Custom MDF Ovals: CNC Router 1/8″ or 3 mm

Custom MDF ovals by CNCROi.com can be made using a variety of techniques and machines, if you wanted them out of stainless steel or glass, Formica or live edge wood, we can make them for you in any quantity or size.

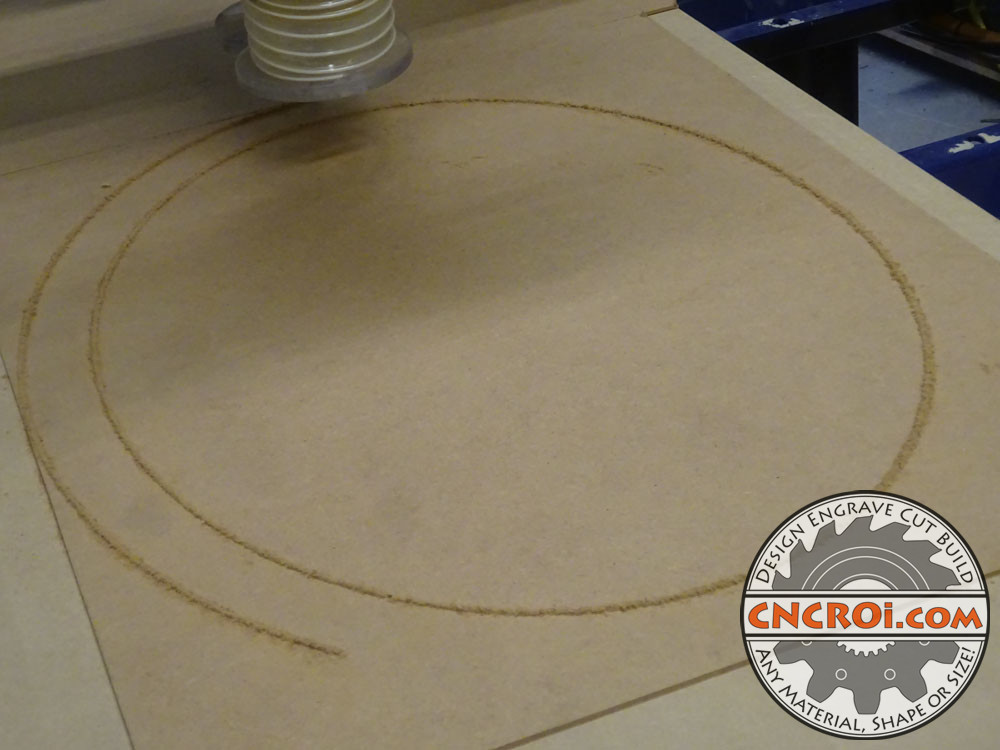

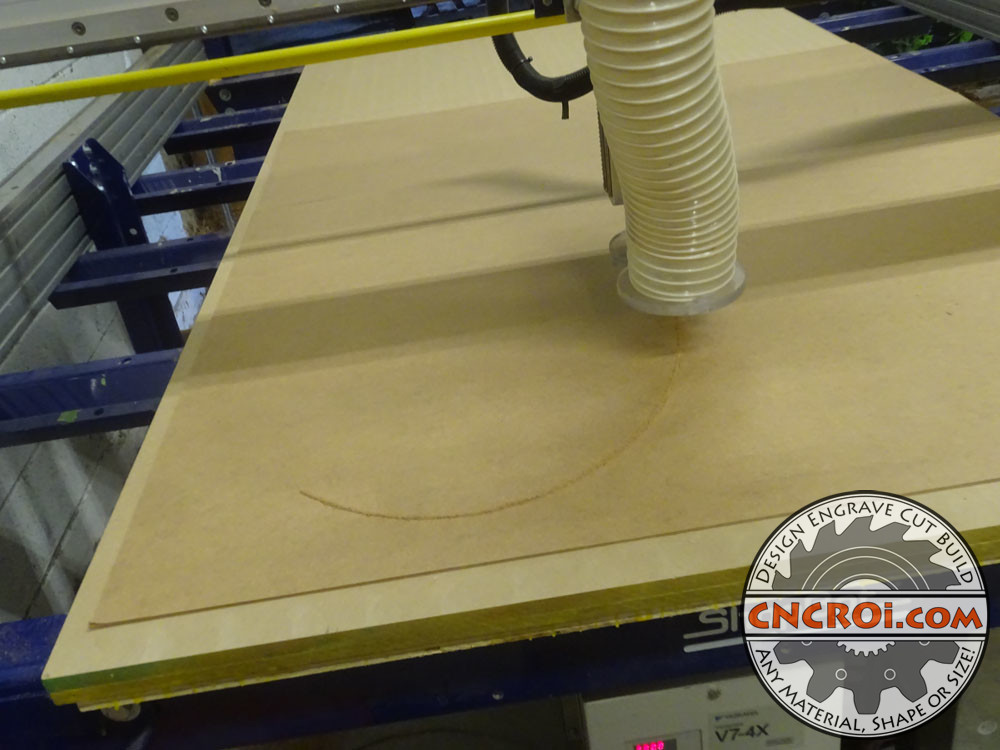

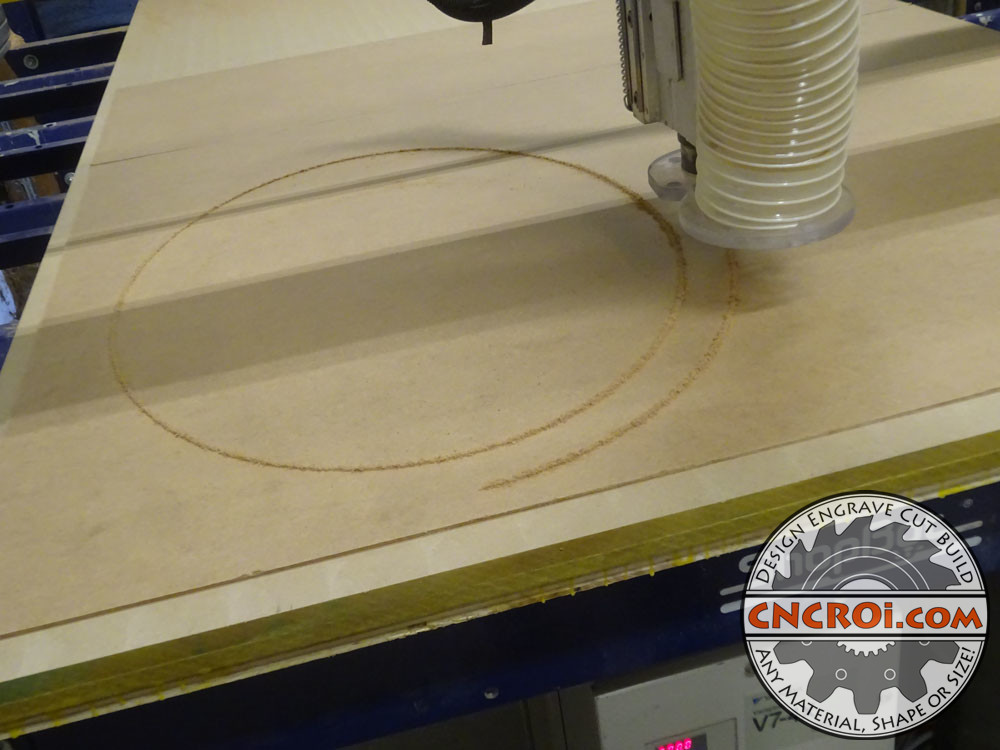

One of the most difficult shapes for a CNC to make is a circle or oval, there are so many things that can be revealed software to hardware by simply making one of these, regardless of size, that indicate whether you have a good machine or a bad one.

I’ve worked with CNC machines before founding CNCROi.com that had a very tough time making smooth shapes, there would be sputtering and jagged movements, not the smooth flow you see when our ShopBot PRSAlpha when it’s making the custom MDF ovals.

If you are wondering what MDF cut out using our laser looks like, here’s a project we did a while back, for this custom MDF oval project, they were too big to fit on our CNC laser and regardless, the spec was faster to cut using our CNC router.

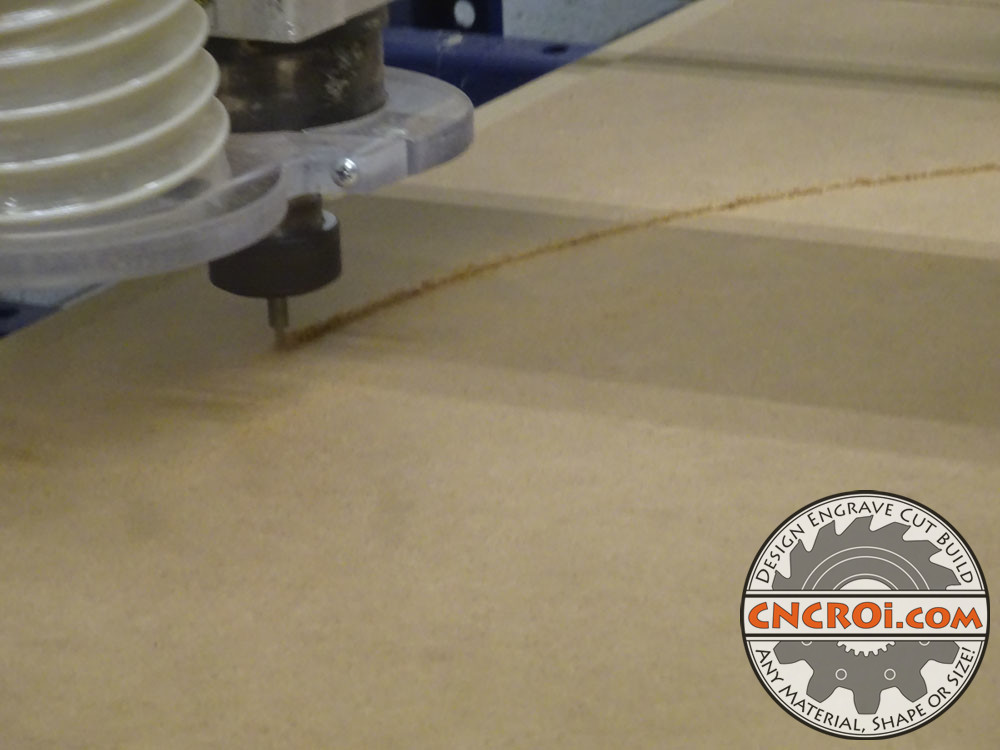

Regardless of the machine we use at CNCROi.com to make your custom project, the level of precision is essentially the same with the only variation being caused by the material itself.

What I really enjoy about making shapes such as these custom MDF ovals in the shop is just how smooth the machine runs then, it’s almost like magic just how agile and free flowing such a huge piece of machinery can be.

Of course, there are real world applications for rather nice things that can be made using free flowing shapes, such as family monograms (happens to be the same material as these custom MDF ovals) and corporate signage.

There are a lot of options to you, a company or individual designer, regarding what CNCROi.com can fabricate for you and additionally, don’t forget the power of paint on MDF as it makes a massive transformative difference in esthetics.

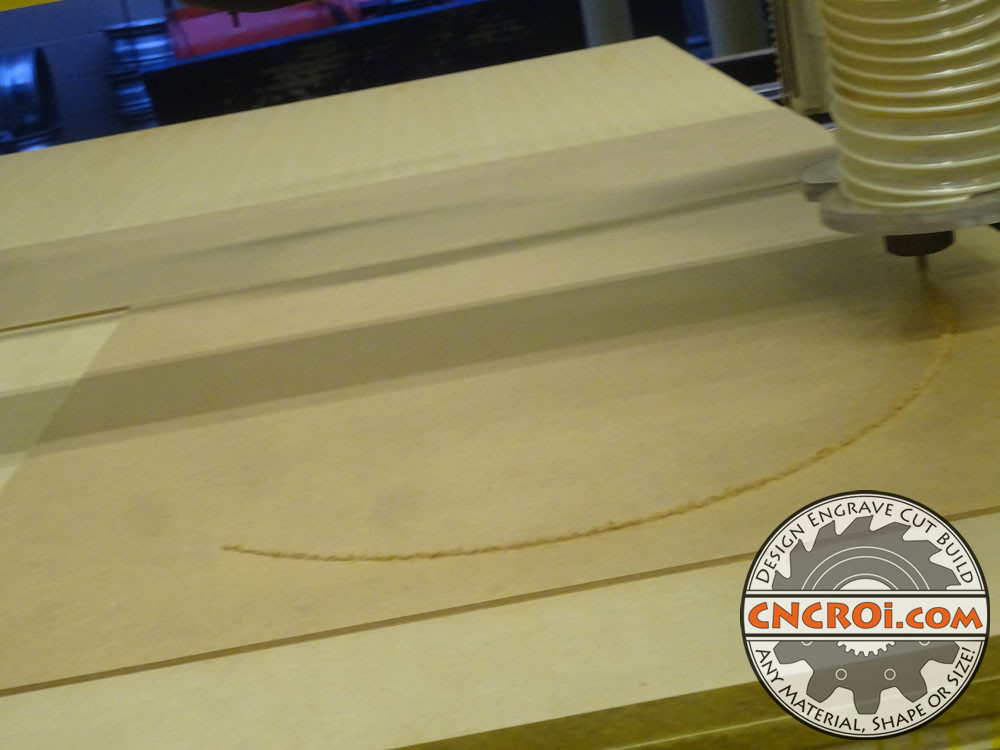

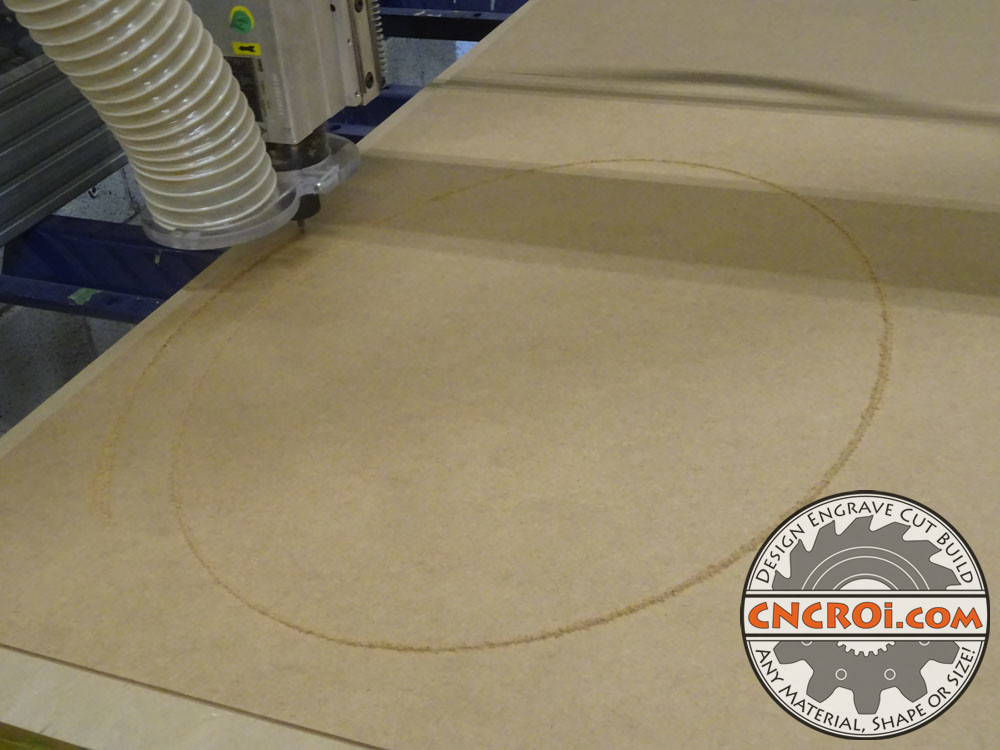

The dust you see around the oval is just that, dust created by our CNC router bit spinning and cutting through the 1/8″ 3 mm MDF, if it was metal, it would be shrapnel but in this form, it’s more of a breathing hazard than a cutting one.

If you are wondering of how MDF compares to metal when it comes to custom fabrication, here’s a great video outlining that.

https://www.youtube.com/watch?v=eHtoBmZbhEY/

The machines may be different, the processes a little changed but overall, the results are interchangeable, in fact, at CNCROi.com, I’ve made several projects where I mixed-up materials and processes to make a finished piece for a client using pretty much the same files for each machine and material type.

If you are wondering how I can get away without having to use screws or nails or clamps to hold down the MDF on my CNC router, it’s because I have a vacuum table, ironically, this is the first project I used it for after updating my sacrificial board.

https://www.youtube.com/watch?v=A3R9u_DI5IE/

Now you know the secret to holding things down without having to use exterior hardware or tooling.

I’ve been designing and fabricating with CNC machines for almost two decades and it never gets old looking at the machine do it’s work, it isn’t just pressing a button, it’s optimizing settings (feed rates, bits, materials… ) and seeing directly the results of your work.

As for the dust foot, there is none on this project because the dust being created is at a minimum and the bit I’m using is extremely small, so it would just get in the way, though I’m still using my dust extraction system more out of habit than need at CNCROi.com.

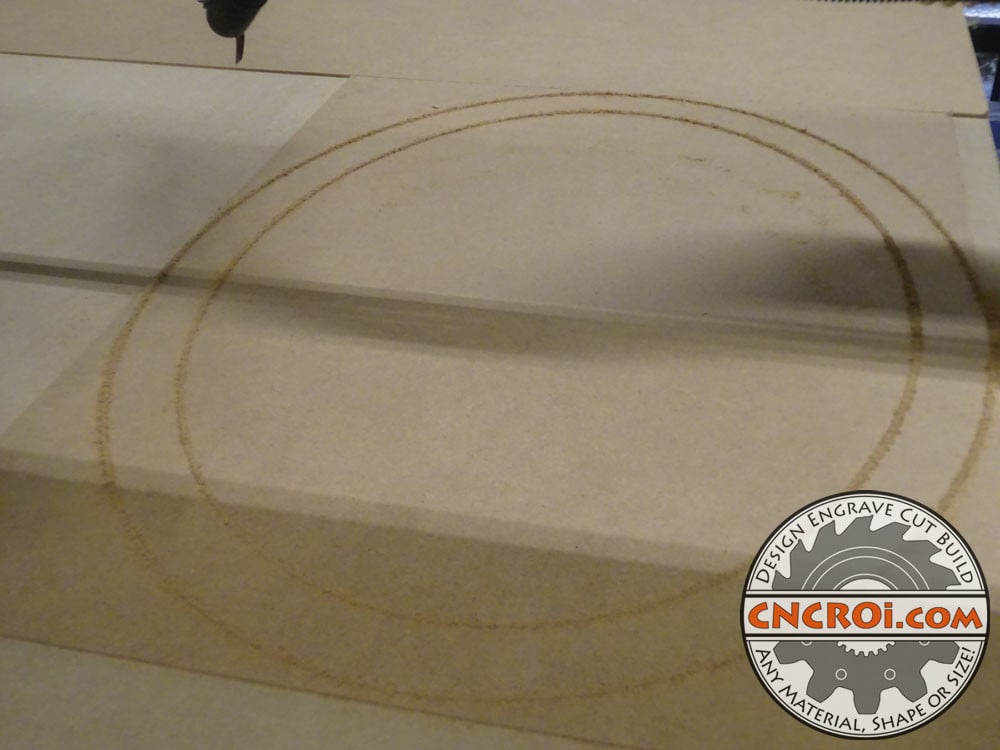

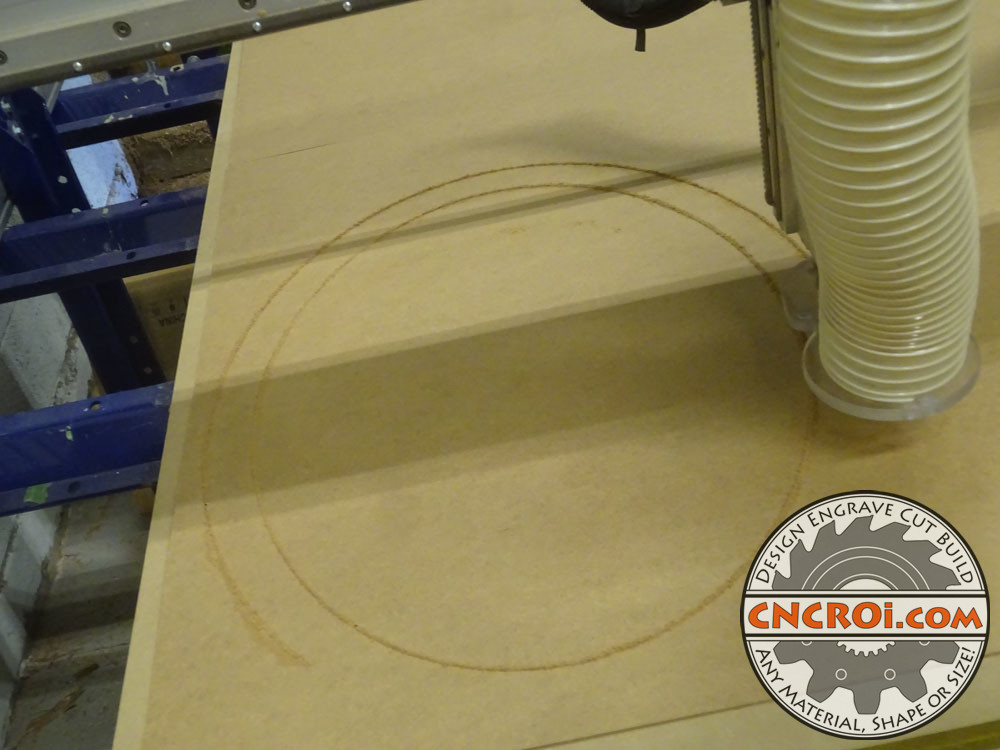

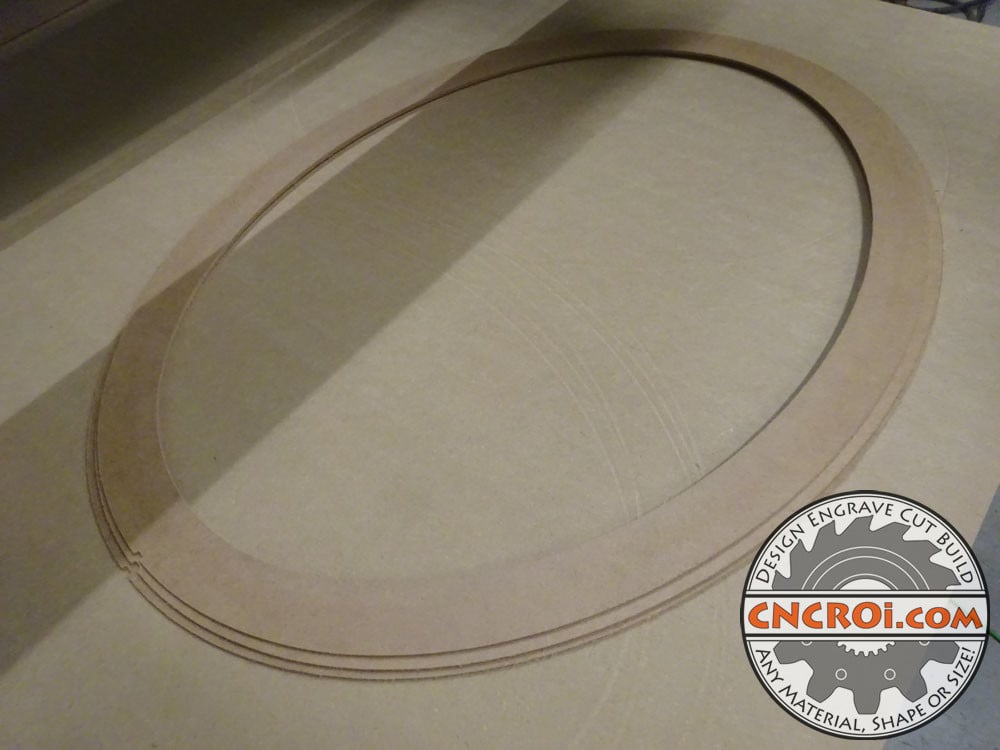

And there we go, another finished custom MDF oval, only one more left to go, these ovals are all different sizes by the way, and their size necessitated another sheet of MDF each time.

If you are wondering what types of shapes CNCROi.com can produce using MDF, it’s endless and using our laser (no bit so ultimate tolerances) you can get a feel of simple animals we can make using the same MDF as these custom MDF ovals.

The additional advantage to laser is that we can actually carve MDF using the laser too, or mix and match, carve with router, cut with laser and vice versa.

https://www.youtube.com/watch?v=AomcVEF0i-s/

As mentioned, the possibilities are absolutely endless when it comes to CNCROi.com and custom fabrication for your needs.

As the last of three ovals are being cut out, you can see that the overall set-up is pretty straight forward when a vacuum system and dust system are in use.

Another application we use our CNC router for a lot in the shop is actually live edge leveling, of which I’m doing more of tonight after this blog post.

https://www.youtube.com/watch?v=wt2bBRtEIHY/

It really never gets boring having fun leveling live edge, it’s such a unique process for each slab, always something interesting going on.

The reason I cut out the inner shape (scrap) before the outer is simply because I want to keep everything together as part of the full sheet as long as possible to prevent things from possibly moving around.

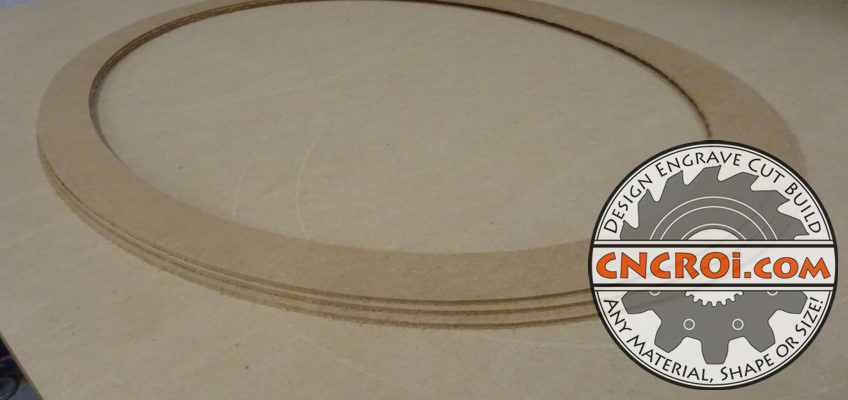

And here are the finished ovals, you can now see they are three different sizes and shape, just needs a bit of clean-up and they are done.

The markings you see on the sacrificial board are about 1/32″ or less than a mm deep, it’s more the pressure of the bit spinning and polishing with the MDF dust tracks than anything else.

If you have a custom MDF job or want custom shapes, regardless of size, shape or materials, contact CNCROi.com to make it for you!