Custom MDF Thermoforming Mold Prototype

CNCROi.com can make custom MDF thermoforming mold prototype and full-on production thanks to our massively overpowered 12 000 pound CNC router with a fixed gantry.

https://www.youtube.com/watch?v=Z4CydeVeIos/

MDF (medium-density fiberboard) thermoforming molds are gaining popularity in the manufacturing industry due to their many benefits, and CNCROi.com has both the expertise and machinery to make them however you want, this small prototype is just that, small, we can make these dramatically larger and even make entire wall collages.

The thermoforming is a process used to shape plastic sheets into a variety of forms, and MDF molds are used as a cost-effective and flexible solution for creating high-quality parts, this is because, unlike hard or soft woods, you don’t have the issue of stress releases that can occur from short term heating to form your part.

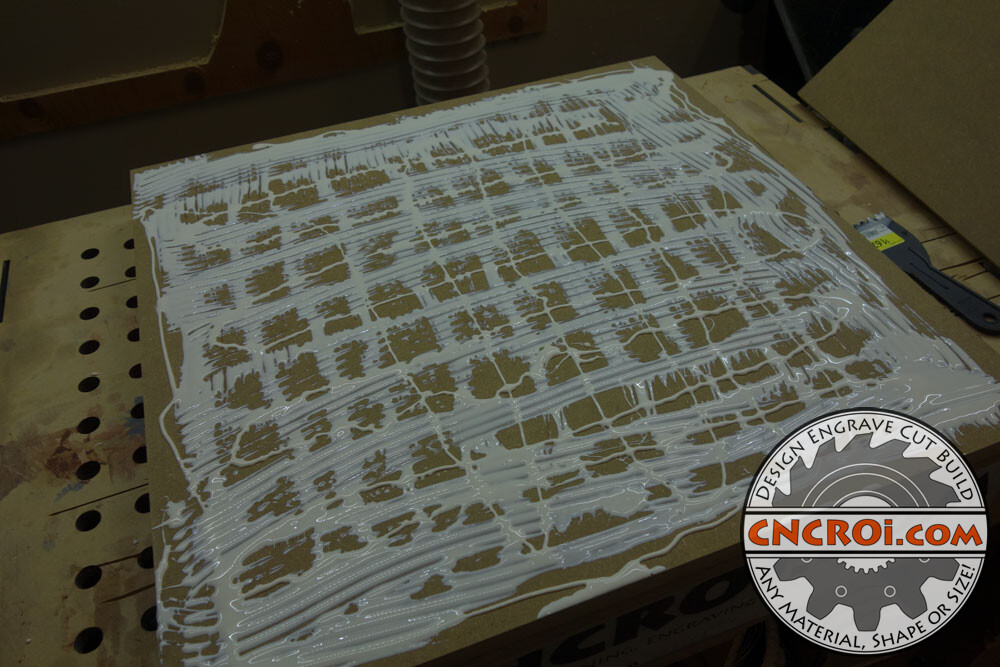

When it comes to making the actual block of MDF that we’ll use to make the custom MDF thermoforming mold prototype, there is no 3″ thick MDF available, so glue, and lots of it, is used to make a solid block from which CNCROi.com will carve from, glue spread and consistency is very important in making solid MDF blocks!

There is an endless variety of “things” that CNCROi.com can engrave using both our laser and router onto just about anything but sometimes the medium has to fit the message, which is why I really liked the mammoth frame I did a while back on my smaller CNC router.

Before going ahead with the prototype, I decided to do a little extra prototyping using a smaller version of this custom MDF thermoforming mold file the client sent to me, just to double check settings, resolutions and other details.

You might think making a prototype of a prototype is kinda redundant, but it’s an important part of production because of the amount of time it takes to actually make these finished molds, this is a VERY VERY SLOW PROCESS, if it works on a smaller scale, it should also work on a larger one!

MDF is a type of engineered wood that is made by combining wood fibers with a synthetic resin binder, as such, it’s known for its uniform density and smooth surface, making it an ideal material for creating thermoforming molds, as such, there is no grain or “defects” such as knots, worm holes or splinters to deal with.

MDF is also easy to shape, mill, and machine, making it a popular choice for prototyping and low-volume production, for higher production, we’d basically follow the same steps as you see here but using aluminium, at a significantly higher cost, but keep in mind, MDF can be supplemented using coatings like resin etc… which can add a lot more strength and durability to the finished MDF mold.

The example I showed in the video is actually from this grape carving I did a while back, having two machines capable of this type of work is incredible, and there is an endless variety of things that can be done in this manner from cottage signs to specialized gifts.

Compared to traditional metal molds, MDF molds are much less expensive to produce, which makes them a great option for small businesses and startups with limited budgets and for larger ones wanting to test out a mold design before having CNCROi.com make the same using aluminium.

MDF molds by CNCROi.com can be produced quickly and easily, reducing lead times and allowing for faster production, just about any design works fine, but keep in mind that this a 3-axis process, meaning parts that are “underneath” will not be carved, that’s where creative assemblies including gluing are important things to consider.

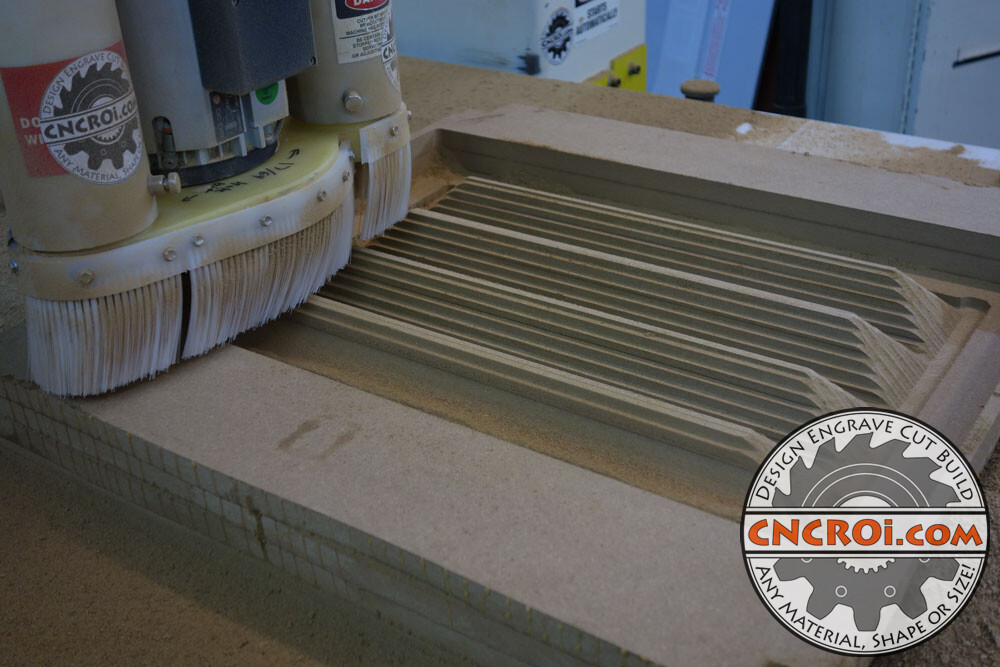

Although CNCROi.com has made custom MDF thermoforming mold projects before, the process generally involves a clearing bit followed by a high resolution bit to clear out material efficiently… and it’s that little bit that takes forever to make the final mold.

MDF is a lightweight material that can be easily shaped and modified to meet the specific needs of a project which means that MDF molds can be customized quickly and easily to create complex shapes and designs, without the high cost and long lead times associated with traditional metal molds, again, there is certainly a specialized niche that MDF molds fit perfectly in, it isn’t for everybody nor ideal for every application.

MDF thermoforming molds are also durable and long-lasting as MDF is a dense and robust material that can withstand repeated use that can also be coated with various materials to increase their durability and extend their lifespan, and of course, you can also augment your MDF mold with metal parts or other materials but the ease of fixing MDF is also an important consideration.

CNCROi.com also has a laser capable of doing some limited carving, but nowhere near the amount of precision in profile control of our CNC routers.

The flexibility and cost-effectiveness of MDF molds have made them a popular choice for creating a range of products, from packaging to automotive parts, even art installations where multiple “same” parts must be produced, you can use these molds to make other molds too!

There are some limitations to using MDF thermoforming molds, they are not suitable for high-volume production runs, as they can wear out over time and may require frequent replacement, this is where their metal, especially aluminium, excel at.

Additionally, MDF molds are not suitable for use with materials that require high-temperature processing over extended periods of time, as they can warp or deform when exposed to heat, that being said, set-up is very important to the longevity of a MDF mold as well.

When it comes to carving MDF, the medium works very well for many applications beyond thermoforming because it’s essentially saw dust and glue, as such, as long as the base is solid, there are very few issues when it comes to dimensional stability, unlike hardwoods or even softwoods or even plastics, which can release stresses and warp during and after production.

The process of creating MDF molds requires precision and expertise to ensure that the mold is accurate and suitable for its intended purpose, but it’s always far cheaper and faster to test out molds using MDF rather than aluminium.

Now that this custom MDF thermoforming mold prototype is finished being CNC machined at CNCROi.com, we can take a look at the results straight off the machine before going forward with removing the sacrificial material that was used to hold this down.

The strata you see are the different layers of MDF that I glued together at the very beginning of this process, again, more glue was put than was necessary, but you don’t want parts of this coming apart during production, as the cost of re-doing jobs is far higher in bits and time than just putting more glue.

When it comes to making custom carvings, you are certainly not limited to just “woods”, engineered or natural, we can also carve other materials including Corian, which is a solid surface material.

I can now use CNCROi.com‘s handy little bandsaw to cut out the custom MDF thermoforming mold prototype, the customer will be doing additional finishing on this to better suit their production needs.

If you look closely at the model, you can see the steps that the bit did in order to produce the finished custom MDF thermoforming mold prototype.

This is the “resolution” I was writing and talking about earlier, these steps can be increased or decreased, for a rougher or smoother finish.

Need a custom MDF thermoforming mold? You’ve found CNCROi.com, contact us right away!