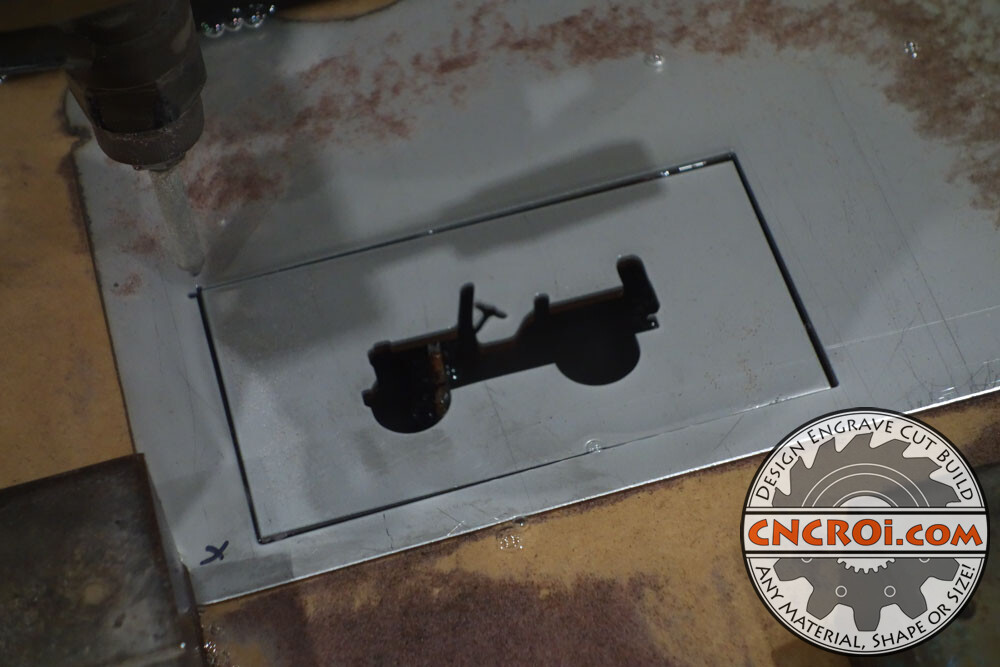

Custom Jeep Stencil: Waterjet Cutting

When it comes to a custom jeep stencil, CNCROi.com can make then however you like using any design and material profile you can imagine.

Custom Jeep stencils are a popular trend among Jeep enthusiasts who want to personalize their vehicles with unique designs and graphics, and CNCROi.com can make them at any size, design and material you want.

Stencils are a type of template that allows you to create a consistent and accurate design on a variety of surfaces, you can use various spray paints or enamel paints with these custom jeep stencils.

For this specific custom jeep stencil, CNCROi.com used the waterjet to cut 14 ga 304 stainless steel, it’s the perfect mix of durability, functionality and affordability.

CNCROi.com can make these types of stencils using any material, wood though plastic, rubber through metal of any thickness or profile.

Probably the most fragile stencils we make are out of paper, yes, paper, they are great for very limited use and as a result, very cost-effective.

The first step in creating a custom Jeep stencil is to design the stencil itself, his can be done using software such as Adobe Illustrator or by hand-drawing the design on paper which CNCROi.com then digitizes one way or another to produce the “paths” that the CNC machine (router, laser, waterjet) will follow to cut through onto your material of choice.

Jeep stencils can be used to create a wide variety of designs and graphics, from simple lettering to intricate patterns and images, some popular designs include the Jeep logo, trail ratings, and popular Jeep sayings such as “Jeep life” or “Go topless.”

Stencils can also be used to create custom designs and graphics, such as personalized names or designs that reflect a particular Jeep owner’s style, keep in mind that the spray paint you use also adds another layer of customization not to be overlooked.

When it comes to stencils, there is no right or wrong way to your designing, we’ve even made multi-use stencils for customers who want to use one stencil to do a variety of branding.

One of the main benefits of using custom Jeep stencils is the ability to create a consistent and accurate design on a variety of surfaces, CNCROi.com stencils can be used on metal, plastic, or glass surfaces and are ideal for creating designs on surfaces with complex shapes or contours.

Stencils also allow for precise placement of designs and lettering, ensuring that the final product looks professional and polished, especially if you plan on doing this using polycarbonate or mylar, then you can get absolute placement easily for the first spray as the material is transparent.

Another benefit of using custom Jeep stencils is the ability to create multiple copies of the same design quickly and easily, once the stencil is created, it can be used to create multiple copies of the design, making it ideal for creating designs for a fleet of vehicles, pay once, use infinitely.

The nice thing about polycarbonate or mylar for a custom stencil is that it’s light weight compared to stainless steel, you can see through it for your initial spray and if it’s large, it can be rolled-up for future use… but don’t use propane with it!

When using a custom Jeep stencil, it is important to use the right materials and techniques to ensure that the design is accurate and long-lasting, a high-quality stencil material, such as Mylar or even metal for flat surfaces, should be used to ensure that the stencil does not tear or stretch during use.

Additionally, the surface being painted should be clean and free from debris to ensure that the paint adheres properly to the surface.

The bubbles and sand that come back up during production of this custom jeep stencil do so because the water is shooting down at a very high PSI, as a result, the water hits the bottom of the waterjet vat and shoots backup, bringing with it, debris that was in the bottom.

Making custom stencils using stainless steel has extra durability, it’s better than mild steel because you don’t have any rusting issues and it’s better than aluminium because that’s below the melting point of a propane torch.

As with all the stencils CNCROi.com produces, there are a few things to keep in mind, the most important are support materials, you want to make sure inner parts that you want to keep have at least two points of contact, if not 3 so they don’t fall out.

Although the size of the stencil doesn’t really matter, we can make very small or big ones at CNCROi.com, different materials and cutting technologies are used when it comes to meeting the tight tolerances required.

The entire process of waterjet cutting this custom jeep stencil is still relatively slow considering other processes that CNCROi.com could have employed to do this type of work but this was the only technology we had at our disposal that could do something this fine on something so small.

The vast majority of our stencils are either done in stainless steel or mylar/polycarbonate, each has their plus and minus.

Once the inside of the custom jeep stencil is cut out, the outside is cut out and thus, the finished stencil will be ready for shipping after a quick clean-up.

You can see a MDF backing on this small sheet of stainless steel, that helps greatly lessen the amount of vibrations that can occur with waterjets from the backwash during the cutting process.

Now that this custom jeep stencil is finished being cut, you can see how precise and fine the finished product is, it’s incredibly sharp and even the finest details are realized.

The customer will now get this in a few days so they can do their work, CNCROi.com is just a cog in the overall wheel, if you want a custom stencil, any material or size, contact us right now!