Custom Mild Steel Bird: CNC Plasma Cutting

Let’s cut a custom mild steel bird at CNCROi.com using our CNC plasma cutter!

CNCROi.com can cut just about anything out of anything, in this case, it’s a mild steel bird, but if you wanted the same bird cut out of wood, plastic, rubber or anything else, we could have done it as well in our shop.

You can see on the growing wall of bling, just the diversity of things that we can cut out of metal, we aren’t limited to just mild steel either, from aluminium to stainless steel, CNCROi.com can cut it all.

Plasma cutting cuts by melting the steel, not sheering or converting it into chips like you’d see with a milling machine, as such, the heat produces a very nice edge quality to the custom mild steel bird and for this specific job, the resolution required is overkill.

A popular item for CNCROi.com to cut out of metal is actually house number signs, they look way better than the store bought alternatives and can be customized however you like.

The customer will be finishing this custom mild steel bird themselves, as such, they only required us to cut it out, and leaving the mill scale on actually protects the surface, once a few layers of paint is applied by them, the bird will last a very long time and look fantastic for years to come.

By vaporizing the mild steel in the path of the plasma cutting torch, it produces a loud noise but also steel dust and smoke, the smoke is extracted outside while the dross (which is minimal) just falls down into the bed of the table.

There are a lot of sparks and fire during the cutting process of the custom mild steel bird production cycle, the nice thing about using a CNC to produce this shape is that it’s completely repeatable, meaning whether you wanted one or a thousand, they would all be identical to the design file created for this project.

CNCROi.com has years of experience cutting various materials, the major advantage of steel over just about anything else is that it can be incredibly thin yet strong at the same time… there is no wood or plastic that I know of that can be this strong at 1/8″ thickness.

If you want a custom BBQ grill, nothing beats the durability and aesthetic of one made out of stainless steel at CNCROi.com.

The advantage of using mild steel over say, stainless steel is cost more than anything else, it’s a very cost-effective material and especially if it will be painted afterwards by the client, just as strong for this application as the more expensive stuff.

As for alternatives to plasma cutting CNCROi.com could have employed to cut this custom mild steel bird, waterjet would have been more expensive due to the constant consumable that is garnet and a slower cutting process while fiber laser cutting this would have taken longer to set-up and thus, cost more for one unit.

I think technically, this custom mild steel bird could have been cut with a hand-torched plasma cutter but wow, it would have been a miserable process especially if this project would have called for more than one to be made, the human body just isn’t made to carefully hold and consistently move a torch at the right height over steel over extended periods of time – I’ve done it at CNCROi.com and it isn’t fun.

As essentially each project we do at CNCROi.com is done on a one-at-a-time basis, if you wanted one bird cut and then an elephant and then a corporate logo or whatever else, it poses no problem and generally, most projects at CNCROi.com are finished within 24 hours so you’d get your custom project just a few days later.

The nice thing about steel signage is the durability, it will pretty much last forever with coats of paint applied every few years.

Looking at the wall behind the plasma cutter at CNCROi.com, you can see a bunch of donkeys cut out, that was made using the same thickness, 12 ga or 1/8″ or 3 mm, stainless steel as this custom mild steel bird and just above that, in black, is a painted mild steel sign I made a while back as well.

You can get a glimpse of the massive fire that’s generated during the plasma cutting of this custom mild steel bird by seeing the bright light emanating from the bottom of the sheet of steel on the table.

For this specific project, there is only one small section that has an inner part, but most of the cutting is done cutting out the projects, as such, the cutting process is relatively fast as there is no going up and down of the torch with the initiation of the plasma arc.

Mild steel, stainless steel, aluminium or titanium, everything works well at our end when it comes to cutting it out.

I really enjoy cutting metal at CNCROi.com since getting my plasma cutter, it’s just such a seamless and fun process compared to what I was doing manually beforehand using power tools.

For this custom mild steel bird, there were not production issues at all, the process is basically (after the design and programming is done), to stick the sheet of mild steel on the table of the plasma cutter, cut it out and then ship it out from CNCROi.com.

As for the amount of material vaporized during the plasma cutting process of this metal bird, it was about 1/16″, so that’s your cut resolution, with thicker material, it may be slightly more or less, it really depends on the feeds, speeds and the design itself.

Cutting even rusted metal is no problem for a plasma cutter, as long as a ground can be established, the plasma cutting process can be initiated and performed.

You can really see wonderful sparks above the sheet of mild steel and fire underneath, standing right next to this with my camera, even with a welding jacket on with helmet and gloves, you can feel the heat of this and you bet, when the cutting of this custom mild steel bird is done, I get to let everything cool down before removing anything from the table.

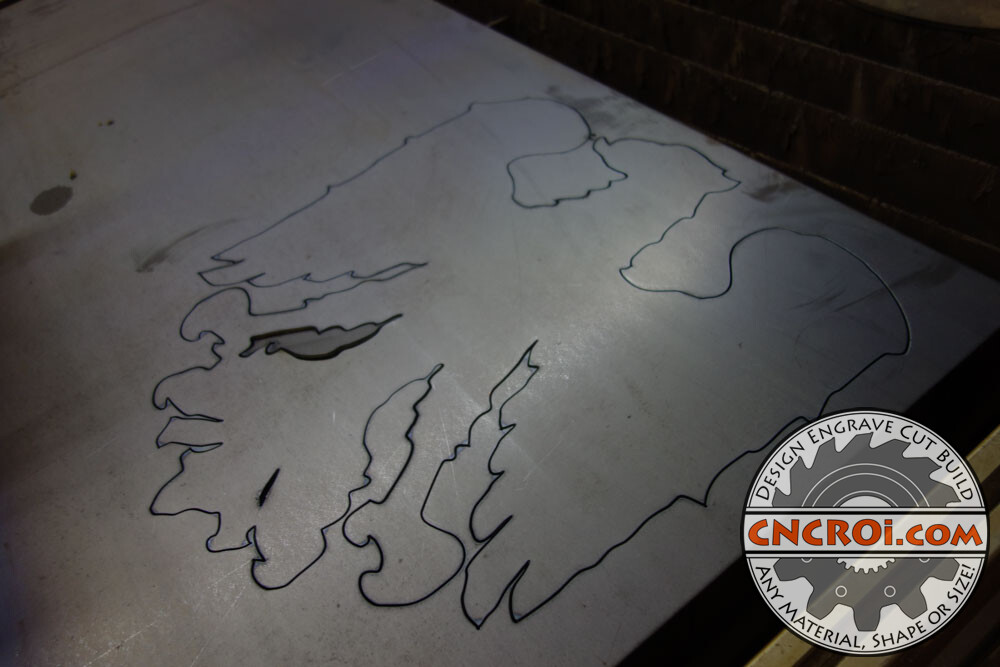

Here’s the finished custom mild steel bird still in it’s mild steel sheet, you can see how little material is vaporized during the cutting process.

Once liberated, the custom mild steel bird is ready to ship after a little clean-up.

Need custom metal cutting? Contact CNCROi.com right now!