the mask is removed, you can see how clear and awesome this custom cake topper really is! What happens after is having it sealed so that the juices from the cake don’t get sucked too much up into the cake topper while the bottom is in the cake.

We still generally make two though as it’s impossible to clean MDF, so the one that goes on the cake goes into the trash or fire pit, the extra is kept for the memories.

Looking at it a bit closer, you can see we have a consistent depth and the extra pass over the letters adds a bit more contrast to the edges, throw-in some shadow production due to the depth and you have an amazing custom cake topper made JUST FOR YOU!

And more shot a bit further back, there is a bit of reflectivity to the custom cake topper after it has been sealed but it’s very minor.

How does that compare to, for instance plywood? Here’s an example… these are before sanding.

You can immediately see the difference in contrast between plywood (there are a lot of varieties btw) and MDF.

Need a custom cake topper and a bunch of other custom stuff for your upcoming event? Contact CNCROi.com right now!